How Long Do Diesel Motors Last? Unlocking Their Lifespan Potential

Table of Contents

- The Core Question: Average Lifespan of Diesel Engines

- By Application: Light-Duty, Heavy-Duty, Industrial, and Marine

- Mileage and Hour Benchmarks

- Key Factors Influencing Diesel Engine Longevity

- Maintenance Practices

- Usage and Driving Conditions

- Engine Design and Build Quality

- Fuel Quality and Additives

- Diesel vs. Gasoline: A Lifespan Comparison

- Design Differences that Drive Durability

- Typical Lifespan Disparity

- Signs Your Diesel Engine Is Nearing Its End

- Performance Indicators

- Auditory and Visual Cues

- Diagnostic Red Flags

- Maximizing Your Diesel Engine’s Lifespan: Practical Tips

- Rebuild vs. Replace: What Makes Sense and When

- Buying a High-Mileage Diesel: My Checklist

- Brand and Engine Family Notes

- Real-World Snapshots from My Experience

- The Bottom Line: Investing in Diesel Longevity

I have owned, maintained, and leaned on diesel engines for years. Pickup trucks that tow heavy on hot days. Generators that hum along during storms. Even a salty marine diesel that taught me patience. Over time I learned a simple truth. Diesel engines can last an incredibly long time if you treat them right. They can also die young if you ignore the basics.

Let me walk you through what I have seen. I will share numbers you can use. I will explain the factors that matter. By the end you will know what to expect from a diesel motor and how to help it go the distance.

The Core Question: Average Lifespan of Diesel Engines

When someone asks me how long diesel motors last I start with the big picture. Use case and care set the ceiling. Diesels in light-duty trucks live a different life than Class 8 semi engines or industrial generators. Hours matter as much as miles in many applications.

By Application: Light-Duty, Heavy-Duty, Industrial, and Marine

- Light-Duty Diesel Vehicles

I put daily drivers like diesel SUVs, pickups, and cars in this group. Think Ford Power Stroke, Ram Cummins, Chevy Duramax, and Volkswagen TDI. Well-maintained engines in this category often see 200,000 to 350,000 miles. I have seen some sail past 400,000 and even push 500,000. Those are the unicorns you get when maintenance is consistent and use is kind. Emissions systems like DPF and EGR add complexity. They often need service or replacement before the core engine needs major work.

- Heavy-Duty Commercial Trucks

Class 8 semi-trucks and buses with engines from Cummins, Detroit Diesel, and PACCAR are built to work hard. It shows in their lifespan. I have watched fleets run engines 750,000 to 1,500,000 miles before a major overhaul. Some go beyond with careful oil analysis and strict service schedules. Highway miles at steady load extend life. Stop-and-go urban work takes a bigger bite out of the clock.

- Marine Diesel Engines

Boats live in a different world. Salt, heat, and constant load can be punishing. Properly maintained marine diesels from Volvo Penta, Yanmar, and Cummins commonly reach 10,000 to 20,000 hours. Fresh water cooling and routine zinc and impeller service help a lot. I have seen engines in clean fresh water environments run well beyond 20,000 hours with one or two rebuilds along the way.

- Industrial Diesel Engines

Generators, construction equipment, and agricultural machines run diesels that can clock serious time. I plan for 20,000 to 50,000 hours for prime movers when maintenance stays tight. Air filtration in dusty conditions matters. Clean fuel matters even more. Engines in standby generators often age out before they wear out because they run so few hours.

Mileage and Hour Benchmarks

Miles and hours tell different stories. In road vehicles miles work fine. In stationary or mixed-use machines I convert hours to an equivalent mileage for context. Here is the simple mental math I use. For light-duty trucks 1 engine hour can equal 25 to 45 miles depending on idling and load. For heavy trucks I often peg 1 hour at 50 miles because highway operation dominates. These aren’t hard rules. They help me compare apples to apples when I look at wear.

Summary benchmarks I use in the field:

- Light-duty diesel vehicles

200,000 to 350,000+ miles

- Heavy-duty commercial trucks

750,000 to 1,500,000+ miles or 15,000 to 30,000+ hours

- Marine diesel engines

10,000 to 20,000+ hours

- Industrial diesel engines

20,000 to 50,000+ hours

Now let’s unpack what pushes an engine toward the high end of those ranges.

Key Factors Influencing Diesel Engine Longevity

Diesel engine lifespan lives and dies on the basics. Oil, fuel, air, heat, and load. You control most of that. The engine’s design and build quality sets the starting line. Your choices set the finish line.

Maintenance Practices

Every long-lived diesel I have met had one thing in common. Someone took maintenance seriously.

- Oil changes and fluid checks

Diesel engines make soot. Soot thickens oil. Clean oil keeps bearings happy and protects turbochargers. I follow the manufacturer’s oil change interval for my use case. Severe service means shorter intervals. Highway cruising can stretch them within spec. I choose synthetic oil when the maker allows it because synthetics resist high heat and shear. I watch coolant, transmission fluid, and differential oil too because drivetrain health influences engine load and heat.

- Fuel and air filter replacements

High-pressure common rail systems demand ultra clean fuel. I replace fuel filters on schedule. I shorten intervals when I get fuel from remote stations or see any contamination. A clogged air filter starves the engine and increases soot. I replace air filters often if I drive in dust. I do not bang them on the ground because that can damage the media.

- Cooling system health

Overheating kills diesels fast. I flush coolant per schedule. I test it for proper additive levels. I replace thermostats that drift. I clean radiators and intercoolers when bugs and dirt plaster the fins.

- Injector and DPF system care

Injectors wear. I watch for rough idle or balance rate issues. I handle them before they wash down cylinders and damage rings. DPFs trap soot and ash. Regens keep soot in check. Ash accumulates slowly and needs professional cleaning or replacement at long intervals. I address EGR valve issues promptly because stuck valves cause heat and soot problems.

- Timely repairs and preventative measures

Small problems become big ones when ignored. A tiny coolant leak can turn into a warped head. A small oil leak can drop level and starve the turbo. I fix the little stuff fast.

Usage and Driving Conditions

How you use a diesel matters as much as how you service it.

- Load and towing

Nothing ages an engine like constant overload. I match my tow weight to the truck’s rating. I use the right gear. I let the engine work in its sweet spot. High load at low RPM invites lugging and high cylinder pressures. I downshift and keep boost steady.

- Driving style

Diesel engines like steady work. They do not love jackrabbit starts or constant short trips. Aggressive throttle use spikes EGTs and soots up emissions hardware. Moderate driving helps the DPF regenerate and keeps fuel economy and wear in balance.

- Idle time vs. operating under load

Extended idling sounds gentle yet it increases soot and dilutes oil with fuel. I use high idle or a PTO strategy if my work demands long idles. I cut unnecessary idle time whenever I can.

- Operating environment

Cold starts increase wear. I plug in block heaters in deep cold. I allow a short warm-up before heavy throttle. Extreme heat stresses cooling systems. Dusty sites wreck air filters. I adjust my maintenance schedule to match reality not wishful thinking.

- Engine braking and downhill control

I use engine braking wisely. It saves my service brakes. It reduces heat in the rotors. It does not meaningfully wear the engine when used properly because it limits fuel and controls boost. I avoid riding the throttle on long grades because that builds heat and invites trouble.

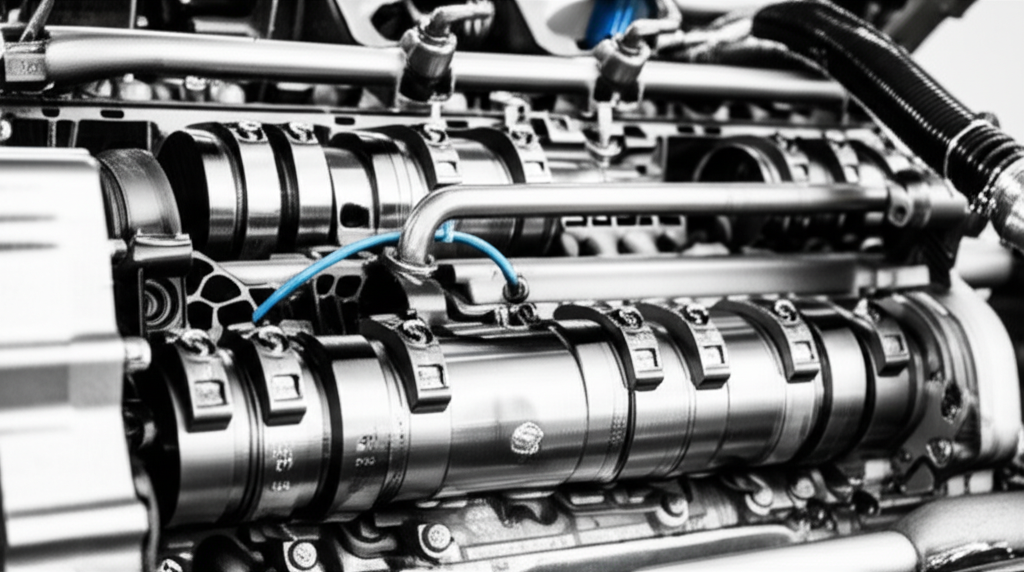

Engine Design and Build Quality

Not all diesel engines are equal. Design choices and component quality drive longevity.

- Manufacturer reputation and engineering

I trust big names that stand behind their products. Cummins, Detroit Diesel, Caterpillar, Volvo, John Deere, Yanmar, and Kubota have long histories in heavy-duty and industrial markets. Light-duty brands like Ford Power Stroke, Ram Cummins, and GM Duramax have strong communities and parts support. That matters when you need a turbocharger, fuel injectors, or a head gasket on short notice.

- Build materials and component durability

Strong blocks and heads. Forged crankshafts and stout connecting rods. Robust camshaft and valvetrain design. Quality timing chains or well-timed belt replacement intervals. These choices set the upper bound on life. Turbocharged engines add complexity yet they also let engines run in efficient power bands. That can be good for life if heat stays controlled.

- Engine type and controls

Older mechanically injected diesels can run forever with simple care. Modern common rail systems deliver power, quiet operation, and clean emissions. They demand clean fuel and precise maintenance. Neither is better for every owner. Pick the system that matches your use and your willingness to maintain it. ECU tuning can improve drivability. Wild tunes that push fueling and boost far beyond stock shorten life fast.

Fuel Quality and Additives

Fuel quality makes or breaks modern diesel systems.

- Impact of contaminants

Water in diesel fuel invites injector damage and pump failure. Rust and dirt chew up high-pressure fuel pumps. I drain water separators. I buy fuel from busy stations when I can. I add biocide if a tank sits.

- Cetane and lubricity

Higher cetane helps cold starts and reduces combustion delay. Good lubricity protects pumps and injectors. Ultra low sulfur diesel lost some lubricity. I use additives with reputable data when I see scuffing failures in a fleet or poor fuel in a region.

- Fuel system cleaning

Deposits on injector tips can hurt spray patterns. I use detergent additives as preventative care a few times a year. I do not expect a bottle to fix a failed injector. I treat additives as maintenance not magic.

Diesel vs. Gasoline: A Lifespan Comparison

When people ask me why diesels often outlast gas engines I point to design and duty cycle.

Design Differences that Drive Durability

- Compression ratios and internal stress

Diesels operate at high compression. Engineers build them with stronger blocks, heads, pistons, and rods. Bearings are larger. Cooling and lubrication systems often carry more capacity. That extra strength buys longevity when you keep heat and soot in check.

- Component strength and construction

Turbocharged diesels run high cylinder pressures under load. The hardware is built for it. Modern designs use high-strength alloys and precision machining. They cost more up front. They pay off in durability when used as intended.

Typical Lifespan Disparity

In my experience a well-maintained diesel in a similar application lasts longer than a comparable gas engine. Highway-driven diesel trucks push past 300,000 miles with fewer bottom-end issues. Heavy-duty diesel tractors stretch to a million miles with planned overhauls. Gas engines can be excellent for light-duty use. They usually cost less to maintain in the first 150,000 miles. Diesels catch up after that if you run big miles or haul heavy.

Signs Your Diesel Engine Is Nearing Its End

Every engine whispers before it cries. I listen for the whispers.

Performance Indicators

- Reduced power and acceleration

A tired diesel feels flat. It struggles under load. It hunts for gears on hills. Loss of compression or injector wear often sits at the root.

- Increased fuel consumption

When fuel economy slides and you have not changed your route or load it is time to investigate. Poor injector spray, dragging accessories, and low compression can all steal efficiency.

- Smoke from the exhaust

Color tells a story. Black smoke points to excess fuel or poor air. White smoke can signal coolant in the cylinder or unburned fuel on a cold start. Blue smoke means oil is burning. Ring wear and turbo seals often sit behind blue.

Auditory and Visual Cues

- Unusual engine noises

Knocking, ticking, or grinding noises demand immediate attention. A deep knock under load scares me because it can mean bearing damage. A light tick can be valvetrain related. I do not ignore either one.

- Fluid leaks

Oil drips look small until they starve the turbo. Coolant trails can hide behind the fan. I fix leaks before they cause cascade failures.

- Warning lights

Check engine and DPF warnings tell you something changed. I scan codes and address causes. I do not clear codes and hope for the best.

Diagnostic Red Flags

- Low compression readings

Compression tests and cylinder leak-down results reveal ring, valve, or head gasket issues. Low compression across several cylinders points toward general wear. One low cylinder hints at a localized problem.

- Excessive blow-by

I watch for vapor puffing out of the oil fill with the engine running. I also watch crankcase pressure. Excess blow-by means combustion gases are slipping past the rings. That is a strong end-of-life marker on high-mileage engines.

Maximizing Your Diesel Engine’s Lifespan: Practical Tips

Here is the playbook I use to push engines toward the top of the lifespan ranges you saw earlier.

- Follow the maintenance schedule religiously

The manufacturer knows the weak points and service intervals. I keep records. I do not skip the small stuff. I stick to the oil change interval that matches my duty cycle. Severe service rules if I tow, idle, or drive in extreme conditions.

- Use high-quality fluids and filters

Cheap filters save pennies and risk dollars. I buy from reputable brands that meet OEM specs. I choose the right viscosity oil and the correct coolant type. I avoid mixing coolants.

- Allow proper warm-up and cool-down

I do not hammer a cold diesel. I let oil reach operating temp before full load. After long climbs or heavy towing I give the turbo a short cooldown at light throttle or idle. That saves the bearings from oil coking.

- Avoid excessive idling and short trips

Short trips seldom reach full operating temperature. That builds moisture in oil and soot in the DPF. I batch errands. I take the long way home when the truck needs a full regen.

- Address minor issues promptly

I treat small fuel leaks, slight misfires, and creeping temps as early warnings. Fast fixes save engines.

- Monitor gauges and listen to your engine

I watch EGTs, coolant temp, oil pressure, and boost if I have those gauges. Modern trucks stream this data. A small change over time signals wear or restriction. I react before a trip not during it.

- Consider fuel system cleaning and additives

I use reputable detergents and lubricity additives as preventative care in regions with poor fuel quality. I do not expect them to fix mechanical failures. I do expect them to keep a clean system clean.

- Keep the intake, intercooler, and exhaust healthy

I clean or replace CAC boots that seep oil. I ensure the intercooler is not full of debris. I service EGR coolers and DPFs as required. Healthy airflow keeps temps down and the engine happy.

- Mind the transmission and gearing

Gearing affects engine load. If the transmission hunts I adjust driving style or address software updates. A strong transmission protects the engine from bad shifts and lugging.

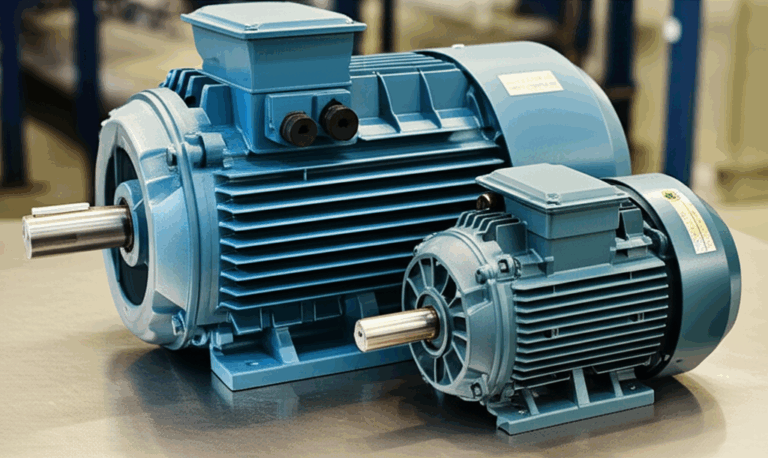

- Pay attention to the supporting electrical systems

Starters, alternators, and diesel generators live next to your engine. Their health influences starts and charging. Alternators and starters rely on stators and rotors made from laminated electrical steel. If you want a refresher on how those pieces work together I like this simple overview of stator and rotor. For a deeper dive into why the laminations matter you can read about electrical steel laminations. It is an electric topic that still matters to diesel reliability because a weak alternator or starter can take down your day.

Rebuild vs. Replace: What Makes Sense and When

At some point every diesel faces a big decision. Do you rebuild or replace. I look at five things before I choose.

- The core engine’s condition

If the block and head are sound then a rebuild has strong value. Scored cylinders or a cracked block tip the scale toward replacement.

- Total vehicle or machine condition

A great engine in a worn-out chassis makes little sense. I assess transmission, axles, suspension, and electronics first.

- Parts availability

Popular engines from Cummins, Power Stroke, Duramax, Detroit, and CAT have excellent parts support. Some older or rare units make parts hunting slow and expensive.

- The duty cycle after the repair

If the machine will work hard for years a quality rebuild can double or triple useful life. If you plan to sell soon a reman or crate engine with a warranty can simplify the choice.

- Cost and downtime

Rebuilds vary in price depending on labor rates and parts. Replacement engines can come with warranties that fleets value. I weigh downtime cost as heavily as parts cost when a machine earns revenue.

Many diesel engines are designed to be rebuilt. That design choice increases lifetime value. It also explains why diesels hold resale value longer than similar gas engines.

Buying a High-Mileage Diesel: My Checklist

People ask me if a diesel with 200,000 or even 300,000 miles is a good buy. My answer is maybe. It depends on history and inspection. Here is the checklist I use.

- Maintenance records

I want to see oil changes at rational intervals. I want receipts for fuel and air filters. I look for coolant service and any injector, turbo, or DPF work.

- Cold start and warm idle

I start the engine cold. I listen for long cranking and rough starts. I watch smoke. I assess idle smoothness and cold EGR behavior.

- Road test under load

I find a hill. I watch for power, boost, and temps. I check for smoke under throttle. I listen for turbo whistle and unusual noises.

- Blow-by and crankcase pressure

I check for visible vapor at the oil fill. I use a manometer on some engines. High blow-by suggests significant wear.

- Compression test or balance rates

Many modern trucks offer injector balance data. A professional compression test gives hard numbers. Strong compression equals a strong bottom end.

- Diagnostics and codes

I scan the ECU. I look at freeze frames. I do not ignore “history” codes. I also confirm that monitors are set. I do not trust a truck with freshly cleared codes and unset monitors.

- Emissions system health

I verify the DPF has completed recent regens. I check ash load if the system reports it. I inspect EGR coolers for leaks and faults. I verify that DEF systems work on SCR-equipped trucks.

- Fluids and filters

I pull the oil cap to check for sludge. I check coolant for oil or combustion gas contamination. I look for metal in fluid filters. I confirm the correct coolant type is present.

- Drivetrain and electrical

I test the alternator output and starting system. If you want a refresher on how electric machines convert energy the basic motor principle helps explain what alternators and starters are doing next to your diesel every day.

If the truck passes most of these with clean records then a high-mileage diesel can be a smart buy. If it fails several and the seller shrugs then I walk away.

Brand and Engine Family Notes

I will not rank brands because every family has highs and lows. I will share what I watch for by category.

- Light-duty diesels

Power Stroke, Duramax, and Ram’s Cummins each offer strong platforms with specific quirks. I learn the generation. I study common failure points like EGR coolers, DPF sensors, turbo actuators, and high-pressure fuel pumps. Parts and support are excellent for all three in North America.

- European and Japanese diesels

VW TDI, Mercedes-Benz Diesel, and BMW Diesel powertrains can run very long with clean fuel and careful maintenance. Emissions components add cost. Access in tight engine bays can raise labor time. I keep that in mind.

- Heavy-duty and vocational diesels

Cummins ISX and X15, Detroit DD series, and CAT engines in older fleets have proven their bones. Overhauls are common at planned intervals. Oil analysis and valve adjustments keep them honest.

- Industrial and agricultural diesels

CAT, John Deere, Kubota, Yanmar, and Volvo Penta dominate here. These engines shine when air and fuel stay clean. I pay special attention to air filtration in dusty construction and agricultural work.

Real-World Snapshots from My Experience

A few stories stick with me because they explain diesel longevity better than a chart.

- The million mile hauler

I watched a fleet of highway tractors spin past 1,000,000 miles before in-frame overhauls. What kept them alive. Oil analysis every interval. Valve sets on schedule. Strict cooling system service. Drivers who understood EGTs and did not lug in the wrong gear. When the fleet tried longer oil intervals without analysis costs rose quickly. They switched back.

- The 300,000 mile pickup

My friend’s 3/4-ton pickup towed a camper every summer and a boat in the fall. He used a mild tow tune at first. He saw rising EGTs on hot grades and backed down. He serviced the DPF and EGR when the dash asked. He changed fuel filters early when he traveled far from home. The truck sold at 320,000 miles with the original long block and a second turbo. It still ran strong.

- The marine workhorse

A small twin-diesel boat I knew ran 12,000 hours in saltwater. The owner religiously changed zincs, impellers, and oil. He flushed with fresh water after most trips. He replaced one heat exchanger and both turbos at around 9,000 hours. The long blocks never came out.

- The farm generator

A standby generator lived an easy life of monthly test runs and a few extended outages. It had under 500 hours when we tested it after a storm. We found fuel growth in the storage tank. The injectors showed corrosion. A simple biocide program and annual fuel polishing would have saved an expensive injector pump.

Diesel Engine Lifespan: Data and Key Statistics

Here is a compact snapshot you can use to set expectations. These are typical ranges I see in the field when owners follow reasonable maintenance and use practices.

| Category/Engine Type | Average Lifespan (Mileage/Hours) | Notes |

|---|---|---|

| Light-Duty Diesel Vehicles | 200,000 – 350,000+ miles | Some exceed 500,000 with exceptional care. Emissions systems often need service first. |

| Heavy-Duty Commercial Trucks | 750,000 – 1,500,000+ miles or 15,000 – 30,000+ hours | Planned overhauls extend life. Highway duty cycles help most. |

| Marine Diesel Engines | 10,000 – 20,000+ hours | Salt and heat accelerate wear. Fresh water cooling extends life. |

| Industrial Diesel Engines | 20,000 – 50,000+ hours | Clean fuel and air are critical. Duty cycle sets the pace. |

Common failure points I plan for before the bottom end wears out:

- Fuel injectors and high-pressure pumps

- DPF and EGR components

- Turbochargers and actuators

- Sensors and wiring in harsh environments

- Cooling system components like water pumps and thermostats

Address these early and the core engine often keeps going.

The Bottom Line: Investing in Diesel Longevity

Here is my honest take. Diesel engines last a long time because they are built for work. The block, crankshaft, pistons, and cylinder head can run for years with the right oil and temperature control. Modern systems like common rail injection and aftertreatment add complexity. They also help diesels meet strict emissions rules while delivering power and fuel economy.

If you want your diesel to live at the top of the ranges we discussed:

- Use clean fuel and change filters on time

- Keep oil fresh and cooling systems healthy

- Avoid long idle and short trips when you can

- Drive with mechanical sympathy not fear

- Fix small problems before they compound

- Watch your alternator and starter health because weak electrical support can sideline even a strong engine. Their guts rely on stacked laminations and careful design like you saw in the overview of electrical steel laminations

Treat your diesel like a partner not a disposable tool. Do that and you will rack up the miles and hours with a smile. Diesel engines reward owners who pay attention. They punish owners who do not. That is the real secret to how long diesel motors last.