How Many Amps Does a Starter Motor Draw? Your Guide to Normal Ranges, Diagnosis & Troubleshooting

Every driver knows that dreaded sound. You turn the key, and instead of a confident roar, you get a slow, groaning crank. Ruh-ruh-ruh… Or worse, just a single, sharp click. It’s a moment that can ruin any morning, and it almost always points to an issue in your vehicle’s starting system. If you’ve ever found yourself wondering what’s happening under the hood and suspect the starter motor might be the culprit, you’ve landed in the right place.

The key to diagnosing these problems often lies in a single question: “How many amps does a starter motor draw?” It’s not just a piece of trivia; it’s a critical diagnostic metric that can tell you almost everything you need to know about the health of your starter, your battery, and even your engine itself. This guide will walk you through what’s really going on, explain what those amperage numbers mean, and empower you to troubleshoot starting problems with confidence.

What We’ll Cover

- What is a Normal Starter Motor Amp Draw? (Direct Answer)

- Key Factors Influencing Starter Motor Amperage Draw

- How to Measure Starter Motor Amp Draw (Step-by-Step Guide)

- Interpreting Your Amp Draw Readings: What Do They Mean?

- Consequences of Incorrect Starter Motor Amp Draw

- Troubleshooting Common Starting Problems Related to Amp Draw

- Maintenance Tips for Optimal Starting System Performance

What is a Normal Starter Motor Amp Draw?

Let’s get straight to the point. There isn’t one single number, because “normal” is a range that depends heavily on your vehicle. Think of it like asking how much a person should be able to lift; it depends on the person. In the same way, a tiny four-cylinder engine requires far less effort to turn over than a massive heavy-duty diesel.

A starter motor’s job is to overcome all the engine’s internal friction and compression to get it spinning. This initial effort requires a massive, instantaneous surge of electrical current, measured in amperes (amps). This is the peak draw. Once the engine is spinning, the required current drops slightly to a sustained cranking draw.

Here’s a breakdown of typical starter motor amp draw ranges to give you a solid baseline:

| Vehicle/Engine Type | Typical Sustained Cranking Amp Draw (Approx.) | Key Factors Influencing Draw |

|---|---|---|

| Small Engines (Motorcycles, Lawn Mowers) | 30 – 100 Amps | Engine size, battery CCA, cable condition. |

| 4-6 Cylinder Gasoline Cars | 100 – 200 Amps | Engine displacement, compression, oil viscosity, battery health. |

| V6/V8 Gasoline Cars & Light Trucks | 150 – 250 Amps | Larger displacement and higher compression naturally require more power. |

| Small-Medium Diesel Engines | 200 – 350 Amps | Much higher compression ratios demand significantly more starting power. |

| Heavy-Duty Diesel Engines (Semi-Trucks) | 300 – 600+ Amps | Extreme displacement, high compression, and often multiple batteries. |

These are ballpark figures. Always consult your vehicle’s service manual for the exact starter motor specifications if you can. The key takeaway is that the amperage draw is a direct measure of the work the starter is doing. If that work becomes harder for any reason, the amp draw will go up. If the power supply is weak, the draw will be ineffective.

Key Factors Influencing Starter Motor Amperage Draw

So, why isn’t there just one number? Because several variables can make the starter’s job easier or harder. Understanding these factors is the first step in real diagnosis.

1. Engine Condition & Resistance

The engine itself is the biggest source of resistance the starter has to fight.

- Engine Displacement and Cylinders: A V8 engine simply has more mass and more cylinders to compress than a 4-cylinder. It’s a heavier lift, so it needs more current.

- Engine Oil Viscosity: Have you ever tried to pour cold molasses? That’s what your engine oil is like on a freezing day. Cold, thick oil creates immense drag on the engine’s internal parts, forcing the starter motor to work much harder. This is why cold weather starter draw is almost always higher.

- Cylinder Compression: Healthy engine compression is good for performance but it means the starter has to squeeze that air-fuel mixture really tightly. An engine with unusually high compression or a mechanical issue like a hydro-locked cylinder (fluid in the cylinder) can cause an extremely high amp draw.

- Internal Engine Issues: In a worst-case scenario, a failing bearing or a seized component inside the engine can stop it from turning altogether. When the starter tries to crank against this immovable object, its amp draw will skyrocket before a fuse blows or something burns out.

2. Battery Health & Capacity

The battery is the power source. If it’s not up to the task, nothing else matters. Think of it as the power plant for the starter’s mission.

- State of Charge (SOC): A fully charged battery can deliver the necessary punch. A weak or discharged battery simply doesn’t have the energy reserves. This can lead to a low amp draw and a slow crank because the starter is being starved of the power it’s demanding.

- Cold Cranking Amps (CCA): This rating is crucial. CCA tells you how many amps a battery can deliver for 30 seconds at 0°F (-18°C) without dropping below a usable voltage. A battery’s CCA must meet or exceed the vehicle’s requirements. As a battery ages, its ability to deliver its rated CCA diminishes, especially in the cold.

- Internal Resistance: All batteries have some internal resistance. As a lead-acid battery gets older, this resistance increases due to sulfation on the plates. This acts like a bottleneck, restricting the flow of current to the starter motor.

3. Electrical System Integrity

The path from the battery to the starter and back must be clear. Any obstruction in this path forces the system to work harder.

- Battery Cables and Connections: This is a huge one. Corroded battery terminals or a loose ground connection act like a kink in a firehose. The electrical current struggles to get through, creating heat and resistance. This resistance in the starter circuit causes a voltage drop, forcing the starter to try and pull even more amps to compensate, which can lead to a cycle of failure. Always check that your terminals are clean and tight.

- Solenoid and Ignition Circuit: The starter solenoid is a powerful electromagnetic switch that does two things: it pushes the starter’s pinion gear into the engine’s flywheel and it closes the high-current circuit from the battery to the starter motor itself. A failing solenoid can cause a “click” with no crank or intermittent starting issues.

4. Starter Motor Internal Condition

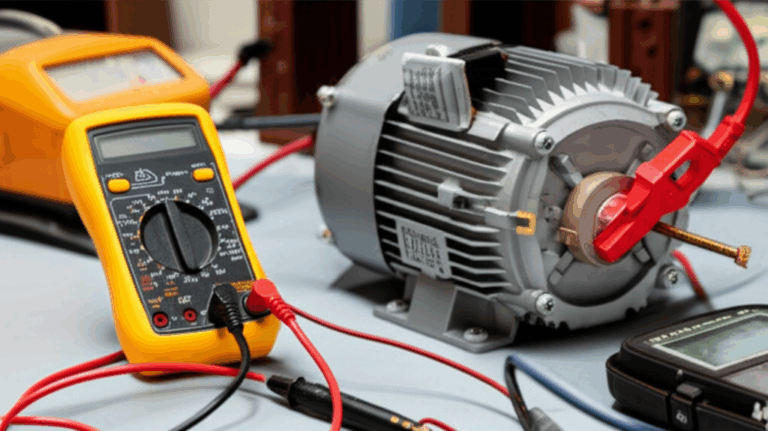

Finally, the starter motor itself can be the source of the problem. At its core, a starter is a small but incredibly powerful DC motor, and understanding the basic motor principle helps in diagnosing its failures. Its internal components wear out over time.

- Worn Brushes or Commutator: Brushes are wearable carbon blocks that transfer electricity to the spinning part of the motor (the armature). The commutator is the segmented copper ring they ride on. As these wear down, the electrical connection becomes poor, leading to a weak or non-functional starter.

- Internal Shorts in Windings: The starter motor is filled with copper windings. If the insulation on these wires breaks down, they can short-circuit. A short circuit creates a path of very low resistance, causing the starter to draw too many amps—often an astronomically high number. The internal core of the starter’s armature and field shoes is made of stacked electrical steel laminations precisely to prevent energy loss and overheating from a phenomenon called eddy currents, but a direct wire short will bypass these efficiencies and draw massive current.

- Worn Bearings or Bushings: These support the armature shaft. If they wear out, the armature can wobble and physically drag against the field windings, creating immense internal friction and a very high amp draw.

How to Measure Starter Motor Amp Draw (Step-by-Step Guide)

Reading about amp draw is one thing; measuring it is another. With the right tool, it’s a straightforward diagnostic test that can save you a ton of guesswork.

A. Essential Tools:

- DC Clamp Meter (Inductive Ammeter): This is non-negotiable. You need a clamp meter that can accurately read high DC amps (a range up to 400A or 600A is ideal). Do not try to use a standard multimeter in series; the current will instantly destroy it. The clamp fits around the battery cable and measures the current inductively without needing to disconnect anything.

- Safety Gear: Safety glasses and gloves are always a good idea when working around batteries and moving engine parts.

B. Safety Precautions:

- Ensure the vehicle is in Park or Neutral with the parking brake engaged.

- Keep your hands, hair, and clothing away from the fan, belts, and pulleys.

- Disable the engine from starting. You only want to measure the cranking amps. The easiest way is to pull the fuel pump relay or fuse. This allows the engine to crank without firing up.

C. Step-by-Step Measurement Procedure:

Interpreting Your Amp Draw Readings: What Do They Mean?

You’ve got your numbers. Now comes the detective work. Your reading will fall into one of three categories, each pointing to a different set of potential problems.

Case 1: Normal Amperage Draw

If your reading is within the expected range for your vehicle (e.g., 160 amps for a V6 engine) and the engine is cranking at a healthy speed, congratulations! Your starter and battery are likely doing their job just fine. If you’re still having an intermittent starting issue, the problem might lie in the ignition switch, a relay, or a neutral safety switch.

Case 2: High Amperage Draw

This is a clear sign that the starter motor is working too hard. The current is flowing, but it’s meeting too much resistance somewhere.

- Slightly High Draw (25-50% over spec): This often points to issues like thick oil in cold weather, slightly corroded cables causing voltage drop, or early-stage failure within the starter (like worn bearings).

- Extremely High Draw (Double the spec or more): This is a red flag for a serious problem. The most common causes are:

- Internal Starter Fault: A short circuit in the armature or field windings is a classic cause.

- Engine Mechanical Issue: The starter is trying to turn an engine that is partially seized, hydro-locked, or has some other severe internal problem.

- Severe Voltage Drop: While it seems counterintuitive, if the battery is weak or the cables are severely corroded, the starter’s voltage will plummet. To try and produce the torque it needs, it will attempt to draw an enormous amount of current, governed by Ohm’s Law.

Case 3: Low Amperage Draw

A low amp reading, especially when paired with a slow or no-crank condition, means the starter isn’t getting the power it needs or is unable to use it.

- Slow Crank & Low Amps: This is the textbook symptom of a discharged or faulty battery. The starter wants more power but the battery can’t supply it. It can also be caused by high resistance in the cables (corrosion, looseness) preventing the current from reaching the starter. This is a common automotive motor problem that starts with the power supply.

- “Click” & No Amps (or very few): If you hear a single click from the solenoid but the amp meter barely moves and the engine doesn’t turn, it means the high-current circuit isn’t closing. The problem is either a failed starter solenoid or a completely open circuit within the starter motor itself (like a broken brush or winding). The small current draw you see is just the solenoid engaging.

Consequences of Incorrect Starter Motor Amp Draw

Ignoring an abnormal amp draw isn’t a good idea. It’s a symptom of a problem that can cause a cascade of other failures if left unchecked.

- Battery Damage: Consistently drawing too many amps puts an immense strain on your battery, shortening its life and potentially causing internal damage.

- Starter Motor Burnout: A starter is designed for short bursts of intense work. A high-draw condition from a struggling engine or bad cables generates a ton of heat, which can melt the windings’ insulation and destroy the motor.

- Wiring and Component Damage: That excessive current has to travel through your vehicle’s heavy-gauge battery cables. High resistance from corrosion creates hot spots that can melt cable insulation, damage terminals, and in extreme cases, lead to electrical fires.

- Getting Stranded: Ultimately, a starting system on the verge of failure is unreliable. The slow crank you hear today could be the no-crank that leaves you stranded tomorrow.

Troubleshooting Common Starting Problems Related to Amp Draw

Let’s connect the dots between symptoms and amp readings.

- Symptom: Engine Cranks Slowly

- Test Result: Low Amp Draw.

- Likely Cause: Weak/discharged battery or high resistance in cables/connections. Start by load testing the battery and cleaning the terminals.

- Test Result: High Amp Draw.

- Likely Cause: The starter is struggling against something. Could be the starter itself (bad bearings), thick oil, or a mechanical engine issue.

- Symptom: Engine Does Not Crank At All (“Clicking” Sound)

- Test Result: Very Low or No Amp Draw on the main cable.

- Likely Cause: The power isn’t getting through the solenoid to the starter motor. This points directly to a bad starter solenoid or a complete internal failure of the motor. It could also be a battery so dead it can’t even close the solenoid properly.

- Symptom: Intermittent Starting Issues

- Likely Cause: This is often the hardest to diagnose. It could be a failing spot on the starter’s commutator, a loose connection that only makes contact sometimes, or a faulty ignition switch or relay. Measuring amp draw during a failure event is key.

The internal design of the motor, with its distinct stator and rotor components (in a starter, these are the field windings and the armature), has many points of potential electrical failure that can lead to these symptoms.

Maintenance Tips for Optimal Starting System Performance

You can avoid many starting headaches with some simple preventative maintenance.

- Regular Battery Checks: Have your battery professionally load-tested once a year, especially before winter. Most auto parts stores do this for free.

- Keep Connections Clean and Tight: Periodically inspect your battery terminals. If you see any fuzzy green or white corrosion, disconnect the battery (negative first!) and clean the terminals and cable clamps with a wire brush and a baking soda/water solution.

- Use the Right Oil: Always use the engine oil viscosity recommended by your vehicle’s manufacturer for your climate. This ensures the starter isn’t fighting against sludge on cold mornings.

Conclusion: The Importance of Monitoring Starter Amp Draw

The number of amps a starter motor draws is more than just a number; it’s the language of your vehicle’s starting system. It tells a story about the health of the battery, the integrity of your cables, the condition of the starter, and the physical resistance of your engine.

By understanding the normal ranges and learning how to interpret high or low readings, you move from guessing to diagnosing. You can pinpoint whether you need a new battery, need to clean your terminals, or need to replace the starter motor. This knowledge empowers you to make informed repair decisions, save money on unnecessary parts, and, most importantly, have a reliable vehicle that starts every time you turn the key.