Can Steel Wool Conduct Electricity? (Yes, and Here’s Why it’s Dangerous)

Of course. Here is the comprehensive, long-form article based on your instructions.

Table of Contents

- My First Shocking Discovery with Steel Wool

- The Simple Answer: Yes, Steel Wool is a Conductor

- Why Steel Wool Conducts Electricity So Effectively

- It’s All About the Metal

- A Tangled Web of Tiny Wires

- The Significant Dangers of Steel Wool and Electricity

- The Immediate Danger: Short Circuits

- An Extreme and Deceptive Fire Hazard

- The Risk to Batteries: Not Just a Science Trick

- Damage to Your Electrical Systems and Electronics

- The Personal Risk: Burns and Electric Shocks

- Factors Influencing Steel Wool’s Electrical Behavior

- The Grade of the Wool Matters

- Voltage and Current: The Power Behind the Reaction

- Oxygen: The Fuel for the Fire

- Common Scenarios and Misconceptions I’ve Seen

- The Famous 9V Battery Fire Starter Trick

- The Cleaning Mistake: Never Use It Near Live Electronics

- The Biggest Myth: Steel Wool as Insulation

- My Essential Safety Precautions When Handling Steel Wool

- Final Thoughts: A Tool to Respect

My First Shocking Discovery with Steel Wool

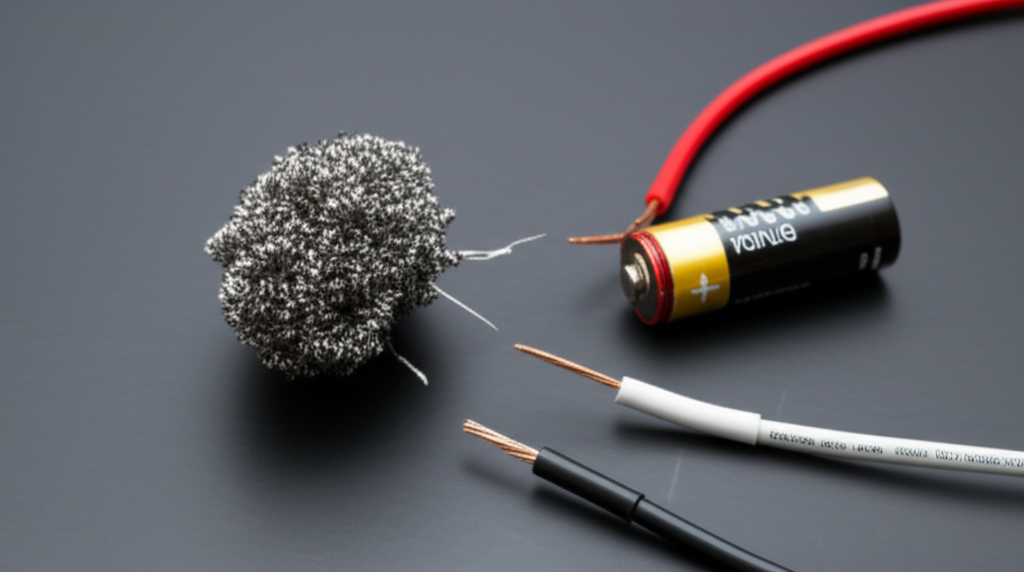

I’ll never forget the first time I truly understood the danger of steel wool. I was a teenager in my dad’s workshop, trying to clean some rust off an old tool. I had a pad of fine steel wool in one hand and was rummaging through a drawer for a wrench. That drawer was a classic “junk drawer”—screws, nuts, bolts, and a few stray 9-volt batteries.

The moment the steel wool brushed against the terminals of one of those batteries, it wasn’t a slow burn. It was an instant, brilliant flash of light. A web of orange sparks raced through the pad, and it burst into a glowing, smoldering mess. It happened so fast I barely had time to drop it. My heart was pounding, and the smell of burnt metal filled the air.

That little incident taught me a lesson that a textbook never could: steel wool isn’t just a simple cleaning tool. It’s a powerful electrical conductor, and if you don’t respect it, you can get into serious trouble. So, if you’re asking, “Can steel wool conduct electricity?” the answer is a resounding, fiery yes. In this article, I want to walk you through exactly why it’s so conductive, the real-world dangers it poses, and how you can use it safely without repeating my near-disaster.

The Simple Answer: Yes, Steel Wool is a Conductor

Let’s get straight to the point. Steel wool absolutely conducts electricity. It’s not an insulator, not even a poor conductor—it’s a good one.

Think about what it’s made of: steel. Steel is a metal alloy, primarily composed of iron and carbon. And one thing we all learn early on in science class is that metals are fantastic at conducting electricity. The reason for this lies deep in their atomic structure. Metals are full of what scientists call “free electrons.” You can picture these electrons as a sea of tiny particles that aren’t tightly bound to any single atom. When you apply a voltage from a source like a battery, these electrons are free to move, creating an electrical current.

So, at its core, steel wool is just metal. But it’s not a solid block of metal. It’s a tangled mass of incredibly fine, sharp metal fibers. This unique structure is what makes it not only a good conductor but also a particularly hazardous one.

Why Steel Wool Conducts Electricity So Effectively

It’s one thing to know that steel wool conducts electricity; it’s another to understand why it does so with such dramatic results. I’ve found that two key factors make it behave the way it does: its metallic composition and its strange, fibrous structure.

It’s All About the Metal

As I mentioned, steel wool is made of steel, which is mostly iron. Iron atoms, like those in most metals, are arranged in a crystalline structure called a metallic bond. In this setup, the outer electrons of the atoms aren’t held tightly in place. They form a delocalized “sea” that can flow freely throughout the material.

When you touch the terminals of a battery to steel wool, you create a complete circuit. The voltage from the battery pushes that sea of electrons into motion, and voilà—you have an electrical current flowing through the steel fibers. It’s a fundamental principle of how electricity works, and a powerful demonstration of a core motor principle where controlled electrical flow creates motion. In steel wool, however, that flow is anything but controlled.

A Tangled Web of Tiny Wires

Here’s where things get really interesting and dangerous. Steel wool isn’t a solid wire. It’s a chaotic bundle of thousands, maybe millions, of incredibly thin strands. This structure has a few critical effects:

Think of it like this: a thick copper wire is like a four-lane highway for electricity—traffic flows easily without much friction. A single strand of steel wool is like a narrow, bumpy country lane. The electricity has to work harder to get through, and that “work” is released as intense heat. When you have millions of these tiny, overheating lanes right next to each other, you get a chain reaction that causes the whole pad to glow red-hot and ignite.

The Significant Dangers of Steel Wool and Electricity

My little workshop scare was just a preview of what can go wrong. Over the years, I’ve learned that the combination of steel wool and electricity presents several distinct and serious hazards. It’s not just a theoretical risk; these are real-world dangers you need to be aware of.

The Immediate Danger: Short Circuits

A short circuit happens when electricity finds an unintended, low-resistance path between two points in a circuit—like from the positive to the negative terminal of a battery. Steel wool is practically designed to create short circuits.

Imagine you’re working on a car and accidentally drop a piece of steel wool across the terminals of the car battery. You’ve just created a direct bridge. An enormous amount of current will instantly flow through the wool, causing it to vaporize in a brilliant, dangerous electrical arc. This can damage the battery, melt tools, and cause severe burns. The same thing can happen on a smaller scale if a stray fiber falls into an electronic device or touches the prongs of a plug near an outlet. The resulting short can blow fuses, trip circuit breakers, or permanently damage sensitive components.

An Extreme and Deceptive Fire Hazard

This is the big one. As my own experience showed, steel wool doesn’t just get hot—it catches fire. The heat generated by the electrical current is more than enough to reach the ignition temperature of the fine steel fibers, which is surprisingly low, around 400°F (200°C).

What happens next is a rapid oxidation process. You’re not just seeing the steel glow; you’re watching it actively burn. The iron in the steel reacts with the oxygen in the air in a fiery, exothermic reaction. Because of the massive surface area of the fibers, this fire spreads through the pad in seconds.

According to the National Fire Protection Association (NFPA), short circuits are a common cause of electrical fires in homes. While they don’t track “steel wool incidents” specifically, it’s easy to see how a forgotten pad of steel wool in the wrong place could easily become the ignition source for a much larger and more devastating fire. It’s a classic example of the fire triangle in action: you have fuel (the steel wool), heat (from the electrical resistance), and oxygen (from the air).

The Risk to Batteries: Not Just a Science Trick

I’ve seen countless videos online showing people starting fires with steel wool and a 9V battery as a survival hack. It works spectacularly well, but it also highlights the danger. Any battery, from a small AA to a large car battery, can provide enough current to ignite steel wool.

When you short a battery with steel wool, it draws current far faster than it was designed to. This can cause the battery to overheat, leak corrosive chemicals, or in very rare and extreme cases with certain battery types, even explode. I always store my steel wool and batteries in completely separate containers for this very reason. It’s a simple precaution that prevents a world of trouble.

Damage to Your Electrical Systems and Electronics

Even if you avoid a fire, the conductive nature of steel wool can wreak havoc on your electronics. The tiny fibers can break off and become conductive dust. If this dust gets inside a computer, a power tool, or an electrical panel, it can settle on circuit boards and create tiny short circuits between components.

This can lead to intermittent glitches, permanent failure, or even a fire inside the device. I once had to diagnose a persistent issue in a piece of workshop equipment, and after hours of troubleshooting, I found a tiny shard of steel wool bridging two contacts on the main board. It was a simple mistake that could have led to a major motor problem or a complete system failure. This is why you should never, ever use steel wool to clean electrical contacts or components while they are energized.

The Personal Risk: Burns and Electric Shocks

Finally, let’s not forget the direct harm to you. The sparks and flames from burning steel wool can easily cause nasty burns. The sparks are actually tiny, molten globules of iron oxide, and they can stick to your skin or clothing.

Furthermore, if you’re using steel wool to bridge a higher-voltage circuit, you’re creating a live, uninsulated wire. Touching it could result in a serious electrical shock. While a 9V battery won’t shock you, household currents or automotive systems certainly can. It’s just not worth the risk.

Factors Influencing Steel Wool’s Electrical Behavior

Not all encounters between steel wool and electricity are identical. The intensity and speed of the reaction depend on a few key variables. Understanding these can help you better appreciate the risks.

The Grade of the Wool Matters

Steel wool comes in different grades, from coarse (#4) to super-fine (#0000). In my experience, the finer the grade, the more spectacular the reaction. A super-fine pad has much thinner fibers and more surface area packed into the same space. This means the individual strands heat up even faster and the fire spreads more quickly. A coarse pad will still conduct and get hot, but it might not ignite as readily as its finer counterpart.

Voltage and Current: The Power Behind the Reaction

The power source is a huge factor. A 1.5V AA battery can make fine steel wool glow, but it might struggle to ignite it. A 9V battery, on the other hand, provides enough voltage to push sufficient current through the fibers to cause immediate combustion. A 12V car battery will do it even more dramatically and violently. Higher voltage and current lead to more heat generated more quickly, resulting in a more intense and dangerous reaction.

Oxygen: The Fuel for the Fire

Remember, the burning of steel wool is an oxidation reaction. It requires oxygen. If you fluff up a pad of steel wool, introducing more air between the fibers, it will burn much faster and more brightly than a tightly compressed pad. This is why the survival trick involves stretching the wool out a bit to ensure good airflow.

Common Scenarios and Misconceptions I’ve Seen

Because steel wool is such a common household item, people often use it in ways that put them at risk without even realizing it. Here are a few common scenarios and dangerous myths I’ve encountered.

The Famous 9V Battery Fire Starter Trick

This is probably the most well-known application of steel wool’s conductivity. It’s often taught as a survival skill for emergency fire starting. You simply touch both terminals of a 9V battery to a fluffed-up piece of steel wool, and it bursts into flame. You can then use the glowing wool to ignite tinder.

While this is an undeniably effective technique, it should only be done in a controlled, intentional manner. It’s a demonstration of a physical principle, not a toy. The danger is that people, especially kids, see this and don’t appreciate the risk. They might leave a 9V battery and steel wool together in a drawer or a backpack, creating a perfect recipe for an accidental fire.

The Cleaning Mistake: Never Use It Near Live Electronics

I’ve heard stories of people trying to clean battery corrosion off terminals or scrub grime near electrical outlets with steel wool. This is an incredibly bad idea. As I mentioned earlier, the tiny conductive fibers that break off can cause shorts. If you’re working near a live circuit, you could get a shock, cause an electrical arc, or start a fire. Always disconnect the power source completely before doing any cleaning or work near electrical components. Better yet, use a non-conductive tool like a plastic brush or a dedicated contact cleaner. The conductive properties of steel are a world away from the controlled design of materials like silicon steel laminations, which are engineered to manage electrical energy, not just short it out.

The Biggest Myth: Steel Wool as Insulation

This one is thankfully rare, but it’s dangerously misguided. Some people mistakenly think that because it looks like wool, it might have insulating properties. Nothing could be further from the truth. Steel wool offers zero electrical insulation. In fact, it does the exact opposite. Packing it around a wire or in an electrical box is like inviting a short circuit to happen. True insulators are materials like rubber, plastic, and ceramic, which do not have free electrons and block the flow of current.

My Essential Safety Precautions When Handling Steel Wool

After years of working in shops and seeing what can go wrong, I’ve developed a strict set of rules for handling steel wool. They’re simple, but they’ll keep you safe.

Final Thoughts: A Tool to Respect

So, can steel wool conduct electricity? Absolutely. It’s a powerful conductor, and its unique fibrous structure makes it an exceptional fire starter when it comes into contact with a power source.

It’s a fantastic tool for polishing wood and cleaning metal, but it carries a hidden electrical hazard that many people overlook. My close call in my dad’s workshop taught me to respect its properties. It’s not something to be feared, but it’s certainly something to be understood. By knowing the science behind it and following a few common-sense safety rules, you can use steel wool for all its intended purposes without ever having to deal with the shocking, fiery surprise of an unexpected short circuit. Stay safe out there.