Bridging the Gap: Why FEA Predictions Deviate from Test Results for Laminated Cores and How to Achieve Accuracy

Your FEA simulation says one thing. Your test results say something else. Sound familiar? This article explains why these gaps happen with laminated cores and shows you exactly how to fix them. You’ll learn the real reasons behind simulation errors and get practical solutions that actually work.

Table of Contents

- Why Do My FEA Results Never Match My Tests?

- What Material Properties Are Causing the Biggest Errors?

- How Do Manufacturing Issues Create FEA-to-Test Gaps?

- Are Your FEA Model Settings Part of the Problem?

- What Testing Errors Make the Gap Look Worse Than It Is?

- How Can Better Material Testing Close the Gap?

- What FEA Techniques Give More Accurate Results?

- How Do Manufacturing Controls Improve Accuracy?

- What’s the Best Way to Validate and Calibrate Your Models?

- Can Real Case Studies Show These Solutions Work?

Why Do My FEA Results Never Match My Tests?

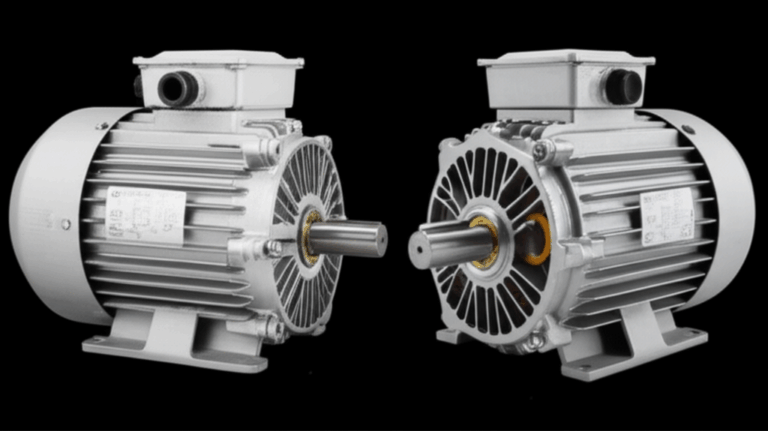

I’ve been there. You spend weeks perfecting your FEA model. The mesh looks beautiful. The boundary conditions seem right. But when you test the actual motor core laminations, the results don’t match. Core losses might be 30% higher than predicted. Torque comes out 15% lower. Temperature rises way beyond your calculations.

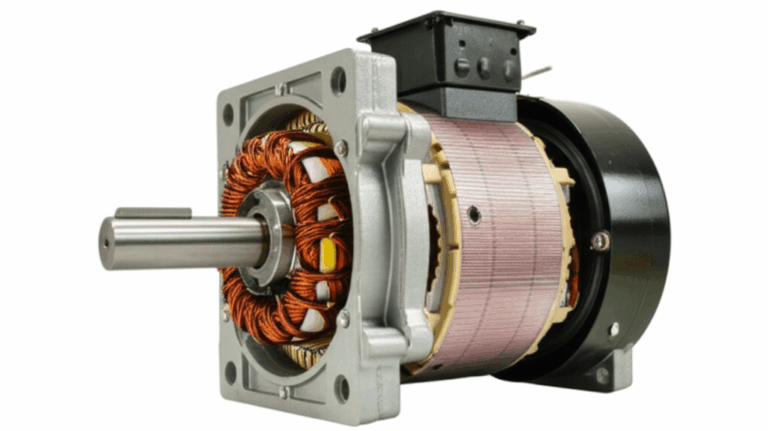

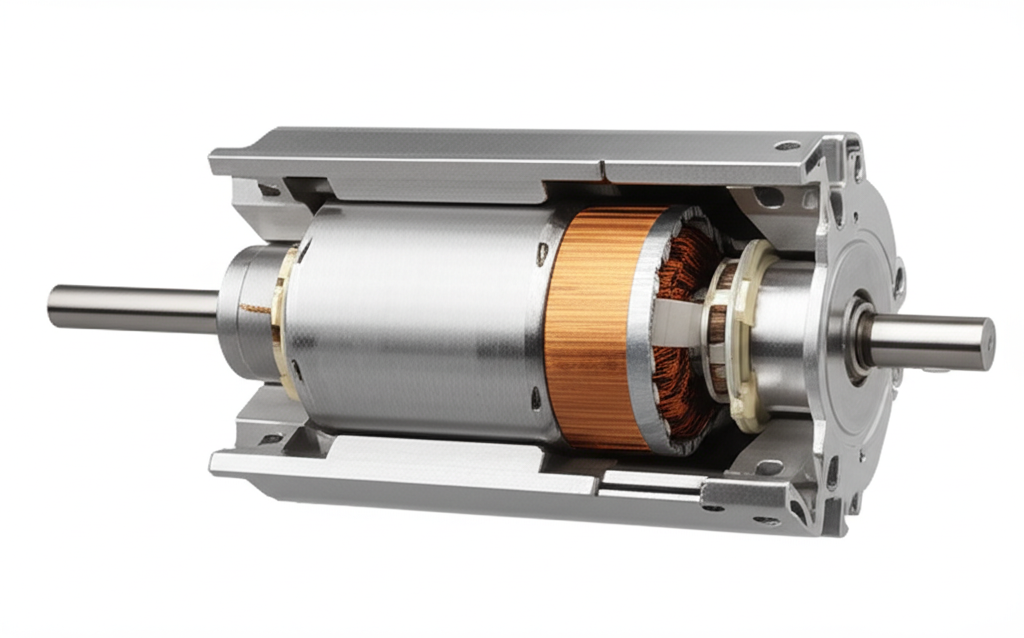

This happens because laminated cores aren’t simple. They’re made of hundreds of thin steel sheets. Each sheet has its own properties. The way you stack them matters. The cutting process changes things. Even the coating between sheets affects performance. Your FEA software can’t know all these details unless you tell it. Most engineers don’t realize how many factors they’re missing until they see the test data.

What Material Properties Are Causing the Biggest Errors?

The B-H curve you’re using is probably wrong. Here’s why: Material suppliers give you data from perfect lab conditions. But your core doesn’t work in perfect conditions. It sees different frequencies. It heats up. The magnetic field isn’t uniform. These things change how the material behaves.

Think about it this way. You wouldn’t use the same recipe for cake at sea level and on a mountain, right? The altitude changes everything. Same with electrical steel. Temperature can shift permeability by 20%. Frequency effects can double your core losses. If your model uses static B-H curves for a motor running at variable speeds, you’re already starting with bad data.

The anisotropy problem makes things worse. Grain-oriented steel behaves differently in different directions. But many FEA models treat it as the same in all directions. That’s like saying wood is equally strong along and across the grain. We know that’s not true. This single mistake can cause 10-15% errors in flux density predictions.

How Do Manufacturing Issues Create FEA-to-Test Gaps?

Manufacturing changes everything about your laminated core. Punching stress is the big villain here. When you cut electrical steel, you damage the edges. The damaged zone might be small – maybe half a millimeter. But in a motor tooth that’s only 3mm wide, that’s a huge percentage. These damaged areas have 50% higher losses and 20% lower permeability.

The stacking factor never matches the ideal. You design for 0.97, thinking the sheets will pack tight. But reality gives you 0.94. That 3% difference means 3% less steel and more air in your core. Air doesn’t conduct magnetic flux well. So your inductance drops and your losses increase.

Inter-lamination contact is another hidden problem. The coating between sheets should insulate them perfectly. But it doesn’t. Poor insulation can increase core losses by 15%. Pressure during assembly makes it worse. Vibration during operation creates new contact points. Your FEA model assumes perfect insulation. Reality laughs at that assumption.

Are Your FEA Model Settings Part of the Problem?

Your mesh might be too coarse. I see this mistake constantly. Engineers use big elements to save computation time. But magnetic fields concentrate in small areas – air gaps, tooth tips, corners. If your mesh can’t capture these hot spots, your results will be wrong. A refined mesh in critical areas can improve accuracy by 10-20%.

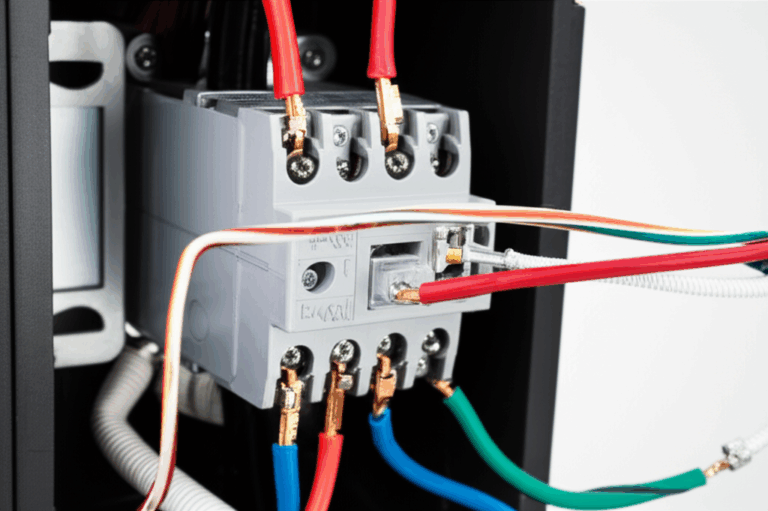

Boundary conditions cause huge errors too. Setting them up seems simple. Apply current here, ground there, done. But real devices don’t work that simply. The power supply has harmonics. Mechanical loads create stress. Temperature varies across the core. Missing any of these coupled effects leads to gaps.

Many engineers still use 2D models for 3D problems. Yes, 2D is faster. But end effects matter. Skewing matters. Asymmetries matter. When you ignore the third dimension, you might miss 15% of your losses. That’s not a small error – that’s a design failure waiting to happen.

What Testing Errors Make the Gap Look Worse Than It Is?

Sometimes the FEA is right and the test is wrong. Shocking, but true. Sensor placement can ruin your measurements. Put a flux sensor too close to an air gap, and you’ll read local effects instead of average behavior. Temperature sensors in the wrong spot miss hot spots completely.

Your test equipment has limits. Power analyzers have accuracy specs – usually 0.5% to 1%. But when measuring small losses, that percentage becomes huge. Environmental factors matter too. A 10°C temperature change in your lab can shift material properties by 5%. External magnetic fields from nearby equipment add noise to your data.

The test setup itself creates problems. Mounting fixtures add mechanical stress. Power cables introduce parasitic inductance. Even the way you connect your stator core lamination affects the results. These aren’t simulation errors – they’re measurement errors making your gap look worse.

How Can Better Material Testing Close the Gap?

Stop trusting generic material data. Test your actual materials. Measure B-H curves at your operating frequencies. Check core losses at different flux densities and temperatures. This takes time and money, but it’s worth it. Real data can reduce your FEA errors by 25%.

Use statistical methods for material variation. Every batch of electrical steel is different. Some sheets are better, some worse. Instead of using average values, model the distribution. Monte Carlo analysis shows you the range of possible outcomes. Now you know if your design is robust or living on the edge.

Advanced material models help too. Vector hysteresis models capture minor loops and rotational losses. Temperature-dependent properties account for heating effects. Stress-dependent permeability shows manufacturing impacts. These models are complex, but they bridge the gap between simple theory and messy reality.

What FEA Techniques Give More Accurate Results?

Start with detailed geometry. Model the actual lamination shape, not simplified versions. Include the insulation layers, even if they’re thin. Small geometric details can change flux paths significantly. That tiny chamfer you ignored? It might be forcing flux through a saturated region.

Use multi-physics simulation. Thermal-magnetic coupling is essential for accuracy. Heat changes material properties. Changed properties affect losses. More losses create more heat. It’s a cycle you can’t ignore. Coupled analysis might take longer, but it prevents 20-30% temperature prediction errors.

Implement better core loss models. The old Steinmetz equation isn’t enough anymore. Use Bertotti’s loss separation method. Consider field-dependent loss maps. Account for minor hysteresis loops. Modern loss models can cut your core loss prediction error from 25% to under 10%.

How Do Manufacturing Controls Improve Accuracy?

Tighter tolerances make FEA more accurate. When your rotor core lamination dimensions vary by ±0.1mm instead of ±0.5mm, your model assumptions get better. Quality control isn’t just about making good parts – it’s about making predictable parts.

Post-processing treatments matter enormously. Annealing after punching can restore 80% of the magnetic properties damaged by cutting. But many manufacturers skip this step to save money. If your cores aren’t annealed, your FEA needs to account for degraded edge properties.

Material certification ensures consistency. Don’t just check that the steel meets minimum specs. Track the actual properties of each batch. When properties drift, update your models. This continuous feedback loop keeps your simulations aligned with reality.

What’s the Best Way to Validate and Calibrate Your Models?

Create standard test procedures. Test the same way every time. Control temperature, humidity, and external fields. Document everything. Consistent testing reveals real trends, not random noise.

Use high-precision equipment. Invest in calibrated sensors and quality data acquisition systems. The extra cost pays for itself when you catch problems early. Remember: bad data leads to bad decisions.

Iterate between testing and simulation. Test a prototype. Update your model based on results. Simulate variations. Test again. Each cycle improves accuracy. After 3-4 iterations, most teams achieve under 10% error. That’s good enough for confident design decisions.

Can Real Case Studies Show These Solutions Work?

Let me share what really works. One motor manufacturer had 25% core loss prediction errors. They invested in dynamic B-H curve testing for their specific steel grade. They modeled punching stress effects. They refined their mesh at tooth tips. Result: Error dropped to 7%.

| Improvement Action | Error Reduction | Implementation Cost | Time to Implement |

|---|---|---|---|

| Dynamic B-H curves | 10-15% | Medium | 2-4 weeks |

| Manufacturing effects modeling | 8-12% | Low | 1-2 weeks |

| Refined meshing | 5-10% | Low | 1 week |

| Multi-physics coupling | 10-20% | High | 4-6 weeks |

| Material batch tracking | 5-8% | Medium | Ongoing |

A transformer company struggled with temperature predictions 40% below actual. They added thermal-magnetic coupling to their FEA. They characterized thermal properties of their insulation. They modeled actual cooling paths, not simplified ones. The new model predicted temperatures within 10%.

These aren’t special cases. They’re normal companies that decided to fix their FEA-to-test gaps. They invested time and effort. But they got predictable, accurate simulations in return. That’s worth more than any software upgrade.

Key Points to Remember

- Material data matters most – Test your actual materials at operating conditions

- Manufacturing changes everything – Model punching stress, stacking factors, and assembly effects

- Mesh refinement in critical areas improves accuracy by 10-20%

- Multi-physics simulation catches coupled effects you’d otherwise miss

- Quality control makes both products and simulations more predictable

- Iterative validation between test and simulation reduces errors below 10%

- Small details cause big errors – Don’t ignore coating, stress, or geometric features

- Investment in better testing pays back through accurate predictions