Does Stainless Steel Conduct Electricity? A Comprehensive Guide to Its Electrical Properties

Have you ever wondered if that shiny stainless steel fork could give you a shock? Or maybe you’re working on a project and need to know if you can use a stainless steel screw in an electrical box. It’s a common question, and the answer is super important for staying safe and making things that work right. The problem is, you hear different things. Some say “all metal conducts,” while others say stainless steel is different. This confusion can be risky.

Well, you’ve come to the right place! In this guide, I’m going to give you the straight, simple answer. We’ll break down exactly how well stainless steel handles electricity, why it’s different from other metals like copper, and where you can (and can’t!) use it safely. By the end, you’ll be a pro on the topic.

Table of Contents

- The Quick Answer: Does Stainless Steel Conduct Electricity?

- What Do “Conductivity” and “Resistivity” Even Mean?

- How Does Stainless Steel Compare to Other Metals?

- Why Isn’t Stainless Steel a Great Conductor? The Secret is in the Mix

- Do All Types of Stainless Steel Conduct the Same?

- What Else Can Change How Well Stainless Steel Conducts?

- So, Where is Stainless Steel Actually Used with Electricity?

- When Should You Absolutely NOT Use Stainless Steel for Electrical Jobs?

- Is Stainless Steel Magnetic, Too? A Quick Detour

- The Final Verdict: Your Guide to Using Stainless Steel Safely

The Quick Answer: Does Stainless Steel Conduct Electricity?

Let’s get right to it. Yes, stainless steel does conduct electricity. All metals do, and stainless steel is a metal alloy. So, if you touch a live wire with a stainless steel ruler, you will get a shock. It is definitely a conductor, not an insulator.

But here’s the catch, and it’s a big one: it doesn’t conduct electricity very well. Compared to the metals we use for wires, like copper or aluminum, stainless steel is a pretty poor electrical conductor. It puts up a big fight against the flow of electricity.

Think of it like this: Imagine electricity is water flowing through a pipe. A copper pipe is wide, smooth, and lets tons of water rush through easily. Stainless steel is like a pipe that’s narrow and full of rocks. Water can still get through, but it’s a slow, difficult trickle. This “fight” against the flow is called electrical resistance.

What Do “Conductivity” and “Resistivity” Even Mean?

These two words sound complicated, but they’re just opposites, like hot and cold.

- Electrical Conductivity: This measures how well a material lets electricity flow. A material with high conductivity, like copper, is a superhighway for electricity.

- Electrical Resistivity: This measures how much a material fights against the flow of electricity. A material with high resistivity, like stainless steel, is like a traffic jam for electricity.

So, stainless steel has low electrical conductivity and high electrical resistivity. We measure resistivity in units like micro-ohm-centimeter. The higher the number, the more it resists electricity. The specific resistance of stainless steel is one of its key electrical properties. Understanding this helps us decide if it’s the right material for a job.

How Does Stainless Steel Compare to Other Metals?

Seeing the numbers really puts things in perspective. You might be choosing materials for a project and realize that while stainless steel is strong and won’t rust, its electrical performance is a deal-breaker. Choosing the wrong metal because you didn’t check the data could make your project fail. It’s frustrating to build something perfectly only to have it short out or overheat.

Let’s look at how stainless steel stacks up against other common metals. We’ll use copper as our benchmark, giving it a score of 100%.

Electrical Conductivity of Common Metals (at 20°C / 68°F)

| Material | Relative Conductivity (vs. Copper = 100%) | Notes |

|---|---|---|

| Silver | 108% | The best conductor, but very expensive. |

| Copper | 100% | The standard for electrical wiring. |

| Gold | 76% | Doesn’t rust, great for tiny connectors. |

| Aluminum | 59% | Lighter than copper, used for power lines. |

| Carbon Steel | 8-12% | Your basic steel, much less conductive. |

| 304 Stainless Steel | 2.4-2.8% | A very poor conductor! |

| 316 Stainless Steel | 2.3-2.5% | Even slightly worse than 304. |

As you can see, the stainless steel vs copper conductivity isn’t even a close race. Copper is about 40 times more conductive than stainless steel! This is why we don’t make house wiring or power cords out of stainless steel. The voltage drop would be huge and it would get very hot.

Why Isn’t Stainless Steel a Great Conductor? The Secret is in the Mix

So, what makes stainless steel so different? To understand this, we need to look at what it’s made of. Pure metals like copper and iron have a very neat and orderly structure. Their atoms are arranged in a perfect crystal grid. This structure leaves lots of free electrons that can jump from atom to atom easily. This easy movement of electrons is what we call electrical current.

Stainless steel, however, is not a pure metal. It’s an alloy, which is a mix of different metals. The main ingredient is iron, but to make it “stainless,” we add a lot of other stuff. The most important alloying elements are:

- Chromium: This is the magic ingredient that makes it resist rust. It forms an invisible protective layer on the surface.

- Nickel: This is often added to make the steel stronger and easier to shape.

- Molybdenum and Manganese: These are sometimes added for even more strength and corrosion resistance.

All these different-sized atoms mixed in with the iron atoms mess up the neat, orderly crystal structure. The metallic bonding is more complex. It’s like throwing a bunch of big rocks and small pebbles into that hallway we talked about. The free electrons try to move, but they keep bumping into these chromium and nickel atoms and scattering in all directions. This disruption is why alloys have lower conductivity than pure metals.

Do All Types of Stainless Steel Conduct the Same?

Nope! There are hundreds of different “grades” of stainless steel, and their electrical properties can be slightly different. The main families you’ll hear about are:

- Austenitic Stainless Steel (300 Series): This is the most common type, including grades like 304 stainless steel and 316 stainless steel. They contain a lot of chromium and nickel, which makes them non-magnetic and gives them great corrosion resistance. It also gives them very high electrical resistivity. The typical resistivity of 300 series stainless steel is among the highest.

- Ferritic Stainless Steel (400 Series): Grades like 430 stainless steel have more iron and less nickel. This makes them magnetic and slightly better at conducting electricity than the 300 series, but still not great. Their ferritic stainless steel conductivity is a small step up.

- Martensitic Stainless Steel (400 Series): Grades like 410 stainless steel are very hard and strong but have similar electrical properties to ferritic grades.

- Duplex Stainless Steel: This is a mix of austenitic and ferritic structures, offering a “best of both worlds” for strength and corrosion resistance, but its conductivity is still low.

So, while there are small differences, the main takeaway is that all common stainless steel grades are poor electrical conductors compared to copper.

What Else Can Change How Well Stainless Steel Conducts?

Besides the grade, a few other things can affect the electrical conductivity of stainless steel.

One big factor is temperature. For most metals, as they get hotter, their atoms vibrate more wildly. This makes it even harder for electrons to get through. So, as you heat up stainless steel, its resistance goes up, and its conductivity goes down. This temperature effect on stainless steel conductivity is a key principle in material science.

Another factor is cold working. This means bending, rolling, or stretching the metal without heating it. This can change the internal structure and slightly increase its resistivity. On the other hand, a process called annealing (heating and then slowly cooling the metal) can make the structure more uniform and slightly improve conductivity. The surface condition also matters; a thick layer of oxidation can interfere with electrical contact.

So, Where is Stainless Steel Actually Used with Electricity?

You might be thinking, “If it’s such a bad conductor, why would we ever use it for anything electrical?” That’s a great question. You’ve identified the problem: you need a material for an electrical application, but the best conductors, like copper, rust and fall apart. The situation gets worse in wet or chemical-filled environments, where corrosion can destroy your project and create a safety hazard.

This is where stainless steel becomes the perfect solution. Its poor conductivity is a weakness, but its amazing strength and corrosion resistance are huge strengths. In some cases, those strengths are far more important.

Here are some electrical applications for stainless steel:

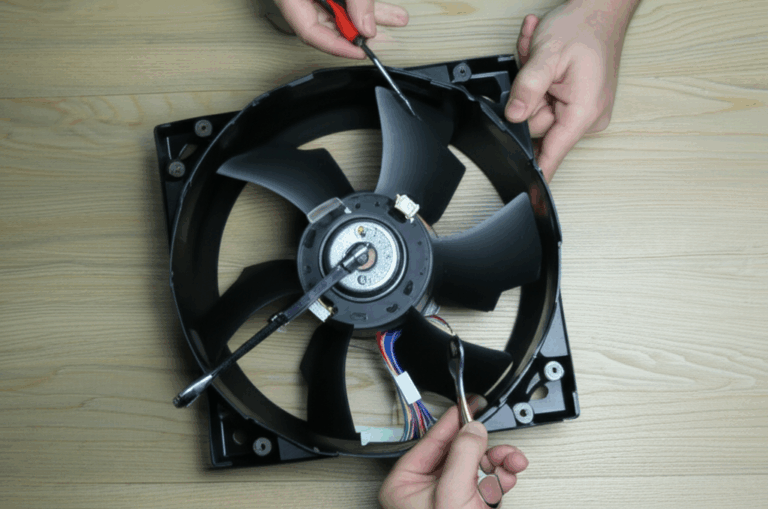

- Electrical Enclosures and Conduits: Those gray boxes on the sides of buildings that hold wires are often made of stainless steel, especially in factories or near the ocean. The main job is to protect the wires from damage and weather, not to conduct electricity. Stainless steel is perfect because it won’t rust away.

- Grounding in Corrosive Areas: A ground wire provides a safe path for electricity to escape in case of a problem. In a chemical plant or on a boat, a copper ground rod might corrode quickly. A stainless steel for grounding applications rod will last much longer, ensuring the safety system stays intact. Its higher resistance is managed by using a thicker rod.

- Heating Elements: Remember how high resistance is like a traffic jam for electricity? That traffic jam creates a lot of friction, which creates heat. We can use this! The coils in your toaster or in an electric water heater are often made of a special stainless steel alloy. We pass a current (electricity) through it on purpose to make it glow red hot.

- Medical Devices: In medical tools and implants, being clean and not reacting with the body is critical. Stainless steel’s moderate conductivity is enough for probes and sensors where its biocompatibility is the number one priority.

In many electrical components, special materials are chosen not for their conductivity but for other properties. For instance, in electric motors, the efficiency depends heavily on the magnetic properties of the core, which is made from stacked layers of metal. These specialized motor core laminations are designed to reduce energy loss, a different job entirely from simply conducting current.

When Should You Absolutely NOT Use Stainless Steel for Electrical Jobs?

Knowing when not to use stainless steel is just as important for safety and success. Using it in the wrong place is a recipe for disaster. It can cause overheating, which is a fire hazard, or it can make your device not work at all because not enough power is getting through. You wouldn’t want the motor in your new drone to fail because you used the wrong screws.

Here’s a simple rule: Never use stainless steel for a path that needs to carry a lot of electrical current efficiently.

Avoid it for these applications:

- House Wiring or Power Cords: This is a job for copper or aluminum, period. Using stainless steel would be incredibly inefficient and dangerous.

- Circuit Board Traces: The tiny metal lines on a circuit board need to carry signals with very little resistance.

- Battery Contacts: You want the best possible connection to get power out of a battery, so materials like brass or gold-plated copper are used.

- High-Power Busbars: These thick bars carry huge amounts of current in industrial settings and must be made from highly conductive copper or aluminum.

The core components of many electrical devices, like the central parts of a motor, require materials with very specific magnetic and electrical properties. For example, high-quality silicon steel laminations are often the top choice over common metals like stainless steel because they are engineered to minimize energy loss and maximize performance.

Is Stainless Steel Magnetic, Too? A Quick Detour

This is another common question that gets tangled up with conductivity. The answer is: it depends on the type!

- Austenitic stainless steels (like 304 and 316) are generally not magnetic.

- Ferritic and Martensitic stainless steels (like 430 and 410) are magnetic.

It’s important to know that magnetism and electrical conductivity are two different properties. A material can be magnetic and a poor conductor (like ferritic stainless steel), or non-magnetic and a good conductor (like aluminum). So, don’t use a magnet to test how well a metal will conduct electricity!

The design of electrical machines often relies on the precise interaction between electrical and magnetic fields. Key parts like the stationary stator and rotor must be built from materials that can manage these forces effectively to create motion.

The Final Verdict: Your Guide to Using Stainless Steel Safely

So, we’ve untangled the mystery. Stainless steel is a conductor, but not a very good one. Its real superpowers are its strength and its refusal to rust. This makes it a hero in some electrical situations and the wrong choice for others.

Choosing the right material is everything. You wouldn’t build a race car out of lead and you wouldn’t build a boat anchor out of aluminum. For high-performance electrical systems, you need materials engineered for the job. Our company, Sinolami, specializes in creating the high-quality core components that power the world’s most efficient motors and transformers. We provide the expert solutions that engineers trust when performance and reliability can’t be compromised.

Key Things to Remember

- Yes, it Conducts: Stainless steel will conduct electricity and can give you a shock. Treat it with the same respect you would any other metal around electricity.

- It’s a Poor Conductor: It has high electrical resistance. It’s about 40 times less conductive than copper.

- Why? It’s an Alloy: The mix of iron, chromium, and nickel atoms disrupts the flow of electrons.

- Use it for Strength and Rust-Proofing: It’s perfect for electrical boxes, conduits, and grounding in tough environments.

- Don’t Use it for Wires: Never use it for jobs that need to move electricity easily, like wiring or circuit components.

- Check the Grade: Different grades have slightly different properties, but all are poor conductors.