How Does a Hydraulic Motor Work? Understanding Its Core Principles and Types

- Table of Contents

- How Does a Hydraulic Motor Work? Understanding Its Core Principles and Types

- Outline

- What Is a Hydraulic Motor?

- How Does Fluid Power Turn Into Rotary Motion?

- What Are the Main Hydraulic Motor Components?

- How Do Gear Motors Work?

- How Do Vane Motors Work?

- How Do Piston Motors Work? (Axial and Radial)

- What About Gerotor Motors and HTLS Units?

- What Performance Numbers Should You Watch?

- How Do You Control Speed and Direction?

- Where Do We Use Hydraulic Motors?

- How Do You Pick the Right Motor?

- How Do You Maintain and Troubleshoot a Motor?

- What Is the Difference: Hydraulic Motor vs Hydraulic Pump?

- What Do Noise, Seals, Bearings, and Materials Do?

- What Is the History and Future of Hydraulic Motors?

- Case Study: A Winch That Must Not Slip

- Data and Stats You Can Use

- FAQ

- Key Takeaways

You see hydraulic motors in big machines. They lift, pull, spin, and steer. In this guide I walk you through the hydraulic motor principle in clear steps. You’ll see how fluid pressure becomes torque and RPM. You’ll spot the parts, the types, and the uses. You’ll learn the hydraulic motor advantages and disadvantages. You’ll also get a simple selection guide you can use today.

Outline

- What is a hydraulic motor and why it matters

- Fluid power basics and Pascal’s Principle in hydraulics

- Hydraulic motor parts breakdown

- Gear hydraulic motor operation

- Vane hydraulic motor explanation

- Piston hydraulic motor working (axial piston motor and radial piston motor)

- Gerotor motor working principle and High-Torque Low-Speed hydraulic motor notes

- Displacement, torque, speed, and hydraulic motor efficiency

- Speed control hydraulic motor tips

- Hydraulic motor applications across industries

- Hydraulic motor selection guide

- Hydraulic motor maintenance and troubleshooting hydraulic motors

- Hydraulic motor vs hydraulic pump

- Noise, seals, bearings, and material science

- History of hydraulic motors and future of hydraulic motors

- Case study and real numbers

I use the PAS framework as we go:

- Problem: You need power and control. You face cost, time, and risk.

- Agitate: Choose wrong and you lose torque. You waste energy. You stop work.

- Solution: Understand how hydraulic motors convert energy. Use the right type. Pick correct specs. Run and win.

What Is a Hydraulic Motor?

A hydraulic motor is a hydraulic actuator that turns pressurized fluid power into rotary motion. It uses fluid pressure to make a shaft spin. That spin gives you torque output of hydraulic motors and hydraulic motor RPM. When you grasp the hydraulic system basics you open the door to better machines.

Let me put it plain. Pump sends oil under pressure. Oil enters the motor. Inside you have power-generating elements like gears, vanes, or pistons. Fluid pushes them. They turn the shaft. That is the hydraulic motor function. That is how hydraulic motors convert energy.

I’ve watched crews fight with stalled drives. The fix was not magic. It was understanding hydraulic fluid power conversion and the force generation in hydraulic motors. Once they got it the machine ran smooth.

How Does Fluid Power Turn Into Rotary Motion?

Hydraulics follows Pascal’s Principle. Pressure in a fluid spreads evenly in all directions. We use that to multiply force. In a motor we use that pressure to push on parts that can move. The result is fluid pressure to rotary motion.

Think of it in steps:

- Pump makes hydraulic motor input pressure.

- Pressure creates a pressure differential in hydraulic motors across the motor’s chambers.

- The moving parts inside see force. They move. They spin the shaft.

- You get continuous rotary motion hydraulics at the output.

This feels like a pump in reverse. In fact you can say hydraulic pumps and motors explained like this: a pump takes mechanical energy and makes pressure and flow. A motor takes pressure and flow and makes mechanical energy. Same dance. Different direction.

What Are the Main Hydraulic Motor Components?

Open a motor in your mind. Here’s a simple hydraulic motor parts breakdown:

- Housing or casing: a strong shell that holds the parts. It keeps the hydraulic oil in place. It also supports the bearing.

- Inlet and outlet ports: where fluid enters and exits.

- Shaft and rotor: the output parts that spin. Think shaft rotation hydraulic motor.

- Power elements: gears, vanes, pistons, a cylinder block hydraulic motor, a swash plate, a cam plate hydraulic motor, a valve plate hydraulic motor, or a gerotor set. The design depends on the type.

- Seals and bearings: hydraulic motor seals keep oil in and dirt out. Hydraulic motor bearings carry load so the shaft spins true.

- Control parts: a valve plate, valve (hydraulics), and sometimes a control piston for variable displacement motor setups.

I like to think of the housing as the bones. The oil is the muscle. The rotor is the heart. When the oil flows the heart turns.

How Do Gear Motors Work?

Gear motors are simple and tough. In gear hydraulic motor operation two or more gears sit in a close fit housing. Oil enters under pressure. The pressure pushes on the gear teeth and the pockets between the teeth and the housing. The gears turn and carry fluid to the outlet. The shaft connects to one gear and delivers torque.

- Characteristics: fixed displacement motor by design. Simple. Robust. Lower cost. Good for industrial hydraulic motors and mobile hydraulic motors that need steady power.

- Tradeoffs: hydraulic motor efficiency is lower than piston units. Some internal leakage happens. They can be noisy.

Use gear motors when you need reliable work. They shine on conveyors and mixers. They handle dirt and heat well. They accept shock loads. That matters in construction equipment hydraulics.

How Do Vane Motors Work?

In vane hydraulic motor explanation we start with a rotor inside an eccentric cam ring. Slots in the rotor hold vanes. Springs or oil push the vanes out. Pressurized oil enters larger chamber spaces. The area difference creates force on the vanes. That force turns the rotor and shaft.

- Characteristics: can be fixed displacement motor or variable displacement motor. Smoother operation than gears. Good mid to high hydraulic motor efficiency.

- Uses: material handling, fans, mixers, and steering. When you want smooth speed control hydraulic motor behavior vane motors stand out.

I’ve used vane motors when a client asked for quiet and smooth. We tuned the valve plate hydraulic motor control and got a sweet curve. No jerks. No stalls.

How Do Piston Motors Work? (Axial and Radial)

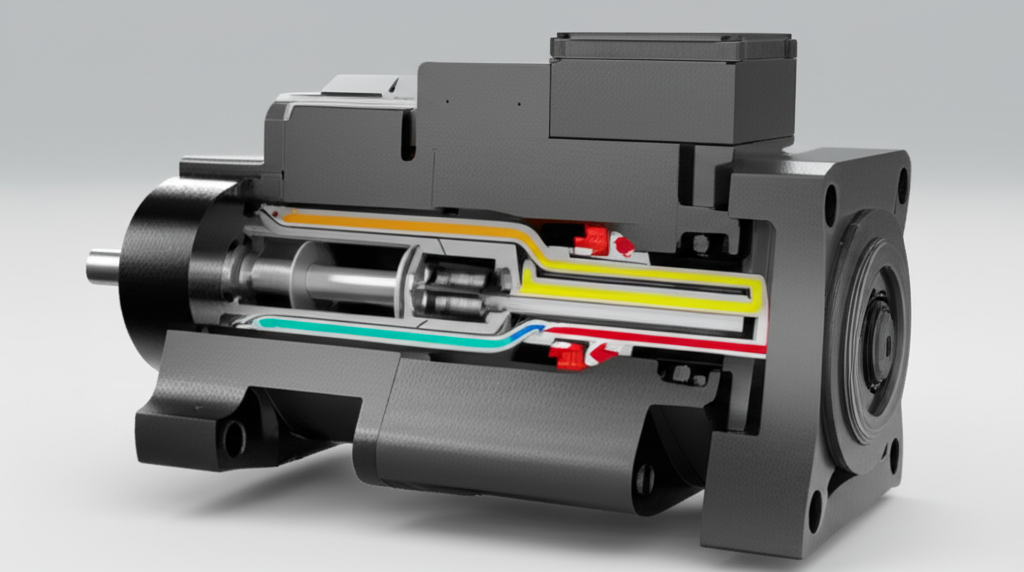

Piston motors deliver top performance. In piston hydraulic motor working the fluid pushes on pistons that slide in and out of a cylinder block. That motion turns the shaft through a swash plate or a crank type part.

- Axial piston motor: pistons sit parallel to the shaft. A swash plate or a bent axis layout converts piston motion into rotation. Axial units offer high power density and excellent hydraulic motor efficiency. You can get variable displacement motor control for power on demand. You’ll see a cylinder block hydraulic motor, a valve plate hydraulic motor, and sometimes a connecting rod or a cam plate hydraulic motor in bent axis styles.

- Radial piston motor: pistons sit around the shaft like spokes. They push on an eccentric cam or a crank. A radial piston motor delivers high torque at low speed. People call this a high-torque low-speed hydraulic motor or low speed high torque motor. It’s a winch and drum drive hero.

These motors cost more. They pay it back in efficiency and life. Use them for heavy duty. Think cranes, drilling, and swing drives.

What About Gerotor Motors and HTLS Units?

Gerotor motor working principle uses an inner and an outer gear set with different tooth counts. The inner gear drives in a rolling motion inside the outer ring. Oil fills and empties chambers as the gears roll. That creates torque on the output shaft. Many call these orbital motors. They often sit in the High-Torque Low-Speed space.

- Benefits: compact, smooth, steady torque. Great for wheel drives and augers.

- Uses: forestry, agriculture, small conveyors, and feeders.

HTLS units shine at very low RPM and high torque. Radial piston and gerotor designs lead here. They give you torque without large gearboxes. That saves space and cost.

What Performance Numbers Should You Watch?

Let’s keep this simple. Your motor must match your job. Here are the big four:

- Displacement: hydraulic motor displacement is the fluid per revolution. More displacement means more torque at a given pressure. Less displacement means more speed at a given flow.

- Torque: hydraulic motor output torque depends on pressure and displacement. You size torque to your load.

- Speed: hydraulic motor RPM depends on flow and displacement. Gear down if you need. Or choose a larger displacement to slow the motor without a gearbox.

- Efficiency: volumetric efficiency shows leakage. Mechanical efficiency shows friction. Overall efficiency is both. Gear motors often run 75–85% overall. Vane motors 80–90%. Piston motors 90–96%. Good design and good oil keep numbers high.

I also watch hydraulic motor specifications like max pressure, max speed, case drain needs, and oil type. I check the hydraulic motor schematic from the maker. I study power transmission hydraulics paths.

How Do You Control Speed and Direction?

You control a motor with valves and circuits. Two big layouts exist.

- Open loop hydraulic system motor: pump sends oil from tank to motor and back to tank. You control speed with flow valves or pump flow. You control direction with a directional valve.

- Closed loop hydraulic system motor: pump sends oil to motor. Return from motor goes back to the pump. This is common in hydrostatic transmission. It gives fine control and quick reversals.

Add smart parts and you get more:

- Servo hydraulic motors with feedback give tight speed control.

- Electro-hydraulic motors live in systems where an electric motor drives the pump and an electronic brain manages valves.

- Regenerative hydraulic motors can use energy recovery in some circuits.

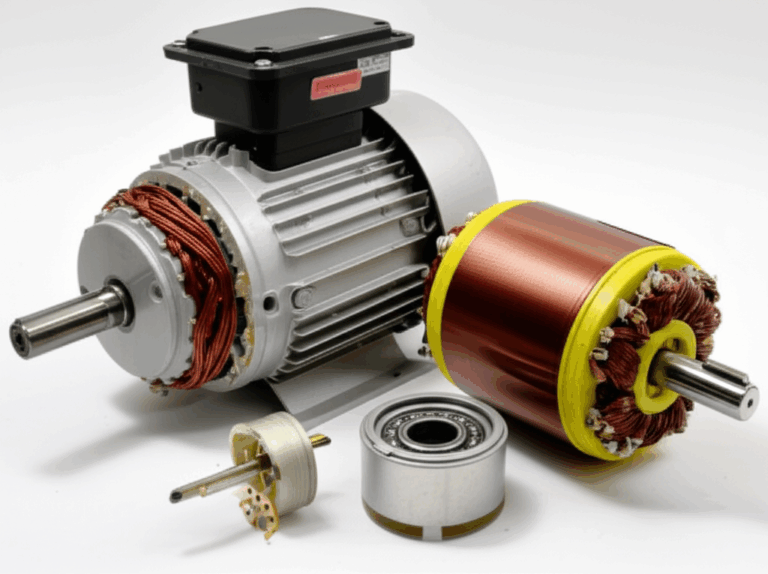

In hybrid machines the electric motor that drives the pump matters. High quality electrical steel laminations inside that motor cut losses and heat. That helps the whole hydraulic system.

If you want a quick refresher on the basics of a motor, see this plain overview of the motor principle. It helps when you compare electric and hydraulic drives.

Where Do We Use Hydraulic Motors?

Everywhere you need high force in a small space. Here are common hydraulic motor applications across industries:

- Industrial machinery: hydraulic motor for conveyors, mixers, grinders, shredders, fans, pumps (as prime mover), injection molding, test rigs, dynamometers, machine tools, and automation.

- Mobile equipment: hydraulic motor for excavators, loaders, cranes, dozers, skid steers, and steering.

- Agriculture: agricultural machinery hydraulic motors in tractors, harvesters, sprayers, forestry equipment, and agricultural sprayers.

- Marine & offshore: marine hydraulic systems run winches, thrusters, and deck cranes.

- Aerospace & defense: hydraulic motor in aerospace for actuation. Hydraulic motor in defense for rugged drives.

- Robotics: hydraulic motor for robotics and precision moves.

- Energy: hydraulic motor for wind turbine yaw systems.

If you ask what makes a hydraulic motor turn in all these jobs the answer is the same. Pressure, area, and force acting on internal moving parts. Simple physics. Big results.

How Do You Pick the Right Motor?

Problem: You need a motor that fits your load and your space. Agitate: Choose wrong and you overheat or stall. You burn money. Solution: Use this hydraulic motor selection guide.

- Define the job: load torque, speed, duty cycle, start-stop needs.

- Select type: gear, vane, or piston. Consider gerotor for compact HTLS duty.

- Choose displacement: size for torque at available pressure.

- Check speed: confirm RPM at available flow.

- Confirm efficiency and heat: calculate power and losses. Check case drain flow.

- Pick fixed displacement motor or variable displacement motor for your control needs.

- Check housing, shaft, and mounting: match the machine. Pick the right seal and bearing life.

- Match the circuit: open loop or closed loop. If you need hydrostatic transmission pick a closed loop hydraulic system motor.

I also check brand strength. Companies like Bosch Rexroth, Parker Hannifin, Danfoss, Eaton, Kawasaki, Linde Hydraulics, M+S Hydraulic, Poclain Hydraulics, Yuken, and Hydac publish solid data. Heavy equipment makers like Caterpillar, John Deere, and Komatsu use these motors in tough work. That tells you something.

In electro-hydraulic systems the pump drive motor quality matters too. If you build or buy electric motors for pump drives look for tight motor core laminations. Good laminations help the electric side run cool and efficient. That supports the hydraulic side.

How Do You Maintain and Troubleshoot a Motor?

Hydraulic motor maintenance is simple if you plan it.

- Keep oil clean. Use the right hydraulic oil function in motor service. Check filters. Test for water and dirt.

- Watch temperature. Heat kills seals and bearings. Fix cooling early.

- Inspect hydraulic motor seals and hydraulic motor bearings. Replace worn parts before they fail.

- Listen for noise. Noise can mean cavitation or aeration.

Troubleshooting hydraulic motors follows a checklist:

- Low torque: check pressure, leakage, and displacement control. Look for internal wear.

- Slow speed: check flow, restrictions, and valves.

- Overheating: check efficiency and case drain. Correct misalignment.

- Vibration: check mounting and coupling.

Repair or replace when needed. Many shops offer hydraulic motor repair and hydraulic motor rebuild. Use maker kits. Follow torque specs. Test on a bench. Log results on a hydraulic motor schematic sheet.

What Is the Difference: Hydraulic Motor vs Hydraulic Pump?

Think of twins that run in opposite ways. A hydraulic pump takes mechanical input and makes pressure and flow. A hydraulic motor takes pressure and flow and makes mechanical output. Both live in fluid mechanics for hydraulic motors and pumps. Both sit in energy conversion in fluid power.

Here are clear notes:

- Motor uses pressure to make torque. Pump uses torque to make pressure.

- Motor output is a spinning shaft. Pump input is a spinning shaft.

- You can back-drive some pumps as motors in test rigs. But not always. Check the specs.

For a quick refresher on how shafts and frames come together in electric drives, you can also review stator and rotor. It helps when you compare hybrids that blend electric and hydraulic power.

What Do Noise, Seals, Bearings, and Materials Do?

Noise hurts life and comfort. Hydraulic motor noise reduction comes from good design and clean oil. Choose smoother types like vane or piston if noise matters. Mount the motor right. Use hoses that dampen ripple.

Seals stop leaks. Pick the right seal (mechanical) material for your oil and temperature. Bearings carry load. Pick the right bearing based on radial and axial force. Get lube to the bearing path. The housing (motor component) must hold everything in line. The shaft (mechanical) must handle torque and bending.

Materials matter too. Hydraulic motor material science looks at wear surfaces and coatings. Makers test different steels and treatments. That boosts life at high pressure. In electro-hydraulic power units the electric motor side needs low-loss cores. That is where precision laminations help. If you build those motors study the quality of electrical steel laminations.

What Is the History and Future of Hydraulic Motors?

The history of hydraulic motors tracks the rise of fluid power in industry. Early units were simple. Then came better seals, better bearings, tighter machining, and smarter valve plates. Today we see innovation in hydraulic motors like:

- Better efficiency through improved valve plates and cylinder blocks.

- Smarter controls with servo hydraulic motors.

- Cleaner systems with better filtration and coolers.

- Electro-hydraulic motors in hybrid machines with digital brains.

- Regenerative hydraulic motors in systems that reuse energy.

The future of hydraulic motors looks bright. Expect more electro-hydraulic systems. Expect tighter control loops. Expect 10–20% better system efficiency in many machines with smart pumps and smart motors. Expect new coatings and fluids. These are real hydraulic motor industry trends.

Case Study: A Winch That Must Not Slip

Problem: A deck winch must lift heavy nets on a cold sea. It needs big torque at low speed. It must hold a load without drift.

Agitate: If the motor stalls the crew waits. If it slips someone can get hurt. The sea does not care.

Solution: We chose a radial piston motor. It is the perfect high-torque low-speed hydraulic motor. It gives steady pull from near zero RPM. The cam plate hydraulic motor layout and the eccentric convert pressure into smooth torque. We used closed loop control for fine moves. We sized displacement for peak torque at our hydraulic motor input pressure. We added a brake valve and a load-holding valve plate hydraulic motor control. We got safe lifts and smooth stops.

This same logic works on a hydraulic motor for winches on land cranes. It also fits a hydraulic motor for drills and a hydraulic motor for shredders that need strong starts.

Data and Stats You Can Use

Here is a quick table of typical efficiency and use. Real numbers vary by maker and model.

| Metric | Gear Motor | Vane Motor | Axial/ Radial Piston Motor |

|---|---|---|---|

| Volumetric Efficiency | 80–90% | 85–95% | 95–99% |

| Overall Efficiency | 75–85% | 80–90% | 90–96% |

| Power Density | Medium | Medium | High |

| Control Options | Fixed | Fixed or Variable | Variable common |

| Typical Uses | Conveyors, mixers | Fans, steering | Cranes, drills, swing drives |

More context:

- Market size: the global hydraulic motor market sits in the multi‑billion range and grows with industrial automation, construction, and agriculture.

- Power density: compared to many electric drives of the same size, hydraulic motors can deliver 5–10x more power per unit weight in some heavy-duty cases.

- Industry adoption: over half of heavy construction equipment uses hydraulic motors for tracks, swing, and work tools.

When you build an electro-hydraulic power unit remember the electric side matters. Quality cores reduce iron loss. If you design motors or buy parts for them take a look at precision motor core laminations.

FAQ

- What makes a hydraulic motor turn? Pressure acting on area produces force. That force acts on gears, vanes, or pistons and makes the shaft rotate.

- Which motor type has the best efficiency? Piston motors. Axial and radial designs reach 90–96% overall in many cases.

- Do I need variable displacement? If you want wide speed range at steady pressure or want to trim energy you will like variable units.

- Can a pump run as a motor? Sometimes. Check the maker’s data. Not all pumps can run as motors safely.

Key Takeaways

- The core principle: Pascal’s principle in hydraulics and pressure differential in hydraulic motors push on internal parts to create torque and continuous rotary motion hydraulics.

- Types: gear, vane, piston, and gerotor. Axial piston motor and radial piston motor cover high power and HTLS needs.

- Specs: watch hydraulic motor displacement, hydraulic motor output torque, hydraulic motor RPM, and hydraulic motor efficiency.

- Control: open loop and closed loop. Hydrostatic transmission gives precise control. Servo hydraulic motors and electro-hydraulic motors add brains.

- Applications: hydraulic motor for conveyors, mixers, grinders, shredders, fans, pumps, injection molding, test rigs, dynamometers, robotics, excavators, loaders, cranes, steering, agricultural machinery hydraulic motors, agricultural sprayers, forestry equipment, marine hydraulic systems, wind turbine yaw, aerospace, and defense.

- Care: hydraulic motor maintenance and troubleshooting hydraulic motors save time and money. Clean oil. Cool oil. Good seals and bearings.

- Design: smart hydraulic motor design and hydraulic motor manufacturing improve life. Use a clear hydraulic motor selection guide.

- Extra learning: study fluid mechanics for hydraulic motors and energy conversion in fluid power. Compare hydraulic motor vs hydraulic pump to build better systems.

- Hybrid tip: electro-hydraulic power units need efficient electric motors. Quality laminations help. If you want a primer on core machine parts read up on stator and rotor.

References

- Bosch Rexroth. Mobile hydraulics and axial piston motor technical data.

- Parker Hannifin. Hydraulic motor catalogs and design guides.

- Danfoss. Orbital (gerotor) motor technical information.

- Eaton. Vane motor application notes.

- Poclain Hydraulics. Radial piston motor documentation.

- Linde Hydraulics. Closed loop drive systems overview.

- Hydac. Filtration and cooling best practices.

- Textbook: Fluid Power and Motion Control basics.