How to Fix a Hydrolocked Motor: A Step-by-Step DIY Repair Guide

Table of Contents

- Introduction: What Hydrolock Really Means for Your Engine

- Immediate Actions: Do NOT Try to Start the Engine

- Diagnosing Hydrolock: Signs and Symptoms to Confirm

- Step-by-Step Guide: How I Fix a Hydrolocked Motor

- Step 1: Locate and Access the Spark Plugs or Glow Plugs

- Step 2: Remove All Plugs Safely

- Step 3: Clear Water from the Cylinders

- Step 4: Assess for Internal Damage

- Step 5: Change the Engine Oil and Filter

- Step 6: Check Other Fluids That May Be Contaminated

- Step 7: Inspect and Clean the Intake System

- Step 8: Reinstall Plugs and Reconnect the Battery

- First Start-Up After a Hydrolock Fix

- Secondary Damage: What to Check and When to Call a Pro

- Costs, Timing, and What “Success” Looks Like

- Hydrolock vs Vapor Lock: Don’t Mix Them Up

- Preventing Hydrolock Next Time

- Quick Note on “Motors” vs Engines (If You’re Working on Electric Equipment)

- Data, Case Studies, and Typical Outcomes

- Conclusion: Fast Action Saves Engines

Introduction: What Hydrolock Really Means for Your Engine

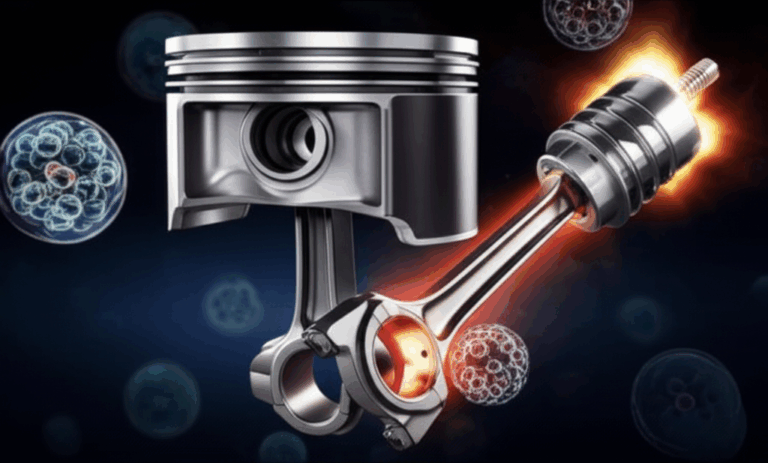

The first time I dealt with a hydrolocked engine, I learned a hard truth. Water does not compress. A gas engine or a diesel relies on air and fuel that squeeze into a tight space in the cylinder. Then the mix ignites. When water sneaks into that space, the piston tries to compress something that won’t compress. Something gives. Often it’s a bent connecting rod. Sometimes it’s worse.

So what is hydrolock? In simple terms, it’s a hydrostatic lock. Liquid gets into one or more cylinders and physically prevents the engine from completing a compression stroke. You’ll hear folks call it a flooded engine. That’s not the same thing as a normal flooded start with too much fuel. Hydrolock is mechanical. It stops the engine from turning. It can destroy parts in an instant.

Why is it dangerous? That sudden stop can bend a connecting rod, crack a piston, damage bearings, smash valve heads, or even crack the engine block or cylinder head. I’ve seen starter motors burn out trying to push through the lock. I’ve also seen oil turn milky after water contamination. None of that is good news.

Can you save a hydrolocked engine? Sometimes. I’ve brought engines back to life after wading through high water. I’ve also had to call customers and say the block is cracked. Your chances go up if you act fast, don’t crank the engine, clear the water properly, and check for internal damage before you rush the first start.

You can do a DIY hydrolock repair if the damage is minor and you move carefully. I’ll walk you through the exact steps I follow in my shop.

Immediate Actions: Do NOT Try to Start the Engine

When hydrolock is even a possibility, stop. Don’t turn the key to test it. Don’t crank it. Don’t bump the starter. Every extra crank can take a minor problem and turn it into a bent rod or worse.

- Why cranking makes it worse:

- Water in a cylinder blocks the piston from reaching top dead center.

- The starter, crankshaft, and connecting rods still try to rotate.

- That pressure can bend a rod, stress bearings, or crack parts.

- Safety first:

- Disconnect the battery. I pull the negative terminal first.

- This stops accidental cranking and protects the electrical system if water reached the starter or harness.

I always start here. It buys you time and prevents a small mistake from blowing up your parts bill.

Diagnosing Hydrolock: Signs and Symptoms to Confirm

Let’s make sure you’re chasing the right problem. Here’s what I look and listen for when I suspect hydrolock.

- Engine won’t crank or turns very slowly.

- The starter tries and the engine barely nudges. It can sound like a dead battery. It can also clunk and stop abruptly.

- Visible water in the air filter box or intake.

- I pop open the air filter box. If it’s wet or the filter is soaked, I get suspicious fast. Water sitting in the intake manifold is a big red flag.

- Unusual sounds right before failure.

- A splash or gulp followed by a hard clunk before the engine died is classic.

- Water in engine oil.

- Pull the dipstick. Milky oil means water contamination. It doesn’t confirm hydrolock on its own. It does confirm water found a way in.

- Recent flood or heavy rain exposure.

- Driving through deep water is the number one cause. Pulling a wake into the intake can do it in seconds. A cracked head gasket or failed injector can also cause hydrolock with coolant or fuel.

Note: Diesel engines can hydrolock too. Hydrolocked diesel engine repair follows the same core steps but glow plugs replace spark plugs during access.

Step-by-Step Guide: How I Fix a Hydrolocked Motor

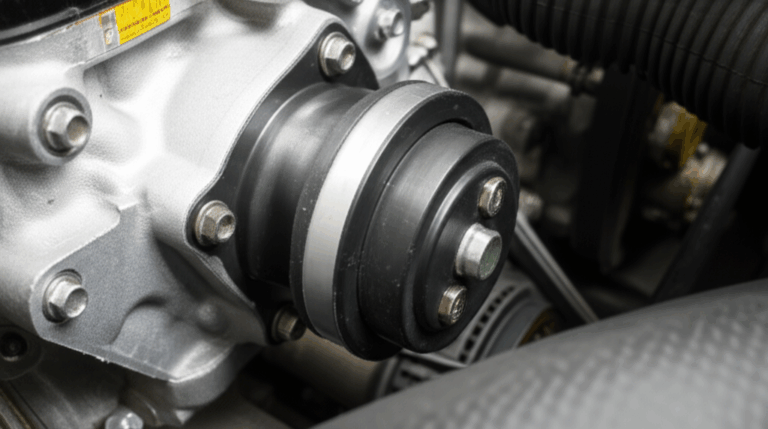

Step 1: Locate and Access the Spark Plugs or Glow Plugs

Tools I keep handy:

- Basic hand tools

- Ratchet, extensions, and the correct spark plug socket

- Torque wrench

- Dielectric grease

- Penetrating oil for stubborn coils or plugs

- Shop towels

- Labels and small bags for bolts and coils

- Compressed air (if available)

I remove the engine cover if there is one. Then I clear the way to the ignition coils or plug wires. I label coil packs by cylinder so everything returns to its original home. On diesels, I locate the glow plugs and the harness.

If the intake tube blocks access, I remove it. I inspect the air intake and throttle body as I go. If I find pooled water, I take note.

Step 2: Remove All Plugs Safely

I blow away debris around each plug well so dirt doesn’t fall in. I remove all spark plugs. Not one or two. All of them. This step matters. If water sits in more than one cylinder and you leave a plug installed, the engine can still lock when you turn it.

As I remove each plug, I:

- Number the cylinder on a piece of tape.

- Check the tip for signs of water, mud, or damage.

- Keep the holes open and clean. I don’t drop anything into the cylinder.

On a diesel, I remove all glow plugs. Some diesels bury them a bit deeper, so patience helps.

Step 3: Clear Water from the Cylinders

Now the engine can breathe. You’ll get soaked if you stand in front of the plug holes. Ask me how I know.

How I clear the cylinders:

- Manually turn the crankshaft slowly.

- I use a crank pulley bolt with a breaker bar. I rotate the engine in its normal direction. Turn slowly. If water is present, it will shoot out of the plug holes. Keep towels nearby.

- Observe the spray pattern.

- If one hole geysers, that’s your flooded cylinder. One cylinder is common. More than one happens after heavy water ingestion.

- Use compressed air with care.

- I blow air into each cylinder to push out mist. I don’t overdo it. I don’t want to blast debris into rings or valves.

- Use a siphon or shop vac if needed.

- For puddles in the intake or large pools inside a cylinder at bottom dead center, a small hose on a shop vac can help.

I keep turning the engine by hand until no more water mist sprays out. If it binds hard again, I stop. That can mean a bent rod or mechanical interference.

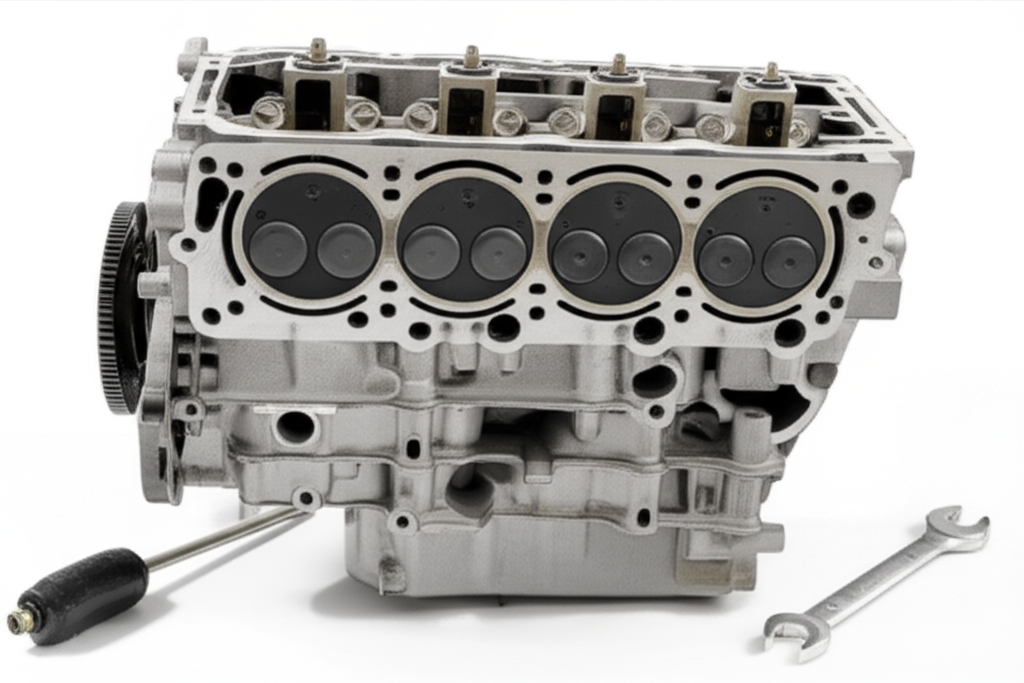

Step 4: Assess for Internal Damage

Clearing the water is half the battle. You still need to see what got hurt. Here’s how I check.

- Visual inspection with a borescope or endoscope.

- I look at piston crowns, cylinder walls, and any obvious scoring or cracks. Smooth walls and intact piston tops are good news.

- Look for signs of bent connecting rods.

- If a piston sits lower than the rest at top dead center, a rod may be bent. Comparing piston heights with a thin rod or straw can help.

- Rotate the engine by hand.

- It should turn smoothly now. Any harsh binding or sudden stop tells me to pause and investigate further.

- Compression test after initial clearing.

- Once I’m confident nothing will lock up again, I may run a compression test. I only do this after clearing water and changing the oil. Low compression on one cylinder can signal a bent valve, damaged rings, or a bent rod.

If I see deep scoring on cylinder walls, a cracked piston, or wildly off compression numbers, I talk replacement or a full engine rebuild. You can’t wish away mechanical damage.

Step 5: Change the Engine Oil and Filter

This step is critical. Water does not lubricate. It destroys bearings.

- Drain the oil. Let it drip fully.

- Replace the oil filter.

- Refill with fresh oil at the correct viscosity.

- If the oil came out milky or you saw a lot of water, I change the oil again after the first short run. Sometimes twice.

I also check the oil pan for damage or dents. Water forces can twist things in ugly ways.

Step 6: Check Other Fluids That May Be Contaminated

If the vehicle sat submerged or took on significant water, I go a layer deeper.

- Transmission fluid:

- On automatics, I check for milky fluid. Water contamination can kill a transmission. If I suspect water, I plan a fluid and filter change.

- Differential and axle fluids:

- Off-roaders who waded through high water often forget diffs. I crack the fill plug and check for milky gear oil.

- Coolant:

- If a cracked head gasket caused hydrolock, coolant levels may be down. I look for cross-contamination in the coolant reservoir.

Step 7: Inspect and Clean the Intake System

You need to keep any new water or debris from returning.

- Replace the air filter. If it got wet, it’s done.

- Inspect air intake ducts.

- I pull the intake tube and look for pooled water. I clean and dry it.

- Check the throttle body and the intake manifold.

- If the intake manifold has pooled water, I drain it. I do not leave pockets of water inside the runners.

- Turbocharger or supercharger systems:

- For turbocharged engines, I check the intercooler for water. I’ve drained a surprising amount from intercoolers after a deep-water gulp. Water in the charge pipes can stall a fresh start or re-hydrolock the engine.

- Supercharged systems can hold pockets too. I check the low points in the tract.

Step 8: Reinstall Plugs and Reconnect the Battery

When I’m confident the cylinders are dry and I’ve changed the oil, I reinstall spark plugs.

- Use the correct torque specs. I don’t over-tighten. I reference the service manual for torque.

- Reinstall coil packs or wires. I add a dab of dielectric grease if needed.

- Reconnect the battery. Negative terminal last when reconnecting.

Now it’s time to try a careful start.

First Start-Up After a Hydrolock Fix

I never hold my breath on the first start. I do listen like a hawk.

- Initial cranking procedure:

- I crank in short bursts. Ten seconds max. Then I pause. This helps oil pressure build and reduces stress.

- Listen for unusual noises:

- Knock. Grind. Any metallic clunk. If I hear it, I stop and reassess. A steady knock under load can mean a bent connecting rod or damaged bearings.

- Monitor warning lights:

- Oil pressure must come up quickly. If it doesn’t, I stop. Check engine light may appear if moisture hit sensors. I scan codes and clear what’s related to transient moisture if everything else checks out.

- Let it reach operating temperature:

- I watch coolant temp and oil pressure. I also keep an eye on exhaust smoke. A bit of white vapor at first can be leftover moisture. Persistent white smoke can point to coolant ingress.

- Post-repair inspections:

- After it idles and warms up, I shut it down. I check oil again. I check for leaks. I check the air intake one more time. Then I take a short, gentle test drive.

If it runs smooth and quiet, you likely dodged the worst. If it runs rough or knocks, I move to a deeper diagnosis.

Secondary Damage: What to Check and When to Call a Pro

Hydrolock can leave a trail. Here are the usual suspects I’ve found after the first start.

- Bent connecting rods:

- Common. The engine may run but knock at certain RPM. Compression will be low on the bent cylinder. You may feel a vibration or rough idle.

- Damaged bearings:

- Water in oil strips lubrication. Rod and main bearings can score and fail later. Listen for a low-end knock. Watch oil pressure.

- Cracked engine block or cylinder head:

- Severe hydrolock can fracture metal. You may see coolant loss, oil in coolant, or coolant in oil. Overheating can follow.

- Valves and timing issues:

- A hydrolock event can bend valves. It can also slip a timing belt or chain if the stop was violent. I check timing belt/chain condition and alignment if anything sounds off.

- Electrical system corrosion:

- Flood exposure oxidizes connectors. I clean and dry critical plugs. I check the starter motor if it struggled.

- Exhaust and catalytic converter:

- A slug of water in the exhaust can damage the catalytic converter or oxygen sensors. Listen for rattles. Watch for lingering codes.

Signs you need a mechanic right now:

- The engine still won’t turn over by hand.

- Loud knocking or grinding noises on start or under load.

- Persistent misfires or rough idle that don’t clear after drying out and replacing plugs.

- Low compression on one or more cylinders.

- Visible cracks or severe scoring in a cylinder during borescope inspection.

Repair versus engine replacement:

- Minor hydrolock repair can be relatively cheap. Think oil changes, plugs, and intake cleanup.

- Major internal damage can push you into a rebuild or replacement. On some vehicles, a remanufactured engine makes more sense than a tear-down.

Costs, Timing, and What “Success” Looks Like

Here’s what I tell people in plain English. If you catch hydrolock early, act fast, and the rods stayed straight, your engine can live a long life. If the engine hammered hard against water, damage can run deep.

Typical ranges I’ve seen:

- Time for a skilled DIYer to clear a minor hydrolock:

- Two to six hours, not counting parts runs.

- Professional turnaround for minor to moderate cases:

- One to three days, scheduling and parts dependent.

- Cost for minor recovery:

- A few hundred dollars. Oil, filters, plugs, and some shop supplies.

- Cost for major internal repair or rebuild:

- Can run into the thousands. Bent rods, bearings, gaskets, machine work, labor.

- Engine replacement:

- Used or reman engines can cost more than the vehicle is worth in some cases.

What success looks like after a fix:

- Smooth idle. No knock. Clean oil. No new warning lights.

- Strong compression across cylinders.

- No smoke after the first few minutes of drying out.

- Normal fuel economy and power on a short test drive.

Hydrolock vs Vapor Lock: Don’t Mix Them Up

People ask about vapor lock when they mean hydrolock. They’re not the same.

- Hydrolock:

- Liquid in the cylinder. Mechanical lock. Engine won’t turn or turns hard. Risk of bent rods and internal damage.

- Vapor lock:

- Fuel vaporizes in the fuel lines. The engine cranks but won’t start or runs poorly until the fuel cools and re-liquefies. Common in older cars with mechanical fuel pumps and high heat. It’s not a mechanical lock.

If your engine won’t turn over after water, that’s not vapor lock.

Preventing Hydrolock Next Time

I’ve fixed enough hydrolocked engines to see patterns. Prevention isn’t flashy. It works.

- Avoid driving through deep water.

- If you can’t see the bottom, don’t go. Water can surge into the intake fast. Your SUV or truck sits higher, yet the intake can still gulp water from a bow wave.

- Slow down if you must cross shallow water.

- Roll through at a steady pace. Don’t plow. Don’t splash. Bow waves are what usually get people.

- Inspect the air intake system.

- Make sure the intake snorkel sits where the factory designed it. Check for missing splash shields. After off-road trips, look for debris or damage.

- Consider a snorkel for off-road rigs.

- A properly installed snorkel moves the air inlet higher. It’s not a submarine button. It simply reduces the risk of water ingestion.

- Keep up with maintenance.

- Fresh air filters, intact intake ducting, and proper crankcase ventilation keep the system healthy.

Quick Note on “Motors” vs Engines (If You’re Working on Electric Equipment)

Hydrolock affects internal combustion engines because they rely on compressing air and fuel inside cylinders. Electric motors don’t compress anything inside a cylinder. If you’re dealing with an electric motor that got wet, you’re looking at different issues like short circuits, insulation damage, or bearing corrosion. If you want a refresher on the fundamentals, this overview of the motor principle helps you see how electric motors generate torque. If you’re troubleshooting a non-starting mower or generator and it’s actually an electric motor problem, this general guide on motor problem patterns can be useful. And if you’re curious about how electric machines are constructed, this quick primer on stator and rotor layouts gives helpful context. For hydrolock though, stick with the steps above. It’s an engine-only issue.

Data, Case Studies, and Typical Outcomes

I’ll share a snapshot of what I’ve seen and what many shops report. Treat these as illustrative ranges. Your vehicle, flooding depth, and how fast you act will shift the result.

I’ve also seen special cases:

- Hydrolock in older cars with lower intakes and less shielding happens fast after heavy rain.

- Direct injection engines can hydrolock with fuel if an injector sticks open. That’s rarer. It’s real.

- Diesel engines can suffer bent rods from even small water slugs. High compression amplifies the problem.

- Marine engines and small engines like generators or snowblowers see hydrolock from wave splash or storage mishaps. Same physics. Same fix basics.

Conclusion: Fast Action Saves Engines

If your motor seized by water or you suspect hydrolock, stop cranking. Disconnect the battery. Pull the plugs. Clear the cylinders. Change the oil. Inspect for internal damage before that first start. Those steps decide whether you get a simple recovery or a long, expensive rebuild.

I’ve been on both ends of this. The engines that survive share one thing in common. The owner acted fast and did it right. If you hear knocking or see low compression after the fix, bring in a pro. Bent rods and damaged bearings will not heal with fresh oil.

Short version:

- Don’t crank a hydrolocked engine.

- Remove plugs and clear water from cylinders.

- Change oil and filter. Check other fluids.

- Inspect the intake. Replace the air filter.

- Start gently. Listen closely. Validate with compression if needed.

- Fix what you find. Don’t ignore knocks or misfires.

Hydrolock feels scary. It is. Yet a careful, step-by-step approach can save your engine and your wallet. Take it slow. Do it right. Then keep water where it belongs. Outside your engine.

Keywords and Concepts Covered Naturally:

- Engine hydrolock repair, water in engine fix, hydrostatic lock symptoms, bent connecting rod repair, how to drain water from engine, hydrolocked engine startup, cost to fix hydrolocked engine, DIY hydrolock repair, engine won’t turn over after water, removing spark plugs hydrolock, checking for engine damage after hydrolock, signs of hydrolocked motor, causes of engine hydrolock, flooded engine damage, motor seized by water, can you fix a hydrolocked engine, hydrolock diagnosis steps, best way to fix hydrolocked engine, professional hydrolock repair, engine rebuild after hydrolock, replacing engine after hydrolock, hydrolocked diesel engine repair, hydrolocked gasoline engine fix, preventing engine hydrolock, water ingestion engine damage, what to do if car engine takes in water, internal engine damage from hydrolock, cylinder damage hydrolock, crankshaft damage hydrolock, starter motor damage hydrolock, piston damage hydrolock, oil change after hydrolock, fuel system check after hydrolock, electrical system check after hydrolock, intake manifold water damage, air filter box water, hydrolock insurance claim, water damage car engine value, hydrolocked engine compression test, timing belt check hydrolock, valve damage hydrolock, engine knocking after hydrolock, rough idle after hydrolock, engine misfire after hydrolock, exhaust system water damage, catalytic converter hydrolock, turbocharger damage hydrolock, supercharger damage hydrolock, engine oil contaminated with water, coolant system check hydrolock, removing water from cylinders, drying out engine after flood, water entry points engine, hydrolock consequences, immediate steps hydrolock, tools for hydrolock repair, torque specs engine repair, gasket replacement hydrolock, engine inspection after water, hydrolock vs vapor lock, engine won’t start after heavy rain, wading through high water car, vehicle submersion damage, car flood damage assessment, hydrolock warranty claim, secondary damage hydrolock, engine noise after water ingestion, exhaust smoke after hydrolock, checking for bent valves, engine cleaning after flood, hydrolock fluid removal, what causes engine seizure from water, hydrolock in older cars, hydrolock in modern engines, direct injection hydrolock, common hydrolock mistakes, average hydrolock repair time, signs of successful hydrolock fix, preventing future hydrolock, how much water causes hydrolock, engine internal damage signs, cost of new engine vs repair, hydrolock troubleshooting guide, engine crank but won’t start after water, hydrolock and oil pan, engine block cracks hydrolock, engine mount damage hydrolock, hydrolock in small engines, marine engine hydrolock, heavy equipment hydrolock, generator hydrolock fix, what engine parts are affected by hydrolock, how to tell if engine is salvageable, step-by-step hydrolock repair

Internal Links Used: