Are Electric Motors More Efficient Than Gas Engines? A Comprehensive Comparison

Every engineer, designer, and fleet manager involved in automotive technology eventually confronts a fundamental question: When you strip away the marketing and look purely at the physics, are electric motors truly more efficient than internal combustion engines? You’ve likely heard the claims, seen the headlines, and grappled with the implications for cost, performance, and environmental impact. If you’re weighing the trade-offs between powertrains and need a clear, data-driven answer, you’re in the right place.

This isn’t just an academic debate. The answer directly influences everything from operational budgets and maintenance schedules to corporate sustainability goals and the future of transportation. Understanding the core efficiency differences is the first step toward making empowered, informed decisions.

What We’ll Cover

- The Definitive Answer: A direct answer to the core question.

- Understanding Efficiency: How we measure energy conversion in vehicles.

- Electric Motor Efficiency: Harnessing power with minimal loss.

- Internal Combustion Engine (ICE) Efficiency: The inherent challenges of combustion.

- Beyond the Motor: A holistic view of well-to-wheel efficiency.

- Real-World Implications: What efficiency means for your wallet, performance, and the planet.

- Factors Influencing Vehicle Efficiency: A look at variables like driving style, climate, and design.

- Conclusion: The clear efficiency winner and future outlook.

The Definitive Answer: Yes, Electric Motors are Significantly More Efficient

Let’s cut right to the chase. Yes, electric motors are fundamentally and dramatically more efficient than internal combustion engines (ICEs). It’s not a small difference or a matter of opinion; it’s a gap rooted in the basic principles of physics and engineering that govern how these two technologies convert stored energy into motion.

An electric motor in a modern EV converts over 85% of its electrical energy into mechanical energy that turns the wheels. In stark contrast, a typical gasoline engine struggles to convert more than 30-40% of the energy stored in fuel into forward motion.

But why is the gap so vast? The answer lies in how each system works and, more importantly, where the energy is lost along the way.

Understanding Efficiency: How We Measure Energy Conversion

Before we dive into the mechanics, it’s crucial to define what “efficient” really means in the context of a vehicle. At its heart, efficiency is the percentage of stored energy that successfully gets converted into useful work—in this case, propelling the car forward. The energy that isn’t converted is lost, primarily as waste heat.

To get a complete picture, we use two key metrics:

While tank-to-wheel efficiency highlights the vehicle’s engineering prowess, well-to-wheel efficiency tells us about its overall environmental and energy footprint.

Electric Motor Efficiency: Harnessing Power with Minimal Loss

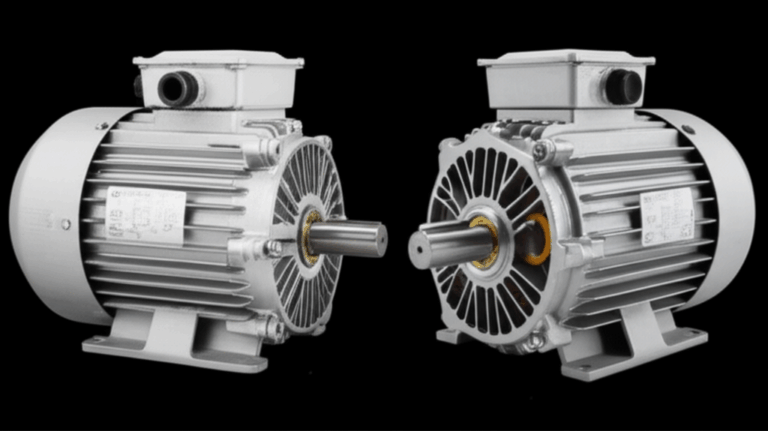

The elegance of an electric vehicle’s powertrain lies in its simplicity. An electric motor operates on a straightforward principle of electromagnetism, creating a direct conversion of electrical energy into the mechanical energy that spins the wheels.

The Core Mechanism

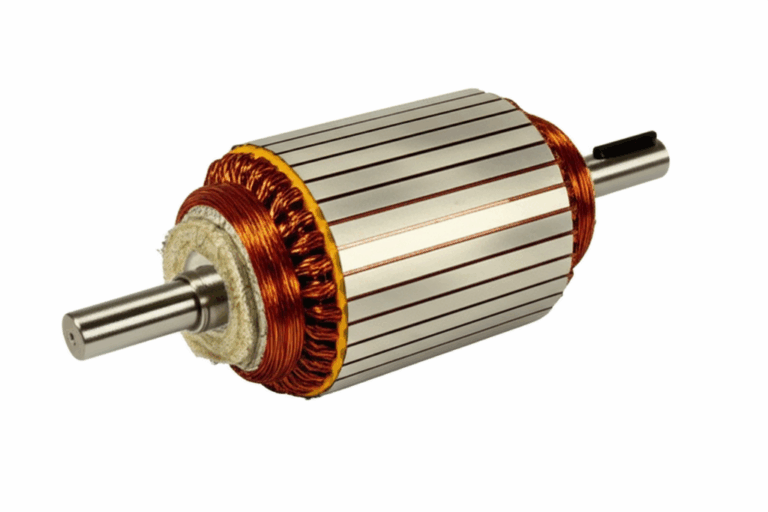

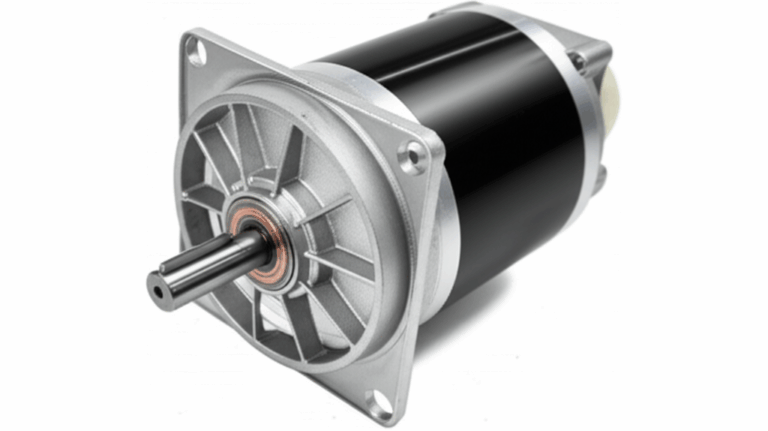

An EV’s powertrain has remarkably few moving parts compared to its gasoline counterpart. It mainly consists of a battery, an inverter (which converts the battery’s DC power to AC power for the motor), and the electric motor itself. The motor uses the electricity to generate rotating magnetic fields, which in turn spin the rotor. This rotational force is then transferred to the wheels, often through a simple single-speed transmission.

Because there is no combustion, there are no controlled explosions, no pistons flying up and down, and no complex valve trains. This direct conversion process is inherently efficient. The primary sources of energy loss are minimal: some electrical resistance in the wiring and components (generating a small amount of heat) and a bit of mechanical friction in the bearings and gears.

Peak and Operating Efficiency

Modern electric motors, like the permanent magnet or induction motors found in today’s EVs, regularly achieve peak efficiencies of 85-95%. This means that for every 100 units of electrical energy drawn from the battery, 85 to 95 of them are used to generate torque and move the car.

What’s more impressive is that EVs maintain high efficiency across a wide range of operating conditions, whether you’re in stop-and-go city traffic or cruising on the highway.

The Ace in the Hole: Regenerative Braking

Perhaps the most significant advantage for EV efficiency is regenerative braking. When you lift your foot off the accelerator or press the brake pedal in an EV, the electric motor essentially runs in reverse. It becomes a generator, converting the car’s kinetic energy (the energy of motion) back into electrical energy, which it then sends back to the battery.

Think about it: in a conventional car, all that forward momentum is scrubbed off by friction brakes, which convert the energy into useless waste heat. It’s like throwing away free fuel every time you slow down. Regenerative braking recaptures a significant portion of this otherwise lost energy, dramatically boosting an EV’s overall efficiency, especially in city driving where acceleration and deceleration are frequent.

Internal Combustion Engine (ICE) Efficiency: The Inherent Challenges

An internal combustion engine is a marvel of mechanical engineering, but it’s also a fundamentally inefficient device. It’s a heat engine, meaning it works by burning fuel to create pressure that pushes pistons, which turn a crankshaft. This multi-stage process is riddled with energy losses at every step.

The Combustion Process

The ICE converts the chemical energy in gasoline into mechanical energy through thousands of controlled explosions per minute. This process is inherently limited by the laws of thermodynamics, which dictate that a significant portion of the energy from a heat-based cycle must be discarded as waste.

Major Energy Loss Factors

So where does all the energy in a gallon of gas go? According to the U.S. Department of Energy, a shocking amount is wasted before it ever reaches the wheels.

- Waste Heat (60-70% Loss): This is the single biggest culprit. The combustion process generates an immense amount of heat. To prevent the engine from melting, a complex cooling system (radiator, water pump, fans) constantly works to dissipate this heat into the atmosphere. More heat is blasted out of the exhaust pipe. This is energy that could have been used for motion but is instead just lost.

- Friction (10-20% Loss): An ICE has hundreds of moving parts—pistons, rings, bearings, valves, camshafts, and gears in the transmission—all rubbing against each other. Overcoming this internal friction consumes a substantial amount of energy. The complex construction of the stator and rotor in an electric motor involves far less mechanical friction.

- Idle Losses: When a gasoline car is stopped at a red light, the engine is still running (idling) to power accessories and be ready to move again. It’s consuming fuel but producing zero forward motion, resulting in 0% efficiency.

- Pumping and Transmission Losses: The engine has to work like an air pump to suck in air and push out exhaust, which takes energy. Additional energy is lost in the multi-speed transmission required to keep the engine in its optimal power band.

When you add it all up, the peak operating efficiency of even a modern gasoline engine is only about 20-40%. In many real-world driving scenarios, like short trips or heavy traffic, the actual tank-to-wheel efficiency can dip into the low teens.

Beyond the Motor: A Holistic View of Well-to-Wheel Efficiency

Critics of EVs often point out that the electricity has to come from somewhere and that the power grid isn’t 100% clean. This is a valid point and it’s why we look at the well-to-wheel efficiency.

Fuel Production and Delivery (Gasoline)

The journey of gasoline is energy-intensive. It begins with extracting crude oil from the ground, transporting it (often across oceans), refining it in massive industrial complexes, and then trucking it to local gas stations. Each of these steps consumes a significant amount of energy, reducing the overall efficiency of using gasoline as a fuel source.

Electricity Generation and Transmission (EVs)

For EVs, the “well” is the power plant. The efficiency here depends on the grid mix. A grid powered by coal will have higher upstream emissions and energy losses than one powered by solar, wind, or hydropower. Energy is also lost during transmission over power lines.

However, even with today’s grid mix in most developed countries, which still includes a significant portion of fossil fuels, the overall well-to-wheel efficiency of an EV is far superior. Why? Because the immense efficiency advantage of the electric motor itself is more than enough to overcome the losses in electricity generation and transmission. As the grid becomes greener with more renewable energy sources, this advantage will only grow.

Here’s a breakdown of the key data points that illustrate the efficiency gap:

| Aspect / Metric | Electric Motor (EV) | Internal Combustion Engine (Gasoline) | Notes |

|---|---|---|---|

| Peak Efficiency | 85-95% | 20-40% | Electric motors convert most of their energy into motion; ICEs lose most of it as heat. |

| Average Operating Efficiency (Tank-to-Wheel) | 77-85% | 12-30% | This is the crucial real-world number. ICE efficiency plummets in city driving and at idle. |

| Energy Loss Type | Primarily minor heat from electrical resistance. | Majorly Waste Heat (60-70%), mechanical friction. | The ICE is a heat engine, fundamentally limited by thermodynamics. |

| Regenerative Braking | Yes (recovers braking energy) | No (all braking energy is lost as heat) | A massive advantage for EVs, especially in urban environments. |

| Powertrain Complexity | Simple (motor, inverter, single-speed) | Highly complex (engine, transmission, fuel, exhaust, cooling systems) | Fewer moving parts mean less friction and higher efficiency. The motor principle is far more direct. |

| Well-to-Wheel Efficiency (Overall) | 60-80% (depending on grid) | 15-25% | Even with grid losses, EVs are 2-3 times more efficient overall. (Source: U.S. DOE) |

| EPA MPGe Example | ~100-130 MPGe | ~25-40 MPG | MPGe (Miles Per Gallon equivalent) is an EPA metric to compare energy consumption. Higher is better. |

Real-World Implications: What Efficiency Means for You

This isn’t just a numbers game. The superior efficiency of electric motors translates into tangible benefits that impact your budget, driving experience, and the environment.

Fuel and Energy Costs

This is the most direct benefit. Because EVs use energy so much more efficiently, the cost per mile is significantly lower. Even though electricity prices vary, charging an EV is almost always cheaper than filling up a comparable gasoline car. Over the lifetime of the vehicle, these fuel savings can add up to thousands of dollars.

Environmental Impact

Higher efficiency means less energy is wasted, which directly leads to a smaller environmental footprint. For every mile driven, an EV simply consumes less total energy. This results in a lower carbon footprint, even when accounting for emissions from electricity generation. As grids transition to renewable energy, the lifecycle emissions of EVs will continue to drop, while gasoline cars will always be tied to the emissions of burning fossil fuels. This also means better local air quality, as EVs produce zero tailpipe emissions, reducing smog and harmful pollutants in our cities.

Performance and Driving Experience

Efficiency also has a surprising impact on how a car feels to drive. Electric motors deliver their maximum torque instantly, from a standstill. This “instant torque” provides smooth, rapid, and silent acceleration that most gasoline engines can’t match. There’s no waiting for the engine to rev up or for the transmission to shift gears. The response is immediate, making EVs feel incredibly quick and responsive in everyday driving.

Maintenance Differences

The mechanical simplicity that contributes to an EV’s efficiency also leads to lower maintenance needs. An electric powertrain has far fewer moving parts. There are no oil changes, spark plugs, fuel filters, or exhaust systems to maintain or replace. While the battery is a long-term consideration, the routine maintenance schedule for an EV is considerably lighter and often less expensive than that of a gasoline vehicle, whose complex engine and transmission require regular service. These benefits are a direct result of a simpler design, starting from the very basics of its motor core laminations.

Factors Influencing Vehicle Efficiency (Both Types)

Of course, the official efficiency numbers are just a baseline. Real-world performance for both EVs and ICE vehicles can be affected by several factors:

- Driving Conditions: EVs excel in city driving due to regenerative braking, often exceeding their EPA-rated efficiency. Gasoline cars are least efficient in stop-and-go traffic. On the highway, at constant high speeds, the efficiency gap narrows slightly as regenerative braking opportunities decrease, but the EV still maintains a significant lead.

- Vehicle Weight and Aerodynamics: Heavier vehicles and those with more aerodynamic drag require more energy to move, regardless of powertrain. This is a universal principle of physics.

- Climate: Extreme temperatures affect both types of vehicles. Cold weather can reduce an EV’s range and efficiency because energy is needed to heat the cabin and keep the battery at its optimal operating temperature. Similarly, extreme cold can reduce an ICE’s efficiency, and both types use energy to run air conditioning in hot weather.

- Technology Advancements: Engineers are constantly working to improve both technologies. Advances in battery chemistry, motor design, and power electronics are making EVs even more efficient. At the same time, improvements in ICE technology, such as hybridization, turbocharging, and cylinder deactivation, are squeezing more efficiency out of gasoline engines, though they remain fundamentally constrained by thermodynamics. A quality stator core lamination is key to pushing these boundaries in electric motors.

Conclusion: The Clear Efficiency Winner and Future Outlook

When you analyze the data, the physics, and the real-world results, the conclusion is undeniable: electric motors are vastly more efficient than internal combustion engines.

They convert a much higher percentage of stored energy into useful motion, waste far less energy as heat, and even recapture energy through regenerative braking—a feat impossible for their gasoline counterparts. This isn’t a small, incremental improvement; it’s a revolutionary leap in powertrain technology.

This superior efficiency is the foundational advantage that leads to lower running costs, a significantly smaller carbon footprint, and a quieter, more responsive driving experience. While factors like battery manufacturing and grid electricity sources are important parts of the bigger picture, the core efficiency of the vehicle itself gives EVs a powerful head start that is only set to grow as our energy infrastructure becomes cleaner.

For any engineer, designer, or procurement manager planning for the future, understanding this fundamental efficiency gap is no longer optional—it’s essential. The shift toward electric vehicles is not just a trend; it’s a move toward a fundamentally more efficient and sustainable mode of transportation.