How to Calculate Motor Efficiency: A Step-by-Step Guide for Energy Savings

Are your energy bills getting higher and higher? A big reason could be your electric motors. These powerful machines do a lot of work but they can also waste a lot of electricity and money. This guide will teach you how to figure out which motors are wasting your money. You will learn a simple way to calculate motor efficiency and find the energy hogs in your workshop or factory.

Table of Contents

What Is Motor Efficiency and Why Does It Matter?

Have you ever noticed a motor getting warm? That heat is wasted energy. Motor efficiency tells us how good a motor is at changing electricity into useful work. A motor with high efficiency uses most of the electricity to do its job like spinning a fan or a pump. A motor with low efficiency wastes a lot of electricity by turning it into heat.

This matters because motors use a huge amount of the world’s power. In a factory they can use more than half of all electricity. When a motor is inefficient it’s like having a hole in your wallet. Money just leaks out in the form of wasted energy. Calculating your motor’s efficiency is the first step to plugging that hole. It helps you find problem motors, save on operating costs and run a greener business.

Knowing the efficiency of electric machines is key to good energy management. It helps you perform an energy audit on your motors and see where you can make improvements. The goal is simple: get the most work done for the least amount of electricity.

What Key Words Do I Need to Know?

Before we do the math let’s learn a few simple words. Don’t worry they’re easy to understand.

- Input Power (P_in): This is the electrical power that goes into the motor from the wall outlet. We measure it in Watts (W) or kilowatts (kW). It’s the total energy the motor consumes.

- Output Power (P_out): This is the useful mechanical power the motor produces at its shaft. It’s the spinning force that does the work. We also measure this in Watts or Horsepower (HP).

- Torque (τ): This is the turning force of the motor. Think of it like the muscle the motor uses to spin something. We measure it in Newton-meters (Nm).

- Speed (RPM): This stands for Revolutions Per Minute. It’s how fast the motor’s shaft is spinning.

- Power Factor (PF): For AC motors this number (from 0 to 1) tells us how effectively the motor is using the electricity. A Power Factor of 1 is perfect but most motors are a bit lower.

- Motor Losses: This is the difference between the input power and output power. It’s the energy that gets lost as heat. Good motor design efficiency aims to reduce these losses.

The main parts that make this all happen are the stator and rotor. The stator is the stationary part and the rotor is the part that spins. The quality of these parts is very important for efficiency.

How Do I Calculate Efficiency the Direct Way?

The simplest way to find efficiency is called the Direct Method. It’s like looking at what you put in and what you get out.

The motor efficiency formula is very simple:

Efficiency (%) = (Output Power / Input Power) x 100

So if you put 1,000 watts of electricity in and get 850 watts of work out the math is:

(850 / 1,000) x 100 = 85% efficiency.

This means 85% of the power did useful work. The other 15% was lost as heat. To use this formula we need to measure the input power and the output power. Let’s see how you do that.

How Do I Measure the Power Going In (P_in)?

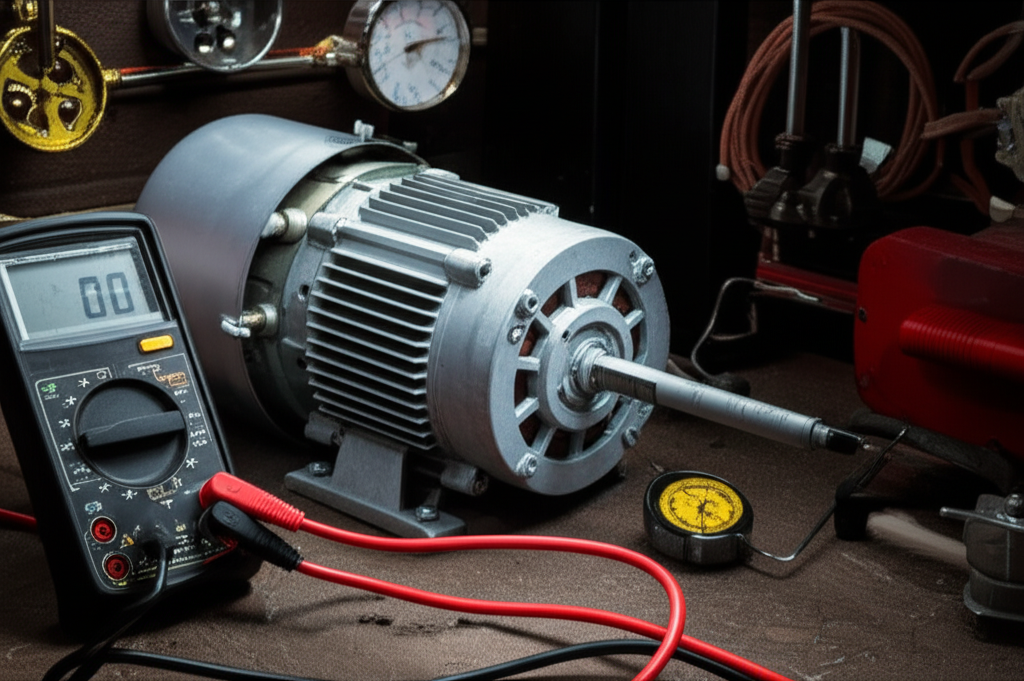

To find the input power you need to measure the electricity going into the motor. You’ll need a few tools like a power analyzer or a voltmeter and a clamp meter.

Here are the electrical formulas for motors:

- For DC Motors: This is the easiest one. The DC motor efficiency calculation is simple.

- P_in (Watts) = Voltage (V) x Current (I)

- For Single-Phase AC Motors: These are common in homes and small shops.

- P_in (Watts) = Voltage (V) x Current (I) x Power Factor (PF)

- For Three-Phase AC Motors: These are big motors used in factories. The three phase motor efficiency calculation is a bit different.

- P_in (Watts) = √3 x Voltage (V) x Current (I) x Power Factor (PF)

- (The square root of 3 is about 1.732)

You use a voltmeter to measure Voltage and a clamp meter to measure Current (Amps). A power analyzer can measure all three things at once which makes it very easy. This gives you the motor electrical input.

How Do I Measure the Power Coming Out (P_out)?

Measuring the mechanical power output motor is a bit trickier. You can’t just use a simple meter. You need to know the motor’s speed and its torque.

Here are the tools you’ll need:

- Tachometer: This tool measures the motor’s speed in RPM.

- Dynamometer: This machine measures the motor’s torque (τ) while it’s running under a load. A dynamometer motor test is the most accurate way to find output power.

Once you have those two numbers you can use this mechanical formula:

P_out (Watts) = (Torque (Nm) x RPM x 2π) / 60

(The number 2π is about 6.28)

Let’s do a quick example. Imagine you test an induction motor.

- You measure the input power (P_in) at 10,000 Watts.

- You use a dynamometer and tachometer to find the output. The torque is 50 Nm and the speed is 1,750 RPM.

- P_out = (50 x 1,750 x 6.28) / 60 = 9,158 Watts.

- Efficiency = (9,158 / 10,000) x 100 = 91.6%.

This direct method is very accurate for motor performance testing.

Is There Another Way to Find Efficiency?

Yes! It’s called the Indirect Method or the Losses Method. You use this when it’s hard to measure the mechanical output power directly perhaps on a big machine.

Instead of measuring the output you measure all the ways the motor loses energy. You then subtract the losses from the input power to find the output power.

The main motor losses are:

The formula looks like this:

Efficiency (%) = ((Input Power – Total Losses) / Input Power) x 100

You can often find these loss values from the motor’s data sheet or from standard tests like IEEE 112. This method is common in labs but can be complex for everyday use. A great deal of these losses is determined by the quality of the stator core lamination and the rotor core lamination.

What Things Can Make My Motor Less Efficient?

Your motor’s efficiency isn’t always the same. Several things can make it worse and cost you more money.

- Motor Load: Most motors are most efficient when they are running at about 75% to 100% of their full load. If a motor is too big for its job and only running at 40% load its efficiency drops a lot. This is why proper motor sizing and efficiency are so important.

- Voltage Problems: If the voltage from your electrical grid is too high too low or unbalanced it can make the motor run hot and waste energy. A small 1% voltage unbalance can increase losses by a lot.

- Poor Power Quality: Things like voltage spikes can hurt your motor’s performance. Power factor correction can help fix this.

- Bad Maintenance: A motor with old bearings or one that is dirty and can’t cool itself will be less efficient. Predictive maintenance can catch these problems early.

- Motor Age: Older motors especially those made before modern NEMA motor efficiency standards are usually much less efficient than new ones.

How Can I Make My Motors More Efficient and Save Money?

Are you tired of paying for wasted energy? Does the thought of a surprise motor failure keep you up at night? The good news is you can do something about it. You can take control of your energy consumption.

Here is your solution for better industrial motor efficiency:

By taking these steps you’re not just saving money. You’re also improving the reliability of your equipment and helping the planet through sustainable energy practices.

Can You Show Me Some Real Numbers?

Seeing the numbers can help you understand how much of a difference this makes. Look at this table to see the impact of motor efficiency.

| Category | Data Point / Statistic | Description / Source | Implications for Motor Efficiency |

|---|---|---|---|

| IE Efficiency Classes | IE1 (Standard): 75-89% IE2 (High): 80-92% IE3 (Premium): 85-95% IE4 (Super Premium): 90-97% | IEC 60034-30-1 standard | Shows there’s a clear path to save energy. Upgrading from an IE1 to an IE3 motor offers big savings. |

| Energy Consumption | Motors use about 45% of all electricity in the world. In factories they use 60-70% of the power. | International Energy Agency (IEA) | This shows that even a small improvement in motor efficiency can have a huge impact on global energy use. |

| Cost of Inefficiency | A 1% increase in motor efficiency can cut operating costs by 1-2% each year. | U.S. Department of Energy (DOE) | This connects efficiency directly to your bottom line. You can earn back the money from a new motor with the money you save on electricity. |

| Case Study (Example) | An old 100 HP motor is 80% efficient. A new one is 92% efficient. If it runs 6,000 hours a year at $0.10/kWh… | Calculation based on standard formulas | The new motor will save about $3,600 every single year in electricity costs. The upgrade pays for itself. |

| VFD Usage | A VFD on a pump or fan can save 20-50% in energy compared to running the motor at full speed all the time. | VFD manufacturer studies | This proves that VFDs are one of the best tools for optimizing motor efficiency in many jobs. |

These numbers aren’t just theory. They show real-world motor energy savings that businesses are achieving right now by focusing on efficiency. The cost of inefficient motors is simply too high to ignore.

What Are the Main Things to Remember?

Calculating motor efficiency is a powerful tool. It puts you in control of your energy costs and helps you run a smarter and more reliable operation.

Here’s a quick summary of what we’ve learned:

- Efficiency is Key: Motor efficiency is the measure of how well a motor turns electricity into useful work. Higher is better.

- Use the Simple Formula: The direct way to calculate efficiency is Efficiency % = (Output Power / Input Power) x 100.

- Measure Correctly: You need to measure the electrical power going in (with a power analyzer) and the mechanical power coming out (with a dynamometer and tachometer).

- Losses Are the Enemy: All motors lose some energy as heat. These losses (copper iron friction) are what make a motor inefficient.

- Many Factors Matter: Efficiency is affected by the motor’s load voltage quality maintenance and age.

- You Can Improve It: The best ways to get better efficiency are to upgrade to premium motors size them correctly and use VFDs.

Don’t let inefficient motors drain your profits any longer. Start by identifying your worst-performing motors and create a plan to upgrade them. The savings will start on day one and continue for the life of the motor.