How to Calculate Overall Efficiency of Pump and Motor: A Comprehensive Guide

Every plant manager, design engineer, and maintenance professional knows the feeling. You look at the monthly energy bill, and a huge chunk of it comes from your industrial motors and pumps. If you’ve ever found yourself wondering just how much energy is being wasted in your pumping systems—and what you can do about it—you’re in the right place. Calculating the overall efficiency of your pump and motor isn’t just an academic exercise; it’s the first and most critical step toward slashing operational costs, improving reliability, and reducing your carbon footprint.

This guide is designed to be your engineering partner. We’ll cut through the complex jargon and give you a straightforward, step-by-step process to measure and understand the real-world performance of your equipment. We’ll start with the problem, explain the core principles, guide you through the calculations, and empower you to make informed decisions that have a real impact on your bottom line.

What We’ll Cover

- Understanding the Components of Efficiency: Breaking down pump, motor, and overall system efficiency.

- Essential Formulas for Overall Efficiency Calculation: The core equations you need, explained in simple terms.

- Step-by-Step Process to Calculate Overall Efficiency: A practical, five-step guide with a real-world example.

- Key Factors Affecting Pump and Motor Overall Efficiency: Uncovering the hidden culprits of energy waste.

- Why Overall Efficiency Matters: Benefits of Optimization: The powerful business case for making improvements.

- Strategies for Improving Pump and Motor Efficiency: Actionable steps to boost performance and save money.

Understanding the Components of Efficiency

Before you can calculate the overall efficiency, it’s crucial to understand that you’re dealing with a chain of energy conversions. Think of it like a relay race. The electrical grid passes the baton (energy) to the motor, the motor passes it to the pump’s shaft, and the pump passes it to the fluid. In each handoff, a little bit of energy is dropped. Our goal is to measure how much energy successfully makes it from the start to the finish line.

The overall efficiency, often called “wire-to-water efficiency,” is the product of two primary efficiencies: the motor’s efficiency and the pump’s efficiency.

A. Pump Efficiency (Hydraulic Efficiency)

Pump efficiency tells you how well the pump converts the mechanical energy it receives from the motor’s shaft into useful work on the fluid. This “useful work” is the energy added to the fluid, which results in flow and pressure.

However, not all the shaft power gets converted. Some is lost to:

- Hydraulic Losses: Friction and turbulence as the fluid moves through the pump’s casing and impeller.

- Mechanical Losses: Friction in the bearings and mechanical seals that support the pump shaft.

- Volumetric Losses: A small amount of fluid leaking back from the high-pressure side to the low-pressure side within the pump.

A high-quality centrifugal pump operating at its Best Efficiency Point (BEP) can have an efficiency ranging from 60% to over 90%, depending on its size and design.

B. Motor Efficiency

Motor efficiency measures how well the motor converts electrical energy from your power source into mechanical energy at its output shaft. The construction of the motor, particularly the quality of its motor core laminations, plays a massive role here by minimizing energy losses.

Like the pump, the motor isn’t perfect. Energy is lost as heat due to:

- Electrical Losses: Resistance in the stator windings (copper losses) and magnetic effects in the core (iron losses).

- Mechanical Losses: Friction in the motor’s bearings and air resistance on the cooling fan (windage).

Modern premium efficiency motors (NEMA Premium / IE3 class) can achieve efficiencies from 88% to over 95%. Older, standard-efficiency motors might only be 75-90% efficient, representing a significant opportunity for energy savings.

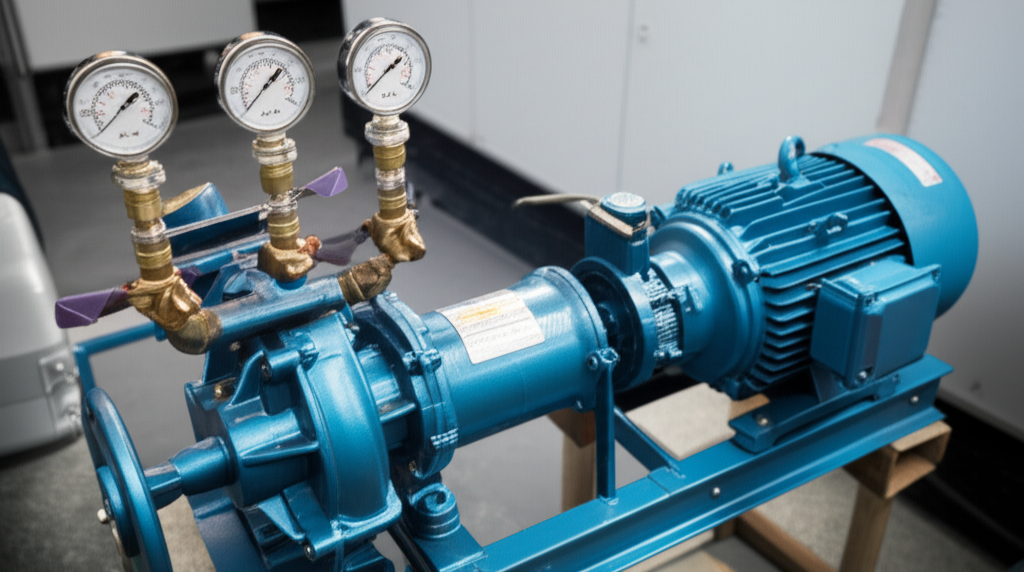

C. Overall System Efficiency (Pump + Motor)

This is the metric we’re ultimately after. The overall efficiency is the ratio of the hydraulic power delivered to the fluid divided by the electrical power supplied to the motor. It gives you the complete picture of your system’s performance, from the wall socket to the water pipe.

Overall Efficiency = Pump Efficiency × Motor Efficiency

You’ll quickly see that even with highly efficient components, the overall efficiency can be surprisingly low. For example, a pump running at 80% efficiency powered by a motor at 90% efficiency results in an overall system efficiency of just 72% (0.80 × 0.90 = 0.72). As U.S. Department of Energy studies have shown, it’s not uncommon for industrial pump systems to have an overall efficiency between 30% and 60% due to improper sizing or operating away from the BEP.

Essential Formulas for Overall Efficiency Calculation

Now, let’s get into the math. Don’t worry, we’ll break down each formula and variable so you know exactly what to measure and where to plug it in.

A. Calculating Pump Output Power (Hydraulic Power)

This is the “useful work” done on the fluid. To calculate it, you need to know how much fluid you’re moving (flow rate) and how much pressure you’re adding to it (head).

Metric Units Formula:

P_hydraulic (kW) = [Q (m³/s) H (m) ρ (kg/m³) * g (m/s²)] / 1000

- P_hydraulic (kW): Hydraulic Power in kilowatts.

- Q (m³/s): Flow Rate in cubic meters per second.

- H (m): Total Head in meters.

- ρ (kg/m³): Density of the fluid. For fresh water, this is approximately 1000 kg/m³.

- g (m/s²): Acceleration due to gravity, which is a constant ~9.81 m/s².

Imperial Units Formula (More Common in the US):

P_hydraulic (hp) = [Q (GPM) H (feet) SG] / 3960

- P_hydraulic (hp): Hydraulic Power in horsepower.

- Q (GPM): Flow Rate in gallons per minute.

- H (feet): Total Head in feet.

- SG: Specific Gravity of the fluid. This is a ratio of the fluid’s density to the density of water. For fresh water, SG = 1.0.

- 3960: A conversion constant that combines units to give you horsepower.

B. Calculating Motor Input Power (Electrical Power)

This is the energy you’re paying for from the utility company. The formula depends on whether you have a three-phase or single-phase motor. Most industrial motors are three-phase.

For 3-Phase Motors (Most Common):

P_electrical (kW) = (V I PF * √3) / 1000

- P_electrical (kW): Electrical Power in kilowatts.

- V (Volts): Voltage (line-to-line). This is the average voltage across the three phases.

- I (Amps): Current (line). This is the average current of the three phases.

- PF: Power Factor. A dimensionless number between 0 and 1 that represents how effectively the motor uses current. You need a power analyzer to measure this accurately.

- √3 (approx. 1.732): The square root of 3, a constant used in three-phase power calculations.

- 1000: A constant to convert watts to kilowatts.

For 1-Phase Motors:

P_electrical (kW) = (V I PF) / 1000

(The calculation is the same, just without the √3 factor.)

C. The Overall Efficiency Formula

Once you have the hydraulic output power and the electrical input power, the final calculation is incredibly simple. This is the “wire-to-water” efficiency we’ve been aiming for.

ηoverall = (Phydraulicoutput / Pelectrical_input) * 100%

Important Note on Units: Make sure your output and input power are in the same units before you divide them! If you calculated hydraulic power in horsepower (hp) and electrical power in kilowatts (kW), you’ll need to convert one.

- 1 hp = 0.746 kW

- 1 kW = 1.341 hp

Step-by-Step Process to Calculate Overall Efficiency

Let’s put the theory into practice. Follow these steps to get a real-world efficiency number for your system.

Step 1: Gather System Data (Measurements)

This is the most hands-on part. You’ll need the right tools to get accurate readings while the pump is running under normal operating conditions.

- Measure Flow Rate (Q): The best tool is a permanently installed or portable ultrasonic flow meter. If you don’t have one, you might be able to time how long it takes to fill a container of a known volume.

- Measure Total Head (H): Head isn’t just pressure; it’s a measure of total energy. You’ll need pressure gauges on both the suction and discharge sides of the pump.

- Total Head (H) = Discharge Head – Suction Head + Elevation Difference + Velocity Head. For many practical applications, simply converting the difference in pressure gauge readings to feet or meters of head will get you close enough. (

Pressure (psi) * 2.31 = Head (feet)for water). - Measure Electrical Input: You’ll need a true-RMS power analyzer or a clamp-on multimeter that can measure Voltage (V), Current (I), and Power Factor (PF). Measuring all three is critical; simply using V and I isn’t enough.

- Determine Fluid Properties: Know what you’re pumping. For most water applications, you can assume a Specific Gravity (SG) of 1.0 and a density (ρ) of 1000 kg/m³. If you’re pumping a different fluid, you’ll need its specific gravity data.

Step 2: Calculate Hydraulic Output Power (P_hydraulic)

Take your measurements from Step 1 and plug them into the hydraulic power formula (imperial or metric).

Step 3: Calculate Electrical Input Power (P_electrical)

Use your voltage, current, and power factor measurements in the electrical power formula.

Step 4: Compute Overall Efficiency

Divide your hydraulic power by your electrical power and multiply by 100 to get your final percentage. Remember to convert units if necessary!

Step 5: Example Calculation

Let’s walk through an example of a three-phase motor powering a water pump.

1. Gathered Data:

- Flow Rate (Q): 800 GPM

- Suction Pressure: 10 psi

- Discharge Pressure: 75 psi

- Elevation difference is negligible.

- Fluid: Water (SG = 1.0)

- Voltage (V): 480 V

- Current (I): 52 A

- Power Factor (PF): 0.88

2. Calculate Hydraulic Output Power (hp):

- First, find the total head. The differential pressure is 75 psi – 10 psi = 65 psi.

- Convert pressure to head:

H = 65 psi * 2.31 = 150.15 feet. - Now, use the formula:

P_hydraulic (hp) = (800 GPM 150.15 ft 1.0 SG) / 3960 -

P_hydraulic = 30.33 hp

3. Calculate Electrical Input Power (kW):

- Use the 3-phase formula:

P_electrical (kW) = (480 V 52 A 0.88 * 1.732) / 1000 -

P_electrical = 38.03 kW

4. Compute Overall Efficiency:

- First, convert both power values to the same unit. Let’s convert kW to hp.

-

P_electrical (hp) = 38.03 kW * 1.341 = 51.0 hp - Now, divide:

η_overall = (30.33 hp / 51.0 hp) * 100% -

η_overall = 59.5%

This result tells us that for every 100 dollars of electricity you put into this motor, you’re only getting about $59.50 worth of work done on the water. The other $40.50 is lost to heat and friction—a clear opportunity for improvement.

Key Factors Affecting Pump and Motor Overall Efficiency

So, your calculation gave you a number. Why isn’t it 100%? Or even 80%? Several factors conspire to chip away at your system’s performance.

- Operating Point: This is the big one. Every pump has a performance curve showing its Best Efficiency Point (BEP)—the specific flow and head where it operates most efficiently. If your system forces the pump to operate far away from its BEP, efficiency plummets, and reliability suffers. An efficiency drop of 10-30% isn’t uncommon when operating far from the BEP.

- Equipment Sizing: An oversized pump or motor is a chronic energy waster. The pump will often be throttled with a valve to reduce flow, which is like driving your car with one foot on the gas and one on the brake. An oversized motor will operate at a lower load, where its efficiency and power factor are typically worse.

- Mechanical Wear: Efficiency isn’t static; it degrades over time. Impeller wear, increased clearances, and worn bearings can cause efficiency to drop by 5-20% over a pump’s life. The fundamental components of the motor, the stator and rotor, are subject to degradation that increases electrical losses.

- Electrical Conditions: Poor power quality can kill motor efficiency. Unbalanced phases, voltage fluctuations, and a low power factor all force the motor to draw more current to produce the same output power, generating excess heat and waste.

- System Design: The pump and motor are only part of the story. High friction losses from undersized pipes, excessive bends, and inefficient control valves all add to the system head, forcing the pump to work harder than necessary.

- Motor Age and Class: Older motors designed before modern efficiency standards (like NEMA Premium / IE3) are simply less efficient by design. Upgrading can offer a quick and significant return on investment.

Why Overall Efficiency Matters: Benefits of Optimization

Focusing on wire-to-water efficiency isn’t just about saving a few watts. It’s a cornerstone of a smart operational strategy with far-reaching benefits.

- Significant Energy Cost Savings: This is the most direct benefit. Since pumping systems can account for over 20% of industrial electricity use, even a modest 10% improvement in efficiency can translate into thousands or even hundreds of thousands of dollars in annual savings.

- Reduced Carbon Footprint: Lower energy consumption directly equates to lower greenhouse gas emissions. Optimizing your systems is a powerful and practical way to meet corporate sustainability goals.

- Extended Equipment Lifespan: A pump operating at its BEP experiences the lowest hydraulic loads and vibration. This reduces stress on bearings, seals, and the motor itself. An optimized system can have a service life 1.5 to 2 times longer than a poorly performing one.

- Improved System Reliability: Inefficiency often goes hand-in-hand with unreliability. Issues like cavitation, vibration, and overheating lead to more frequent breakdowns and costly unplanned downtime. An efficient system is a stable system.

- Compliance with Regulations: Governments worldwide are implementing stricter energy efficiency standards, like the DOE’s pump regulations in the US. Proactively optimizing your systems ensures you stay ahead of compliance requirements.

Strategies for Improving Pump and Motor Efficiency

Once you’ve calculated your efficiency and identified the potential for improvement, what are the next steps?

- Right-Sizing Equipment: The most fundamental step is to ensure your pump and motor are correctly sized for your actual system requirements, not some theoretical maximum. This may involve trimming an impeller or replacing an oversized unit.

- Implementing Variable Frequency Drives (VFDs): For systems with variable flow or pressure demands, a VFD is a game-changer. Instead of using a throttling valve, a VFD adjusts the motor’s speed to precisely match the demand, offering potential energy savings of 20-50%. The ROI for a VFD can often be less than two years.

- Regular Maintenance & Monitoring: Implement a predictive maintenance program. Monitor vibration and temperature to catch wear before it leads to failure. Regularly check and maintain bearing lubrication and mechanical seals. Inside the motor, degradation of parts like the rotor core lamination can increase electrical losses over time, which can be monitored through thermal imaging.

- System Design Optimization: Look beyond the pump itself. Can you increase pipe diameters to reduce friction loss? Can you replace inefficient valves? A holistic system approach often yields the biggest gains.

- Utilizing High-Efficiency Motors: If you’re running older motors, upgrading to NEMA Premium (IE3) or even Super Premium (IE4) models is a straightforward win. For specialized applications, motors like a high-performance bldc stator core can offer even greater efficiency and control.

Your Engineering Takeaway

Understanding and calculating your pump and motor’s overall efficiency is the foundational skill for any modern energy management program. It transforms an abstract energy bill into a concrete, measurable performance metric that you can actively improve.

Here are the key takeaways:

- Overall efficiency is a product: It’s the pump’s efficiency multiplied by the motor’s efficiency. A weakness in one brings the whole system down.

- Measure, don’t guess: Use proper tools like power analyzers and flow meters to get accurate data.

- The formulas are your friends: The calculations for hydraulic and electrical power are your path to a clear, objective efficiency number.

- Think beyond the components: The system’s design and operating point often have a greater impact on efficiency than the individual pump or motor ratings.

By taking the time to perform these calculations, you are empowering yourself and your team to move from being reactive to proactive. You can now identify the worst offenders, build a business case for upgrades, and track the results of your improvements. Start with one system, prove the savings, and build a culture of efficiency that pays dividends for years to come.