How to Check Motor Efficiency: Your Complete Guide

Is your company’s electric bill giving you a headache? It feels like a giant, mysterious expense that just keeps growing. You know you need to cut costs but you don’t know where to start. The frustrating part is that a huge chunk of that money might be vanishing into thin air from machines you use every single day.

This guide is here to help you solve that mystery. We’re going to pull back the curtain on one of the biggest energy users in any business: electric motors. You will learn easy, practical ways to check if your motors are working hard or hardly working. By the end of this article, you’ll have the power to spot energy-wasting motors, save your company a lot of money, and prevent costly breakdowns before they happen.

Table of Contents

- What is Motor Efficiency, Anyway?

- Why is Checking Motor Efficiency a Big Deal?

- What are the Key Things That Hurt Motor Performance?

- What Tools Do You Need to Play Motor Detective?

- How Do the Pros Check a Motor’s Efficiency? (The Direct Method)

- How Can You Check Efficiency in the Field? (The Indirect Method)

- Is There a Magic Tool for This? (The Power Analyzer Method)

- What If I Don’t Have Fancy Tools? (The Nameplate Method)

- I Found an Inefficient Motor. What Do I Do Now?

- Beyond Efficiency: What Else Should I Check?

What is Motor Efficiency, Anyway?

Let’s keep this simple. Motor efficiency is like the gas mileage of your car. You put gas (electricity) in and you get miles (work) out. An efficient motor gives you a lot of work for the electricity it uses. An inefficient motor wastes a lot of that electricity, turning it into useless heat instead of useful motion.

The simple formula looks like this:

Efficiency (%) = (Power Going Out / Power Going In) x 100

- Power Going In is the electrical power you take from the wall socket. We measure this in kilowatts (kW).

- Power Going Out is the mechanical power the motor uses to spin a shaft, run a fan, or pump water. We measure this in horsepower (HP) or kilowatts (kW).

A motor with a 95% efficiency rating is great. It means that 95 cents of every dollar you spend on electricity for that motor is doing real work. Only 5 cents is wasted. A motor with 80% efficiency is wasting 20 cents of every dollar. That adds up fast!

Why is Checking Motor Efficiency a Big Deal?

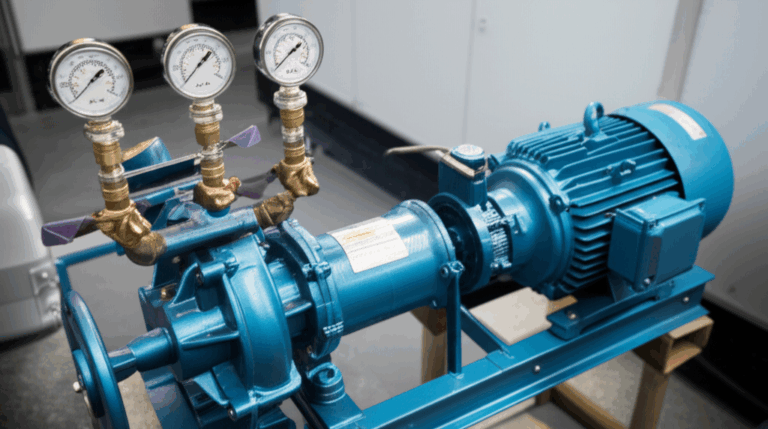

You might be thinking, “It’s just a motor, who cares?” But ignoring your motor’s health is like letting a silent thief steal from your company every single day. The problem is often much bigger than you realize. Did you know that electric motors can use 60-70% of all the electricity in an industrial plant? That’s a huge slice of your utility bill!

Here’s why you need to pay attention:

- You’ll Save a Ton of Money: This is the big one. Finding and fixing inefficient motors leads to direct cost savings. A tiny 1% improvement in efficiency on a 50 HP motor can save you over $460 every single year. Imagine if you have dozens of motors!

- You’ll Prevent Breakdowns: An inefficient motor is often an unhealthy motor. It might be running too hot or vibrating too much. These are signs of motor degradation. Checking its efficiency is part of predictive maintenance. It helps you spot trouble before the motor dies, preventing expensive downtime.

- Your Motors Will Last Longer: When a motor runs efficiently, it runs cooler and with less stress. This can dramatically extend its lifespan, saving you money on replacements.

- You’ll Help the Planet: Using less electricity means a smaller carbon footprint. Improving your motor efficiency is a simple way to meet your company’s sustainability goals and reduce greenhouse gas emissions.

The crazy part is that almost all of a motor’s cost happens after you buy it. The purchase price is only about 3% of its total cost over its life. The other 97% is the electricity it eats. That’s why efficiency is king.

What are the Key Things That Hurt Motor Performance?

Several sneaky problems can drain your motor’s efficiency. Being aware of these helps you know what to look for during a motor performance assessment.

- Wrong Size for the Job: This is a huge one. Many motors are oversized, like using a giant monster truck to deliver a pizza. A motor is most efficient when it’s running at about 75% to 100% of its full power. If it’s running at 50% load or less, its efficiency can drop by 5-10%. That’s wasted energy and money.

- Poor Power Quality: Motors like clean, steady power. If you have voltage imbalance (where the power on the three wires isn’t equal) or “dirty” power with harmonic distortion, the motor has to work harder and gets hotter. This wastes energy.

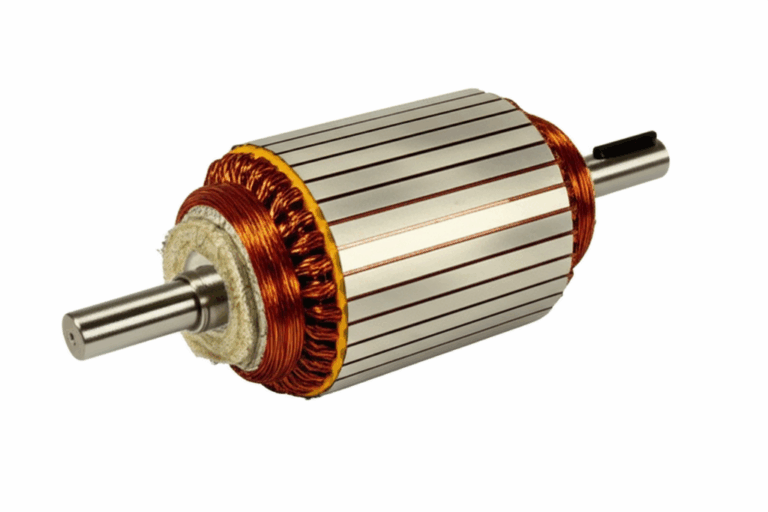

- Old Age and Wear: Just like anything else, motors get old. The parts inside wear out. Worn bearings, poor lubrication, and insulation degradation all create more friction and heat, lowering efficiency. The quality of the internal components is key. For instance, the stator and rotor must work together perfectly to avoid energy loss.

- Running Too Hot: If a motor is in a hot room or is clogged with dirt, it can’t cool itself properly. Heat is the enemy of efficiency. A thermal imaging motor check can spot these hot spots right away.

What Tools Do You Need to Play Motor Detective?

You don’t need a whole laboratory to start checking your motors. You can get a lot of good information with a few key tools.

Basic Tools for the Field:

- Clamp Meter: This is a must-have. It clamps around a wire to measure the current (Amps) the motor is drawing without having to disconnect anything.

- Voltmeter (or Multimeter): This measures the voltage going to the motor. Many clamp meters have this built-in.

- Tachometer: This little tool measures how fast the motor’s shaft is spinning in Revolutions Per Minute (RPM).

- Power Analyzer/Wattmeter: This is the superstar of motor testing. This one device can measure voltage, current, power factor, and the actual power (kW) all at once. It’s the best way to get a clear picture of the input power.

Advanced Diagnostic Tools:

- Dynamometer: This is a lab-grade tool for the most accurate dynamometer test. It directly measures the motor’s output torque and speed.

- Thermal Imager: These cameras see heat. They can instantly show you if a motor or its bearings are overheating, a sure sign of trouble.

- Vibration Analyzer: This tool “listens” to the motor’s vibrations. It can detect tiny problems like shaft misalignment or bad bearings long before they cause a failure.

How Do the Pros Check a Motor’s Efficiency? (The Direct Method)

The most accurate way to check motor efficiency is called the Direct Method. This is what motor manufacturers like Siemens and ABB use.

Think of it like putting a car on a special rolling road at a mechanic’s shop. The machine, called a dynamometer, puts a load on the motor and measures its exact output torque and speed. At the same time, a power analyzer measures the exact electrical input power.

Procedure:

This method is the gold standard for accuracy. However, it’s expensive, complicated, and you can’t do it while the motor is running in your factory. It’s mostly for labs and testing facilities.

How Can You Check Efficiency in the Field? (The Indirect Method)

So how do you check a motor that’s already installed and working? You use the Indirect Method, also called the Loss Segregation method. This is a very practical approach for an energy audit.

Instead of measuring the good work the motor is doing, you figure out all the ways it’s wasting energy. All these little bits of wasted energy are called losses.

The main types of motor losses are:

- Copper Losses: This is heat created by electricity flowing through the motor’s copper wires.

- Core Losses: This is energy lost in the motor’s steel core as magnetic fields change. The quality of the motor core laminations is critical for keeping these losses low.

- Friction & Windage Losses: This comes from the bearings rubbing and the fan that cools the motor.

- Stray Load Losses: These are the little “mystery” energy leaks that are hard to measure.

By doing a few tests (like a no-load test) and taking some measurements, an engineer can calculate each of these losses. They add them all up to find the total wasted power. This method is great because it tells you why a motor is inefficient, but it can be complex and requires some good estimates.

Is There a Magic Tool for This? (The Power Analyzer Method)

Yes, there is something close to a magic tool for this! Many modern power analyzers or motor analyzers make this whole process much easier. They offer a great balance of accuracy and convenience for field use.

Here’s how it works:

This is the most common and practical method used by maintenance teams today. It’s fast, pretty accurate, and also gives you other valuable information about your power quality.

What If I Don’t Have Fancy Tools? (The Nameplate Method)

What if you’re on the factory floor and all you have are your eyes and maybe a simple clamp meter? You can still get a rough idea of your motor’s efficiency with the Nameplate Method. It’s the least accurate, but it’s better than nothing for a quick assessment.

Procedure:

This method is just a ballpark estimate, but it can quickly help you spot badly oversized motors that are wasting a lot of energy.

I Found an Inefficient Motor. What Do I Do Now?

Okay, so you’ve done your detective work and found an energy-hog motor. Don’t just let it sit there leaking money! You have several powerful options to fix the problem and improve your motor’s performance.

| Strategy | When to Use It | Potential Energy Savings |

|---|---|---|

| Right-Sizing Motors | When a motor is constantly running at less than 50% of its load. | 5-15% |

| Install VFDs | For equipment where the speed can change, like fans and pumps. | 20-50% |

| Regular Maintenance | On all motors, especially older ones. | 2-10% |

| Upgrade to Premium Motors | When an old motor fails or needs replacing. | 2-8% |

- Right-Size Your Motors: If you found an oversized motor, replace it with a smaller one that correctly matches the job. The new, smaller motor will run in its sweet spot, saving energy.

- Install a Variable Frequency Drive (VFD): A VFD is like a dimmer switch for a motor. For applications like fans and pumps, you often don’t need them running at full speed all the time. A VFD can slow the motor down, and the energy savings are huge. A 20% drop in speed can cut energy use by nearly 50%! Modern motors, especially those with a high-quality bldc stator core, work perfectly with VFDs.

- Focus on Maintenance: A simple maintenance schedule can work wonders. This includes proper lubrication for bearings, keeping the motor clean so it stays cool, and checking for proper shaft alignment.

- Upgrade to a Better Motor: When an old motor finally gives up, don’t just buy the cheapest replacement. Spend a little more on a NEMA Premium or IE3 efficiency motor. It will pay for itself in electricity savings. A better motor starts with better parts. At Sinolami, we create premium core lamination stacks that are the foundation of these high-efficiency motors.

- Motor Rewind vs. Replace: Be careful with a motor rewind. While it can fix a failed motor, a poor rewind job can actually lower its efficiency. Always compare the cost of a high-quality rewind to buying a new premium-efficiency motor.

Beyond Efficiency: What Else Should I Check?

Checking motor efficiency is a great start, but a full motor system assessment looks at the bigger picture.

- Power Factor: This is a measure of how effectively your motor is using the current. A low power factor means you are drawing more current than you need to, which can increase your utility bills. Many power analyzers measure this.

- Vibration and Thermal Analysis: As we mentioned, using a vibration analyzer and thermal imager are key parts of predictive maintenance. They help you find mechanical and electrical problems that hurt efficiency and can lead to failure.

- Motor Asset Management: Don’t just look at one motor. Create a plan for all your motors. Know how old they are, how critical they are, and when they should be tested or replaced. This proactive approach prevents surprises and keeps your whole operation running smoothly.

By checking your motors, you are not just fixing a machine; you are improving your company’s bottom line and operational health.

Key Takeaways to Remember

- Motors Are Thirsty: Electric motors are likely the biggest electricity user in your facility, making them a huge opportunity for savings.

- Efficiency is Money: Checking and improving motor efficiency directly lowers your electric bill and reduces operational costs.

- You Have Options: There are many ways to check efficiency, from a quick nameplate check to using a powerful motor analyzer.

- Find the Leaks: Most inefficiency comes from oversizing, poor power quality, or simple wear and tear.

- Take Action: Once you find a problem motor, you can right-size it, add a VFD, perform maintenance, or upgrade to a new high-efficiency model.

- Be Proactive: Don’t wait for a motor to fail. Regular checks and a good maintenance plan will save you from headaches and expensive downtime.