Do You Have to Winterize an Outboard Motor? Yes, Absolutely!

Table of contents

- Why I Never Skip Outboard Motor Winterization

- Why Winterizing Your Outboard is Non-Negotiable

- Preventing Catastrophic Freeze Damage

- Combating Corrosion and Rust

- Safeguarding the Fuel System

- Maintaining Essential Lubrication

- Extending Engine Lifespan and Preserving Resale Value

- What Happens If You Don’t Winterize Your Outboard? The Risks

- Costly Repairs and Replacements

- Reduced Performance and Reliability

- Voided Warranties and Insurance Issues

- Key Areas Addressed During Outboard Winterization

- Fuel System

- Engine Powerhead

- Cooling System

- Lower Unit

- Battery

- External Components and Controls

- My Step-by-Step Outboard Winterization Checklist

- Tools and Supplies I Use

- Steps for 4-Stroke Outboards

- Steps for 2-Stroke Outboards

- Small Portable Outboards vs Large Outboards

- In-Water vs Driveway Winterization

- When to Winterize Your Outboard Motor

- Timing is Crucial

- Regional Considerations

- DIY Winterization vs Professional Service

- When to DIY

- When to Call a Pro

- What I Pay and Why It Still Saves Money

- Winter Storage Tips That Protect the Whole Rig

- Dry Storage vs Wet Storage

- Rodent Prevention and Ventilation

- Boat Covers and Shrink Wrap

- Trailer and Bearing Care

- Common Questions I Hear Every Fall

- Conclusion: Don’t Skip Winterization. It’s an Investment, Not an Expense

— — —

Why I never skip outboard motor winterization

I learned this lesson the hard way. Years ago I parked my boat in the driveway after a late November trip. I told myself I’d get to it next weekend. That freeze arrived early. Spring came with a sickening surprise. My gear lube looked like milk, the motor coughed on start-up, and a corroded fuel line split under pressure. I saved a few bucks in the fall. I paid for it all winter.

Since then I treat outboard motor winterization like changing the oil in my truck. I do it every year without fail. When friends ask me, “Do you have to winterize an outboard motor?” I give a short answer. Yes. Absolutely. Then I explain why.

Why winterizing your outboard is non-negotiable

Preventing catastrophic freeze damage

Water expands when it freezes. That simple physics lesson breaks expensive parts. Your outboard’s cooling passages, thermostat housing, and water pump hold residual water. If you store the engine tilted or trap water in the lower unit, you invite freeze damage. I’ve seen cracked housings, blown seals, and a ruined impeller after one hard snap. Draining water from the outboard and storing it vertical prevents most of this. In very cold regions some owners also run marine antifreeze through muffs to displace water. I’ll explain when that makes sense and when it doesn’t a little later.

Combating corrosion and rust

Moisture and salt do their worst work in winter. The engine sits. Condensation forms. Metal parts oxidize. Internal corrosion can start on cylinder walls, bearings, and in the exhaust passages. Externally the trim and tilt rams, control cables, and electrical connectors suffer. I fog the powerhead, spray a marine anti-corrosion coating, and grease moving parts. That simple routine stops surface rust and preserves internal components.

Safeguarding the fuel system

Ethanol in today’s gas attracts water and separates if you store fuel too long. That phase separation leads to condensation in the fuel tank and gumming in carbs or injectors. Stale fuel turns to varnish and clogs idle jets and injectors. A marine grade fuel stabilizer prevents this. On carbureted engines I also drain the carburetor bowls for winter. On fuel injected engines I stabilize the fuel and run the motor long enough to get treated fuel through rails and injectors. That prevents winter engine startup issues in the spring.

Maintaining essential lubrication

Fogging oil is the secret handshake of outboard winterization. It coats cylinder walls, piston rings, and bearings to prevent rust. I fog through the intake on two-strokes and through fogging ports or the throttle body on many four-strokes if the manufacturer allows it. On four-stroke outboards I also change engine oil and the oil filter before storage. Dirty oil carries acids and moisture. I want clean oil sitting in the crankcase, not contaminated oil chewing at internal surfaces.

Extending engine lifespan and preserving resale value

Winterizing is preventative maintenance at its best. It keeps the cooling system clear, the fuel system clean, and the lubrication fresh. That preserves compression and keeps corrosion at bay. Engines that get proper winter care often run 1,500 to 2,500+ hours. Many last 15 to 20 years or more with reliable service. Skipping winterization shortens that arc. Buyers know it too. A documented winterization history helps resale value.

What happens if you don’t winterize your outboard? The risks

Costly repairs and replacements

I’ve watched friends roll the dice and lose. Here are real-world costs I’ve seen or paid:

- Freeze damage: A cracked housing or cooling passage can run $500 to $1,500. A compromised powerhead climbs quickly to $1,500 to $5,000 or more.

- Fuel system cleanup: Varnished carbs or fouled injectors often cost $200 to $800 by the time you rebuild or replace parts.

- Water pump damage: A deformed impeller and scored housing can cost $200 to $500 including labor.

Compare that to the average cost to winterize an outboard. Most shops charge $150 to $400 depending on the engine size and whether they include an oil change and gear lube. Even a 150 HP four-stroke that runs $250 to $350 looks cheap next to a single freeze repair.

Reduced performance and reliability

Neglect shows up on day one of spring. No-start complaints. Rough idle. Bogging under throttle. Overheating because a thermostat stuck or the impeller shed a vane. Winter is hard on any machine that sits. Boats add water and salt to the mix. You can avoid that spring service-line purgatory with two hours of work in the fall.

Voided warranties and insurance issues

I’ve read marine insurance policies that exclude damage caused by neglect. Improper or absent winterization can fall under that umbrella. Manufacturers want you to follow the maintenance schedule too. If you ignore the manual and gamble with freeze damage or severe corrosion, you can end up outside warranty coverage. Don’t rely on a policy to bail you out from something you could have prevented.

Key areas addressed during outboard winterization

Fuel system

- Add a marine fuel stabilizer for outboards to the tank. Follow the label for dosage.

- Run the engine long enough to pull stabilized fuel through lines, the water separator filter, and the engine fuel filter. I like to run 10 to 15 minutes on muffs.

- Replace the water separator filter and engine fuel filter if the interval calls for it.

- Carburetor drain winterization: On carb models, drain the bowls so fuel cannot evaporate and leave varnish.

- Inspect all fuel lines and the primer bulb. Ethanol can harden or crack older hoses. Replace if you see cracks or soft spots.

Engine powerhead

- Fogging oil outboard motor process: Fog cylinders to prevent rust. Use the method your manufacturer recommends. Some engines want fogging through the intake. Others want a fogging spray directly into cylinders with plugs removed.

- Four-stroke specific: Do an engine oil change winter service and swap the oil filter. Change warm oil so contaminants leave with the drain.

- Spark plug inspection winter step: Pull plugs to read them, regap or replace as needed, then reinstall after fogging.

- Check hoses and belts where applicable. Many four-strokes use a timing belt that has an hour or age interval. Inspect for cracks per the manual.

Cooling system

- Draining water from outboard: After your final flush, store the engine in the full down position. Gravity helps empty the cooling passages and the gearcase.

- Antifreeze for boat engine: Outboards usually do not need antifreeze if you store them vertical and let them drain fully. Some owners in extreme cold still run non-toxic marine antifreeze through from a tank with muffs. It displaces water and adds a corrosion inhibitor. Follow your manual. Don’t mix house RV antifreeze with raw water unless it is rated for marine engine cooling use.

Lower unit

- Lower unit oil change outboard: Drain and refill the marine gear lube. Milky oil means water ingress. That calls for new seals and a pressure test.

- Propeller removal winter step: Pull the prop, check for fishing line at the prop shaft seal, and grease the propeller shaft before reinstalling.

- Inspect the water pump impeller. Many owners do impellers every 2 to 3 years. If you had any overheat alarms, do it now.

Battery

- Marine battery winter storage: Remove the battery and clean the terminals. Store it in a cool, dry place on a battery tender or trickle charger. A fully charged battery resists freezing better than a discharged one.

- Label your battery cables so you reconnect them correctly in spring.

External components and controls

- Marine anti-corrosion spray and marine grease usage: Lube pivot points, throttle and shift linkages, steering cable fittings, and the prop shaft.

- Anode inspection winter step: Replace sacrificial anodes if they are more than half gone. They protect more expensive parts from galvanic corrosion.

- Power trim and tilt system: Wipe the rams and check the fluid level. Don’t store the motor tilted if you can avoid it.

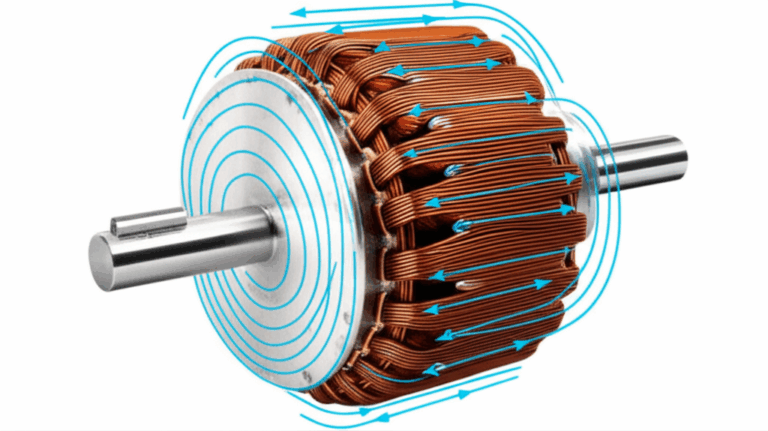

- Cowl protection winter: Clean under the cowl. Wipe down electrical connections. Use dielectric grease on connectors. You can learn more about how a charging stator pairs with a rotor if you want deeper context on why clean, dry electricals matter; this primer on the stator and rotor relationship explains the fundamentals nicely.

My step-by-step outboard winterization checklist

Tools and supplies I use

- Fuel stabilizer for outboard engines

- Fogging oil

- Engine oil and oil filter for four-strokes

- Marine gear lube and new drain screw gaskets

- Water separator and in-line fuel filters

- Marine grease and anti-corrosion spray

- Spark plugs and a gapping tool if I plan to replace them

- Muffs for flushing outboard and a garden hose

- Torque wrench and basic hand tools

- Desiccant packs for storage compartments

- A proper boat cover and tie-downs

- A battery tender for marine batteries

Steps for 4-stroke outboards

1) Pre-winter boat check. Walk the rig. Note any fuel leaks, chafed hoses, or weeping seals. Fix small issues now. They don’t get better sitting through winter.

2) Stabilize the fuel. Add stabilizer to the fuel tank and run the engine on muffs. I run until the thermostat opens and the engine reaches operating temperature.

3) Change the oil and filter. Warm oil drains faster and carries contaminants out. Refill with the grade your manual calls for. Spin on the new oil filter and check for leaks.

4) Fog the engine if the manufacturer allows fogging through the intake or plugs. Many modern four-strokes with oxygen sensors want a specific method or a mist designed for them. Always follow the service manual.

5) Replace the engine fuel filter and the water separator filter. Prime the system and check for leaks.

6) Drain and refill the lower unit with marine gear lube. Replace gaskets on the drain and vent screws. Look for metal on the magnet and milkiness in the lube.

7) Pull the prop. Grease the shaft. Reinstall the prop and torque the nut.

8) Inspect anodes and replace as needed. Check the thermostat housing for crust or deposits if you had temperature issues.

9) Lube linkages and steering. Use marine grease on pivot points and cable fittings. Spray a light film of anti-corrosion spray on external metal parts.

10) Battery tender setup. Remove the battery. Clean and coat the terminals. Put it on a tender in a dry place.

11) Store the engine vertical. Let it drain. Cover the boat well and leave some ventilation so moisture does not build up.

Steps for 2-stroke outboards

Most steps mirror a four-stroke with a few key differences.

- Oil system: If you have oil injection, check the tank and lines. If you premix, make sure the tank has stabilized fuel with the correct oil ratio.

- Fogging is even more important on two-strokes. I fog through the intake until the engine stumbles. Then I shut it down and fog each cylinder directly through the spark plug holes.

- Two-strokes do not need an engine oil change. You still change the lower unit gear lube.

- Replace plugs if they look fouled. Two-strokes often run better with fresh plugs each season.

Small portable outboards vs large outboards

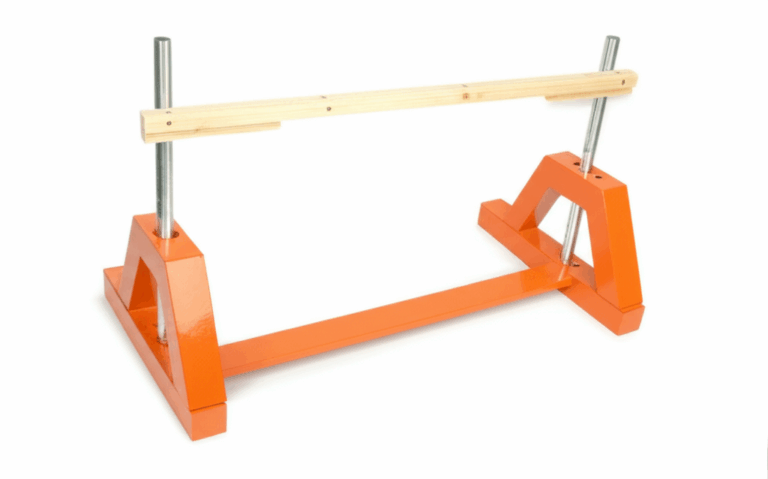

- Winterizing smaller outboards is quick. Run stabilized fuel, fog the engine, drain the carb, and change the gear oil. Store the motor upright on a stand. Pull the prop and check for fishing line even on the tiny ones.

- Large outboard winterization adds items like a water separator filter, more complex cowl and harness connections, and often a thermostat inspection. Plan more time. Still, a DIY outboard winterization on a big motor falls within reach if you follow the manual and take it step by step.

In-water vs driveway winterization

- Winterizing boat in the driveway gives you easy access to tools, parts, and the muffs for flushing outboard passages. It’s my preference.

- Winterizing boat in water can work if you have shore water and a safe way to run the motor on muffs. Many marinas offer winterization at the slip. If your boat will remain in the water, you still need to winterize the motor and address bilge pumps, batteries, and dock lines. I prefer dry storage vs wet storage in freezing climates because ice and storms can do damage you cannot always prevent.

When to winterize your outboard motor

Timing is crucial

Don’t wait for the first hard freeze. I winterize at the end of my boating season or as soon as the forecast dips near freezing. If you sneak in a late fall run, you can winterize again. The extra stabilizer and fogging won’t hurt anything.

Regional considerations

- Northern climates: Winterize early and be thorough. Think about rodent prevention, desiccant in compartments, and a proper shrink wrap or tight cover for snow load. Some owners in very cold regions run non-toxic antifreeze through the cooling system to displace water and add corrosion inhibitors. It’s optional for most outboards if you store them vertical and let them drain. Your manual should guide you.

- Mild climates: If you still get cold snaps, don’t gamble. You may store the boat in a garage and use a battery tender. I still stabilize fuel if the boat will sit more than 30 days.

- High humidity areas: Focus on ventilation during winter storage. Crack the cover a touch and add desiccant to lockers to prevent mildew.

DIY winterization vs professional service

When to DIY

- Your engine is simple and you have basic tools.

- You want to learn and save money.

- You have a clean space and enough time. For a smaller motor, DIY winterization takes 1 to 3 hours. Larger motors take longer if you include oil and gear lube service.

- You follow the marine service manual winter guidance for your brand. Yamaha Outboards, Mercury Marine, Honda Marine, Suzuki Marine, and Evinrude publish detailed schedules and steps.

When to call a pro

- You have a complex four-stroke with high hours and you want a full inspection.

- You need to preserve warranty terms or a dealer stamp matters for your records.

- You noticed issues like water intrusion in gear lube, overheating, or fuel leaks. A marine mechanic can pressure test the lower unit, check the thermostat and water pump impeller, and verify compression.

- You don’t have time or a suitable place to do the work.

What I pay and why it still saves money

I’ve paid between $150 and $400 for professional outboard winterization depending on horsepower and what’s included. A 150 HP four-stroke with oil, filter, gear lube, fogging, and a full inspection tends to land around $250 to $350 in my market. That is cheaper than one stuck thermostat repair or a carb rebuild on a multi-carb two-stroke. I look at it as insurance against avoidable problems.

Winter storage tips that protect the whole rig

Dry storage vs wet storage

Dry storage wins in freezing areas. It removes ice risk and reduces electrolysis exposure. If you must store in the water, winterize everything and consider a de-icer around the slip. Dry storage in a garage or barn also helps electronics and wiring. You reduce condensation and salt air exposure for the ignition system and connectors. If you’re curious why stators are built to resist eddy current losses in charging systems, this explainer on stator core lamination shows the laminated steel concept that appears in many alternators and small motors.

Rodent prevention and ventilation

Mice love warm seats and tasty wiring. I stuff stainless scrub pads in openings, use peppermint oil or commercial deterrents, and remove any food. I leave small vents under the cover and throw desiccant packs in lockers. Moist air corrodes. Dry air preserves.

Boat covers and shrink wrap

A proper boat cover matters. Support it so water and snow slide off. Don’t trap moisture. Shrink wrap works well for long outdoor storage. Cut vents into it or add vent caps. If you store inside, a breathable cover might be better than plastic.

Trailer and bearing care

Trailer tire care winter tip one. Inflate to the correct pressure and chock the wheels. I move the trailer a few feet mid-winter so the tires don’t flat-spot. Trailer bearing protection winter tip two. Repack or service bearings if they’re due. Check lights and the winch strap. These details pay off on the first spring launch.

Common questions I hear every fall

Do I need to run antifreeze through my outboard?

Usually no if you store the engine all the way down and let it drain. Many outboards self-drain fully. In very cold climates, some owners choose to run non-toxic marine antifreeze from a bucket through the muffs. It displaces any pockets of water and adds corrosion protection. Follow the manual. Don’t store the motor tilted up with trapped water.

Should I start the engine once a month in winter?

I don’t. Starting a cold engine without a proper flush and load can add moisture and fuel wash to the cylinders. I’d rather winterize well and leave it alone. In spring I install a fresh battery, prime the fuel system, and go.

What about ethanol-free fuel?

If you can get ethanol-free marine gas, use it. It stores better. I still add a stabilizer because even non-ethanol fuel goes stale over time.

Do I need to fog a modern four-stroke?

Check the manual. Many manufacturers still recommend fogging before long-term storage. Some specify how to fog through a service port or the intake for engines with sensors. If fogging isn’t recommended, you still change oil and stabilize fuel.

What about the trim and tilt system?

Cycle the trim and tilt. Wipe the rams clean. Check fluid level. Store the engine down so the rams aren’t exposed all winter. That also helps the cooling passages drain.

How do I protect electrical connections?

Clean and dry the under-cowl area. Use dielectric grease on connectors and a light anti-corrosion spray on exposed metal. Moisture causes resistance and corrosion. That can upset charging systems and ignition components. If you want a quick look at what makes small motors and alternators efficient, this overview of electrical steel laminations explains how laminated steel reduces losses in magnetic circuits.

What if I plan to use an engine block heater?

Outboards don’t use block heaters like inboards. If you need heat, store the boat indoors or in a temperature-controlled space. A safe space heater in a confined area can be risky. I avoid that.

What if my boat will sit only a month or two?

If it sits more than 30 days, I stabilize the fuel and run the motor long enough to pull treated fuel through the system. If a freeze is possible, I complete a full winterization.

What if I have a brand-new outboard?

Congrats. Follow your manufacturer’s maintenance schedule. Many warranties expect documented service. That includes out of season boat maintenance and proper winterization.

Do anodes matter in fresh water?

Yes. They protect the lower unit and other metal parts from galvanic corrosion even in fresh water. Use the correct anode material for your water type. Replace sacrificial anodes when they’re half gone.

Conclusion: Don’t skip winterization. It’s an investment, not an expense

Here’s my bottom line after years of boating in cold climates. Outboard motor winterization isn’t optional. It’s cheap insurance. You prevent freeze damage. You fight corrosion. You protect the fuel system. You keep lubrication where it belongs. You also protect your wallet and your spring plans.

I’ve winterized on the driveway in the dark with a headlamp because a cold front moved in. I never regretted it. I’ve also tried to save a few dollars and pushed it off. I paid more later. Spend a little time now and avoid the headache. Your engine will thank you with an easy start in spring and years of dependable service.

Quick recap you can follow today

- Add a marine grade fuel stabilizer and run the engine to circulate it through.

- Change engine oil and filter on four-strokes. Fog the cylinders per the manual.

- Drain and refill the lower unit gear oil. Inspect for water intrusion.

- Pull the prop. Grease the shaft. Check for fishing line near the seal.

- Lube linkages and steering. Inspect and replace anodes if needed.

- Remove and maintain the battery on a battery tender.

- Store the engine vertical. Cover the boat without trapping moisture.

If you’re new to all this, start with your owner’s manual. Treat it like your outboard’s winter survival guide. When in doubt, a good marine mechanic can walk you through the first time or knock it out for you. Then head into winter with peace of mind. You did it right.

Note: If you enjoy learning how motors and charging systems work under the cowl, this clear explainer on the stator and rotor relationship pairs well with the laminated steel overview in stator core lamination and the broader look at electrical steel laminations. Not required for winterization. Just handy context for the curious.