DIY Guide: How to Replace a Windscreen Wiper Motor (Step-by-Step)

Short summary: Your wipers matter when rain hits. If the motor fails you lose a clear view. In this simple guide I show you how to replace a wiper motor step by step. You learn the tools you need, how to stay safe, how to test the new part, and how to fix common problems. Read on and save time and money.

Table of Contents

- What does a wiper motor do and why replace it?

- What are the signs of a failing wiper motor?

- Is DIY right for you? Cost, time, and difficulty

- What tools and parts do you need?

- How should you prepare and stay safe?

- Step-by-step wiper motor guide

- How to test, adjust park, and align arms

- Troubleshooting after replacement

- Care and maintenance to make it last

- Model notes and special cases

- When should you call a pro?

- References

- Summary

What does a wiper motor do and why replace it?

A wiper motor turns electric power into motion. It drives the wiper linkage that moves the wiper arms and wiper blades across the windshield. You get a clear view in rain and snow. When the motor fails the wipers stop. You lose sight of the road. That is not safe.

I have seen common wiper motor problems in many cars. Water ingress can leak past a weather seal or a gasket and cause corrosion. The plastic gear stripping wiper motor issue can pop up when blades stick to ice. Sometimes a weak ground wire for wiper motor or a bad power supply to wiper motor causes trouble. When I diagnose faulty wiper motor issues I check these first.

If your wipers quit in a storm you have a problem. You feel stuck and worried that you cannot drive. That fear is real. Let’s agitate it for a second. Wet roads are slick. Your family rides with you. You need clear glass to react fast. Now the solution. You can replace wiper motor at home with a simple step-by-step wiper motor guide. You can do a DIY wiper motor replacement and get your view back today.

What are the signs of a failing wiper motor?

You may spot broken wiper motor symptoms like wipers that do not move. You may hear a click from the Relay (wiper) yet the arms stay put. You may smell a burning smell from wipers. You may see wipers stop mid-sweep or wipers won’t park in the right place. Sometimes the wipers slow in rain when the motor gets weak.

Watch for symptoms of a failing wiper motor like noise from wiper motor area. Check if you get a blown fuse wiper motor. You may see relay clicking but no wipers. Use a Multimeter to do a continuity test wiper motor circuit and resistance testing wiper motor. Check wiper motor current fluctuations and do checking wiper motor current draw. If needed review a wiring diagram wiper motor or wiper motor schematic to trace diagnosing open circuit wiper motor or diagnosing short circuit wiper motor.

If you have a rear blade that does not move you may need rear wiper motor fitting. If only one side quits you may have passenger side wiper motor or driver side wiper motor linkage trouble. If the wipers move but park wrong you likely need park position adjustment wiper motor or proper wiper arm alignment.

Is DIY right for you? Cost, time, and difficulty

Let’s talk time, money, and skill. The wiper motor replacement time for a first timer runs 3 to 5 hours. If you have done this before you may finish in 1 to 3 hours. The difficulty level DIY wiper motor is moderate. You will handle trim and bolts. You will test power. You can do it with care and patience.

What about the wiper motor replacement cost? The cost of new wiper motor varies by car. Parts run $50 to $300 for OEM wiper motor replacement or aftermarket wiper motor options. You can save with used wiper motor installation yet test it first. A professional mechanic cost wiper motor job adds $150 to $400 in labor. That helps you weigh DIY against professional wiper motor installation.

Here is a quick data table you can use.

| Data point | Typical range | Notes |

|---|---|---|

| Average DIY time | 1–3 hours (experienced) 3–5 hours (beginner) | Depends on access and scuttle panel removal |

| Professional labor cost | $150–$400 | Region and model vary |

| New part cost | $50–$300+ | Original Equipment Manufacturer (OEM) costs more than Aftermarket parts |

| Expected lifespan | 10–15+ years | Can drop to 5–7 years with harsh use |

What tools and parts do you need?

You do not need a shop full of gear. A simple set works great. Here is your checklist of tools for wiper motor replacement.

- Socket wrench set

- Screwdriver set (Phillips and flathead)

- Trim removal tools

- Pliers and Wire strippers

- Torque wrench

- Multimeter

- Grease/lubricant

- Penetrating oil for removing seized wiper motor

- Shop towels/rags

You also need parts. You will buy a new Wiper motor assembly from an Automotive parts store. You can choose OEM or Aftermarket parts from makers like Bosch, Valeo, or Denso. Check the Vehicle owner’s manual to confirm the wiper motor location and the right part number. Inspect the wiper linkage. If the joints feel loose you may need wiper motor linkage repair or even when to replace entire wiper assembly. Grab extra Plastic clips, Gasket, wiper motor grommet replacement items, and Bolts/nuts in case you break old ones.

Pro tip: Better motors use better steel inside. The quality of the core can change how smooth the motor runs. If you want to learn how this works take a look at motor core laminations and why high-grade electrical steel laminations cut losses and heat. That background helps you pick parts with confidence.

How should you prepare and stay safe?

Work on a level spot. Set the brake. Open the Hood (bonnet). Turn the key off and remove it. Now disconnect battery for wiper motor work. Pull the negative terminal on the Battery (vehicle) to stay safe.

Lay fender covers or towels to start protecting vehicle paint during repair. Keep small parts in a tray. Mark the wiper arms park spot on the windshield with tape. That note saves you time later. Review safety precautions wiper motor repair in your manual. Do not force stuck parts. Use oil and a puller if needed.

I also check the Fuse box and do a wiper motor relay check before I start. You may find a simple fault like a blown fuse wiper motor or bad Relay (wiper). That fix is quick. If fuses keep blowing you may have a short in the Wiring harness or Control module (BCM/ECM) or a bad Wiper switch (stalk). Fix that first.

Step-by-step wiper motor guide

Follow this front wiper motor installation walk-through. The steps also help with car wiper motor change, truck wiper motor installation, van wiper motor replacement, and SUV wiper motor fitting. A universal wiper motor fitting may need small changes. A manual wiper motor conversion is a special case and is not covered here.

- Step 1: Prepare the car

- Park on flat ground. Key off. Remove the key.

- Disconnect the negative battery cable.

- Protect paint with towels.

- Step 2: Remove wiper arms

- Lift the arms and lock them up if they have a tab.

- Pop off the caps. Loosen and remove the nuts.

- Gently wiggle and pull the arms off the splined shafts. Use a puller if they stick. This is the safe way to remove wiper arms.

- Step 3: Open the way with cowl panel removal

- The Scuttle panel and Cowl trim sit at the base of the glass. Find all Plastic clips, screws, or bolts.

- Pull the washer hose if fitted. Unclip any Electrical connector nearby.

- Lift the panel. This clears the motor bay. On some cars you also need windscreen trim removal.

- Step 4: Unplug and disconnect the wiper motor

- Find the Wiper motor assembly and the Electrical connector for wiper motor.

- Press the tab and unplug it. Check for a tight Ground connection.

- Pop the wiper linkage off the motor shaft. There may be a clip or a small nut.

- Step 5: Windshield wiper motor removal

- Remove the mounting bolts for wiper motor.

- Note the wiper motor bracket installation and part orientation. Take a photo so you remember.

- Pull the motor free with care. Watch the Firewall (vehicle) area so you do not scratch it.

- Step 6: Install wiper motor

- Fit the new motor in the same position. Start the bolts by hand.

- Tighten to the right torque settings wiper motor from the manual if given.

- Refit the linkage to the shaft. Add wiper motor shaft lubrication to the joint if the maker calls for it. This helps prevent water damage wiper motor and wear.

- Step 7: Wire and test

- Plug in the connector. Make sure the power supply to wiper motor and Ground connection are solid.

- Reconnect the battery. Turn on the key.

- Test wiper motor operation on all speeds. Try intermittent wiper motor fix mode, low, high, and the washer. Do the blades make a full sweep and park right. If not stop and adjust.

- Turn the key off. Disconnect the battery again before you finish the build.

- Step 8: Refit panels and arms

- Reinstall the cowl. Reconnect hoses and clips. Replace broken Plastic clips with new ones. This helps with plastic trim clip replacement.

- Tighten all screws. Seat the panel to keep out water.

- Align the wiper arms to the tape marks. This is wiper blade adjustment after motor replacement.

- Tighten the arm nuts. Do not overdo it.

- Step 9: Final check after wiper motor replacement

- Reconnect the battery and run a final test.

- Confirm the sweep and park position adjustment wiper motor looks right.

- Clean up your tools and old parts. Follow your local rules to recycle the old motor.

That is the full reassembly instructions wiper motor at a glance. Take your time. Keep parts in order. You will get it done.

How to test, adjust park, and align arms

Before you bolt the cowl back make sure the motor parks in the right spot. Some motors need a set-up step. You can power the motor with the linkage off. Turn it to park. Then stop it. That way you know the shaft sits at park. Now set the linkage and arms so the blades sit low on the glass.

This is also when you check the electrical connector for wiper motor, the wiper motor fuse location, and the wiper motor relay check if the new motor will not run. If your system has a multi-function switch wiper motor stalk and a Control module (BCM/ECM) you may need to clear a fault code after you plug it back in. Not always yet some cars ask for it.

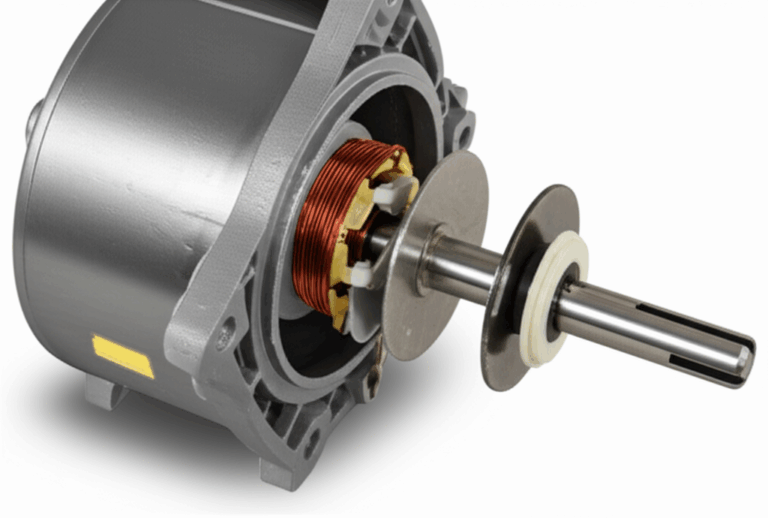

Have a 2-speed unit. You can learn how to wire a 2-speed wiper motor with a simple wiring diagram wiper motor in your manual. Check Voltage at the pins. Make sure Electric current flows on low and high. Use your Multimeter to confirm continuity and resistance. If you have trouble a primer on how electric motors work and stator and rotor parts helps. You can also scan stator and rotor basics to see why correct park matters.

Troubleshooting after replacement

If the wipers not working troubleshooting starts after you install the new unit start simple. Check the fuse. Confirm the wiper motor fuse location in the manual. Listen for the Relay (wiper) click. If you hear a click yet no motion check the Ground connection and the signal at the plug.

If the wipers park high you may need proper wiper arm alignment. Pull the arms. Set them lower. Try again. If the wipers mount tight yet you still get chatter or noise from wiper motor area check the wiper linkage joints. They may need grease or wiper motor refurbishment. If you see rusted wiper motor issues on the mount add Silicone sealant around grommets and replace the Gasket to keep water out.

Here is a quick wiper motor troubleshooting chart.

| Symptom | Possible cause | Quick fix |

|---|---|---|

| No movement | Fuse blown or bad relay or no power | Check fuse and relay then test for voltage at motor |

| Click but no sweep | Linkage off or stripped spline | Reattach linkage or replace arm or gear |

| Stops mid-sweep | Bad park switch inside motor | Replace motor or module |

| Slow in rain | Weak motor or binding linkage | Lubricate linkage or replace motor |

| Will not park | Wrong arm alignment or park switch fault | Reset arms or replace motor |

| Burning smell | Stalled motor due to ice load | Clear ice and check current draw |

If you run into a deep wiring issue you may need to checking wiring harness wiper motor continuity. Look for diagnosing open circuit wiper motor breaks or diagnosing short circuit wiper motor to ground. Watch Voltage drop under load. That points to a bad connector.

Care and maintenance to make it last

Your motor can last a long time. How long does a wiper motor last. Many run average lifespan wiper motor of 10 to 15 years. Some fail sooner in harsh weather. You can stretch life with smart care.

- Keep the glass clean. Grit wears blades and loads the motor.

- Change wiper blades on schedule. Old blades drag. They force the motor to work harder.

- Clear snow and ice by hand. Do not use the wipers as a snowplow or you risk overload and Stripped gears.

- Check the wiper linkage for play. Grease joints with Grease/lubricant.

- Seal the cowl to prevent water damage wiper motor. Fix loose panels and renew grommets.

Curious why motors fail. Inside each motor sit a stator and a rotor. They have thin steel sheets called laminations. Better laminations waste less power as heat. That keeps motors cooler and helps them live longer. If you are a maker or a buyer for a shop you can learn how stator core lamination and rotor stacks affect motor life. See motor core laminations and what high grade electrical steel laminations do inside small electric wiper motor replacement parts.

Model notes and special cases

Models differ yet the core steps stay the same. On a Ford Focus the cowl clips can be tight. On a VW Golf the Scuttle panel sits under the edge of the glass. On a Honda Civic you should protect the cowl edge which can crack. BMW (specific models) and Audi (specific models) sometimes place the motor deep under covers. Toyota Camry has a clear layout and easy arm access. Nissan Qashqai may hide extra screws under caps. Chevrolet Silverado trucks give you room yet the arm splines can seize.

Some General Motors (GM) trucks need an extra ground strap to cure a slow sweep. Many European cars use capped torx Bolts/nuts on the cowl. Use the right bit. Always read the Vehicle owner’s manual for specific model wiper motor tutorial notes and torque specs.

Working on the back glass. The rear wiper motor fitting steps look the same yet access changes. Remove the rear trim panel. Unclip the hose. Then swap the motor. Watch for tiny Plastic clips. Have spares ready.

When should you call a pro?

I love DIY. Still some jobs call for help. If your car needs dash removal. If the wiring fails the test. If the wiper motor module replacement must be coded to the car. Call a Professional mechanic. A shop has scan tools to test Voltage, Electric current, and software links to the Control module (BCM/ECM). They know the wiper motor bolt size and torque settings wiper motor by heart.

Also think about legal requirements for wipers. Many places ask for working wipers and washers by law. Your annual vehicle inspection wiper check will fail if the sweep does not work. If you do not feel safe. If time is tight. A pro can get it done fast and right.

References

- Haynes and Chilton service manuals for your vehicle. Model specific torque and wiring.

- RepairPal and AAA for typical costs and time ranges.

- NHTSA and local road safety groups for visibility and weather safety tips.

- Bosch, Denso, Valeo catalogs for part numbers and fitment.

- Your Vehicle owner’s manual for fuse and relay maps and wiper motor fuse location.

Summary

- You can replace wiper motor at home with basic tools.

- Always disconnect battery for wiper motor work first.

- Remove arms and do cowl panel removal to reach the unit.

- Unplug the Electrical connector for wiper motor and lift the old motor out.

- Fit the new one. Tighten to spec. Reconnect the wiper linkage.

- Test all modes. Set the park position adjustment wiper motor. Then refit panels and wiper arms.

- If you get wipers stop mid-sweep or wipers won’t park fix the arm alignment or check the park switch.

- Do preventative maintenance wipers. Clean glass. Replace wiper blades. Clear ice by hand.

- Use your Multimeter for wiper motor troubleshooting chart checks like continuity test wiper motor circuit and checking wiper motor current draw.

- Pick solid parts. OEM from Bosch, Valeo, or Denso or quality Aftermarket parts. Learn the basics of stator and rotor and motor core laminations for insight.

- Keep water out with good grommets and Silicone sealant to stop Water ingress and Corrosion.

- If you face deep wiring faults or coding needs. Choose professional wiper motor installation.

I wrote this as a wiper motor repair guide you can trust. I pointed out the impact of faulty wipers on driving and the average lifespan wiper motor so you can plan. I showed you how to install wiper motor fast with simple steps. If you want to go deeper on motor theory study how electric motors work and stator and rotor basics. These explain why good motor core laminations matter inside the motors that keep your view clear.