How An Electromagnetic Motor Works: Unraveling the Science of Motion

- Table of Contents

- How An Electromagnetic Motor Works: Unraveling the Science of Motion

- Why should you care about motors?

- What is an electromagnetic motor in simple words?

- How does electricity make a magnetic field?

- What are the main motor parts, and what do they do?

- How does a simple DC motor spin step by step?

- What makes AC motors different from DC motors?

- What laws and rules guide motor motion?

- How do we control motor speed and direction?

- Where do we use motors at home, in cars, and in factories?

- How do we boost efficiency and cut energy loss?

- What do history and inventors teach us?

- What do all these motor words mean?

- Key facts and numbers you can trust

- Handy FAQs

- Main takeaways

Motors take electrical energy and turn it into mechanical energy. That means they use electric current to make rotational motion at a shaft. You see motors in fans, cars, robots, and even your toothbrush. In this guide I’ll explain how an electromagnetic motor works. I’ll keep it clear and friendly. You’ll learn the motor principle, the parts, and the laws that make it run. I’ll also show you how smart design cuts waste and boosts efficiency.

Why read this? You use motors every day. When you get how they work, you make smarter choices. You can spot problems. You save energy. You pick the right motor for the job.

Why should you care about motors?

Problem: We live in a world that runs on motors. They use almost half of the world’s electricity. That is huge.

Agitate: When motors waste power, your bill goes up. The planet pays the price. Your machines run hot. They wear out fast. You lose time and money.

Solution: Learn how motors work. Know the electromagnetism at the heart of it. Understand motor design, motor maintenance, and motor speed control. Use better cores and better laminated steel to lower loss. Choose the right AC motor or DC motor. You get more torque, less heat, and longer life.

What is an electromagnetic motor in simple words?

An electromagnetic motor turns electricity into motion with magnets and coils. A current in a coil winding makes a magnetic field. That field pushes against another field. The push makes torque. Torque makes the rotor spin. The spin turns the shaft. The shaft does work.

Two big kinds stand out: direct current (DC) motors and alternating current (AC) motors. Some DC motors use brushes and a commutator. Others use electronics and no brushes. We call those brushless DC motors (BLDC). Many AC motors use induction or run synchronous with the line frequency.

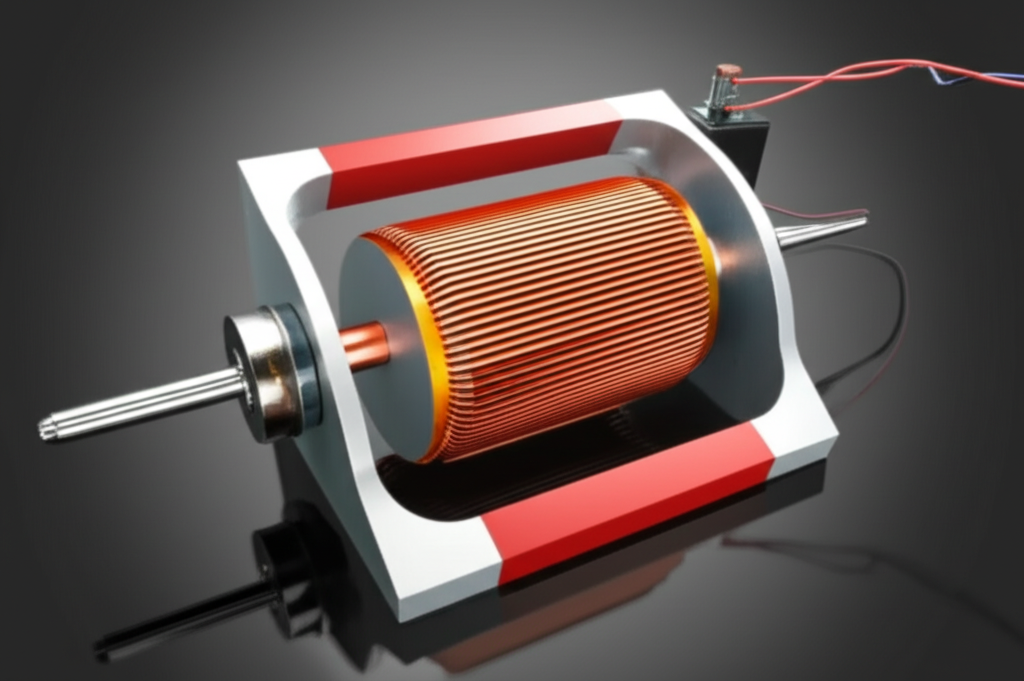

If you look inside, you’ll see a stator that stays still and a rotor that turns. You may see permanent magnets or electromagnets. You will always see wires that carry current. You will also find bearings, a housing, and a strong shaft.

For a simple picture, think of a magnet and a compass. The magnet pulls the compass needle. In a motor, the fields push and pull on purpose to make steady spin.

If you want to go deeper on the core idea, read this clear primer on the motor principle.

How does electricity make a magnetic field?

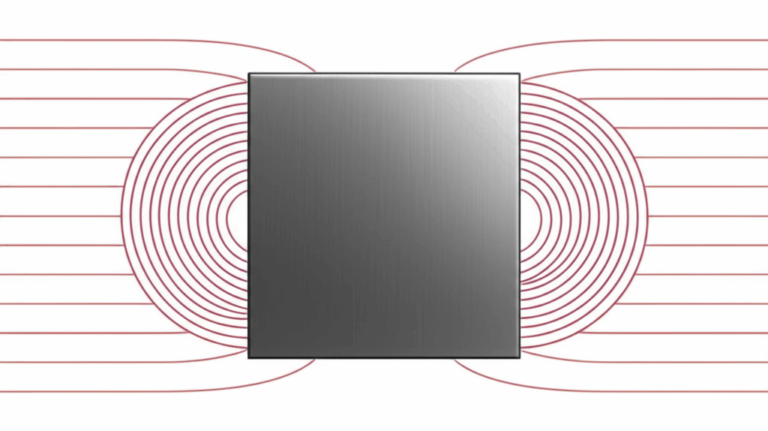

In 1820, Hans Christian Ørsted showed that electric current makes a magnetic field. When current flows in a wire, it forms magnetic field lines around the wire. We can point with the right-hand rule to see the field direction.

That field can push on other magnets. If the field meets another field, you get magnetic attraction or magnetic repulsion. The push creates force. In motors we aim the fields at the right angle to make the most Lorentz force on the armature or rotor.

This is the heart of the electromagnetism explained story. You feed voltage and current into a coil. The coil becomes an electromagnet with a North pole and a South pole. Those magnetic poles interact with the stator field. The result is motion.

What are the main motor parts, and what do they do?

- Stator: The still frame that holds the field. It can use field coils or permanent magnets. The quality of the stator core lamination matters. Thin electrical steel layers cut eddy currents and reduce heat.

- Rotor (Armature): The turning part. It sits inside the air gap. In many designs it holds a coil or bars. A strong rotor core lamination reduces loss and helps torque generation.

- Commutator and Brushes: In a brushed DC motor, the commutator swaps the current direction in the armature. Brushes carry current to the rotor. The swap keeps the push in the same spin direction.

- Shaft and Bearings: The shaft carries mechanical energy output. Bearings keep it turning with low friction.

- Housing: The case that holds the parts. It protects the motor and helps cool it.

- Power Supply: The source that feeds voltage and current. It can be a battery for DC or the power grid for AC.

Great motors start with great steel stacks. You can explore full lines of motor core laminations to see how core design supports performance.

How does a simple DC motor spin step by step?

1) You turn on the power supply. Current flows through the armature copper windings.

2) The coil becomes an electromagnet. It has a North pole and a South pole.

3) The stator field pulls and pushes on the coil. The Lorentz force acts on each wire. The pair of forces generates torque on the rotor.

4) The rotor starts to move. It picks up rpm (revolutions per minute).

5) The commutator and brushes flip the current right when the coil crosses the center. The flip changes the coil poles. The push stays in the same spin direction. That is commutation at work.

6) The spin keeps going. The motor converts electrical energy into mechanical energy every moment.

With a brushless DC motor (BLDC), you lose the brushes and commutator. You use sensors and a motor driver to switch current in the phases. That is electronic commutation. It improves motor efficiency and cuts wear.

What makes AC motors different from DC motors?

AC motors use the fact that alternating current (AC) changes direction with frequency. This creates a changing magnetic flux in the stator. Two big types stand out.

- Induction Motor: The stator makes a rotating magnetic field. The field induces electromotive force (EMF) in the rotor. Current flows in rotor bars. That creates its own field. The two fields pull on each other and make torque. The rotor chases the stator field. It runs with a small lag called slip. The common rotor build is the squirrel cage rotor, though some designs use a wound rotor.

- Synchronous Motor: The rotor locks with the stator field and turns in step with line frequency. We say it runs synchronous. Many Permanent Magnet Synchronous Motors (PMSMs) use strong magnets for high power and efficiency.

Some AC motors handle single-phase power. Others need three-phase. Many tools use a universal motor that can run on AC or DC. You also see series motors and shunt motors in DC land, each with a different way to wire the field coil.

What laws and rules guide motor motion?

- Lorentz Force: A current-carrying wire in a magnetic field feels a force. The force equals current times field times length at right angles. That force drives the torque.

- Faraday’s Law of Induction: A changing magnetic flux in a loop creates EMF. This is key in induction motors and in the generator principle (inverse). Spin a motor with no power. It becomes a generator.

- Lenz’s Law: The induced current opposes the change that made it. In motors, this explains back EMF and why motors resist sudden speed changes.

- Fleming’s Left-Hand Rule: It helps you find the force direction on a current in a field. The thumb shows motion. The first finger shows field. The second finger shows current.

Use the right-hand rule for field direction around a wire. Use the left-hand rule for force on a conductor in a field. These rules help you draw a simple electric motor diagram or follow a motor working animation.

How do we control motor speed and direction?

You can adjust motor speed with voltage, current, and frequency.

- DC speed control: Change the voltage, or use pulse-width modulation in a motor driver. A motor control unit (MCU) sets timing in BLDC motors for smooth rotational motion.

- AC speed control: Use a variable frequency drive (VFD) to change line frequency and voltage. VFDs let you save energy and set the rpm you want.

- Position control: Servo motors and stepper motors move in precise steps. A stepper motor jumps to known positions. A servo motor uses feedback for accurate torque and angle. Robots love both.

Good control makes room for smart tricks like regenerative braking. When you slow a motor, it can act like a generator and feed power back. That saves energy.

Where do we use motors at home, in cars, and in factories?

Motors sit in every room. In the kitchen you see them in blenders and fridges. In the bedroom they run fans. In the laundry they spin washers. A modern home can have dozens of small motors. Some homes have hundreds.

Big motors power pumps, presses, conveyors, and industrial machinery. Plants rely on AC induction motors. Why? They work hard. They last. They don’t break the bank. Many plants use VFDs for savings.

In cars you meet electric vehicles (EVs). Many use Permanent Magnet Synchronous Motors or AC induction motors. They give high horsepower and kilowatt output with top motor efficiency. Trains use strong synchronous motors. Wind farms use generators built on the same electromagnetic field principles.

You even find motors in medical devices. Pumps move fluids. Imaging tools need precise servo motors. Small BLDC motors keep noise low and life long. That helps patients rest.

How do we boost efficiency and cut energy loss?

I’ve seen good motors run cool and quiet. I’ve seen bad ones run hot and loud. The difference often hides in the magnetic core and the magnetic circuit. Better steel and better build lower loss.

Here’s the big picture:

- Use laminated core stacks to fight eddy currents. Thin sheets with insulation block loop currents.

- Pick steel with the right magnetic permeability, low coercive force, and high retentivity that still suits the job. Avoid saturation where the core can’t carry more flux density.

- Design for the right air gap. Too big wastes field. Too small risks rub and noise.

- Set the right winding configuration. Keep resistance low but safe. Use enough copper windings and the right phases.

- Keep hysteresis loss down with good alloys.

If you work with cores and need a supplier, explore electrical steel options like silicon steel laminations, CRGO lamination core, and CRNGO lamination grades. The right choice for your stator and rotor can move you from average to great.

What do history and inventors teach us?

History builds our know-how. Michael Faraday showed how changing fields make current. André-Marie Ampère helped link current and force. Hans Christian Ørsted found the field around a wire. William Sturgeon and Joseph Henry made early electromagnets. Thomas Davenport built one of the first practical DC motors in 1834. Nikola Tesla pushed AC motors and made them shine.

When we honor these names, we remember a clear truth. The science is solid. We stand on strong ground.

What do all these motor words mean?

Let’s keep a short guide handy. I’ll keep it simple.

- Electric motor principle: Fields push on current and create force.

- Electromagnetism: The link between electricity and magnetism.

- Lorentz force: The push on a current in a magnetic field.

- Faraday’s law of induction: Changing flux makes EMF.

- Lenz’s Law: The new current fights the change.

- Stator / Rotor / Armature: Still part / spinning part / rotor coil.

- Commutator / Brushes: The switch and contacts in brushed DC motors.

- Coil winding: Wire wrapped to make a magnet.

- Permanent magnet / Electromagnet: Always-on magnet / coil-made magnet.

- Magnetic poles / North pole / South pole: Ends of a magnet.

- Torque generation: The twist that turns the shaft.

- Rotational motion: Spinning movement.

- Electrical energy conversion: Turning electricity into motion.

- Mechanical energy output: Work at the shaft.

- Motor efficiency: How much input becomes output.

- Motor types: DC, AC, induction, synchronous, BLDC, series, shunt, universal, servo, stepper.

- Simple electric motor diagram / motor working animation: Ways to see the idea.

- Motor speed control: How we set the rpm.

- Electromotive force (EMF): The push that drives current.

- Magnetic flux: How much field passes through a loop.

- Current direction: Which way the electrons flow.

- Electromagnetic induction: Making current with changing flux.

- Power supply: The source that feeds voltage and current.

- Magnetic force / Right-hand rule / Left-hand rule (Fleming’s): The rules for direction and push.

- Field coil: The coil that makes the field.

- Series motor / Shunt motor / Universal motor: Ways to wire DC fields.

- Servo motor / Stepper motor: Motors that move with precision.

- Motor driver / MCU: Electronics that run the motor.

- Electrical engineering basics / Physics of motors: The science behind it.

- History of electric motors: The path from lab to life.

- Practical applications: How we use motors.

- Motor maintenance: Keep bearings, brushes, and windings healthy.

- Motor design: Choices that hit goals for power and life.

- Energy conversion process: Step-by-step from current to torque.

- Magnetic core / Air gap / Bearings / Shaft / Housing: Key build parts.

- Electric current / Voltage / Resistance / Power / Circuits: The basic electric words.

- Transformers (for AC): Change voltage with a magnetic core.

- Generator principle (inverse): A motor in reverse makes electricity.

- Magnetic permeability / Reluctance / Hysteresis: How the core carries field and where it loses energy.

- Winding configuration / Phases (single-phase, three-phase): How we arrange coils.

- Rotor bars / Squirrel cage rotor / Wound rotor: Induction rotor styles.

- Slip (induction motor): The speed lag that makes torque.

- Frequency / rpm / Horsepower / Kilowatt: Speed and power units.

- Regenerative braking: Slow down and make power.

- Variable frequency drive (VFD): AC speed control.

- Electromagnetic field / Magnetic circuit / Flux density: Field terms for design.

- Coercive force / Retentivity / Saturation: Magnet facts that affect loss and torque.

- Eddy currents / Laminated core / Copper windings / Iron core: Loss and build facts.

- Motor sound: Noise can tell you about balance and bearings.

You’ll also hear about electrical steel laminations, silicon steel laminations, transformer lamination core, EI core, and UI lamination core when you choose cores. These terms tie to the steel grades and shapes we use in motors and transformers.

Key facts and numbers you can trust

Here are numbers that matter when you plan, buy, or fix motors.

| Category | Metric or Detail | Value or Description | Why it matters |

|---|---|---|---|

| Energy Use | Share of global electricity used by motors | About 45–50% worldwide. In industry it can reach 70%. | Shows why motor efficiency is key. |

| Motor Efficiency | Modern IE3/IE4 motors | About 90–96% at full load | Less heat and waste. More work per watt. |

| Common Type | Most used in plants | AC induction motors hold 80–90% of uses | Tough and cost effective. |

| History | First practical DC motor | 1834 by Thomas Davenport | The start of real-world use. |

| EV Choice | Motors in EVs | Mostly Permanent Magnet Synchronous Motors or AC induction motors | High power density and great control. |

| Home Count | Motors in a home | Dozens to hundreds | Motors are everywhere in daily life. |

| Rules | Efficiency standards | IE3 or higher in many regions | Saves energy and money. |

These facts match trusted groups in energy and industry. They align with long-used physics and field data.

Handy FAQs

Q: Why does a motor get hot?

A: Heat comes from resistance, eddy currents, and hysteresis in the magnetic core. Good laminated core steel lowers these losses. Clean bearings and good airflow help too.

Q: What is the air gap and why is it small?

A: The air gap is the space between stator and rotor. A small gap boosts magnetic flux and torque. Too small raises risk of rub. Designers balance both.

Q: What does back EMF do?

A: As the rotor spins, it acts a bit like a generator. It sends EMF back that opposes the supply. This limits current at speed and protects the motor.

Q: How loud should a motor be?

A: Some motor sound is normal. A new whine or grind points to bearings or misalignment. Check fast to avoid damage.

Q: What is slip in an induction motor?

A: It is the small speed gap between the rotor and the synchronous field speed. Slip makes the torque.

PAS moments you can use right now

Problem: Your fan runs hot. The motor trips. Your bill climbs.

Agitate: Heat shortens life. Stops cost you time. Noise bugs your team. You feel stuck.

Solution: Pick the right motor type. Size it for the horsepower and kilowatt you need. Use a VFD for better motor speed control. Choose strong cores with tight stator and rotor stacks. If you specify cores, look into high-grade laminations and tight stacking. You can also review proper winding configuration and phases for your load.

Problem: Your robot arm misses steps.

Agitate: Bad parts fail. Orders slip. Customers frown.

Solution: Switch to a servo motor for tight control or tune your stepper motor with the right MCU and driver. Set the current direction profile so the torque covers peak loads. You can add regenerative braking to cut heat in fast stops.

Problem: You can’t describe what you need to your vendor.

Agitate: Misunderstanding leads to the wrong motor construction.

Solution: Use the terms in this guide. Say what rpm, horsepower, frequency, voltage, and phases you need. Ask about flux density, saturation, and core loss. Request details on lamination grade and stack method. Share your applications of electric motors and duty cycles.

A quick look at cores and laminations

I’ve toured shops that stamp and stack cores. The right steel grade makes a big difference. You want thin sheets, clean edges, and tight stacks. That’s how you reduce eddy currents and hysteresis loss. The result is a cooler, quieter motor with higher efficiency.

- Stator stack: The slot shape sets room for coil winding. The steel grade sets magnetic permeability and loss.

- Rotor stack: The skew of rotor bars can cut motor sound and torque ripple. The steel grade matters here too.

Curious about designs and options? See how a stator core lamination supports winding space and low loss. Check how a rotor core lamination shapes torque and slip. If you need a full view, explore complete motor core laminations and how choices in electrical steel laminations and silicon steel laminations affect results.

Try this simple picture in your head

Picture two teams in a tug-of-war. One team is the stator field. The other team is the rotor field. They don’t pull straight. They pull at an angle so the rope spins around. That spin is your rotational motion. The coach flips the players right as they pass the center. That flip is your commutator or your electronic commutation. The coach follows Fleming’s Left-Hand Rule to get the direction right. Everybody wins when the design keeps loss low and power high.

When you need a transformer, not a motor

Motors and transformers share many ideas. A transformer does not spin. It moves energy from one coil to another through a transformer lamination core. Designers use EI core and UI lamination core shapes. They pick CRGO lamination core or CRNGO lamination steel to reduce hysteresis and eddy currents. Many motor plants also make transformer parts because the magnetic circuit and steel are close cousins.

A note for young learners

If you’re a kid and love science, try this. Wrap wire around a nail. Touch both ends to a battery for a second. The nail becomes a magnet. That’s an electromagnet. Now imagine many coils and a smart switch. You just felt the core of a motor. Ask an adult before you try. Batteries can get hot. Safety first.

You can look at a simple electric motor diagram or watch a motor working animation online. Try to point your thumb for motion and your fingers for field with the left-hand rule. It’s a handy trick.

References

- International Energy Agency reports on motor energy use and efficiency.

- IEC and NEMA standards for IE3 and IE4 motor classes.

- Classic works by Michael Faraday, André-Marie Ampère, and Nikola Tesla.

- Engineering textbooks on electromagnetism, Faraday’s Law, Lenz’s Law, and Lorentz Force.

- Industry guides on variable frequency drive (VFD) and motor control unit (MCU) applications.

Main takeaways

- Motors turn electrical energy into mechanical energy with magnets and coils.

- Stator, rotor, commutator, and brushes are key in DC designs. Induction and synchronous action rule in AC designs.

- Lorentz force, Faraday’s Law, and Lenz’s Law explain motion and loss.

- Better laminated core steel cuts eddy currents and boosts motor efficiency.

- VFDs, MCUs, and smart motor drivers give tight control.

- Homes, cars, and industrial machinery depend on motors every day.

- Use the right winding configuration, phases, and core grade to hit your goals.

- Watch rpm, horsepower, kilowatt, and frequency to match your load.

- Good motor maintenance keeps bearings, windings, and cooling in shape.

- You can save energy with smart choices and regenerative braking.