Are DC Motors More Efficient? Unpacking Electric Motor Efficiency

Every design engineer, procurement manager, and product developer eventually faces the big question: which motor is the right choice? You’re juggling cost, performance, reliability, and increasingly, energy consumption. If you’ve found yourself weighing the trade-offs between motor types and wondering if the buzz around DC motor efficiency is justified, you’re in the right place. The answer isn’t a simple “yes” or “no”—it’s a fascinating engineering story that depends on the type of motor and, most importantly, the job you need it to do.

This guide will break down the complexities of motor efficiency. We won’t just give you a verdict; we’ll equip you with the fundamental knowledge to make an informed decision for your next project, whether it’s for an electric vehicle, an industrial robot, or a high-end appliance.

In This Article

- What Does “Motor Efficiency” Really Mean?

- DC Motors vs. AC Motors: A Fundamental Look at Efficiency

- Key Factors Influencing Motor Efficiency (Regardless of Type)

- Real-World Applications Where DC Motor Efficiency Shines

- Conclusion: The Verdict on DC Motor Efficiency

What Does “Motor Efficiency” Really Mean?

Before we can compare motors, we need to be on the same page about “efficiency.” In the simplest terms, motor efficiency is a ratio: the mechanical power you get out of the motor divided by the electrical power you put in.

Efficiency (%) = (Mechanical Power Output / Electrical Power Input) x 100

Think of it like a leaky bucket. The water you pour in is the input electrical power (measured in Watts). The water you can actually use from the tap at the bottom is the useful output mechanical power (torque and speed). The water that leaks out the sides is wasted energy. In a motor, these “leaks” aren’t water—they’re energy losses that manifest primarily as heat, but also as noise and vibration.

These losses come from several sources:

- Copper Losses (I²R Losses): This is heat generated by the electrical resistance in the motor’s copper windings. The more current you push through, the hotter the wires get and the more energy is wasted.

- Core Losses (Iron Losses): These losses occur within the motor’s magnetic core, which is typically made of stacked electrical steel laminations. They are a combination of:

- Hysteresis Loss: Energy lost as the magnetic domains within the core material resist being constantly reoriented by the changing magnetic field.

- Eddy Current Loss: Small, unwanted circular currents induced in the core by the changing magnetic field. These currents generate heat, just like the element in an electric stove.

- Mechanical Losses: This is energy lost to friction in the bearings and, in some motor types, the friction between brushes and the commutator.

- Stray Losses: A catch-all for miscellaneous losses that are harder to pinpoint, often occurring at high frequencies or high loads.

A motor with 95% efficiency is one that successfully converts 95% of its electrical fuel into useful work, losing only 5% as waste heat. A motor at 70% efficiency is losing nearly a third of its energy. Over the lifetime of a product, that difference in energy consumption can be enormous.

DC Motors vs. AC Motors: A Fundamental Look at Efficiency

So, are DC motors the more efficient choice? The answer is: it depends entirely on which type of DC motor you’re comparing to which type of AC motor. The distinction is critical. Let’s break down the major players.

The Efficiency Advantage of Brushless DC (BLDC) Motors

When people talk about the high efficiency of modern DC motors, they are almost always talking about Brushless DC (BLDC) motors. These are the rock stars of the motor world for a reason, and they often boast an efficiency range of 85-95% or even higher.

What makes them so good?

- No Brushes, No Problem: The biggest advantage is right in the name. BLDC motors don’t have mechanical brushes or a commutator. This single design choice eliminates a huge source of friction, electrical arcing, and component wear. It’s like replacing a clunky mechanical gear shifter with a seamless electronic one—you instantly get rid of major energy losses and a maintenance headache. The construction often relies on a precision-engineered bldc stator core to maximize magnetic field efficiency.

- Smart Magnets: In a BLDC motor, strong permanent magnets are placed on the rotor (the spinning part). This means the motor doesn’t have to waste any electricity creating a magnetic field in the rotor. That energy is saved, directly reducing copper losses and improving overall efficiency.

- Precise Electronic Control: BLDC motors rely on an electronic controller that uses sensors (or sophisticated algorithms) to switch the current in the stator windings at exactly the right time. This electronic commutation is far more precise and efficient than the mechanical slapping of brushes against a commutator, ensuring the magnetic fields are always optimized for torque production.

- Better Heat Management: Because most of the heat-generating electrical activity happens in the stationary stator windings, it’s much easier to dissipate that heat. The stator can be mounted directly to the motor housing, which can act as a heat sink. A cooler motor is a more efficient motor.

These factors combine to give BLDC motors incredible power density (more power in a smaller package), a longer lifespan, and superior efficiency, especially across a wide range of speeds and loads.

Brushed DC Motors: Efficiency Considerations

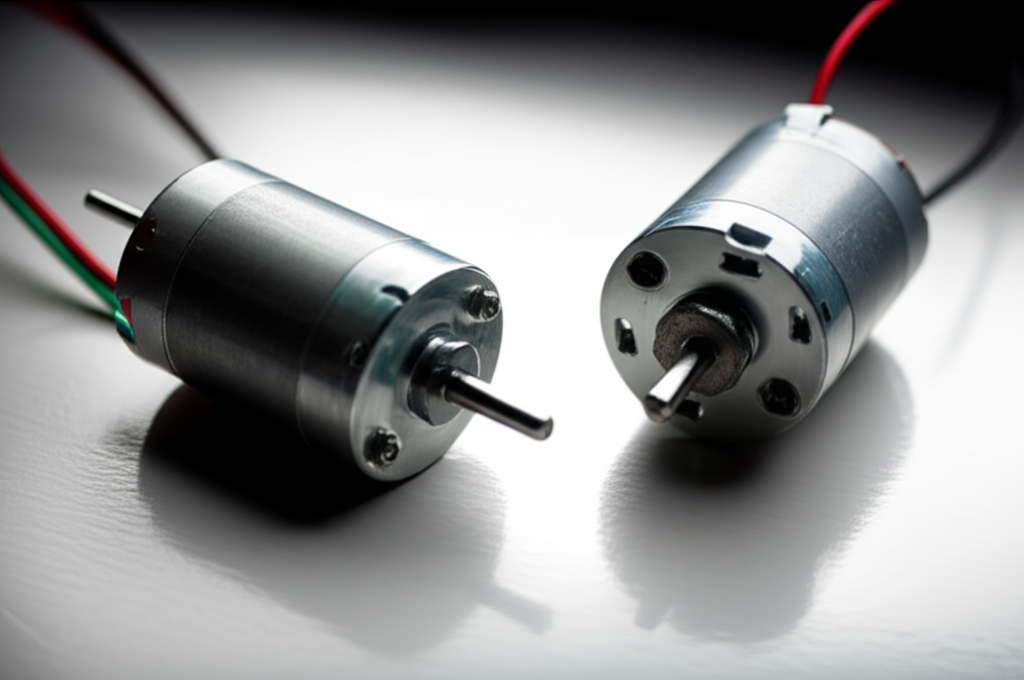

The classic brushed DC motor is a brilliant piece of simple, effective engineering. It’s been a workhorse for over a century in everything from toys to car windows. Its efficiency, however, is a different story, typically falling in the 60-80% range, with smaller motors often being much less efficient.

The sources of inefficiency are the very things BLDC motors were designed to eliminate:

- Brush Friction: The physical contact between the carbon brushes and the spinning commutator constantly generates friction and heat, which is pure wasted energy.

- Commutator Losses: As the brushes switch between commutator segments, electrical arcing can occur. This creates heat, erodes the components, and represents another significant electrical loss.

- Limited Optimal Range: Brushed motors are often most efficient at a specific speed and load. When you operate outside this narrow “sweet spot,” their efficiency can drop off dramatically.

Despite these drawbacks, their simplicity, low cost, and excellent starting torque mean they still have a place. But for applications where peak energy efficiency is the primary goal, they are rarely the first choice.

AC Induction Motors: A Common Benchmark

The most common motor in the world, especially in industrial settings, is the AC induction motor. They are robust, reliable, and relatively inexpensive. When it comes to efficiency, a standard AC induction motor might have an efficiency of 75-90%.

However, high-efficiency versions (like NEMA Premium or IEC IE3/IE4 classes) can push well into the 90-96%+ range, making them highly competitive. So where’s the catch?

The main challenge for AC induction motors is their operating profile. Their design relies on inducing a current in the rotor, which requires the rotor to spin slightly slower than the rotating magnetic field of the stator—a phenomenon called “slip.” This slip is essential for operation but is also an inherent source of energy loss.

More importantly, AC induction motors are most efficient when running at or near their full rated load. Their efficiency plummets at partial loads. If you have a pump or fan that runs at full speed all day, a premium efficiency AC motor is a fantastic choice. But if your application involves frequent starts and stops or variable speeds, that same motor will spend much of its time operating in an inefficient range, wasting significant energy.

AC Synchronous Motors (Including Permanent Magnet Synchronous Motors – PMSM)

This is where the lines between “AC” and “DC” begin to blur in modern motor technology. A Permanent Magnet Synchronous Motor (PMSM) operates on AC power (usually from an inverter) but shares a key design principle with BLDC motors: it has permanent magnets on its rotor.

This design gives it the best of both worlds:

- No Slip Losses: The rotor is “locked in” and spins at the same synchronous speed as the stator’s magnetic field. This completely eliminates the slip losses found in induction motors.

- Incredibly High Efficiency: With no rotor current losses and no slip losses, PMSMs are champions of efficiency, often reaching 88-97%+. They maintain this high efficiency across a very broad range of speeds and loads, making them ideal for variable-speed applications.

In fact, the technology behind a PMSM is so similar to a BLDC motor that they are often considered part of the same high-efficiency family. They are the motor of choice for most modern electric vehicles (EVs) precisely for this reason. A quality rotor core lamination is critical to their performance, ensuring the magnetic fields are channeled effectively with minimal loss.

| Motor Type | Typical Efficiency Range (Full Load) | Key Efficiency Characteristics / Advantages | Disadvantages / Limitations | Common Applications |

|---|---|---|---|---|

| Brushless DC (BLDC) | 85-95%+ | – Very High Efficiency: Especially good across a wide speed range and at partial loads. – No Brush Losses: Eliminates friction and arcing. – Permanent Magnets: Reduces rotor current losses. – High Power Density. | Requires electronic controller (more complex & costly). | EVs, drones, robotics, medical devices, high-end appliances, computer fans, industrial servos, aerospace. |

| Permanent Magnet Synchronous Motor (PMSM) | 88-97%+ | – Excellent Efficiency: Often the highest available, especially with advanced control. – No Rotor Current: Permanent magnets on rotor. – High Power Factor, Low Losses. – Superior dynamic response. | Requires sophisticated electronic control (VFD/inverter). | EVs (e.g., Tesla models), wind turbines, high-performance industrial applications, traction motors, servo drives. |

| Brushed DC Motor | 60-80% | – Simple control, low initial cost. – Good starting torque. – Efficiency can be decent at specific operating points. | – Lower Overall Efficiency: Due to brush friction, commutator losses, and arcing. – Wear and tear of brushes and commutator (maintenance). | Small appliances, toys, automotive power windows, basic robotics, small pumps, low-cost variable speed applications. |

| AC Induction Motor (Standard) | 75-90% | – Robust, simple construction, low maintenance. – Low initial cost. – Widely available. | – Efficiency drops significantly at partial loads. – Rotor slip causes losses. – Lower power factor (can be compensated). | Pumps, fans, compressors, conveyors, general industrial machinery, large household appliances. |

| AC Induction Motor (Premium/IE3/IE4) | 90-96%+ | – High Efficiency: Improved design minimizes losses. – Significant energy savings. | Higher initial cost than standard induction motors. – Still less efficient at partial loads than BLDC/PMSM. | Energy-conscious industrial applications, continuous operation machinery, facilities aiming for reduced energy bills. |

Key Factors Influencing Motor Efficiency (Regardless of Type)

Choosing a motor type is only half the battle. Within any category, several design and operational factors can dramatically affect a motor’s real-world efficiency.

- Motor Design & Materials: This is fundamental. The quality of the materials makes a huge difference. Using higher-grade magnetic steel for the motor core laminations reduces core losses. Using higher-purity copper with thicker windings reduces copper losses. Even the physical design—like the width of the air gap between the stator and rotor—is optimized to maximize magnetic flux and minimize wasted energy.

- Operating Point (Load & Speed): As we’ve discussed, almost no motor is equally efficient at all speeds and loads. Every motor has an “efficiency map” or curve that shows its peak efficiency point. Sizing a motor correctly for its application is critical. An oversized motor that spends most of its life at 25% load will be far less efficient than a smaller motor operating consistently at its 80% load sweet spot.

- Control System: For BLDC and PMSM motors, the electronic controller or Variable Frequency Drive (VFD) is not an accessory—it’s an integral part of the system. The efficiency of the power electronics in that controller directly impacts the total system efficiency. A poorly designed controller can introduce electrical noise (current ripple) that creates extra heat and reduces motor efficiency.

- Thermal Management: Heat is the enemy of efficiency. As a motor heats up, the electrical resistance of its copper windings increases, which in turn leads to even greater copper losses. A well-designed system that effectively dissipates heat will not only extend the motor’s life but also allow it to run more efficiently.

- Maintenance: Over time, things wear out. Bearings can develop friction, cooling fans can get clogged with dirt, and alignments can shift. A proper maintenance schedule is essential for keeping any motor, AC or DC, running at its peak efficiency.

Real-World Applications Where DC Motor Efficiency Shines

The theoretical advantages of BLDC and PMSM motors translate into tangible benefits in some of today’s most demanding applications.

- Electric Vehicles (EVs): This is the poster child for high-efficiency motors. Every percentage point of efficiency translates directly to more range from the battery. EVs use PMSM and BLDC motors because they deliver high efficiency across the wide range of speeds and torques involved in real-world driving—from stop-and-go city traffic to high-speed highway cruising. Their ability to act as generators during regenerative braking to recapture energy is another massive efficiency win.

- Robotics & Drones: In battery-powered applications like robotics and drones, efficiency is paramount for extending operating time. The high power density of BLDC motors means you get powerful, precise control in a lightweight package, which is critical for both flight time and agile robotic movements.

- Portable Devices & Power Tools: For cordless drills, saws, and vacuums, BLDC motors provide a double benefit. Their higher efficiency means longer battery life, and their compact size allows for more ergonomic and lightweight tool designs. This is a clear case where consumers can feel the difference.

- Medical Equipment: In devices like surgical tools, medical pumps, and patient ventilators, the precision, low noise, and reliability of BLDC motors are indispensable. Their high efficiency also reduces waste heat, which can be critical for sensitive medical applications.

- HVAC Systems: Modern high-efficiency furnaces, air conditioners, and heat pumps increasingly use variable-speed BLDC motors for their blower fans. By precisely matching the fan speed to the heating or cooling demand, they avoid the massive energy waste of older systems that could only run at full blast or turn off completely. This has been a key driver in improving the energy ratings (like SEER) of HVAC equipment.

- Industrial Automation: In manufacturing lines, servo motors (which are often based on BLDC or PMSM technology) are used for precise positioning and motion control. In applications with frequent starts, stops, and load changes, their high efficiency at partial loads can lead to energy savings of 20-40% compared to older systems using AC induction motors.

Conclusion: The Verdict on DC Motor Efficiency

So, are DC motors more efficient? Let’s give a clear, actionable answer.

If you’re comparing modern Brushless DC (BLDC) motors and Permanent Magnet Synchronous Motors (PMSM) to other motor types, then the answer is a resounding yes. They are generally the most efficient electric motors available today, especially in applications that involve variable speeds and loads. They have fundamentally superior designs that eliminate major sources of energy loss common in other motors.

However, the classic brushed DC motor is inherently less efficient due to losses from its brushes and commutator. While simple and low-cost, it is not the choice for peak energy savings.

The real takeaway is this: choosing the “most efficient” motor isn’t about picking “AC” or “DC.” It’s about matching the right motor technology to the specific demands of your application.

- For battery-powered devices, variable-speed applications, or any system where efficiency across a broad operating range is critical, BLDC and PMSM motors are the undisputed champions.

- For applications that run continuously at a constant, high load, a premium-efficiency AC induction motor can be an excellent and cost-effective choice.

- For simple, low-cost, or intermittent-use applications where efficiency is not the primary concern, the brushed DC motor still holds its own.

Ultimately, understanding your application’s load profile is the key. By looking beyond a single datasheet number and considering how the motor will perform in the real world, you empower yourself to make a design decision that optimizes not just for performance, but for a lifetime of energy savings.