How to Calculate 3 Phase Motor Efficiency: Your Easy Step-by-Step Guide

Are your electric motors secretly eating up your profits? It’s a huge problem I see all the time. A motor might look like it’s running just fine but it could be wasting a ton of energy and money. In this guide, I’m going to show you exactly how to figure out how efficient your 3-phase motors are. We’ll go step-by-step through the simple formulas. You’ll learn what numbers you need and how this quick check-up can start saving you cash right away.

Table of Contents

- Why Should You Bother Calculating Motor Efficiency?

- What Is Motor Efficiency, Really?

- What Information Will You Need?

- Step 1: How to Calculate the Power Going Into Your Motor

- Step 2: How to Find the Power Coming Out of Your Motor

- Step 3: The Final Calculation (With an Easy Example!)

- Are There Other Ways to Measure Efficiency?

- What Kills a Motor’s Efficiency?

- What Tools Do You Need for an Accurate Test?

- How This Simple Math Can Save You Big Bucks

- Frequently Asked Questions (FAQ)

- Key Takeaways

Why Should You Bother Calculating Motor Efficiency?

I get it. You’re busy. You have a million things to do. Why should you spend time on this? Here’s the hard truth: your motors use a huge amount of electricity. In many factories, they can be responsible for over 70% of the electric bill.

When a motor is not efficient, it’s like having a hole in your wallet. Money is just leaking out every minute it runs. This wasted energy turns into heat, which can even damage the motor over time. By finding these energy-wasting motors, you can:

- Slash your operational costs. A small improvement in efficiency can lead to big savings.

- Spot problems early. A drop in efficiency can be a warning sign that a motor needs maintenance or is about to fail.

- Make smart replacement decisions. Knowing the numbers helps you decide if it’s cheaper to buy a new, high-efficiency motor instead of running an old energy hog.

Ignoring this is like throwing money away. But with a few simple calculations, you can take back control and make your facility much more profitable.

What Is Motor Efficiency, Really?

Let’s break this down. Motor efficiency is super simple at its core. It’s just a measure of how well a motor turns electricity into useful work. Think of it like a recipe. You put in ingredients (electrical power) and you get out a finished cake (mechanical power).

No motor is perfect. Some of the electricity you put in gets lost along the way. It turns into heat because of friction or electrical resistance. Efficiency tells you what percentage of the electricity becomes actual spinning power. The basic formula looks like this:

Efficiency (%) = (Power Coming Out / Power Going In) × 100

A motor is made of key parts, and the interaction between the stator and rotor is where the magic happens. But this process isn’t perfect. The main places where energy gets lost are called motor losses. These include:

- Copper Losses: Heat lost in the copper wires.

- Iron Losses: Energy lost in the motor’s metal core.

- Friction and Windage Losses: Energy used to overcome the friction of the bearings and air resistance.

A motor with 95% efficiency is great. It means 95% of the electricity becomes work, and only 5% is wasted as heat. A motor with 80% efficiency is wasting four times as much energy!

What Information Will You Need?

Before you can do any math, you need to gather some information. It’s like being a detective. You have two main places to look for clues: the motor’s nameplate and real-world measurements.

First, go look at the motor nameplate. It’s a little metal tag on the side of the motor. It has a ton of useful info. You’ll want to write down these numbers:

- Voltage (V): The rated voltage for the motor.

- Current (A): The rated current, often called Full Load Amps (FLA).

- Power (HP or kW): The motor’s horsepower or kilowatt rating.

- Power Factor (PF or cos φ): This tells you how effectively the motor is using current. If it’s not listed, you’ll have to measure it.

- Speed (RPM): The rated speed the motor should run at under a full load.

Second, you need to see what the motor is actually doing while it’s running. The nameplate numbers are for perfect lab conditions. Your shop floor is not a perfect lab. You’ll need some tools to get these field measurements:

- Actual Line Voltage (V): What is the voltage right now?

- Actual Line Current (A): How much current is it drawing right now?

- Actual Power Factor (PF): This is a very important measurement.

- Actual Speed (RPM): How fast is the shaft actually spinning?

Step 1: How to Calculate the Power Going Into Your Motor

Okay, let’s get to the fun part. The first step is to calculate the electrical power going into your motor. We call this the Input Power (Pin). You’ll need the measurements you just took from the running motor for this.

The formula for the input power of a 3-phase motor is:

Input Power (Watts) = √3 × Voltage × Current × Power Factor

Let’s break that down:

- √3: This is the square root of 3, which is about 1.732. You always use this number for 3-phase power calculations.

- Voltage (V): This is the actual line-to-line voltage you measured.

- Current (A): This is the actual line current you measured.

- Power Factor (PF): This is the actual power factor you measured with a power analyzer.

You must measure these values. Don’t just use the numbers from the nameplate! The nameplate tells you what the motor should do at full load. Your motor might be running at a partial load, which changes everything. Using real measurements gives you the true story of what’s happening.

Step 2: How to Find the Power Coming Out of Your Motor

Now that you know the power going in, you need to find the useful power coming out. This is the mechanical work the motor is doing, like spinning a fan or a pump. We call this the Output Power (Pout).

There are two main ways to figure this out.

Method A: Using the Horsepower (HP) Rating

This method is easier but less exact. It’s a good estimate if you know the load on your motor. For example, if your motor is running a pump that needs 10 horsepower (HP) to run, then your output power is 10 HP. You just need to convert HP to Watts, which is the same unit we used for input power.

The conversion is simple:

1 Horsepower = 746 Watts

So, the formula is:

Output Power (Watts) = HP × 746

If your 10 HP motor is fully loaded, its output is 10 × 746 = 7460 Watts. But be careful! If the motor is only running at half its load (5 HP), then its output is only 3730 Watts.

Method B: Using Torque and Speed

This is the most accurate way but it’s harder. It requires special tools to measure the torque (the twisting force) and the exact speed (RPM) of the motor’s shaft. You would use a dynamometer for this, which is usually only done in a lab.

The formula is:

Output Power (Watts) = (Torque (Nm) × Speed (RPM) × 2π) / 60

For most people, Method A is good enough to get a solid idea of your motor’s efficiency in the field.

Step 3: The Final Calculation (With an Easy Example!)

You’ve done the hard work. You have your Input Power (Pin) and your Output Power (Pout). Now you just plug them into our main efficiency formula.

Efficiency (%) = (Pout / Pin) × 100

Let’s walk through a real-world example.

Imagine you have a motor running a conveyor belt. You take some measurements:

- Voltage: 480 V

- Current: 15 A

- Power Factor: 0.85

You also know that the motor is putting out about 10 horsepower (HP) of work.

First, calculate the Input Power (Pin):

Pin = 1.732 × 480 V × 15 A × 0.85

Pin = 10,598 Watts

Next, calculate the Output Power (Pout):

Pout = 10 HP × 746 W/HP

Pout = 7,460 Watts

Finally, calculate the efficiency:

Efficiency = (7460 / 10598) × 100

Efficiency = 70.4%

This motor is wasting almost 30% of the energy you’re paying for! Seeing a number like this is a huge red flag. It tells you that this motor is a good candidate for a check-up or replacement.

Are There Other Ways to Measure Efficiency?

Yes, there are more advanced methods that engineers use. The direct method is what we just talked about: you measure the input and the output. This is great for field tests.

The indirect method, also called the loss segregation method, is much more complex. Instead of measuring the output power, you measure all the little ways the motor loses energy (like copper losses, iron losses, etc.). Then you subtract those losses from the input power to find the output power. This is very accurate but requires special equipment and is usually done by experts following standards like IEEE 112 or IEC 60034-2-1.

For everyday checks, you can rely on the nameplate data for a rough idea. But remember, the nameplate shows the efficiency at full load. Most motors don’t run at full load all the time. Efficiency drops off a cliff when a motor is running at a light load (like 25% of its rated power).

What Kills a Motor’s Efficiency?

Several things can hurt your motor’s performance and make it waste energy. If your calculated efficiency seems low, it might be because of one of these culprits.

- Running at Partial Load: Motors are happiest and most efficient when they are running at about 75% to 100% of their rated load. An oversized motor that is only doing a little bit of work is very inefficient.

- Poor Power Quality: Messy power from the grid can harm your motor. Things like unbalanced voltage or harmonic distortion create extra heat and waste energy.

- Age and Wear: As a motor gets older, the bearings can wear out. This adds friction. The internal parts can also degrade. A poor motor rewind can also lower efficiency.

- Bad Maintenance: A motor that’s covered in dirt can’t cool itself properly. It will run hot and waste energy. Poor lubrication also adds friction and wastes power. The quality of internal parts, like the stator core lamination, plays a huge role in preventing energy loss, and these parts can degrade over time.

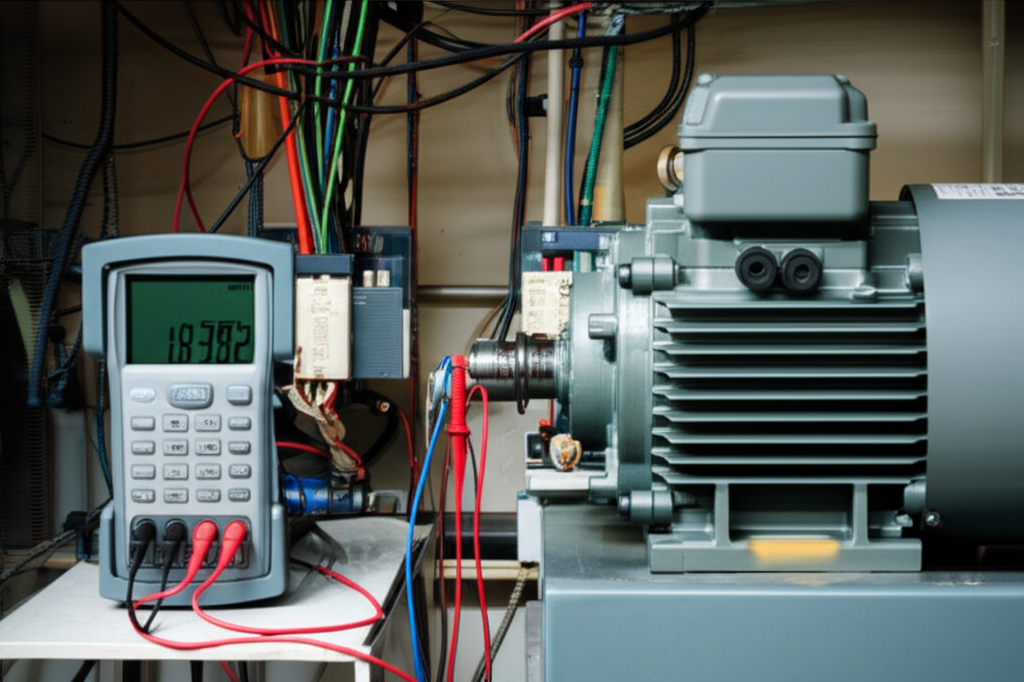

What Tools Do You Need for an Accurate Test?

If you want to get serious about measuring efficiency, you’ll need a few tools. You don’t need a full lab, but having the right gear makes a big difference.

- Power Analyzer: This is the king of motor testing tools. It measures voltage, current, and power factor all at once. It does the input power calculation for you!

- Clamp Meter: A good clamp meter can measure the current (Amps) just by clamping around one of the motor’s wires. It’s safe and easy.

- Digital Multimeter (DMM): This is a basic tool for measuring voltage.

- Tachometer: This tool measures the rotational speed (RPM) of the motor’s shaft. Some use a laser, others make contact with the shaft.

Using these tools will give you the accurate field measurements you need for a trustworthy efficiency calculation.

How This Simple Math Can Save You Big Bucks

Okay, let’s bring this home. Calculating efficiency isn’t just a fun science experiment. It’s a business tool. By identifying inefficient motors, you can create a plan that saves real money.

Look at these examples:

| Industry | Problem | Solution | Annual Savings |

|---|---|---|---|

| Textile Plant | 35 old motors running at 85% efficiency. | Replaced with new NEMA Premium motors at 92.4% efficiency. | $28,000 |

| HVAC System | An oversized 75 HP motor running at only 40% load. | Replaced with a correctly sized 50 HP motor and a VFD. | $6,500 |

These are not small numbers! In the case of the textile plant, the new motors paid for themselves in less than two years. The key is knowing where to look. By doing efficiency calculations, you can find the worst offenders in your facility.

When you decide to replace a motor, choosing one with high-quality components is vital. Modern motors are built with better materials and designs, such as advanced motor core laminations, which significantly reduce iron losses and improve overall performance. This is why a new NEMA Premium motor is so much better than an old standard motor.

Frequently Asked Questions (FAQ)

What is a good efficiency for a 3-phase motor?

It depends on the size. For large motors (over 100 HP), you should look for efficiency over 95%. For medium motors (10-100 HP), anything over 91% is good. Small motors will naturally have lower efficiency, but you should still look for the best in their class.

How does power factor affect the efficiency calculation?

Power factor is a key part of the input power formula. A low power factor means the motor is drawing more current to do the same amount of work. This extra current doesn’t do any work, it just creates heat in the wires, which is wasted energy.

Can I just use the efficiency number on the motor nameplate?

You can, but it’s only accurate if your motor is brand new and running at its full rated load. In the real world, this is almost never the case. Measuring the actual operating conditions gives you the true efficiency.

What are NEMA and IEC?

They are organizations that set standards for motors. NEMA (National Electrical Manufacturers Association) is used mostly in North America. IEC (International Electrotechnical Commission) is used in most of the rest of the world. Their efficiency standards, like NEMA Premium and IEC IE3, help you choose energy-efficient motors.

Key Takeaways

You made it! Calculating 3-phase motor efficiency might seem scary at first, but it’s not so bad when you break it down.

Here’s what to remember:

- Efficiency is key to saving money. It’s the measure of how well your motor turns electricity into work.

- The main formula is Efficiency % = (Output Power / Input Power) x 100.

- You must measure the actual voltage, current, and power factor of the running motor to get the true Input Power.

- You can estimate Output Power by converting the motor’s loaded Horsepower to Watts (1 HP = 746 W).

- Low efficiency is a red flag. It tells you a motor is wasting energy and may need maintenance or replacement.

- Using this knowledge to upgrade to high-efficiency motors can save you thousands of dollars every year.