How to Connect a VFD to a Single-Phase Motor: My Simple Guide for Speed Control

Have you ever wished you could slow down your drill press for a cleaner hole? Or maybe quiet down a noisy fan? Many workshop tools have simple single-phase motors that only have one speed: full blast. This guide will show you how to use a magic box called a VFD to get full speed control. I’ll walk you through everything, step-by-step, so you can make your tools work better and safer.

Table of Contents

- What is a VFD, and Can It Really Work on My Motor?

- Is Your Single-Phase Motor a Good Match for a VFD?

- How Do I Choose the Right VFD?

- Let’s Get Wiring! A Step-by-Step Connection Guide

- What Are VFD Parameters and How Do I Set Them?

- Why Does My Motor Get Hot at Low Speeds?

- What Other Problems Might I Run Into?

- Is It Worth the Effort? The Big Payoff

- Frequently Asked Questions (FAQ)

- Key Things to Remember

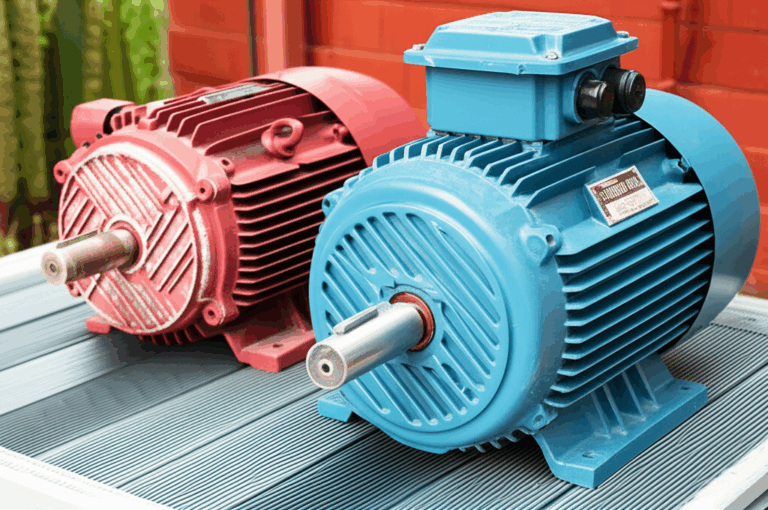

What is a VFD, and Can It Really Work on My Motor?

You have a problem. Your lathe, fan, or drill press has a single-phase motor. It’s a workhorse, but it’s loud and only runs at full speed. This lack of control can ruin a delicate project or just be plain annoying. You can’t get the exact motor RPM control you need, and the harsh startup jolts your machine, wearing out belts and gears over time. It feels like you’re stuck in the slow lane of technology.

Now, imagine being able to turn a simple knob to get the perfect speed for any job. That’s what a Variable Frequency Drive (VFD) does. A VFD, sometimes called a single phase variable speed drive, is a smart electronic controller that changes the power going to your motor. By changing the power’s frequency (measured in Hertz (Hz)), it changes the motor’s speed. It gives you a soft start, slowly ramping up the motor instead of slamming it on. This saves wear and tear and can even lower your power bill.

So, can you use one on a single-phase motor? The short answer is yes, but with a big “but.” Most VFDs are designed for three-phase motors. We will use a common type of VFD that takes single-phase power in and puts three-phase power out. We’ll just use two of the three outputs to run our single-phase motor. This trick works great for some motors but can destroy others. The key is knowing what kind of motor you have.

Is Your Single-Phase Motor a Good Match for a VFD?

Not all single-phase motors are created equal. Trying to hook up a VFD to the wrong kind is a recipe for disaster. It can cause motor heating issues or even burn out the motor completely. The problem lies with parts inside some motors that help them start, like a start capacitor or a centrifugal switch. A VFD’s power can confuse these parts. The quality of the motor’s internal components, like the stator core lamination, also affects how well it handles the VFD’s output.

Let’s break down the common types of single-phase AC induction motors and their VFD compatibility.

| Motor Type | Works with a VFD? | Why or Why Not? |

|---|---|---|

| PSC (Permanent Split Capacitor) | Yes, usually | These are simple. They don’t have a start switch to get in the way. Often found in fans. |

| Shaded-Pole Motor | Yes, usually | Very simple design, also common in small fans and appliances. Works well with a VFD. |

| Capacitor-Start Motor (CSIR/CSCR) | No, not without changes | The start switch and start capacitor will fight the VFD. You must disconnect them first. |

| Universal Motor | No | These are more like DC motors with brushes. They need a different type of speed controller. |

So, how do you know what you have? Look at the motor’s nameplate or listen when it starts. Capacitor-start motors often have a loud “click” a second after they start as the centrifugal switch disengages. If you have a PSC or shaded-pole motor, you’re in luck! If you have a capacitor-start motor, you must do some surgery by removing the centrifugal switch and bypassing the start capacitor. This is an advanced step and can damage your motor if done wrong. When in doubt, it’s often easier and safer to use a VFD with a compatible motor from the start.

How Do I Choose the Right VFD?

Choosing the right VFD can feel like ordering coffee at a fancy cafe. There are so many options! But don’t worry, it’s pretty simple if you know what to look for. Your main goal is to pick a VFD that can handle your motor without breaking a sweat. It’s a key part of your motor control system.

First, you need to match the horsepower (HP) or kilowatt (kW) rating. Look at your motor’s nameplate to find its HP or kW. You want a VFD with a rating that is the same or, even better, a little higher. This gives you some wiggle room. For example, if you have a 1 HP motor, get a VFD that is rated for at least 1 HP. This is called VFD sizing for single phase motor.

Next, check the voltage (V) and amperage (A). If you have a 220V single phase motor, you need a VFD that can take 220V single-phase input. The VFD’s output amperage should also be higher than the motor’s full load amps (FLA) listed on its nameplate. Getting these numbers right is crucial for overload protection and safe operation. Think of it as a phase converter vs VFD single phase setup, where the VFD is a much smarter converter.

Finally, look for a few key features. A good VFD should have different control modes like V/Hz control (the most common and simplest) or sensorless vector control (for better torque at low speeds). Make sure it has inputs for external controls. This lets you add a speed knob (potentiometer) or start/stop buttons. Some VFDs also have options for a braking resistor, which helps the motor stop quickly. This is great for tools like lathes where you need fast stops.

Let’s Get Wiring! A Step-by-Step Connection Guide

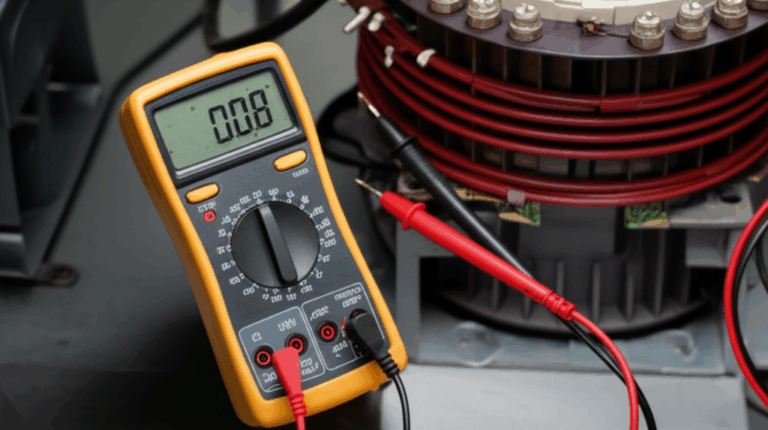

Okay, this is the fun part! But first, a serious warning: Electricity is dangerous. Before you touch a single wire, you must turn off the power at the circuit breaker. Use a voltage tester to make sure it’s really off. This is non-negotiable. Your safety is more important than any project.

Here’s a simple single phase VFD connection guide. We’ll cover both the main power and the fun control stuff.

1. Mount the VFD:

Find a clean, dry spot for your VFD with plenty of airflow. VFDs make a little heat, so they need to breathe. Don’t stuff it in a packed cabinet. Follow the NEMA ratings or IP ratings for your VFD enclosure if you’re in a dusty shop.

2. Wire the Power Circuit:

This is the high-voltage part. You’ll see a terminal block on the VFD.

- Input Power: Connect your incoming 220V or 110V power to the VFD’s input terminals. These are usually labeled L1 and L2/N.

- Grounding: This is the most important wire! Connect the ground wire from your power source to the ground terminal on the VFD. It often has a symbol that looks like a little Christmas tree.

- Motor Connection: Now connect the motor to the VFD’s output terminals. These are usually labeled U, V, and W. For a single-phase motor, you will typically use U and V. You MUST disconnect any old switches or plugs from the motor. The motor should be wired directly to the VFD. Don’t forget to also connect the motor’s ground wire to the VFD’s ground terminal. Using a shielded cable for this connection is a best practice to prevent electrical noise.

3. Wire the Control Circuit (Optional but cool):

This is the low-voltage part that lets you control the VFD.

- Speed Control: To add a speed knob, you’ll do some simple potentiometer wiring VFD single phase. A potentiometer has three legs. You’ll connect them to the VFD’s analog input terminals, usually labeled something like +10V, AIN, and GND.

- Start/Stop: You can wire a simple switch to the VFD’s digital input terminals to start and stop the motor. You can even add a switch for forward reverse control.

Always, always, always double-check your VFD wiring diagram single phase motor that came with your VFD. Every model is a little different.

What Are VFD Parameters and How Do I Set Them?

You’ve wired it all up. Now you need to teach the VFD about your motor. This is done by setting parameters. Think of them as settings in a phone menu. It sounds scary, but you only need to change a few basic ones to get started. Don’t let VFD programming single phase motor intimidate you.

First, you need to do the motor data entry. Find your motor’s nameplate again. You will enter these values into the VFD:

- Motor Rated Voltage: The volts (V) it’s designed for.

- Motor Rated Current: The full load amps (FLA). This sets up the electronic thermal overload to protect your motor.

- Motor Rated Frequency: Usually 50 Hz or 60 Hz.

- Motor Rated Speed: The revolutions per minute (RPM) at full speed.

Next, you’ll set how you want the motor to behave.

- Acceleration/Deceleration Time: This controls how fast the motor speeds up and slows down. A setting of 3-5 seconds is a good starting point for a smooth soft start.

- Minimum/Maximum Frequency: This sets your speed limits. You can set the max to 60 Hz (full speed) and the min to something like 10 Hz to prevent it from running too slow.

- Control Method: Choose V/Hz. It’s the simplest and works well for most single-phase motors on fans or pumps.

Finally, you might want to adjust the carrier frequency or PWM frequency. If your motor makes a high-pitched whining sound, increasing this number can often make it quieter. However, a higher carrier frequency can make the VFD run a little warmer. It’s a trade-off.

Why Does My Motor Get Hot at Low Speeds?

You’ve got your VFD running, and it’s great! You can slow your machine way down. But after a while, you touch the motor and it’s really hot. What’s going on? This is a common issue with low speed operation single phase VFD.

The problem is the fan. Most motors have a fan on the back that is attached to the motor shaft. When the motor spins fast, the fan spins fast, and it keeps the motor cool. But when you use a VFD to slow the motor down to 25% of its speed, the fan is also spinning at only 25% of its speed. It’s not moving enough air to cool the motor down, especially if the motor is working hard. The complex interaction between the stator and rotor generates heat, and without proper cooling, things can get dangerous.

This extra heat is a big deal. It can damage the motor’s insulation and windings over time, leading to a much shorter life. If you plan to run your motor at very low speeds for long periods, you should think about adding an external cooling fan. This is just a separate, small fan that you mount to blow air over the motor all the time, no matter how fast or slow the motor itself is spinning. It’s a simple fix that can save you from a big headache later.

What Other Problems Might I Run Into?

While a VFD is a fantastic tool, it’s not always a perfectly smooth ride. You might run into a few bumps in the road. Knowing what to look for can make VFD troubleshooting single phase motor much easier.

One common issue is electrical noise, called EMI or RFI. The VFD works by chopping up electricity very fast, and this can create static that messes with radios, TVs, or even other sensitive electronics in your shop. This is why using a shielded cable to connect the VFD to the motor is so important. A good ground connection and an EMI filter on the VFD’s input power can also help a lot. This noise is related to harmonic distortion, a side effect of how VFDs work.

You might also see VFD error codes on the display. Don’t panic! These are clues. An “overcurrent” fault might mean your acceleration time is too short or the load is too heavy. An “overvoltage” fault could happen if you try to stop a heavy load too quickly without a braking resistor. Your VFD’s manual will have a list of all the error codes and what they mean. Look for undervoltage overvoltage protection settings in your manual to help prevent these.

Finally, you might have a motor not starting VFD single phase problem. This is often a simple wiring or parameter issue. Double-check that your start/stop switch is wired correctly and that the VFD is programmed to listen to it. Sometimes the simplest mistake, like a loose wire on the terminal block, is the culprit. Investigating a motor problem often starts with checking the most basic connections.

Is It Worth the Effort? The Big Payoff

After all this talk of wiring, parameters, and potential problems, you might be wondering if it’s worth it. For me, the answer is a huge YES. The benefits you get from adding a VFD to the right machine are game-changing.

Think about it. You’ve taken a basic, one-speed tool and given it a brain.

- Total Speed Control: You can now perfectly match the speed to the job. This means cleaner cuts on a lathe, less burning on a drill press, and the perfect airflow from a fan.

- Longer Machine Life: The soft start feature is like a gentle wake-up for your motor and machine. No more jarring starts that shake belts, gears, and bearings. This reduces wear and tear, saving you money on repairs.

- Energy Savings: For machines like fans or pumps, slowing them down just a little bit can save a lot of electricity. Instead of running full blast all the time, the VFD only uses the power it needs.

- Quieter Operation: Slowing down a machine often makes it much quieter, which is a big plus for any workshop.

A VFD gives you a level of control and sophistication that was once only available on expensive industrial machines. For a relatively small investment in a VFD and a bit of your time, you can dramatically improve the performance and versatility of your equipment. For a home workshop or small business, that’s a huge win. You’ve solved the problem of being stuck with one speed, and now you have a tool that is far more useful and professional.

Frequently Asked Questions (FAQ)

Q: Can I use a VFD that takes 3-phase input power for my single-phase motor?

A: No. You must use a VFD that is specifically rated for single-phase input power. These are very common in smaller sizes.

Q: Will a VFD give my single-phase motor more power?

A: No, a VFD cannot increase the motor’s horsepower. It only controls its speed. You cannot get more power out than what the motor was designed for.

Q: What is the difference between V/Hz and Sensorless Vector Control?

A: V/Hz (Volts per Hertz) is the simplest control method and works great for variable torque loads like fans. Sensorless Vector Control is a more advanced mode that gives better torque and speed regulation at low speeds, which is better for machines like conveyors or lathes.

Q: Do I need a professional to do this?

A: If you are not comfortable and knowledgeable about working with electricity, then yes, you should absolutely hire a qualified electrician or automation specialist. Safety is the top priority.

Key Things to Remember

- Safety First: Always turn off and lock out the power before working on wiring.

- Check Motor Compatibility: VFDs work best with PSC or Shaded-Pole motors. Capacitor-start motors require risky modifications.

- Size the VFD Correctly: Match the VFD’s HP, voltage, and amps to your motor. It’s better to go a little bigger than too small.

- Use Shielded Cable: Connect the VFD to the motor with shielded VFD-rated cable to reduce electrical noise.

- Program Basic Parameters: You must tell the VFD about your motor’s voltage, amps, and speed to protect it properly.

- Watch for Overheating: At low speeds, your motor may get hot. Consider an external fan if you run it slow for long periods.

- Read the Manual: Your VFD’s manual is your best friend. It has all the specific diagrams, parameters, and troubleshooting tips you need.