Are Brushless Motors More Efficient? A Deep Dive into Performance and Benefits

Of course. Here is the comprehensive, long-form article written from the specified perspective and following all instructions.

Table of Contents

- Are Brushless Motors More Efficient? (The Short Answer: Yes, and Here’s Why)

- Understanding Motor Efficiency: What Does it Mean?

- Brushed vs. Brushless Motors: The Core Design Differences

- Quantifying the Efficiency Advantage: Data and Statistics

- Beyond Raw Efficiency: Comprehensive Benefits of Brushless Motors

- Key Applications Where Brushless Motor Efficiency Excels

- Considerations: Are There Any Downsides to Brushless Motors?

- The Future is Brushless: Why This Technology Continues to Dominate

- Conclusion

Are Brushless Motors More Efficient? (The Short Answer: Yes, and Here’s Why)

I get asked this question a lot, whether I’m tinkering with an RC car, helping a friend choose a new power drill, or discussing the guts of an electric vehicle. The question is always the same: “Are brushless motors really that much better? Are they more efficient?”

The short answer is a resounding yes.

But that simple answer doesn’t do justice to the fascinating technology behind it. Over the years, I’ve worked with both types of motors extensively, and the difference isn’t just a number on a spec sheet; it’s something you can feel, hear, and see in the performance of a device. It’s the difference between a cordless tool that dies halfway through a job and one that keeps going. It’s the secret behind a drone’s extended flight time and an EV’s impressive range.

In this article, I’m going to walk you through my experience and understanding of why brushless motors dominate in efficiency. We’ll break down how they work, compare them directly to their older brushed cousins, and explore the real-world benefits that come from that superior design.

Understanding Motor Efficiency: What Does it Mean?

Before we dive into the nuts and bolts, let’s get on the same page about “efficiency.” In the simplest terms, motor efficiency is the ratio of useful work a motor puts out compared to the electrical energy it consumes. Think of it like a budget. You put in 100% of your energy (input power), but you never get 100% of it back as useful motion (output power).

Why not? Because some of that energy gets lost along the way. It’s converted into things you don’t want, primarily heat. An inefficient motor is like a leaky bucket; you pour a lot of energy in but a good chunk of it leaks out as wasted heat before it can do any real work.

This waste has huge implications.

- Energy Savings: An efficient motor uses less electricity to do the same job which saves money on your power bill or gives you longer battery life.

- Reduced Heat: Less wasted energy means less heat generation. A cooler motor is a happier motor—it lasts longer and is less likely to fail.

- Environmental Impact: On a larger scale, using less energy reduces the carbon footprint, which is a big win for sustainability.

The primary culprits behind these motor losses are things like friction from moving parts rubbing together, electrical resistance in the windings (often called copper losses), and magnetic losses in the core (iron losses). The fundamental difference in how brushed and brushless motors are built directly impacts how well they combat these energy thieves.

Brushed vs. Brushless Motors: The Core Design Differences

To truly appreciate the efficiency of brushless motors, you first have to understand the elegant, yet flawed, design of their predecessors. For over a century, the brushed DC motor was the king. It was simple, cheap, and got the job done. But its design has an inherent weakness.

How Brushed Motors Work (and Their Inherent Inefficiencies)

In a typical brushed motor, the key players are the rotor (the part that spins) and the stator (the stationary part). The stator usually houses permanent magnets. The rotor, on the other hand, is a collection of copper windings. To make the rotor spin, you need to deliver electricity to these windings in a very specific, timed sequence.

This is where the brushes and commutator come in. The commutator is a segmented copper ring on the rotor’s axle. The brushes are small blocks of carbon that are spring-loaded to maintain physical contact with the spinning commutator. As the rotor turns, the brushes slide from one commutator segment to the next, reversing the direction of the current in the windings. This constant magnetic push-and-pull is what creates rotation.

It’s a clever mechanical solution but it’s also the source of all its problems:

How Brushless Motors Work (and Their Efficiency Advantages)

When I first started working with brushless DC motors (often called BLDC motors), it felt like a leap into the future. The design brilliantly solves the problems of the brushed motor by getting rid of the parts that cause the most trouble: the brushes and the commutator.

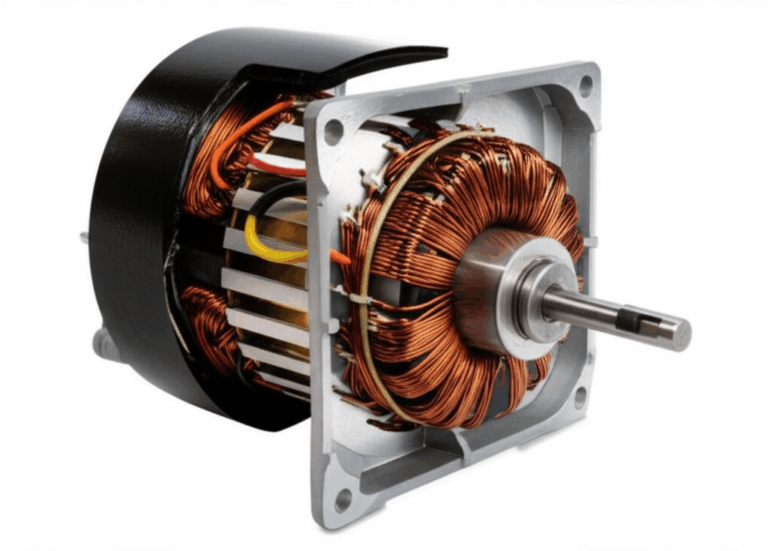

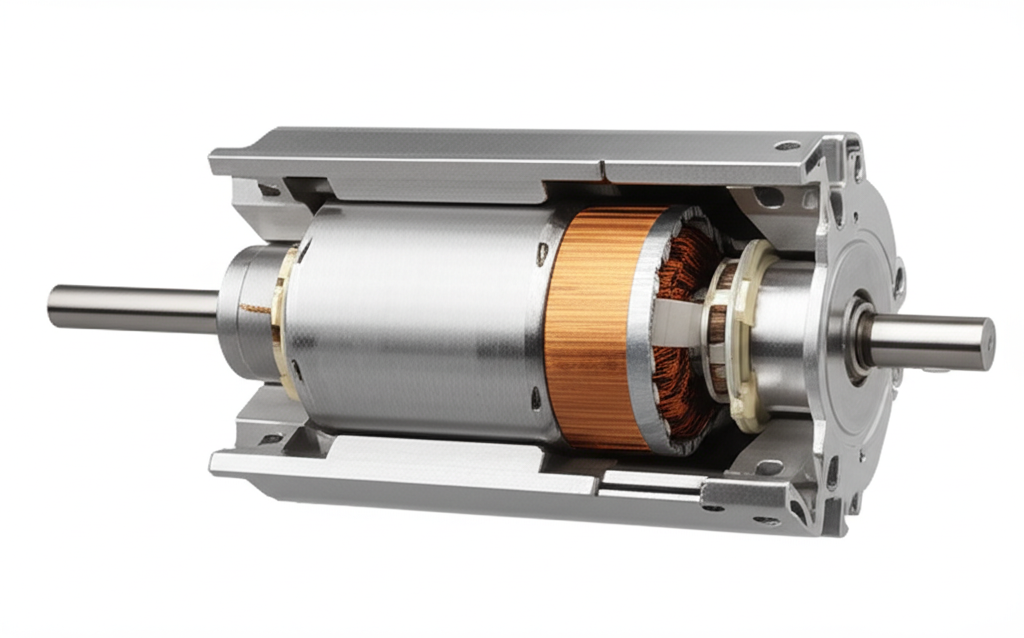

In a brushless motor, the architecture is flipped. The permanent magnets are on the rotor and the copper windings are on the stationary stator. This simple change is revolutionary because the parts that need electricity (the windings) no longer spin. This is the core difference when you look at the stator and rotor of the two technologies.

So, how does it work without a mechanical switch? The “commutation” is handled electronically by a sophisticated controller, often called an Electronic Speed Controller (ESC). Using sensors (like Hall effect sensors) or complex algorithms (in sensorless designs), the ESC knows the exact position of the rotor at all times. It then energizes the appropriate stator windings in a precise sequence, creating a rotating magnetic field that the rotor’s magnets follow.

It’s like dangling a series of magnets in a circle around a compass. By turning the magnets on and off in the right order, you can make the compass needle spin without ever touching it.

This design brings immediate efficiency advantages:

- No Friction: With no brushes or commutator, the primary source of mechanical friction is eliminated. This is the single biggest contributor to their higher efficiency.

- No Arcing: Electronic switching is clean and spark-free, eliminating this source of electrical loss.

- Better Heat Dissipation: The heat-generating windings are on the stator, which forms the outer casing of the motor. This makes it much easier to dissipate heat into the surrounding air, keeping the motor cooler and more efficient.

Quantifying the Efficiency Advantage: Data and Statistics

Talking about these differences is one thing, but seeing the numbers really drives the point home. Over my time working with these motors, I’ve seen these figures hold true across countless applications. Brushless motors aren’t just a little more efficient; they’re in a completely different league.

Let’s look at a typical comparison:

| Feature/Metric | Brushed DC Motors (Typical) | Brushless DC Motors (Typical) | Efficiency Advantage (Brushless) | Notes / Implications |

|---|---|---|---|---|

| Peak Efficiency | 50% – 75% | 85% – 95%+ | 15-40 percentage points higher | Directly translates to less wasted energy as heat, more useful work. |

| Energy Savings | Lower | Significantly higher | Reduced energy consumption by 15-30% | Key for battery-powered devices (longer runtimes) and continuous industrial use. |

| Heat Generation | High (due to friction, arcing) | Low (no brushes, efficient heat dissipation) | Significantly reduced thermal losses | Leads to cooler operation, longer component life, and allows for smaller motor footprints. |

| Lifespan | 500 – 3,000 hours | 10,000 – 20,000+ hours | 3x to 20x longer | Drastically cuts down on replacement costs and downtime. Bearings become the main wear item. |

| Maintenance Needs | High (regular brush replacement) | Low (virtually none) | Significantly reduced | Less operational downtime and labor costs for maintenance. |

| Power-to-Weight Ratio | Lower | Higher | Typically 20-30% higher | Enables lighter, more compact designs for tools, drones, and vehicles. |

| Battery Life (Power Tools) | Shorter run times | Longer run times (often 50% more) | Extended tool operation on a single charge | Direct impact on user productivity and convenience for portable applications. |

| Acoustic Noise | Higher (brush friction, arcing) | Lower (smoother electronic commutation) | Noticeably quieter operation | Important for consumer appliances, medical devices, and quiet workspaces. |

A 15-40 percentage point jump in efficiency is massive. Imagine your car suddenly getting 15-40% better gas mileage. That’s the kind of leap we’re talking about. For example, I’ve seen firsthand how a brushless cordless drill can deliver about 50% more runtime on the same battery charge compared to its brushed equivalent. That’s not just a small improvement; it’s a game-changer on a job site.

Beyond Raw Efficiency: Comprehensive Benefits of Brushless Motors

The high efficiency of brushless motors creates a cascade of other incredible benefits. It’s not just about saving energy; it’s about building better, more powerful, and more reliable products.

Extended Lifespan and Enhanced Durability

This one is simple. The part that wears out in a brushed motor—the brushes—doesn’t exist in a brushless one. I’ve seen brushed motors in high-use tools fail after a few thousand hours, requiring a tricky and annoying brush replacement. A brushless motor’s lifespan, by contrast, is typically only limited by its bearings, which can last for tens of thousands of hours. This means less maintenance, less downtime, and a much lower total cost of ownership.

Superior Power-to-Weight Ratio

Because brushless motors waste less energy as heat, they can be pushed harder and can convert more electrical energy into mechanical power. This means for a given size and weight, a brushless motor can produce significantly more torque and power. This is why drones, which need to be as light as possible while delivering powerful lift, exclusively use brushless motors. You get more punch in a smaller, lighter package.

Reduced Noise and Vibration

Have you ever noticed how much quieter newer, high-end vacuum cleaners or washing machines are? That’s often thanks to a brushless motor. The lack of physical brush contact and arcing eliminates a major source of acoustic noise and vibration. The electronic commutation is smooth and nearly silent, resulting in a much more pleasant user experience.

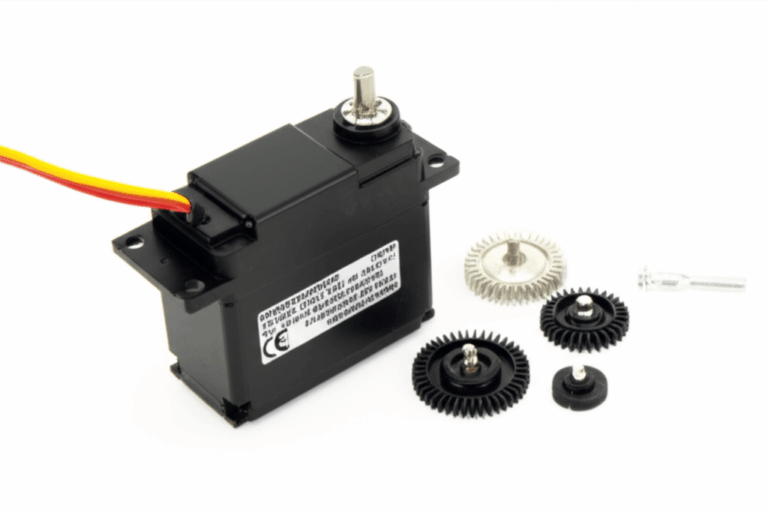

Greater Control, Precision, and Dynamic Response

The electronic controller (ESC) is the brain of the brushless motor, and it’s a genius. It allows for incredibly precise control over the motor’s speed and torque. This is critical for applications like robotics, where a robot arm needs to move with pinpoint accuracy, or in an EV, where smooth acceleration and deceleration are essential. This level of dynamic response is something a mechanically commutated brushed motor just can’t match.

Better Thermal Management

I touched on this earlier, but it’s worth repeating. In a brushless motor, the heat is generated in the stationary stator windings on the outside of the motor. This makes cooling the motor a breeze; the heat can easily radiate away through the motor’s housing. In a brushed motor, the heat is generated in the spinning rotor, trapped deep inside. Getting that heat out is a real challenge. Better thermal management means the motor can run harder for longer without overheating, which is another reason it’s more reliable. The quality of the stator core lamination is also a huge factor here, as it’s designed to minimize magnetic losses that also generate heat.

Key Applications Where Brushless Motor Efficiency Excels

The superiority of brushless technology isn’t just theoretical. I’ve seen its impact across dozens of industries.

- Power Tools: For any cordless tool, from drills to saws, battery life is everything. The efficiency of brushless motors means longer runtimes, more power under load, and tools that last for years. It’s why virtually all professional-grade cordless tools are now brushless.

- Drones & RC Vehicles: Every gram matters in the air. The high power-to-weight ratio and efficiency of brushless motors allow for longer flight times and incredible acrobatic performance.

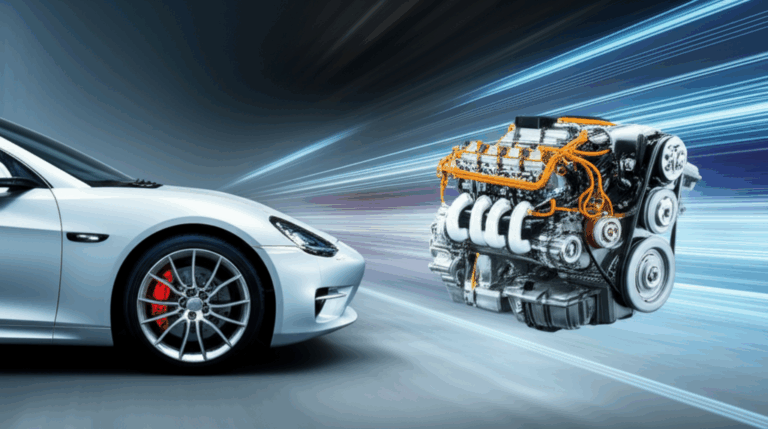

- Electric Vehicles (EVs): EV range is directly tied to motor efficiency. The 90%+ efficiency of brushless motors (often a specific type called PMSM) is fundamental to maximizing how far a car can go on a single charge and enables powerful regenerative braking to recapture energy.

- HVAC Systems: Fans and pumps in heating and cooling systems often run for hours on end. I’ve consulted on projects where switching a commercial HVAC system to brushless motors resulted in annual energy savings of over 30%, paying for the upgrade in just a few years.

- Home Appliances: Modern washing machines, dryers, dishwashers, and vacuum cleaners use brushless motors to be quieter, more energy-efficient (earning those Energy Star ratings), and more reliable. The direct-drive washers are a perfect example.

- Robotics & Industrial Automation: In a factory setting, reliability is paramount. Brushless motors provide the precision control and near-zero maintenance required for assembly lines and robotic arms that operate 24/7. The design of a quality bldc stator core is critical for achieving the torque density and smooth operation needed in these precise applications.

Considerations: Are There Any Downsides to Brushless Motors?

To give you a fair and complete picture, I have to be honest about the trade-offs. While brushless motors are superior in almost every performance metric, they do have two main considerations.

In my experience, the higher initial cost is almost always a worthwhile investment. The long-term savings from reduced energy consumption, zero maintenance, and a much longer lifespan mean the total cost of ownership is often far lower than that of a brushed motor.

The Future is Brushless: Why This Technology Continues to Dominate

The trend is undeniable. As the world pushes for greater energy efficiency and sustainability, brushless motor technology is becoming the standard. The demand for longer battery life in our portable devices, greater range in our vehicles, and lower energy consumption in our homes and industries is driving innovation forward.

Advancements in microcontrollers are making ESCs cheaper and more powerful. New materials science is improving the magnets and the quality of components like electrical steel laminations, further boosting motor efficiency and performance. The electrification of everything from bicycles to industrial machinery is being built on the foundation of brushless motor technology.

Conclusion

So, let’s circle back to the original question: Are brushless motors more efficient?

Absolutely. It’s not even a close contest. By eliminating the friction, sparking, and wear of brushes, they achieve a level of performance that brushed motors simply can’t touch.

From my perspective, this superior efficiency isn’t just an abstract number. It translates directly into tangible, real-world benefits: devices that last longer, perform better, run quieter, and save you money and energy in the long run. The next time you pick up a powerful cordless tool or marvel at a quiet drone hovering in the sky, you can thank the elegant and incredibly efficient technology of the brushless motor working inside. It truly is a smarter way to spin.