Brushed vs. Brushless Motors: What’s the Difference and Which Is Right for You?

Introduction: The Heart of Motion

You want a motor that hits your targets on efficiency, torque, noise, and cost. You also want to avoid surprises in the field. That choice often boils down to brushed vs brushless DC motors. Engineers know the specs look close on paper. In practice the differences show up as longer battery life, cooler operation, and fewer maintenance calls. Here’s the twist. The motor’s lamination stack and core material play a bigger role than many product teams expect. If you ignore laminations you leave efficiency and reliability on the table.

This guide explains how brushed and brushless motors work, how commutation and control affect performance, and why motor core laminations drive real-world outcomes. You’ll get a clear comparison, application guidance, and a practical selection checklist. We’ll also show where lamination material and manufacturing processes influence heat, noise, and lifespan. Use this to make a confident design or purchasing decision.

In This Article

- The Engineering Fundamentals: What’s Really Going On Inside

- Brushed Motors: The Classic Design

- Brushless Motors: The Modern Advancement

- Brushed vs. Brushless: The Core Differences

- Motor Laminations 101: Why They Matter for Both Types

- Matching Options to Applications

- Practical Selection Guide: Factors to Consider

- Reliability, Thermal, and EMC Considerations

- Controls and Performance Tuning

- Cost and Total Cost of Ownership

- Your Engineering Takeaway and Next Steps

The Engineering Fundamentals: What’s Really Going On Inside

Let’s start simple. A DC motor turns electrical energy into mechanical motion through magnetic fields. The stator supplies one field. The rotor carries another. Put the fields at angles and you get torque. Reverse current at the right time and the rotor keeps chasing the moving field. That reversal is the commutation process.

- Brushed DC Motor basics:

- The stator typically uses permanent magnets.

- The rotor carries windings that become electromagnets.

- A commutator and carbon brushes switch current as the rotor spins.

- Brushless DC Motor (BLDC) basics:

- The stator carries windings.

- The rotor carries permanent magnets.

- An Electronic Speed Controller (ESC) performs electronic commutation. Hall effect sensors or back EMF detection tell the ESC where the rotor sits.

Think of commutation like a well-timed relay race. In a brushed motor the baton pass happens physically at the commutator. In a brushless motor the ESC calls the handoffs with perfect timing and no contact. Contact creates friction and electrical arcing. Electronics avoid both.

Now zoom into the steel core where magnetization happens. The magnetic flux doesn’t pass through a single solid block in well-designed motors. You use thin, insulated laminations stacked into a stator and rotor core. Why? Changing fields induce “eddy currents” inside conductive material. Those currents act like tiny electrical whirlpools. They waste energy as heat and they steal torque. Laminations break those big whirlpools into small ripples. Less heat. Better efficiency. Lower current draw at the same load. You also fight hysteresis loss. That’s the energy you lose flipping magnetization back and forth with every electrical cycle. Material choice and lamination thickness control both losses.

Two takeaways:

- Commutation strategy shapes efficiency, torque ripple, speed control, and maintenance.

- Lamination material and thickness drive core loss which directly impacts motor heat generation, battery life impact, and lifespan.

Brushed Motors: The Classic Design

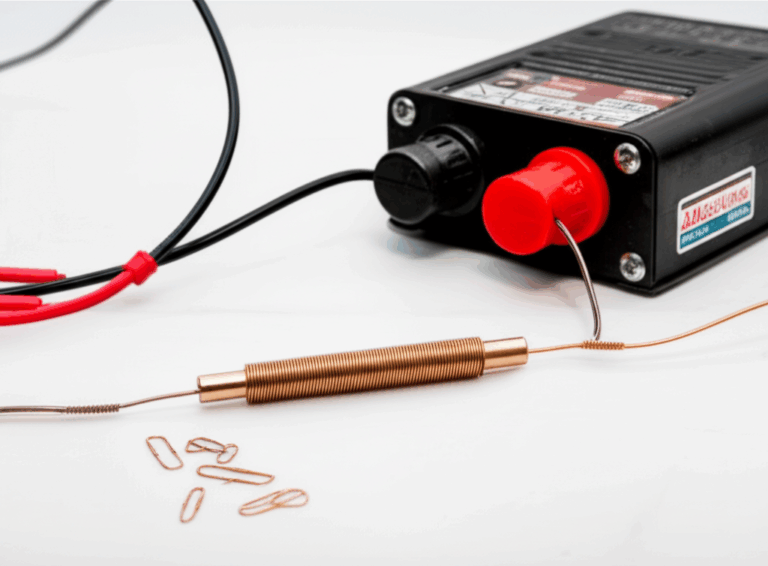

How a Brushed Motor Works

A Brushed DC Motor uses brushes and a segmented commutator to reverse current in the rotor windings. The brushes press against the commutator as the shaft turns. Each segment aligns with a rotor coil. The brush/commutator interface switches current every time the rotor moves to the next segment. The stator provides a stable magnetic field with permanent magnets or sometimes field windings. The rotor acts as a set of electromagnets that flip as needed. The result is continuous torque output with a direct mechanical commutation mechanism.

Key Characteristics and Advantages of Brushed Motors

- Simpler control and wiring. You can vary voltage or use basic PWM to regulate speed.

- Low initial cost. Commodity designs exist for toys, small appliances, and entry-level power tools.

- Wide availability. Rebuild kits and off-the-shelf replacements are common.

- Good startup torque. The design can deliver punch at low speed in simple applications.

Disadvantages of Brushed Motors

- Brushes and commutator wear. Expect brush replacement and commutator cleaning. Maintenance interrupts service life.

- Lower efficiency. Friction and electrical sparking add losses. Efficiency typically sits around 75 to 80% for many designs.

- Shorter lifespan. Brush wear often limits continuous-use life to about 1,000 to 3,000 hours.

- Higher noise and EMI. You hear brush noise. You also see electromagnetic interference from sparking.

- More heat. Friction and higher copper loss increase temperatures which stresses insulation, bearings, and windings.

Where they still shine:

- Low cost consumer electronics motors.

- Automotive actuators like window lifts and seat adjusters.

- Simple toys and pumps.

- Legacy industrial motors where maintainability and low purchase price matter.

Brushless Motors: The Modern Advancement

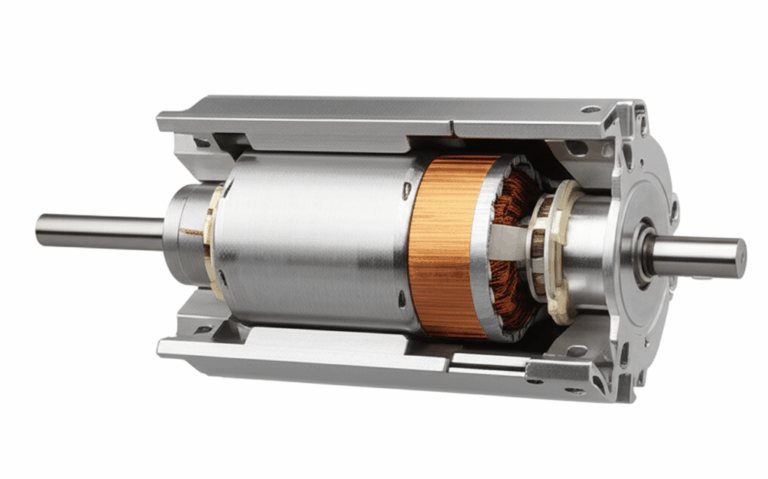

How a Brushless Motor Works

A Brushless DC Motor flips the roles. The stator carries windings. The rotor carries permanent magnets. An ESC performs commutation electronically. You can use a sensored brushless motor with Hall effect sensors for precise low-speed control and smooth startup. Or you can use a sensorless brushless motor that infers rotor position from back EMF which simplifies wiring and improves reliability in harsh environments.

The ESC uses motor control algorithms to manage phase currents. Most controllers use PWM to modulate voltage. Many high-performance systems use field oriented control (FOC). FOC aligns current vectors with the rotor’s magnetic field. It reduces torque ripple and increases efficiency. You get better motor responsiveness and tighter speed control. You also enable regenerative braking in electric vehicles and e-bikes when the system design allows power to flow back into the battery pack.

Key Characteristics and Advantages of Brushless Motors

- Higher efficiency and power density. Typical efficiency sits between 85 and 90% and top designs exceed 90%.

- Longer lifespan. No brushes means fewer wear parts. Bearing life usually sets the limit.

- Lower maintenance. You eliminate brush replacement and commutator service.

- Better speed and torque control. ESCs deliver precise commutation which improves acceleration and low-speed torque stability.

- Less heat, noise, and EMI. No brush friction. Windings sit on the stator where you can sink heat effectively.

Disadvantages of Brushless Motors

- Higher initial cost. The motor and ESC add up. Sensor hardware raises cost further.

- More complex control. You need a competent controller design and firmware. That means more engineering up front.

- Startup in sensorless systems can be tricky at very low speed under heavy load. Sensored designs solve it but add parts.

Common applications:

- Drones, RC planes, and RC car motors where power-to-weight ratio rules.

- High-performance power tools and industrial automation.

- Electric vehicle traction motors and e-bike drives.

- Robotics arms and precision servo motors with integrated feedback.

- High-end appliances like vacuum cleaner motors and washing machine motors.

Brushed vs. Brushless: The Core Differences

- Commutation mechanism:

- Brushed: Physical contact. Wear and sparking occur.

- Brushless: Electronic timing via ESC. No contact.

- Components and construction:

- Brushed: Windings on rotor. Stator often uses permanent magnets.

- Brushless: Windings on stator. Rotor carries permanent magnets.

- Efficiency and power output:

- BLDC wins on motor efficiency comparison and continuous power output. It also delivers higher peak power output at a given size due to lower thermal limits in the stator.

- Lifespan and durability:

- Brushless motors last longer due to the absence of brushes and commutator wear. Bearings set the limit for both types.

- Maintenance requirements:

- Brushed: Plan brush replacement and commutator maintenance. Stock motor rebuild kits for critical systems.

- Brushless: Set it and forget it except for bearings and perhaps firmware updates.

- Cost considerations:

- Brushed motors cost less up front. BLDC reduces energy bills and maintenance which often cuts total cost of ownership in steady-duty or high-use scenarios.

- Speed and torque control:

- BLDC delivers more precise speed control and higher low-speed torque using FOC. Brushed designs can cog at low RPM due to commutator geometry.

- Heat, noise, and EMI:

- BLDC runs cooler and quieter with lower electromagnetic interference. Brushed motors run hotter due to friction and higher copper loss.

- Application fit:

- Use brushed motors for low-cost, low-duty tasks or where simple voltage control is required.

- Use brushless motors where efficiency, power density, and reliability matter or where battery life matters.

Data snapshot for context:

- Efficiency: Brushed ~75–80%. Brushless ~85–90% with top designs >90%.

- Lifespan: Brushed often 1,000–3,000 continuous hours. Brushless 10,000–20,000 hours or more depending on bearings and cooling.

- Run time: Cordless tools moved to BLDC and often gained up to 50% longer run time and 25–50% more torque in similar form factors.

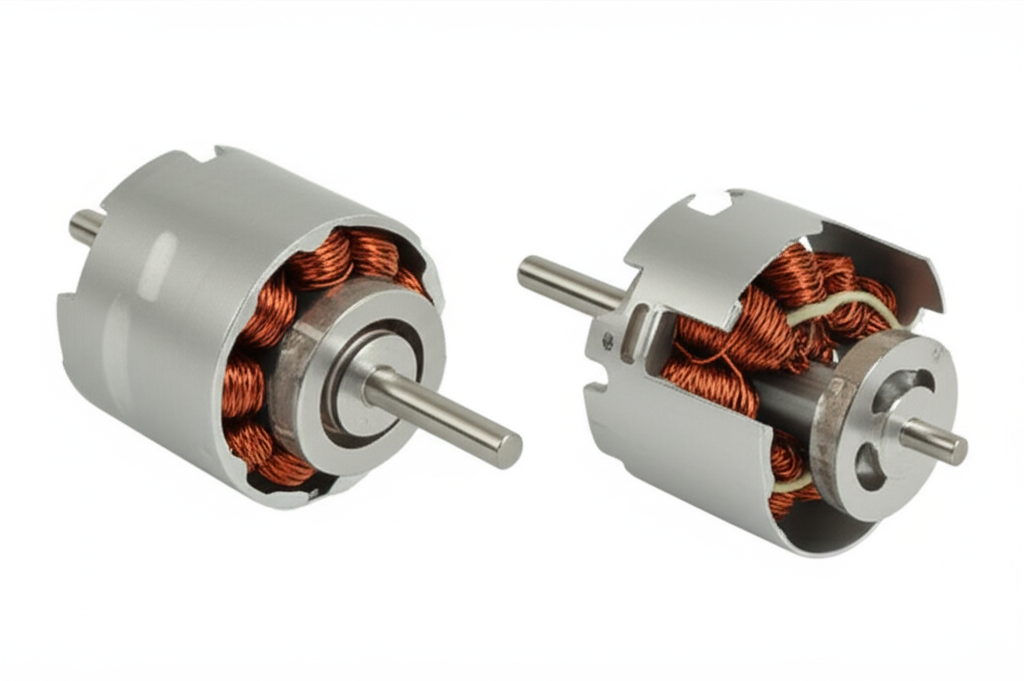

Motor Laminations 101: Why They Matter for Both Types

Here’s where many teams win or lose the performance game. The lamination stack and material choice control core losses. That affects heat generation, current draw, and torque stability. You can build a great ESC and still waste watts in the steel core if you pick the wrong material or thickness.

- What is a lamination stack?

- Thin sheets of electrical steel with an insulating coating. You stack and bond or interlock them to form the stator and rotor core.

- Why laminations reduce loss:

- Eddy currents need loops to flow. Insulation between sheets breaks those loops which slashes eddy current loss.

- Thinner sheets mean smaller loops and lower loss at higher electrical frequencies.

- Hysteresis loss:

- Every magnetization flip wastes energy. Materials with lower coercivity reduce hysteresis loss. The B–H curve tells you how the material responds to magnetization.

Material considerations:

- Silicon steel laminations (non-oriented):

- The workhorse for DC and low-to-mid frequency AC applications. Balanced cost and performance. Good for BLDC stators with typical electrical frequencies.

- CRNO/CRNGO laminations (cold-rolled non-oriented):

- Similar non-oriented family for motors where the magnetic field rotates in many directions.

- CRGO laminations (grain-oriented):

- Used mostly in transformers where the flux stays in one direction. Not ideal for rotating machines because properties vary by direction.

- Cobalt alloys:

- Offer high saturation flux density and low losses at higher frequencies. Expensive. You see them in aerospace and high power density machines where every gram counts.

- Amorphous and nanocrystalline materials:

- Very low core loss at high frequencies. These materials can be brittle and costly. Best for specialized high-speed machines or compact drives.

Thickness guidance:

- Thinner laminations reduce eddy current loss at higher frequency. If your electrical frequency rises due to high pole count or high RPM you need thinner sheets.

- Thicker laminations can work for low-frequency or low-speed designs where stamping cost outweighs small efficiency gains.

Manufacturing and assembly processes:

- Stamping:

- Best for high-volume production. Low cost per part once you amortize tooling. Watch burr height and edge quality which affect magnetic performance and insulation integrity.

- Laser cutting:

- Great for prototyping or complex, low-volume designs. No hard tooling. Beware of heat-affected zones which can increase local losses. Post-processing can mitigate it.

- Waterjet and wire EDM:

- Useful for special alloys or when thermal effects must be avoided. Slower and more expensive for volume.

- Bonding and interlocking:

- Interlocking laminations act like LEGO bricks. You get a strong stack without welding which preserves magnetic properties. Bonding adhesives can further cut vibration and acoustic noise. Welding can degrade local magnetic properties unless done carefully with controlled heat input.

- Insulation coatings:

- Classify coatings by interlaminar resistance and thermal class. Insulation must survive your operating temperature and the stack pressing process.

Fit these choices to your design. For example a BLDC drone motor with high electrical frequency benefits from thin laminations and low-loss silicon steel or cobalt alloys. A low-speed brushed pump motor can use thicker and cheaper non-oriented steel. A medical device with tight noise targets benefits from bonded stacks that reduce vibration.

If you want to go deeper on structures and options start with these resources:

- Explore complete motor core laminations to see typical stack constructions.

- Review stator core lamination options and how tooth shape, slot geometry, and insulation affect winding fill and torque density.

- Compare rotor core lamination approaches for internal vs external rotor BLDC designs.

- Material selection matters. See common grades under electrical steel laminations.

Matching Options to Applications

Let’s map brushed vs brushless and lamination choices to common applications. You can scan this and quickly shortlist a path.

- Power tools motors:

- Premium cordless tools moved to BLDC. Users get longer run time and better torque under load. Thin non-oriented silicon steel and bonded stators help with vibration and heat. Brushed motors still appear in entry-level drills where cost dominates.

- Drones and RC vehicles:

- Brushless wins. High power density and sensorless startup work well with props and wheels. Pancake motors and external rotor BLDC designs maximize torque per volume. Thinner laminations improve efficiency at high electrical frequency.

- Robotics motors and servo motors:

- Brushless with sensored control. FOC improves positioning and smoothness. Low-cogging designs and skewed stator teeth reduce torque ripple. Precision winding and tight lamination tolerances matter.

- Electric bike motors and scooter motors:

- Brushless hub or mid-drive with regenerative braking. Torque at low speed and efficiency at cruising speed both matter. Use robust insulation and coatings to handle road spray and dust.

- Electric vehicles:

- Traction motors use brushless AC topologies like permanent magnet synchronous motors which are cousins of BLDC. You still rely on laminations to control core loss under high switching frequencies in the inverter. Thermal management and cooling methods become a system-level design.

- Industrial motors:

- BLDC and AC induction motors dominate. Induction motors use VFDs for speed control. Laminations remain critical for heat and efficiency. For explosion-proof motors and harsh environments favor robust coatings and sealed housings with appropriate IP rating.

- Consumer electronics motors:

- Fans, HVAC motors, and compressor motors increasingly use electronically commutated designs for efficiency and noise control. Coreless motors appear in small devices where inertia must be low.

- Home appliances:

- Washing machine motors moved toward BLDC for quiet operation and higher efficiency. Vacuum cleaner motors use high-speed BLDC with careful balancing and low-loss laminations.

- Medical device motors:

- Reliability, noise, and EMI control drive choices. BLDC with bonded stacks and shielded ESCs help meet regulatory targets.

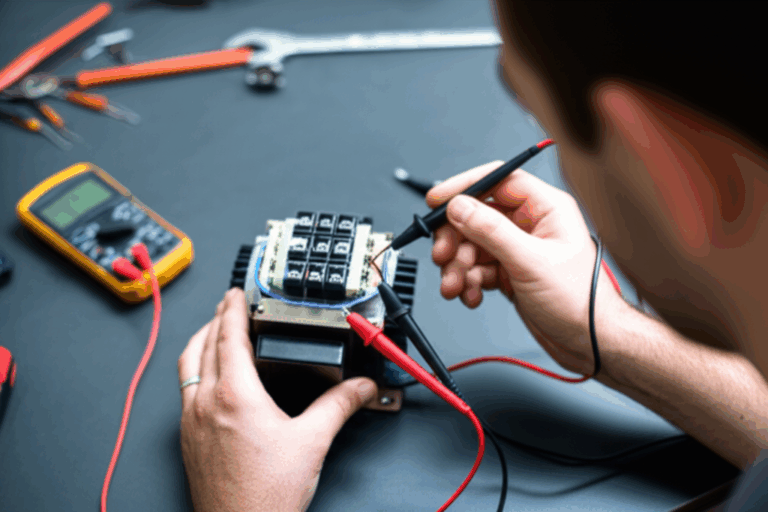

Practical Selection Guide: Factors to Consider

Use this checklist during concept selection and supplier discussions.

- Budget:

- If purchase price drives the decision use brushed. If total cost of ownership matters brushless often wins due to reduced energy and maintenance.

- Performance needs:

- Target power density, torque output, and speed control. Brushless with FOC gives the best low-speed torque and efficiency curves.

- Lifespan and reliability:

- Brushless lasts longer. Plan for bearing life and lubrication strategy.

- Maintenance tolerance:

- Choose brushed only if you can service brushes and commutators. Otherwise select brushless to avoid downtime.

- Operating environment:

- Dust, shock, and water expose weaknesses. Pick appropriate sealing and consider waterproof motors, dust resistance, and shock resistance. For hazardous locations specify explosion-proof motors.

- Thermal management:

- Estimate core loss and copper loss. Verify stack temperature with your cooling methods and airflow. Set insulation class to match peak temperature.

- Control strategy:

- Decide sensorless vs sensored brushless. Sensorless simplifies hardware. Sensored delivers smooth startup and low-speed control. For brushed motors confirm PWM strategy and consider EMI filters.

- Electrical compatibility:

- Match voltage and current requirements to the battery pack or PSU. Confirm motor current draw at peak and continuous loads. Check your ESC or motor controller current rating and heat sinking.

- Mechanical integration:

- Space constraints push you toward internal vs external rotor choices. Consider gearboxes and motors as a set. A gearbox can trade speed for torque efficiently which may allow a smaller motor.

- Compliance and noise:

- EMI and acoustic noise targets drive design choices for switching frequency, shielding, and lamination bonding.

Reliability, Thermal, and EMC Considerations

Heat kills motors. It breaks down insulation and cooks bearings. It also shortens magnet life if you run too hot for too long.

- Thermal management:

- Use efficiency data and loss models to size heat sinks and airflow. Windings on the stator in BLDC motors shed heat better than rotor windings in brushed designs which improves continuous ratings.

- Bearings:

- Bearing life sets practical lifespan for brushless designs. Pick proper lubrication and seals for your environment.

- Vibration in motors:

- Lamination bonding and rotor balancing reduce vibration. Skewing stator slots mitigates cogging torque.

- EMI and noise pollution:

- Brushed motors spark at the commutator which creates electromagnetic interference. Brushless motors avoid this and let you manage EMI through ESC switching strategies and filters.

- IP rating motors:

- Define the needed ingress protection early. IP-rated housings and potting compounds protect windings and sensors.

- Failure modes:

- Brushed: brush wear, commutator pitting, winding shorts from heat, and bearing failure.

- Brushless: controller failure, sensor failure in sensored systems, demagnetization at high temperature, and bearing failure.

Controls and Performance Tuning

Control electronics translate into feels-fast velocity and torque control on the bench.

- PWM:

- Simple speed control for brushed motors. BLDC ESCs also use PWM to control phase voltage.

- Back EMF:

- Sensorless BLDC controllers detect rotor position from back EMF. This reduces wiring and improves reliability in harsh environments.

- Hall effect sensors:

- Provide rotor position for smooth startup and low-speed torque. You trade complexity for precision.

- Field Oriented Control:

- FOC aligns current with the rotor field. It improves efficiency and torque linearity. It reduces acoustic noise and heat under load.

- Regenerative braking:

- BLDC systems can return energy to the battery under deceleration. Great for EVs, e-bikes, and logistics robots. Not useful for brushed setups without special arrangements.

- Startup and acceleration:

- Sensorless BLDC can stumble under heavy load at zero speed. Sensored solutions, or a clutch/gearbox, solve it.

- Winding configurations:

- Delta vs wye winding changes torque and speed characteristics at a given voltage. Wye often delivers higher torque per amp at lower speed which suits heavy loads.

- Internal vs external rotor:

- External rotor BLDC (outrunner) increases torque at low speed due to larger effective radius. Internal rotor designs spin faster with lower inertia which suits high RPM fans or spindles.

- Coreless and pancake motors:

- Coreless motors remove iron from the rotor to cut inertia which boosts responsiveness. Pancake motors offer a flat form factor for tight spaces.

Cost and Total Cost of Ownership

You can buy a small brushed DC motor for under $10. A comparable BLDC motor often costs two to three times more plus the ESC. That’s the sticker price. Energy and maintenance tell the full story.

- Energy:

- At 10–20% higher efficiency a BLDC motor draws less current for the same shaft power. Batteries last longer. Utility bills drop in steady-duty applications.

- Maintenance:

- Brushed motors require brush replacement and commutator service every 500–1,000 hours in many duty cycles. Downtime costs more than spare parts in production environments.

- Reliability:

- Brushless drives reduce unscheduled downtime which protects throughput and delivery schedules.

- Scaling:

- For high-volume manufacturing stamped laminations and standardized ESC platforms reduce unit cost. For prototypes and low-volume runs laser-cut laminations and off-the-shelf controllers cut lead time.

Total cost of ownership often favors brushless motors for high duty cycles or battery-powered systems. Brushed motors hold ground in low-cost products with intermittent use.

Your Engineering Takeaway and Next Steps

Here’s the bottom line in plain terms.

- If you want higher efficiency, longer lifespan, better speed control, and lower noise pick brushless with a right-sized ESC.

- If you need the lowest upfront cost and simple control pick brushed and budget for maintenance.

- Don’t ignore laminations. Material, thickness, and stack construction dictate core loss which hits heat, efficiency, and battery life.

- Match control strategy to your use case. Sensorless reduces parts. Sensored yields smooth low-speed torque and predictable startup.

- Design for the environment. Target the right IP rating, shock and dust resistance, and thermal management from the start.

Actionable next steps:

- Define your duty cycle and electrical frequency. That sets lamination thickness and material shortlists.

- Estimate copper and core loss at peak and continuous points. Validate with a prototype and thermal test.

- Choose your commutation approach. For BLDC decide sensorless vs sensored and whether you need FOC.

- Align winding configuration and gearbox selection with torque-speed targets.

- Engage your lamination supplier early. Share flux density targets, slot geometry, coating requirements, and stack assembly method.

If you need a quick primer or a deeper dive on core components and stack construction review:

- The overview of motor core laminations.

- Practical options for stator core lamination.

- Design choices for rotor core lamination.

- Material families covered under electrical steel laminations.

You can now make a confident brushed vs brushless call. You also know how lamination choices move the needle on efficiency, heat, and lifetime. That gives you leverage in design reviews and a stronger hand in supplier conversations.

Additional technical notes and context for specialists:

- DC vs AC motor types:

- Brushed and brushless DC cover most small to medium motion tasks. AC induction motors and synchronous motors rule large industrial applications with VFDs for speed control.

- Performance metrics to track:

- Efficiency curves, torque constant, Kv, back EMF, continuous vs peak ratings, thermal resistance, current draw at load, and insulation class.

- Motor sizing:

- Use your load profile to size continuous and peak torque. Select continuous power output and thermal path first. Then check acceleration and braking limits.

- Cooling methods:

- Natural convection, forced air, and liquid cooling. Stator-mounted windings simplify heat sinking in BLDC designs.

- EMI management:

- Use proper cable shielding, dv/dt filters, and layout discipline. Higher PWM frequency can reduce acoustic noise at the cost of switching loss.

- Environmental specs:

- IP rating, waterproof motors, dust resistance, chemical exposure, and explosion-proof certification for hazardous zones.

- System integration:

- Battery compatibility, voltage requirements, and current requirements shape controller selection. Confirm regenerative braking strategy and battery charge acceptance limits.

- Construction differences:

- Skewed laminations reduce cogging torque. Interior permanent magnet rotors improve field weakening and high-speed capability in EV traction motors.

Finally remember the big picture. Better laminations cut losses. Better control cuts ripple and noise. The right motor type puts those gains to work in your application. You do not have to guess. Prototype early, measure heat and efficiency, and lock in your stack design with a supplier who can scale.