How Do Servo Motors Work? Precision Control Starts With Smart Lamination Choices

Every engineer asks the same question at some point. How do servo motors hit a target position so fast and so accurately without melting down or shaking themselves apart. The short answer is closed‑loop control. The long answer includes the quiet hero inside every high‑performance servo: properly engineered motor core laminations. If you want consistent accuracy, fast dynamic response, low noise, and long life, you cannot ignore the lamination material, thickness, and manufacturing process. They set the ceiling for efficiency and thermal performance. They also influence torque ripple, acoustic noise, and servo bandwidth.

You might be optimizing a robot joint. Maybe you are selecting a servo drive for a packaging line. Or you are a procurement manager weighing material grades against delivery and cost. This guide gives you a clear path. We unpack servo control basics, then translate lamination science into practical design and sourcing decisions.

In This Article

- What Is a Servo Motor? The Basics in Plain English

- Closed-Loop Fundamentals: Command, Feedback, and PID

- Where Laminations Fit: Reducing Core Losses and Heat

- Material Options for Servo Motor Laminations

- Manufacturing and Assembly: Stamping, Laser, Bonding, and More

- Servo Types and What Their Cores Need

- Servo vs. Stepper: Why Feedback and Laminations Matter

- Sizing and Selection: What Design and Procurement Should Ask

- Data and Standards You Can Trust

- Matching Materials and Processes to Your Application

- Practical Integration Tips That Touch Laminations

- Your Engineering Takeaway

What Is a Servo Motor? The Basics in Plain English

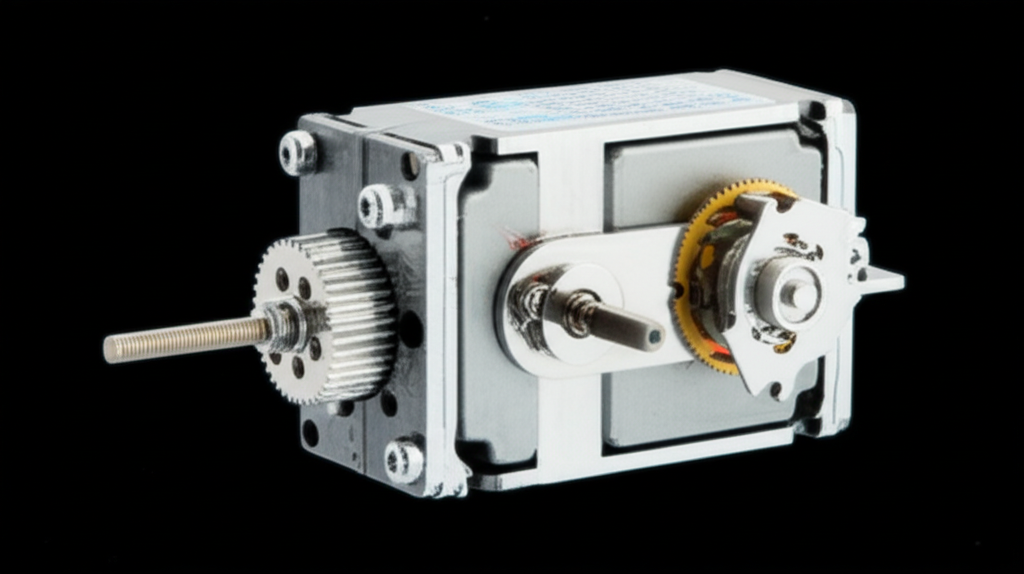

A servo motor is a rotary or linear actuator that precisely controls position, speed, and torque. It does not just spin. It goes where you tell it, then it holds that position against disturbances. Servos do that by closing the loop with a sensor that reports the actual position or speed. The control circuit compares actual with desired, then drives the motor to reduce the error. That is the core of a servomechanism.

Key parts you will see in any servo system:

- The motor: DC, AC, or brushless servo motor depending on the application.

- The sensor: Encoder, resolver, or potentiometer for position and speed feedback.

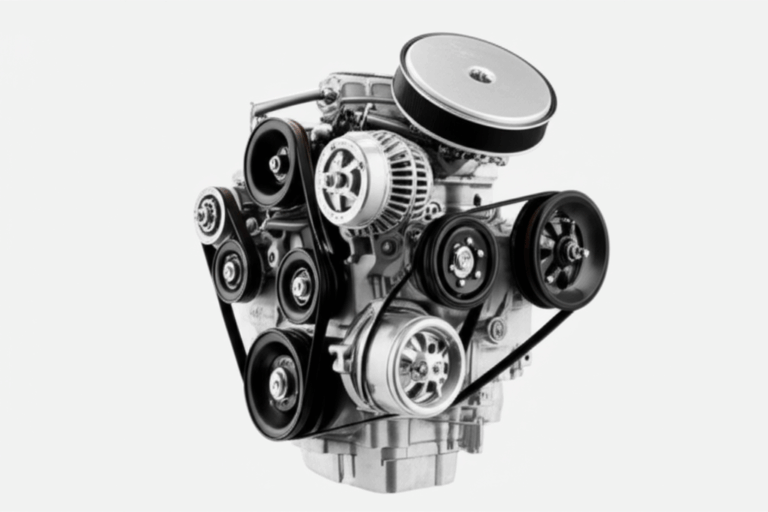

- The gearbox: Often present to multiply torque and improve resolution.

- The control circuit: A servo drive or controller that runs a control algorithm such as PID.

- The power stage: Usually an H‑bridge or three‑phase inverter that actuates the motor windings.

You will also see command interfaces like PWM servo control for hobby servos or fieldbus/EtherCAT for industrial drives. Modern systems use encoders with high resolution. They support precision motor control in robotics, CNC machines, and automated guided vehicles.

Closed-Loop Fundamentals: Command, Feedback, and PID

Let us translate the working principle of a servo motor into five steps:

1) Command signal. The controller sets a desired position, speed, or torque. Think “go to 90 degrees” or “hold 1500 RPM.”

2) Drive output. The servo drive applies voltage and current to the motor. The motor begins to move.

3) Feedback collection. The encoder measures the actual position or speed. It streams that data to the controller.

4) Error detection. The controller compares the desired state to the actual state. That difference is the error signal.

5) Correction. A control algorithm such as PID (proportional‑integral‑derivative) adjusts the drive output to reduce the error. This runs continuously, which is why servos react quickly to load changes.

You can imagine this loop like parking a car in a tight spot. You aim, you look, you correct, and you stop right on the line. The feedback makes it possible. Without it, you would overshoot again and again.

This framework applies to DC servo motors, AC servo motors, and brushless servo motors. The specific control strategy and tuning differ. The loop stays the same. Tuning parameters, encoder resolution, inertia mismatch, and system stiffness all affect response time, overshoot, servo motor jitter, and bandwidth.

Where Laminations Fit: Reducing Core Losses and Heat

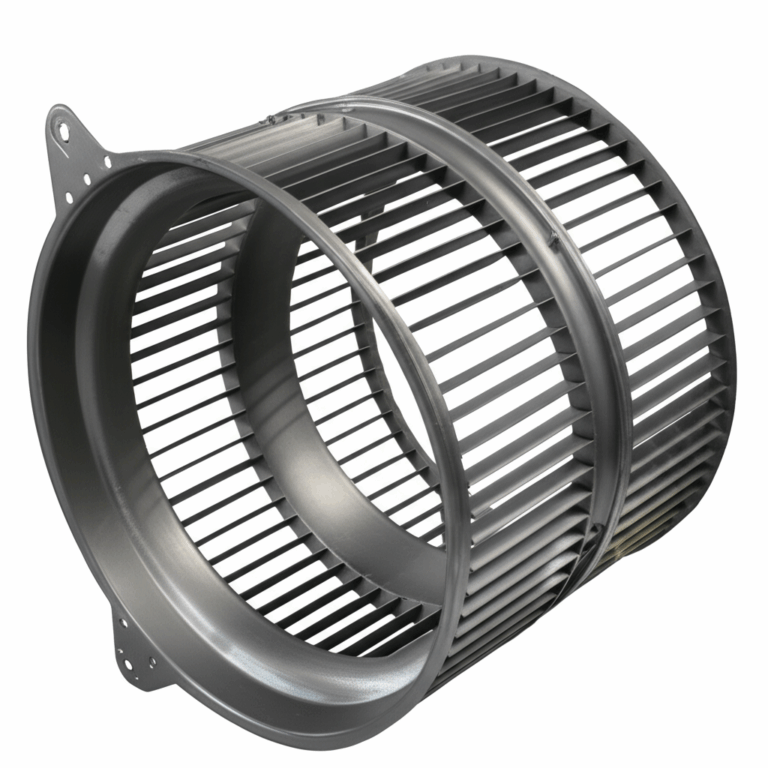

So where do laminations come in. Inside every servo motor you will find a stator core and a rotor core built from stacked electrical steel laminations. The stack looks like a deck of cards. Thin, insulated steel sheets reduce eddy currents. Those currents are circulating electrical “whirlpools” driven by changing magnetic fields. They waste energy as heat.

Picture water flowing in a river. Large whirlpools rob energy from the main flow. Thin lamination sheets with insulation break big whirlpools into small ones. The result is less loss and lower temperature. Lower heat equals better efficiency, more torque at low speed, and longer service life.

Two primary core losses matter:

- Eddy current loss. It increases with lamination thickness, frequency, and magnetic flux density. All else equal, halving the lamination thickness reduces eddy current loss by roughly four times because loss scales with thickness squared.

- Hysteresis loss. It depends on material properties such as coercivity and the shape of the B‑H curve. Lower-coercivity electrical steels cut this loss.

Why should a servo designer care. Closed‑loop control can correct position errors. It cannot cheat physics. If the core runs hot due to high losses, you will hit thermal limits. You will see reduced continuous torque, limited duty cycles, and less stability at high bandwidth. Good laminations help the servo hold position with less heating and less drive current. That means quieter operation and better precision.

If you want a deeper dive on material choices and how they translate into core performance, this overview of electrical steel laminations is a good starting point.

Material Options for Servo Motor Laminations

Electrical steels fall into two broad families for motor applications:

- Non‑oriented electrical steel (NOES). Used in most motors and generators. It offers near‑isotropic magnetic properties in the plane of the sheet. Grades vary by silicon content, thickness, and core‑loss performance.

- Grain‑oriented electrical steel (GOES). Optimized for transformers where the magnetic flux stays aligned with the rolling direction. Not a typical choice for rotating machines.

Common NOES choices include traditional M‑grades (e.g., M19) and EN 10106/10107 grades. Silicon additions raise electrical resistivity and reduce core loss. That improves efficiency. You will see thicknesses such as 0.50 mm, 0.35 mm, 0.27 mm, and even 0.20 mm in high‑end servos. Thinner laminations reduce eddy current losses at higher electrical frequencies. The trade‑off is cost and stack factor. Thinner sheets need more pieces to reach the same stack height. More insulation layers reduce the effective metal cross‑section.

Key material properties to weigh:

- Magnetic permeability. How easily the material channels magnetic flux. Higher permeability reduces magnetizing current and helps with torque production. You can think of permeability like a sponge’s ability to soak up water.

- Coercivity. The resistance to demagnetization. Lower coercivity cuts hysteresis loss.

- Core‑loss ratings at frequency and flux density. Look at manufacturer test curves rather than a single number.

- Mechanical strength and punchability. Matters for stamping longevity and burr control.

- Insulation coating class and thickness. Coatings impact interlaminar resistivity, bondability, and thermal rating.

For procurement, align material choices with standards when possible. Look for test data that follows recognized methods. Industry often references ASTM A677 for non‑oriented electrical steel and IEC 60034 for rotating machines. You will also see EN 10106 and EN 10107 for European grades. Standards do not replace application testing. They do provide a baseline for comparison.

Manufacturing and Assembly: Stamping, Laser, Bonding, and More

Material choice sets the potential. Manufacturing quality determines how much of that potential you keep. Tolerances, burr height, heat‑affected zones, and assembly methods all influence servo motor efficiency, noise, and reliability.

Here is a balanced guide to common processes.

Stamping

- What it is: Mechanical punching of laminations with hardened dies. Often progressive tools for high volume.

- Pros: Best unit cost for volume. Excellent repeatability when tooling is dialed in. Tight feature control for slots and tooth tips.

- Cons: Tooling investment. Tool wear can raise burr height if not managed. Requires robust QA to maintain lamination factor.

- When it fits: Production runs with stable designs. Standard geometries for industrial automation servos and CNC machine servo motors.

Laser Cutting

- What it is: CNC laser cuts profile from sheet. No hard tooling.

- Pros: Low NRE cost. Fast iterations. Complex features and quick prototype turns. Ideal for development and small batches.

- Cons: Heat‑affected zone can change magnetic properties near the cut edge. Requires post‑process or smart parameter control. Slower than stamping for volume.

- When it fits: Prototyping, pilot runs, complex low‑volume designs in robotics and medical devices.

Wire EDM

- What it is: Electrically erodes material with a wire electrode submerged in dielectric fluid.

- Pros: Very precise edges. Minimal burrs. Excellent for tight tolerances and research.

- Cons: Slow. Costly for large volumes.

- When it fits: Critical development parts. Complex rotor flux barriers. High‑precision test coupons for core‑loss characterization.

Stack Assembly Methods

- Interlocking. Tabs and notches hold sheets together. Works like LEGO bricks. No welding heat, which protects magnetic properties. Good for many stator stacks.

- Welding. Fast and strong. However, weld heat can locally degrade properties. Use carefully with proper heat control and post‑treatment if needed.

- Riveting or cleating. Mechanical fasteners through the stack. Simple tooling. Can disturb flux paths if placed poorly.

- Bonding/adhesive. Insulation coatings or added adhesives create “bonded stacks.” Excellent stiffness and low vibration. Higher process control and cleanliness required. Great for precision servo applications with strict noise targets.

Skewing and Cogging Control

Servo motors fight cogging torque because it shows up as ripple in position and speed. A slightly skewed stator or rotor reduces cogging and torque ripple. Skew complicates manufacturing and stacking. Bonded or interlocked stacks often handle skew better than welded stacks.

Quality Metrics to Monitor

- Burr height and edge quality at tooth tips and slot edges.

- Lamination factor (stacking factor). Actual steel fraction in the stack height.

- Insulation integrity across the stack.

- Core‑loss testing at relevant frequency and flux density.

- Dimensional tolerances on slot width, tooth pitch, and OD/ID.

If you want a single page that connects the dots between material, profile accuracy, and stacking methods for servo and other motors, keep this resource handy on motor core laminations.

Servo Types and What Their Cores Need

Servo motor is an umbrella term. The lamination strategy depends on the specific motor type and operating mode.

DC Servo Motors

- Usually brushed DC motors with a feedback device such as a potentiometer or encoder.

- Laminations: Armature laminations on the rotor carry slots for windings. The stator may use permanent magnets.

- Considerations: Mechanical commutation produces ripple and heat at the commutator. Eddy currents rise with speed. Thin laminations help at higher speeds. Burr control on rotor slots is critical to prevent wire damage.

AC Servo Motors (PMSM and BLDC)

- Most modern industrial servos use permanent‑magnet synchronous motors (PMSM) or BLDC architectures with sinusoidal or trapezoidal control. The sensor can be an optical encoder, magnetic encoder, or resolver.

- Laminations: The stator core carries the three‑phase windings. The rotor carries surface or buried magnets. Stator slot geometry and skew have big impacts on cogging torque, torque ripple, and acoustic noise.

- Considerations: Electrical frequency rises with speed and pole count. Thin laminations and low‑loss grades pay off. Control algorithms like field‑oriented control run at high PWM carrier frequencies. That reduces current ripple but adds switching harmonics. Good laminations help keep switching loss heat manageable in the iron.

Synchronous Reluctance and Hybrid Topologies

- Some servos use saliency and flux‑barrier rotors without magnets. Rotor laminations become more complex. Wire EDM or fine stamping tolerances matter a lot. The payoff is robust torque without rare earth magnets.

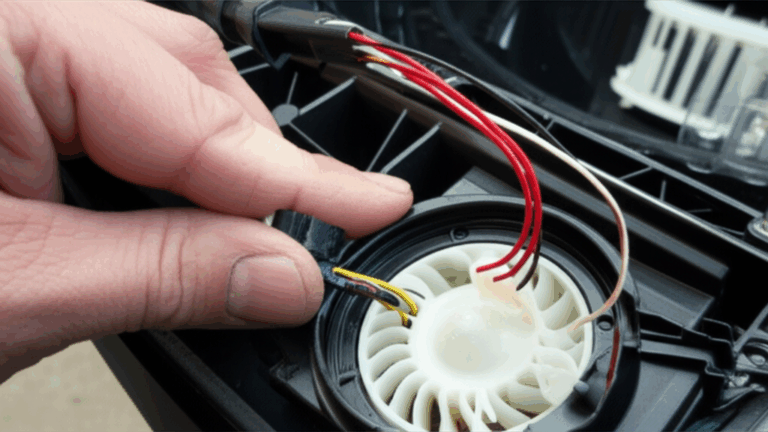

Small Hobby Servos (RC)

- Inside many “standard” hobby servos you will find a small DC motor, plastic or metal gears, and a potentiometer for feedback. The motor still relies on laminated cores. Tolerances and cost pressures drive material and process choices. Requirements differ from industrial automation servos. The fundamentals stay the same.

Working on BLDC or PMSM servo projects. The geometry and insulation details on the stator stack matter. This overview of a BLDC stator core shows how slot shape and manufacturing choices affect performance.

Servo vs. Stepper: Why Feedback and Laminations Matter

Steppers move in discrete steps with open‑loop control. They are simple and cost‑effective. They hold position at standstill using holding current. They lose steps under overload or resonance because there is no feedback to correct the error. Microstepping improves smoothness but does not change the open‑loop nature.

Servo motors use closed‑loop control. They measure actual position and correct errors in real time. That gives higher accuracy, higher torque at low speed, and better dynamic response. Laminations matter in both. They matter more in servos because the system pushes the machine harder and demands lower heat rise at high bandwidth.

A quick comparison:

- Control: closed loop vs. open loop.

- Movement: continuous vs. incremental steps.

- Efficiency: servos draw only the power needed. Steppers can waste energy holding position.

- Applications: servos dominate CNC, robotics, medical devices, and aerospace actuation where dynamic precision is king.

Sizing and Selection: What Design and Procurement Should Ask

Engineering and sourcing align best when the critical questions are clear. Use this checklist to connect performance targets to lamination choices.

Define the motion profile

- Position control, speed control, or torque control.

- Peak vs. continuous torque and speed.

- Acceleration and deceleration requirements. They drive current peaks and copper loss. They also stress the iron with higher electrical frequency.

Pin down the control and feedback

- Encoder resolution and accuracy. Higher resolution helps the controller hold position sharply. It also exposes torque ripple if the core and winding create cogging.

- Control algorithm and tuning strategy. PID parameters, feedforward terms, notch filters for resonance. Plan for tuning rather than guessing.

Translate performance into core needs

- Electrical frequency at your speed and pole count. Higher frequency leans toward thinner laminations and lower‑loss grades.

- Target flux density range. Avoid chasing high B if it spikes hysteresis and core loss.

- Bandwidth goals. Reduce cogging and torque ripple at the source with skew, optimized tooth geometry, and bonded stacks where appropriate.

Risk and reliability factors

- Heat rise and ambient conditions.

- Mechanical shock and vibration. Choose robust stack assembly.

- Environment. Moisture, chemicals, and insulation class.

Manufacturing and QA

- Required OD/ID and slot tolerances. They drive process choice.

- Acceptable burr height. Clarify limits at tooth tips.

- Documentation. Request core‑loss curves and material grade certificates that reference standards such as IEC 60034 and ASTM A677.

For stator concerns around slot geometry, insulation integrity, and stacking method, you can ground discussions with a quick reference on stator core lamination. For rotor skew, magnet fit, and flux‑barrier accuracy, keep this overview of rotor core lamination at hand during design reviews.

Data and Standards You Can Trust

You do not need a PhD in materials to make sound choices. Stick to first‑principles trends and reference credible standards.

Key relationships

- Eddy current loss rises with the square of lamination thickness and linearly with material resistivity’s inverse. Halve the thickness and you roughly quarter the eddy loss, all else equal.

- Hysteresis loss scales with frequency and depends on coercivity and the shape of the B‑H loop. Lower coercivity grades reduce that loss.

- Switching harmonics from PWM can heat the core. Higher PWM carrier frequencies reduce torque ripple but can nudge iron losses up. Balance with thermal margin.

Standards to reference

- IEC 60034 series for rotating electrical machines. Widely used for definitions, test methods, and temperature rise limits.

- ASTM A677 for fully processed non‑oriented electrical steels. Look for test methods and core‑loss characterizations aligned with this or equivalent standards.

- EN 10106 and EN 10107 for European electrical steel product definitions.

Where to find trustworthy data

- Electrical steel producer datasheets with frequency‑dependent core‑loss curves.

- Servo motor manufacturer application notes for winding and control harmonics.

- Peer‑reviewed papers in IEEE Transactions on Industry Applications or IEEE Transactions on Magnetics. Use them for trends and methods rather than cherry‑picking single numbers.

Matching Materials and Processes to Your Application

No single solution fits every servo. Match the lamination strategy to the job.

Robotics and Cobots

- Priorities: low cogging, low acoustic noise, high precision, compact size.

- Guidance: Thin laminations, skewed stator, bonded stacks for stiffness. Choose low‑loss NOES grades. Keep slot fill high without stressing the insulation.

CNC Machine Servo Drives

- Priorities: high bandwidth, repeatable torque, long duty cycles.

- Guidance: Progressive stamped laminations with tight burr control. Consider 0.35 mm or thinner sheets at higher speeds. Validate core‑loss at your switching and electrical frequencies.

Packaging and Printing

- Priorities: fast index moves, good holding torque, thermal stability.

- Guidance: Optimize for lower heat rise during frequent starts and stops. Use low‑loss steel and bonded stacks to tame vibration.

AGVs and Mobile Platforms

- Priorities: energy efficiency, weight, continuous operation.

- Guidance: Focus on low‑loss grades and thin laminations to save battery. Confirm lamination coatings support environmental conditions.

Medical Devices

- Priorities: quiet operation, precise motion, compliance with safety standards.

- Guidance: Bonded stacks for low vibration. Skew to reduce torque ripple. Validate thermal performance at expected duty cycles.

Aerospace and Defense

- Priorities: power density, reliability, tight quality control.

- Guidance: High‑grade NOES or cobalt alloy for extreme conditions if justified by analysis. Validate with strict QA and documentation.

If your team wants a broad reference that connects stator, rotor, and full stack decisions, this guide to motor core laminations is a practical place to align engineering and sourcing.

Practical Integration Tips That Touch Laminations

A few hands‑on points will save time during bring‑up and tuning.

- Watch the thermal budget. Core losses show up first as a heat rise in the stator teeth and yoke. Place temperature sensors near the stator. Validate hot‑spot temperatures under worst‑case PWM and load.

- Balance electrical frequency and lamination thickness. If you raise pole count for better control smoothness, you raise electrical frequency. Thinner laminations often restore efficiency.

- Aim for low cogging early. Use skew or fractional slot combinations. Then let the control loop clean up the rest. It costs less to prevent ripple in steel than to cancel it in software.

- Match PWM frequency to the iron. Higher carrier frequency smooths current and reduces torque ripple. It can increase switching loss in the drive and iron loss in the core. Test both ends of your range.

- Tuning follows mechanics. A stiff, bonded stack with tight fits gives the controller a predictable plant. You will see faster servo motor response time and less overshoot.

If you are designing for a PMSM or BLDC servo, review stator slot shapes and stack methods early. This quick look at a BLDC stator core shows common choices and trade‑offs.

Your Engineering Takeaway

Let’s wrap the whole topic into clear action items.

- Servo motors work because of closed‑loop feedback. Command, measure, correct, repeat.

- Laminations set the thermal and efficiency foundation. Thin, well‑insulated sheets reduce eddy currents. Low‑coercivity steel reduces hysteresis loss.

- Material choice matters. Non‑oriented silicon steels dominate servo applications. Check permeability, coercivity, and frequency‑dependent core‑loss curves. Align with standards such as IEC 60034 and ASTM A677.

- Process quality matters as much as material. Stamping wins volume. Laser and EDM win development and complex features. Control burrs, lamination factor, and insulation integrity.

- Assembly impacts noise and precision. Interlocking and bonding protect magnetic properties and raise stiffness. Skew reduces cogging and torque ripple.

- Match choices to the job. Robotics and medical equipment demand low noise and ripple. CNC servos demand thermal stability at high bandwidth. Mobile platforms demand efficiency.

- Validate with data. Use representative frequency and flux density in core‑loss tests. Measure temperature rise near teeth. Tune PID after the mechanical stack meets stiffness targets.

Next step. If you are scoping a new servo design or preparing a sourcing package, document your electrical frequency range, lamination thickness target, material grade options, and acceptable assembly methods. Include specific test expectations for burr height, lamination factor, and core loss. Share that with your lamination supplier early. You will get better quotes and better motors.

For a fast primer you can share with your team on materials and stack decisions, see these focused resources:

- Overview of electrical steel laminations

- Stator‑specific considerations in stator core lamination

- Rotor‑specific considerations in rotor core lamination

- System‑level context in motor core laminations

- BLDC stator details in BLDC stator core

If you want a second set of eyes on materials, stack method, or tolerances, schedule a short technical consultation with an engineering team that builds laminations every day. Come with your torque‑speed curve, duty cycles, and a straw‑man lamination spec. You will leave with a tighter design and a clearer sourcing plan.

Extra notes for searchers who want a quick glossary and connection to the broader servo topic:

- Servo motor explanation: A servo is a motor plus a sensor plus a control loop. It controls position, speed, and torque precisely.

- Relevant components: encoder in a servo motor, servo motor controller, servo motor driver, and the feedback mechanism that turns an error signal into motion.

- Control basics: PWM servo control for simple systems and PID for industrial drives. Proportional, integral, and derivative terms shape response and stability.

- Performance terms you will see: torque control, speed control, servo motor accuracy, bandwidth, resolution, backlash, resonance, servo motor noise, servo motor heating, and servo motor lifespan.

- Applications: robotics servo motors, CNC machine servos, packaging machinery, medical devices, aerospace, and AGVs. All share the same foundation. Laminations set the baseline for efficiency and heat. The control system does the fine work on top.