How Does a Permanent Magnet Generator Work? Unveiling the Power of Magnetic Fields

Have you ever wondered how a giant wind turbine makes electricity from just a breeze? Or how an electric car can get power back when it brakes? The secret often lies inside a powerful little machine called a permanent magnet generator. This article will show you exactly how these amazing devices work, using simple words and easy examples. You’ll soon see why they are so important for our future.

Table of Contents

- What Is a Permanent Magnet Generator Anyway?

- How Do You Get Electricity from a Magnet?

- What Are the Main Parts of a PMG?

- How Does It All Work Together, Step-by-Step?

- Are There Different Kinds of PMGs?

- Why Are Permanent Magnet Generators So Good?

- Are There Any Downsides to Using PMGs?

- Where Do We Use These Generators?

- How Are PMGs Different from Other Generators?

- What Does the Future Hold for PMGs?

What Is a Permanent Magnet Generator Anyway?

Imagine you need a reliable way to make electricity. For years, people have used generators that need their own power just to get started. They have complex parts that wear out, need lots of maintenance, and waste energy. This is a huge problem when you need power in a remote place, like an offshore wind turbine, or in a small space, like an electric car. Wasted energy and constant repairs cost a lot of time and money.

A Permanent Magnet Generator, or PMG, is a special type of generator that solves this problem. It uses powerful magnets, like Neodymium magnets, to create a magnetic field all by themselves. They don’t need any extra electricity to work! This makes them super efficient and simple.

Think of it like this: a regular generator is like a flashlight that needs batteries to power its own light bulb and another set of batteries to power the machine itself. A PMG is like a magic flashlight that has a permanent light source built-in, so it only needs power to turn on. This PMG working principle is a game-changer for renewable energy and many other fields.

How Do You Get Electricity from a Magnet?

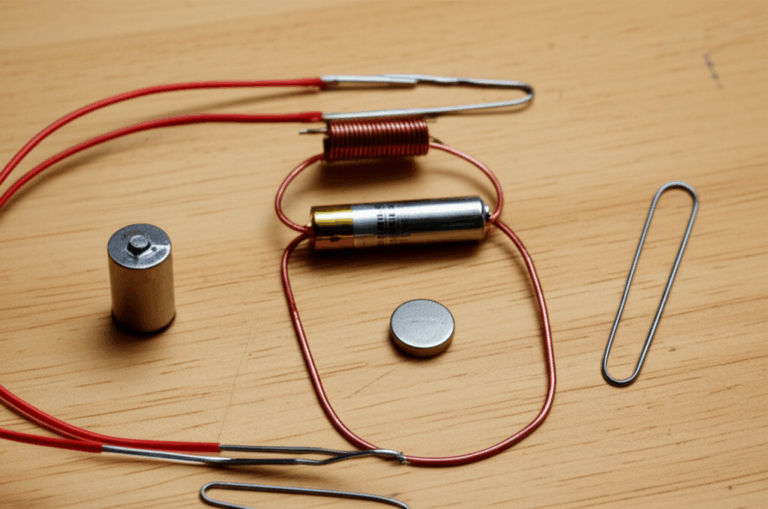

It sounds like magic, but it’s actually science! The core idea behind how a PMG works is a principle called Electromagnetic Induction. A brilliant scientist named Michael Faraday discovered it almost 200 years ago. His discovery is now known as Faraday’s Law of Induction.

Faraday’s Law says that if you move a wire through a magnetic field, or move a magnetic field past a wire, you will create an electrical voltage in that wire. When you have a voltage, you can make an electric current flow. That’s electricity! The key is relative motion. Something has to be moving. The faster you move the wire or the magnet, the more voltage you create.

There’s another rule that works with Faraday’s Law called Lenz’s Law. It helps us know which direction the electricity will flow. It’s a bit like pushing a swing. The generator creates a current that makes its own tiny magnetic field, which pushes back against the main magnet. This is called back EMF and is why you need energy to turn the generator in the first place. You can’t get energy from nothing!

What Are the Main Parts of a PMG?

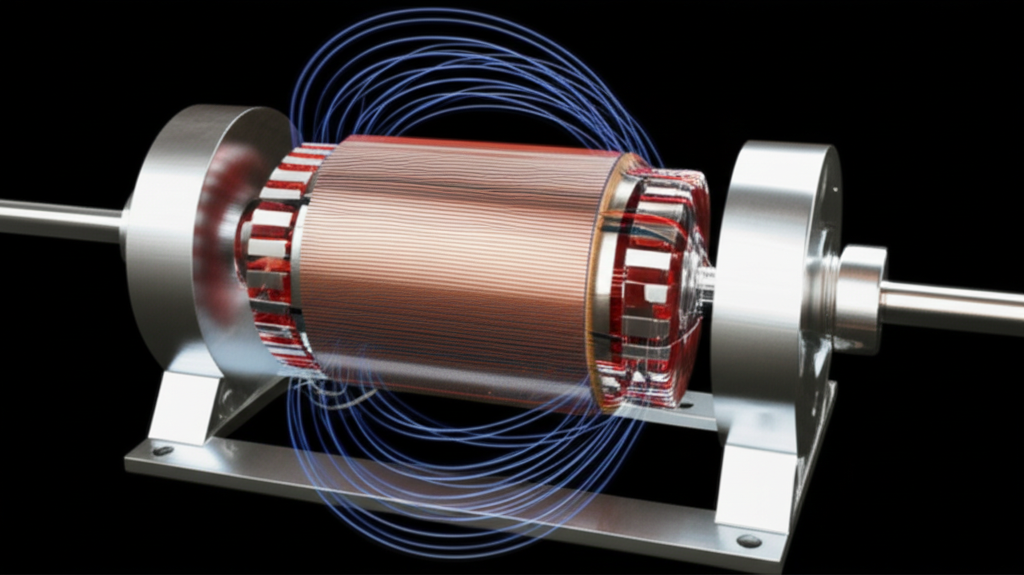

A permanent magnet generator has two main characters in its story. Their teamwork is what makes electricity happen. You’ve got the rotor, which is the part that spins, and the stator, which is the part that stays still. The relationship between the stator and rotor is the heart of the machine.

The Rotor: The Spinning Heart

The rotor is the moving part. It’s connected to something that provides mechanical energy, like the blades of a wind turbine or the engine in a boat. The most important things on the rotor are the permanent magnets. These aren’t your normal fridge magnets. They are super-strong rare earth magnets, usually made from materials like Neodymium or Samarium-Cobalt. They have a North Pole and a South Pole, creating a powerful and constant magnetic field.

The Stator: The Power Collector

The stator is the stationary part that surrounds the rotor. Its main job is to catch the energy from the rotor’s moving magnetic field. The stator has coils of copper wire neatly wound around a core. This is called the armature winding. When the rotor’s magnetic field cuts across these copper wires, electricity is generated right there! The core is often made of many thin layers of metal to make it more efficient. The quality of the stator core lamination is critical to prevent energy losses, like eddy current losses.

| Component | What it is | What it does |

|---|---|---|

| Rotor | The spinning part | Holds the permanent magnets and creates the moving magnetic field. |

| Stator | The stationary part | Holds the copper coils where electricity is made. |

| Magnets | Strong magnets | Provide a constant magnetic field without using electricity. |

| Coils | Copper wires | Generate voltage and current when the magnetic field passes them. |

How Does It All Work Together, Step-by-Step?

So, you have the parts. How does a PMG actually convert mechanical energy into electricity? Let’s walk through the energy conversion principles.

Are There Different Kinds of PMGs?

Yes! While they all use the same basic principle, engineers have come up with different designs for different jobs. The most common type is the Permanent Magnet Synchronous Generator (PMSG). The “synchronous” part means the rotor’s magnetic field spins at the exact same speed as the electric current it creates.

There are also different shapes. A radial flux generator has magnets that face outwards from the center, like the spokes on a bike wheel. An axial flux permanent magnet generator is flatter, like a pancake, with magnets facing each other across a gap.

One of the coolest types is the direct drive generator. Many machines use a gearbox to increase speed, but gearboxes can be heavy, noisy, and break down. A direct-drive PMG connects directly to the power source, like the hub of a giant wind turbine. This makes the whole system simpler, lighter, and much more reliable.

Why Are Permanent Magnet Generators So Good?

There’s a reason PMGs are getting so popular. They offer huge advantages over older generator types. If you’re building a system that needs to be efficient and tough, a PMG is often the best choice.

Here are some of the biggest benefits:

- Super High Efficiency: PMGs are incredibly efficient, often reaching 90% to 98% efficiency. They don’t waste energy creating their own magnetic field. This means more of the mechanical energy from wind or water gets turned into useful electricity.

- Small and Powerful: They have a very high power density. This means you get more power from a smaller, lighter machine. They can be 2-3 times more power-dense than other generators, which is perfect for electric vehicle PMG motors and portable power systems.

- Tough and Reliable: PMGs have a simple, brushless permanent magnet generator design. Old generators used “brushes” that would wear out and need replacing. With no brushes, PMGs have fewer parts that can fail. This leads to up to 50% lower maintenance costs and a longer life, which is a huge deal for machines that are hard to get to.

- Great at Low Speeds: They work very well even at low or changing speeds. This is why they’re ideal for renewable energy, where the wind doesn’t always blow at the same speed.

Are There Any Downsides to Using PMGs?

Of course, no technology is perfect. PMGs have a few challenges, though engineers are working hard to solve them.

The biggest issue is cost. The powerful rare-earth magnets they use, like Neodymium, can be expensive. This can make the cost of permanent magnet generators higher at the start, though they often save money over time due to lower maintenance costs.

Another risk is demagnetization of permanent magnets. If the generator gets too hot (above 80°C to 200°C for some magnets), the magnets can lose their strength forever. This is why generator thermal management and good cooling systems are so important. Finally, some designs can have cogging torque, which is a slight magnetic “bumpiness” at very low speeds, but this can be reduced with clever designs in both the stator and the high-quality rotor core lamination.

Where Do We Use These Generators?

You can find PMGs working hard in all sorts of amazing places. Their unique advantages make them the perfect choice for some of the world’s most advanced technology.

- Renewable Energy: This is their biggest stage. You’ll find them in massive offshore wind turbines, like the VESTAS V164, and in small-scale wind and hydropower permanent magnet generator systems for homes and farms. They are also being used in new tech like wave and tidal energy converters.

- Electric Vehicles (EVs): Most modern EVs use a Permanent Magnet Synchronous Motor (PMSM) to drive their wheels. This motor works just like a PMG but in reverse. And when the car brakes, the motor switches to generator mode, using the wheels’ motion to create electricity and recharge the battery. About 70-80% of EV motors are this type!

- Marine and Aerospace: From ship propulsion systems to auxiliary power units on airplanes, the reliability and high power density of PMGs are a perfect fit.

- Industrial Machines: High-performance generator control systems in robotics and factory machines use PMGs for precise and efficient motion.

How Are PMGs Different from Other Generators?

It helps to see how PMGs stack up against other types. The main competitor is the wound rotor synchronous generator. This type uses copper coils on its rotor instead of magnets. It has to be “excited” by sending electricity to these coils to create a magnetic field. This uses up energy and requires brushes and slip rings, which wear out.

Another type is the induction generator. These are simple and rugged, but they are generally less efficient than PMGs and need to be connected to the grid to start working. A PMG is more of a standalone powerhouse. In high-stakes applications where efficiency and reliability are everything, the choice is often a high-quality PMG built with superior motor core laminations to ensure top performance.

What Does the Future Hold for PMGs?

The future of permanent magnet generators is incredibly bright. The world’s shift towards clean energy and electric transportation means we need more efficient and reliable machines than ever before. The global PMG market is expected to grow by 7-9% every year for the rest of the decade.

Researchers are working on innovations in PMG technology, like creating new magnet materials that don’t rely as much on expensive rare-earth elements. They are also developing smarter power electronics and control systems to make them even more efficient and easier to connect to the grid. As this permanent magnet technology improves, you can expect to see PMGs powering even more of our world.

Key Takeaways

Let’s wrap up with the most important things to remember about how a permanent magnet generator works:

- It uses permanent magnets on a spinning part (the rotor) to create a constant magnetic field without using any extra power.

- It works because of electromagnetic induction. When the rotor’s magnetic field moves past stationary copper wires (on the stator), it creates an electric current.

- They are super efficient. PMGs waste very little energy, turning more mechanical motion into electricity.

- They are reliable and low-maintenance. Their simple, brushless design means fewer parts to break down.

- They are used everywhere! You’ll find them in wind turbines, electric cars, hydropower plants, and advanced machinery.