How Fast Do Motor Scooters Go? Your Comprehensive Guide

Every engineer has heard the deceptively simple question: “How fast do motor scooters go?” Product designers and procurement managers hear it too. Underneath that question lives a web of engineering trade-offs. Speed depends on engine or motor architecture, gear reduction, aerodynamics, regulations, and—if you’re working on electric platforms—the quality of your motor laminations and magnetic materials. If you need a clear, authoritative breakdown that helps you design, buy, or specify scooter drivetrains with confidence, you’re in the right place.

Speed sells. Safety matters. Cost governs. Your goal is to balance all three without surprises on the road or at the BOM table. Let’s tackle the problem, explain the fundamentals, guide your options, and empower your next step.

In This Article

- Understanding Scooter Speed: Top Speed vs. Practicality

- The Core Factors Influencing Motor Scooter Speed

- Inside the Motor: Laminations, Magnetic Materials, and Losses

- Average & Maximum Speeds by Scooter Category (Data-Driven Insights)

- Legal Implications: Scooter Speed, Licensing, and Road Access

- Comparing Scooter Speeds: What to Expect

- Can You Make a Scooter Faster? Modifications & Performance Upgrades

- Choosing the Right Speed for Your Needs

- Engineering Guide: Material and Manufacturing Choices for Scooter Motors

- Which Application Is This For? Best-Fit Decisions

- Quick Answers to Common Speed Questions

- Conclusion: Speed, Safety, and Smart Riding Choices

Understanding Scooter Speed: Top Speed vs. Practicality

When someone asks how fast motor scooters go, they might mean three different things:

- Maximum or top speed. The absolute fastest a scooter can travel in ideal conditions with a single rider on level ground.

- Cruising speed. The comfortable, sustained speed without running a motor or engine at the ragged edge.

- Acceleration. How quickly a scooter reaches 30 mph or 60 mph. That jump-off-the-line behavior often matters more in city traffic than the headline number.

Different users value different aspects:

- Commuters want predictable acceleration and a relaxed cruising speed that keeps up with traffic.

- Fleet managers look for reliable performance at a specific load and route profile.

- Engineers care about the physics: how engine displacement, motor torque, CVT setup, vehicle mass, and aerodynamics combine to deliver speed under real-world conditions.

Speed is crucial for safety and legal compliance. If your scooter cannot flow with traffic, it raises risk. If it exceeds legal limits for its class, it can trigger licensing and insurance issues. Keep those downstream consequences in view while you design or choose a model.

The Core Factors Influencing Motor Scooter Speed

A scooter’s speed envelope reflects a handful of core variables. You can treat these as levers in design, specification, or selection.

Engine Displacement (CCs): The Primary Determinant

For combustion scooters, engine size correlates with speed and acceleration.

- 50cc scooters: Entry-level machines often run 25–40 mph (40–65 kph). Many jurisdictions classify them as mopeds with legal speed restrictions around 28–30 mph.

- 125cc scooters: Balanced performance for city and suburb. Expect 55–65 mph (90–105 kph) with adequate acceleration for mixed traffic.

- 150cc scooters: These add headroom. You’ll see 60–70 mph (95–115 kph) and better uphill performance.

- 250cc+ and maxi-scooters: Highway-ready power and near-motorcycle performance. Typical real-world top speeds span 75–100+ mph (120–160+ kph).

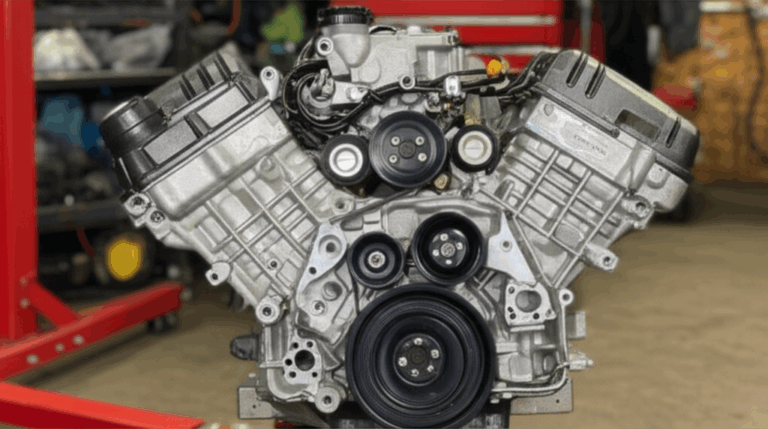

Engine Type: 2‑Stroke vs. 4‑Stroke vs. Electric Motors

- 2‑stroke scooters often deliver snappy torque for a given displacement. They can feel quicker off the line, yet emissions regulations limit their presence in many markets.

- 4‑stroke engines dominate modern scooters. They offer better fuel economy, wider support, and lower emissions.

- Electric scooters span a wide spectrum. “Electric scooter” can mean a 20 mph urban e-moped or a high-performance platform running 60–75+ mph with strong torque throughout the range. Motor wattage, controller limits, and battery voltage set the ceiling. Torque is instant, and tuning choices shape both top speed and thermal behavior.

Scooter Weight & Aerodynamics

Weight affects acceleration and hill-climbing. Aerodynamics dominate at higher speeds. A taller rider or big top case can increase drag and trim a few mph off the top end. Streamlined fairings on maxi-scooters help them cruise at freeway speeds with less strain.

Rider Weight & Passenger Load

Heavier riders or two-up riding raise the demanded torque. A 50cc or 125cc scooter can lose 5–10 mph off the top speed and feel sluggish off the line under heavier loads. That’s normal physics at play.

Terrain & Environmental Conditions

Hills demand power. Headwinds increase drag. Hot days and high altitude reduce air density which affects combustion output and cooling margin. You’ll see larger speed hits on lower-powered scooters.

Maintenance & Scooter Condition

Speed falls when maintenance slips:

- Underinflated tires raise rolling resistance.

- A worn drive belt hurts a CVT’s ratio control.

- A clogged carburetor chokes combustion.

- Fouled spark plugs or misadjusted valves sap power.

- On electric scooters, poor battery health triggers voltage sag at higher loads which limits speed.

Gearing & Transmission Systems

Most combustion scooters use a CVT with a variator and centrifugal clutch. Variator weights, belt width, and driven pulley setup shift the effective gear ratio across the rev range. Tuning can emphasize acceleration, top speed, or a compromise. Electric scooters often use a fixed reduction gear or a two-stage gear reduction with a carefully selected ratio to balance gradeability and max velocity.

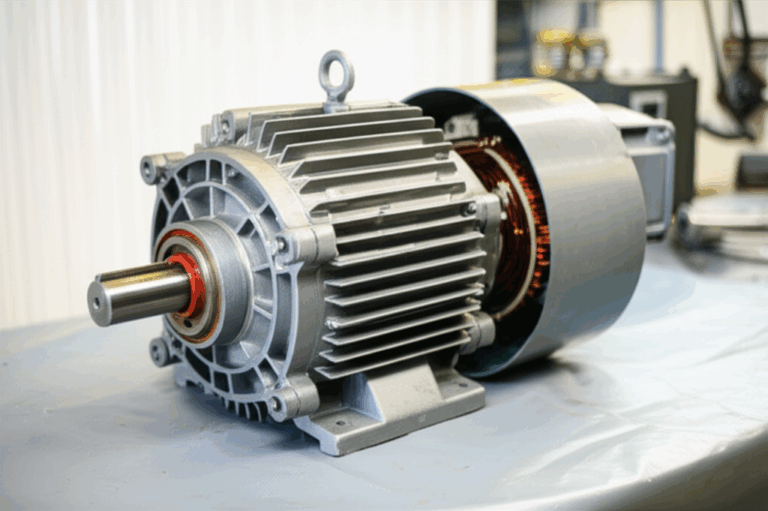

Inside the Motor: Laminations, Magnetic Materials, and Losses

If your scooter is electric, the motor and its magnetic steel define efficiency, thermal limits, torque density, and usable top speed. Even combustion scooters rely on electrical machines for starter-generators or accessory systems. Laminations matter.

Here’s the gist in plain terms:

- Eddy currents are tiny whirlpools of electricity spinning in the steel when the magnetic field changes. Those whirlpools waste energy as heat.

- Hysteresis loss is the cost of flipping magnetic domains back and forth with every electrical cycle. It scales with frequency and depends on the steel’s chemistry and microstructure.

Thinner, insulated laminations break up those eddy “whirlpools” which reduces eddy current losses. Better grades of electrical steel lower hysteresis loss. Smarter stacking and bonding reduce parasitics and improve thermal paths. That cocktail of choices gives you higher motor efficiency, cooler operation, more peak torque before thermal roll-off, and a higher sustained speed without derating.

Key fundamentals to align:

- Electrical frequency rises with motor speed and pole count. High‑pole motors deliver strong torque at low rpm which suits scooters. They also push core loss higher at the same mechanical rpm due to higher electrical frequency.

- Lamination thickness should scale with frequency. Thinner laminations reduce eddy losses at higher electrical frequencies.

- Material selection balances cost and performance. Non‑oriented silicon steel is common. Premium grades and cobalt‑based alloys unlock higher power density at a premium price.

If you’re new to this space, start with the basics:

- Use proven non‑oriented electrical steels for BLDC and PMSM scooter motors.

- Consider thinner gauges as your maximum electrical frequency climbs.

- Use quality interlaminar insulation to block eddy current loops between sheets.

- Validate the stack factor and bonding method in your thermal model because real stacks rarely match textbook behavior.

For deeper reading on materials and their role, see these primers:

- Overview of available electrical steel laminations

- How a stator core lamination influences winding utilization and slot fill

- Why the rotor core lamination geometry drives torque ripple and saliency

Average & Maximum Speeds by Scooter Category (Data-Driven Insights)

Engine displacement and motor power still offer the clearest shorthand for how fast a scooter goes. Use the ranges below as practical guidance for design targets and buyer expectations.

50cc Scooters: City Cruisers & Moped Laws

- Typical top speeds: 25–40 mph (40–65 kph)

- Many regions cap 50cc class speeds at ~30 mph. Manufacturers add limiters to meet moped laws and licensing tiers.

- Derestricting a 50cc scooter can raise top speed yet may break laws and void warranties.

125cc Scooters: The Urban‑Suburban Sweet Spot

- Typical top speeds: 55–65 mph (90–105 kph)

- Light highway use can work in favorable conditions.

- Expect more stable cruising speeds in the mid‑50s. Steep grades and headwinds will trim that.

150cc Scooters: Balanced Power for Mixed Riding

- Typical top speeds: 60–70 mph (95–115 kph)

- Suited for urban, suburban, and moderate highway sections.

- Extra torque makes two‑up riding more comfortable.

250cc+ Scooters (Maxi‑Scooters): Highway Dominators

- Typical top speeds: 75–100+ mph (120–160+ kph)

- Designed for long distance and freeway cruising.

- Aerodynamics and chassis stability support higher sustained speeds.

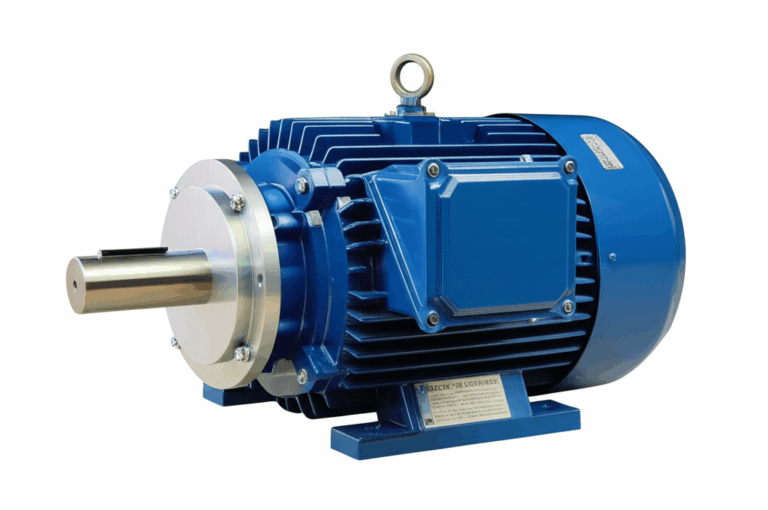

Electric Scooters: Range of Performance

- Typical top speeds: 20–75+ mph (32–120+ kph), depending on motor wattage, battery voltage, controller current limits, and regulations.

- High‑performance e‑scooters rival mid‑displacement gasoline scooters. Urban e‑mopeds target regulated city speeds with emphasis on range and thermal stability.

Table: Typical Top Speeds and Characteristics of Motor Scooters by Engine Displacement

| Engine Displacement (CCs) | Typical Top Speed (MPH) | Typical Top Speed (KPH) | Common Use Case | Highway Legal (USA) | License Requirement (USA) | Notes |

|---|---|---|---|---|---|---|

| 50cc | 25-40 mph | 40-65 kph | Urban, short commutes | No | Varies (often standard DL or Moped permit) | Often restricted to 30 mph (48 kph) by law in many regions; some can be derestricted. Not suitable for main roads or highways. |

| 125cc | 55-65 mph | 90-105 kph | Urban, suburban, light highway | Yes (with speed capability) | Motorcycle endorsement (M1/M2) | Good for city and suburban use; can handle some highway stretches but might struggle to keep up with fast traffic, especially on steeper grades. |

| 150cc | 60-70 mph | 95-115 kph | Urban, suburban, highway | Yes | Motorcycle endorsement (M1/M2) | A popular choice offering a good balance of power for city and comfortable highway capability. Can maintain higher speeds more easily. |

| 250cc – 400cc | 75-90 mph | 120-145 kph | Highway, touring | Yes | Motorcycle endorsement (M1/M2) | Maxi-scooters; excellent highway cruisers, comfortable for longer distances, offering stable performance at higher speeds. |

| 500cc+ | 90-100+ mph | 145-160+ kph | Touring, high-performance | Yes | Motorcycle endorsement (M1/M2) | High-end maxi-scooters, providing strong acceleration and top speeds suitable for extensive highway travel and long-distance touring. |

| Electric Scooters | 20-75 mph (varies) | 32-120 kph (varies) | Urban to highway | Varies | Varies (depends on power/speed) | Speed depends on motor wattage and battery; some high-performance models rival gasoline scooters, while others are restricted for urban use. |

Notes for practical engineering:

- Rider weight shifts every number. Test at representative load conditions.

- Wind resistance rises with speed squared. You feel that jump after 45 mph.

- Speedometer accuracy varies. GPS comparisons often show optimistic dials by a few mph.

Legal Implications: Scooter Speed, Licensing, and Road Access

Speed and legal classification are inseparable:

- Many US states and EU countries classify “mopeds” based on top speed and engine size. A 50cc scooter limited to 28–30 mph often qualifies for simpler licensing. The moment you derestrict, the classification can change.

- Highway legality depends on both capability and statutes. Some US interstates require a minimum speed of 40–50 mph. A 50cc scooter will not qualify on performance or legal grounds.

- Local regulations vary. Scooter speed limit UK rules differ from scooter speed limit USA rules. In the UK, AM or A1 licenses and L‑plate requirements tie back to engine size and restricted top speed. In the US, every state sets its own moped vs motorcycle thresholds.

Check the local code before you tune, buy, or ship. It protects your rider and your warranty position.

Comparing Scooter Speeds: What to Expect

- Scooter vs. moped: Mopeds usually cap top speed around 30 mph. Scooters exceed that with larger engines or motors and stronger acceleration.

- Scooter vs. motorcycle: Motorcycles win on outright speed and highway acceleration. Maxi‑scooters close that gap for commuting practicality.

- Scooter vs. car: In congested traffic, a scooter’s agility makes better time. On freeways, cars cruise faster with more stability in crosswinds.

Can You Make a Scooter Faster? Modifications & Performance Upgrades

Yes. Yet you need to understand the trade-offs and legal consequences.

Common speed enhancements:

- Variator tuning: Lighter or heavier roller weights shift CVT behavior. You can favor acceleration or top speed.

- CVT belt and clutch: Performance drive belts and different clutch springs change engagement and ratio control.

- Exhaust and intake: On carbureted scooters, freer-flow exhausts and re‑jetted carburetors can help. Fuel injection maps better match modern engines.

- Big bore kits: Increasing displacement boosts torque and speed. It also stresses cooling and can shorten engine life if not set up well.

- Gearing: Slight changes to the final gear reduction change top speed and gradeability.

- Electric controller tuning: Raising current limits or top speed settings delivers more speed at the cost of heat and range.

- Speed limiter removal: Many 50cc scooters have limiters. Derestricting raises speed but can violate local laws.

- Extreme mods: Turbo scooter speed or nitro scooter speed make for exciting experiments. They demand serious engineering and tuning to stay safe and reliable.

Risks and legal ramifications:

- You can void the warranty.

- You can change the legal classification which affects insurance and licensing.

- You can outstrip your brakes, tires, and cooling system which compromises safety at speed.

If you proceed, use a professional who understands the system end‑to‑end. A dyno, proper fueling, and thermal monitoring save engines and reputations.

Choosing the Right Speed for Your Needs

You don’t need the fastest scooter. You need the right scooter.

- Urban commuting and errands: A 50cc or electric moped speed class scooter works well up to 30 mph corridors.

- Suburban travel and longer routes: A 125cc or 150cc platform hits the sweet spot with 55–65 mph capability for mixed roads.

- Highway cruising and touring: Look at 250cc–500cc+ maxi‑scooters for stable 70–80 mph cruising. High‑speed electric scooter models can fit if charging strategy supports your route.

- Recreational riding: Match your preferred roads. Hillier terrain rewards extra torque.

For design teams: Set speed targets around your intended duty cycle. Build in headroom for hills, headwinds, and load. That margin becomes customer delight.

Engineering Guide: Material and Manufacturing Choices for Scooter Motors

Electric scooters live and die by motor and inverter efficiency. Laminations are a major lever you control.

Material considerations:

- Silicon steels (non‑oriented M‑grades): The default choice for general purpose motors. Good value and predictable performance. Higher grade steels reduce core loss which improves efficiency and top speed under thermal limits.

- Cobalt alloys: Excellent at high power density and temperature. Cost rises fast. You’ll see them where you must push torque in a tight package, such as aerospace or premium performance machines.

- Insulation coatings: Choose coatings that withstand your bonding and annealing processes without degrading. Good interlaminar insulation blocks eddy currents between sheets.

Manufacturing and assembly processes:

- Stamping: The workhorse for production volumes. Accurate, fast, and economical when you amortize tooling. Watch for burr control and die maintenance which affect eddy current paths and stack factor.

- Laser cutting: Ideal for prototyping and complex, low‑volume designs. Heat‑affected zones can raise local losses unless you optimize parameters or post‑process.

- Wire EDM: Offers superb edge quality at higher cost and slower throughput. You’ll see it in precision protos and specialty parts.

- Stacking methods:

- Interlocking laminations: Think LEGO bricks. This approach creates rigid cores without welding and minimal heat input.

- Bonded cores: Resin bonding can improve mechanical integrity and damp vibration. It also adds a thermal and electrical consideration between laminations.

- Welding or cleating: Strong joints but heat can change magnetic properties in the heat‑affected zones. Use sparingly and away from active flux paths.

Thermal and mechanical validation:

- Model stack factor, coating thickness, and bonding lines. Real stacks have less iron than CAD thinks which changes flux density and loss.

- Validate losses with test coupons that match your process. IEC 60404 methods and industry practices help you get apples‑to‑apples data.

- Coordinate lamination thickness with electrical frequency. Higher pole counts and higher rpm demand thinner gauges.

If you need a consolidated reference on industrial options and scope, see this overview of motor core laminations.

Which Application Is This For? Best‑Fit Decisions

Match your material and process to your scooter’s mission.

- Urban e‑mopeds and delivery scooters:

- Priorities: Efficiency at lower speeds, stop‑start durability, cost control.

- Materials: Standard non‑oriented silicon steels with moderate thickness.

- Processes: Stamping for volume. Laser cutting for early iteration. Interlock or bonding for consistent stacks.

- Mid‑speed commuters (55–65 mph target):

- Priorities: Cooler operation under sustained load, improved efficiency, quiet NVH.

- Materials: Better loss grades or thinner laminations to reduce eddy losses at higher electrical frequencies.

- Processes: Stamping with tight burr control. Bonded stacks for rigidity and precision.

- High‑speed performance scooters:

- Priorities: Power density, thermal headroom, peak torque response.

- Materials: Premium silicon steels or cobalt blends for top‑end applications where cost is secondary.

- Processes: High precision laminations and robust bonding. Careful rotor balance to manage high rpm.

Be honest about limitations. Laser cutting is a prototyping hero yet stamping wins in high‑volume production on cost and repeatability. Bonding adds integrity yet demands careful process control. Welding is strong yet can hurt local magnetic properties.

Quick Answers to Common Speed Questions

Use this section to sanity‑check your targets and communicate with non‑technical stakeholders.

- How fast is a 49cc scooter? Similar to 50cc scooter top speed. Expect 25–40 mph depending on restrictions and tuning.

- What speed can a 50cc scooter reach? Plan for 30 mph with legal limiters. Derestricting may get you closer to 40 mph in ideal conditions.

- Is 60 mph fast for a scooter? For a 125cc, 60 mph is a solid real‑world top end. For a 150cc, it’s an easy cruising speed. For 50cc, it’s not feasible without radical changes.

- Can a 125cc scooter go 70 mph? Some can touch it with favorable aerodynamics and tuning. Most 125cc scooters sit in the 55–65 mph bracket.

- How fast does a 200cc scooter go? Expect 65–75 mph with better hill performance than 150cc.

- Scooter acceleration 0–60: Maxi‑scooters and high‑power electrics can post motorcycle‑like numbers. Smaller classes focus on 0–30 mph where city traffic lives.

- Scooter speedometer accuracy: Many OEM speedometers read optimistically by a few mph. Validate with GPS when you test.

- Electric scooter range vs speed: Higher speed drains the battery faster due to aerodynamic drag and higher current draw. Range can drop sharply above 35–40 mph.

- High‑speed electric scooter: Look for higher voltage systems, robust controllers, and well‑cooled motors. Check highway legal and e‑scooter speed regulations by region.

- Scooter for adults top speed vs scooter for teenagers speed: Class regulations and licensing drive limits for younger riders. Adult‑class scooters can run faster with the right license.

- Rider weight scooter speed impact: Heavier loads reduce top speed and acceleration. Model your target mass realistically.

- Scooter uphill performance and downhill performance: Grade resistance demands torque. Strong brakes and regen control the downhill side for electrics.

- Wind resistance scooter speed: Headwinds can cut 10–15 mph off a low‑power scooter’s top end.

- Scooter tire pressure speed: Keep tires at spec for best rolling resistance and stability. Low pressure robs speed and raises heat.

- Scooter fuel consumption at speed: Drag rises with speed squared. Expect rising fuel burn or Wh/mile beyond 40–45 mph.

- Scooter engine wear speed and break‑in speed: Follow OEM procedures. Hard early use can shorten life.

- Variator, clutch, CVT, gear reduction: These control how the engine or motor’s power reaches the wheel. Small changes make noticeable differences at the wheel.

- Scooter top speed calculator: Use it to estimate based on torque curve, CdA, rolling resistance, gear ratio, and weight. Validate with track or chassis dyno data.

- Electric moped speed and E‑scooter speed regulations: Cities regulate e‑moped classes tightly. Check local rules before you ship, sell, or tune.

Brand and Category Benchmarks to Calibrate Expectations

You’ll see a range of real‑world results across OEMs:

- Vespa and Piaggio focus on style and refined urban performance with 50cc, 125cc, and 150cc lines.

- Honda, Yamaha, Suzuki, Kymco, SYM, Aprilia, and Genuine Scooters cover the full span from 50cc city models to maxi‑scooters with freeway power.

- NIU and Super Soco lead widely adopted electric moped and scooter platforms. Top speeds range from city‑legal caps to highway‑capable variants in select markets.

Maxi‑scooters frequently headline Top 10 fastest scooters lists with models near or above 100 mph. Slowest scooter model distinctions usually land in the moped class where legal caps define the outcome.

Legal and Licensing Snapshot

- License for 50cc scooter speed: Some regions allow a standard driver’s license. Others require a moped permit. Local rules vary.

- Motorcycle license for scooter speed: Once you cross moped limits on speed or displacement, you usually need a motorcycle endorsement.

- Highway legal scooter: Authorities set minimum speed rules. If your scooter cannot sustain that speed, it’s not safe or legal for that highway.

As a rule of thumb, scooters below 125cc struggle on high‑speed highways. Urban and suburban roads match their design intent better.

Electric Motor Design: Why Laminations Affect Speed and Efficiency

Let’s zoom back inside the motor for a practical example.

Imagine a BLDC hub motor or a mid‑mount PMSM that spins to high electrical frequencies at highway speeds. If you choose thicker laminations than the frequency warrants, eddy current losses spike. The motor runs hot. The inverter reduces current to stay within thermal limits which trims your top speed. Swap to thinner laminations with a good insulation coating. Eddy losses fall. The motor runs cooler at a given torque. Now your controller can hold more current longer which sustains higher road speed without overheating.

You can also shape torque and speed by your slot geometry and rotor design. Salient rotors increase reluctance torque. Skewed slots reduce cogging and acoustic noise. All of those micro‑decisions trace back to lamination tooling and stack construction.

For stator and rotor fundamentals in one place see the overview on stator core lamination and rotor core lamination.

Regional Regulations: A Practical View for Teams and Buyers

- Scooter speed limit USA: State laws define moped caps around 30 mph with licensing tied to that limit. Streets and highways carry their own minimums.

- Scooter speed limit UK: AM or A1 license categories and CBT training set limits by engine size and power. Mopeds cap their top speed by law.

- E‑scooter speed regulations: Cities regulate stand‑up e‑scooters tightly. Those requirements differ from street‑legal electric scooters with seats and VINs. Don’t mix them when you plan a product line.

If you manage a global product, you’ll design around the strictest regime or you’ll create market‑specific SKUs with different speed limiters.

Data and Practical Caveats

- Rider weight can cut top speed by 5–10 mph on small scooters.

- Headwinds and altitude reduce effective top speed and acceleration.

- Poor maintenance saps performance: belt wear, carburetor deposits, misaligned variators, low tire pressure, and fouled plugs all show up as lost mph.

These are known effects in the field. They explain why a showroom number rarely matches every real‑world ride.

Material and Process Selection: A Step‑By‑Step Approach

If you’re specifying a scooter motor and want to support a specific top speed without thermal penalties, use this sequence:

- Mechanical rpm at top speed and pole pairs give you electrical frequency.

- Add a margin for overspeed conditions and field weakening.

- Thinner at higher frequency reduces eddy losses.

- Higher grade steels reduce hysteresis which matters at sustained high speeds.

- Validate with real parts not only with catalogs.

- Laser‑cut prototypes can mislead on loss unless you correct for HAZ. Stamped parts tell the truth for production.

You’ll converge on a motor that runs cooler at speed and that meets your performance promises.

“Which Application Is This For?” A Straight Answer

- City‑only delivery fleets: Keep speed modest and push for maximum efficiency and quick acceleration to 30 mph. Your lamination choice focuses on low‑frequency performance and cost.

- Mixed urban‑suburban commuters: Target 55–65 mph. You’ll need better steel grades and tighter thermal control. Laminations shift thinner as electrical frequency rises.

- Highway e‑scooters: Design for frequent high‑frequency operation and long cooling soak periods. Use higher‑end electrical steels and robust bonding. Validate at temperature.

If you want a single resource to socialize with your team, share the high‑level overview of motor core laminations. It frames the trade‑offs clearly.

Putting It All Together: Combustion and Electric Scooters

Combustion scooters live or die on displacement, tuning, CVT setup, and aerodynamics. Variator weights, clutch engagement, and final gear reduction define their acceleration and top‑end. The carburetor vs fuel injection choice influences response, altitude compensation, and maintenance.

Electric scooters shift the optimization to motor, inverter, battery, and thermal management. Laminations, slot geometry, magnets, and control algorithms define torque and efficiency. Battery voltage and controller limits define peak rpm and speed. Range vs speed trade‑offs become front and center. Higher speeds tax range due to drag and higher current draw.

Both platforms rely on the same physics: drag grows fast with speed, hills demand torque, and weight magnifies both.

Engineering Takeaway: The Short List

- “How fast do motor scooters go?” depends on engine or motor size, tuning, aerodynamics, weight, terrain, and legal limits.

- 50cc: 25–40 mph. 125cc: 55–65 mph. 150cc: 60–70 mph. 250cc+: 75–100+ mph. Electric: 20–75+ mph depending on system design and regulations.

- Real‑world top speeds fall with heavier riders, headwinds, hills, and poor maintenance.

- For electric scooters, lamination grade and thickness directly impact core loss and thermal headroom which shape sustained top speed.

- Manufacturing choices—stamping vs laser cutting, interlock vs bonding—change stack factor, loss, and cost.

- Always align speed capability with legal classification, licensing, and highway minimums.

Ready to turn targets into specs? Pull in your motor supplier early. Share your speed, load, and duty cycle. Ask them to recommend lamination thickness, steel grade, and stacking method for your electrical frequency. If you’re evaluating supply partners and want a quick primer on options, review electrical steel laminations then compare stator and rotor strategies via stator core lamination and rotor core lamination. When you’re ready to explore full core solutions at production scale, see motor core laminations.

Final Words: Speed, Safety, and Smart Riding Choices

Speed should serve the application. Commuters need predictable acceleration and a relaxed cruising speed. Fleet operators want durability at a known route speed. Engineers and procurement teams must choose materials and processes that deliver the promised mph without flirting with thermal limits or legal issues.

Use realistic loads when you test. Respect regional laws. Calibrate your lamination stack to your electrical frequency. A well‑designed scooter feels eager in town, calm at speed, and efficient every day. That’s the sweet spot you can build and buy with confidence.

Additional SEO Guidance for Readers and Teams:

- 50cc scooter top speed, 125cc scooter top speed, 150cc scooter top speed, 250cc scooter top speed, and electric scooter top speed benchmarks help frame product positioning.

- Consider scooter horsepower by cc, torque vs horsepower scooter behavior, scooter engine RPM speed correlation through CVT ratio, automatic scooter speed vs manual scooter speed behavior, and scooter transmission type speed impact.

- Track scooter maintenance speed effects: tire pressure, belt condition, carburetor cleanliness, fuel type, oil type, and break‑in speed procedures.

- Remember scooter weight vs speed, rider weight scooter speed, scooter carrying capacity speed, scooter passenger speed, and scooter cruising speed when you set marketing claims.

- Keep legalities in mind: scooter legal requirements speed, license for 50cc scooter speed, motorcycle license for scooter speed, scooter class speed regulations, highway speeds, highway legal scooter rules, scooter top speed by engine size, do scooters go on highways, scooter highway legal speed, and what speed a “street legal” scooter implies.

If you balance these factors with a clear eye on materials and manufacturing, your design hits its marks. Your purchasing supports it. Your riders enjoy it. And your brand stands behind it.