How to Fix an Inflatable Blower Motor: A Complete Troubleshooting & Repair Guide

Table of Contents

- Introduction

- What is an inflatable blower motor and why should you care?

- Is it safe to fix a blower at home?

- How does the blower motor work inside?

- What symptoms do you see and what do they mean?

- How do you do basic power checks?

- Why does the motor hum but not spin?

- How do you test and replace a run capacitor?

- How do you clear debris and fix the impeller?

- How do you handle weak airflow or overheating?

- What advanced checks can you try?

- What tools and parts do you need?

- Should you repair or replace the blower?

- How can you stop future blower failure?

- Case studies, numbers, and a clear action plan

- Quick fixes by symptom (table)

- Do you need a pro and what about warranty?

- References

- FAQ

- Key takeaways

When your inflatable blower stops, the fun stops. I have seen sad kids by a flat Bounce House. I have seen a Holiday Inflatable sag in the yard. This guide gives you a simple path to inflatable blower troubleshooting and repair. You will learn how to do a DIY blower motor fix, how to spot common blower motor faults, and how to choose repair vs replace blower with clear steps that work.

What is an inflatable blower motor and why should you care?

Here is the Problem. Your Inflatable Blower will not start. Or it hums. Or it blows weak air. The inflatable stays flat. Your party or holiday plan stalls. You feel stuck.

Let me Agitate a bit. You try again. Nothing. The On/Off Switch clicks but nothing happens. The Circuit Breaker might trip. The GFCI (Ground Fault Circuit Interrupter) might pop. You hear a hum from the Electric Motor but the Impeller Fan does not spin. The kids wait. The clock ticks. Stress builds.

Here is the Solution. I will show you a clear blower motor repair guide that starts with safety. Then we test power. Then we check the Run Capacitor. Then we look at the Impeller Blades, the Motor Shaft, the Bearings (Motor), the Wiring (Electrical), and more. You will see how to do a voltage test blower motor, a continuity test blower wiring, and testing a run capacitor with a Multimeter. You will know how to check blower motor and when to get professional blower repair service.

Is it safe to fix a blower at home?

Yes it can be safe if you follow rules. Start with safety tips blower repair. Unplug the Power Cord before you open the Motor Housing. Wear Safety Glasses and Work Gloves. Use a Test Light or Continuity Tester to be sure power is off. Respect Voltage (Power Supply) and Amperage (Motor). Keep dry hands. Stay away from water.

You must also think about preventing electrical shock. Use a Surge Protector when you test. Do not work in rain. Do not touch bare Wiring (Electrical). If you see Water Damage, stop and let it dry. If you see a short circuit blower motor or motor insulation breakdown, stop and call a pro.

How does the blower motor work inside?

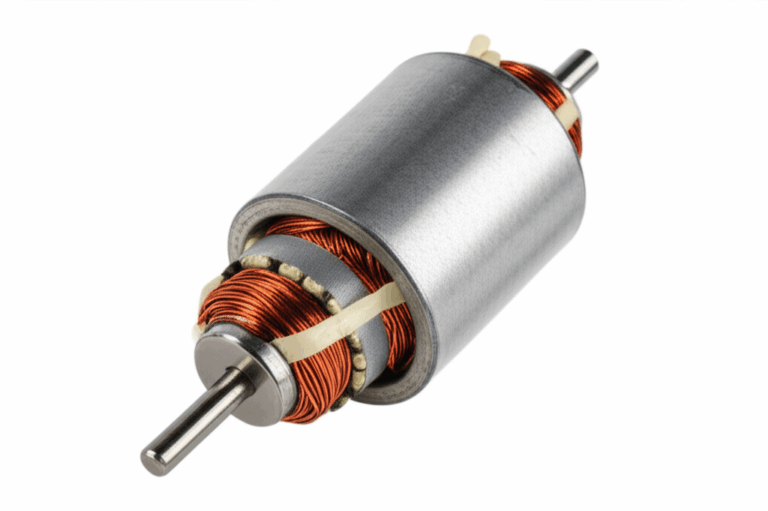

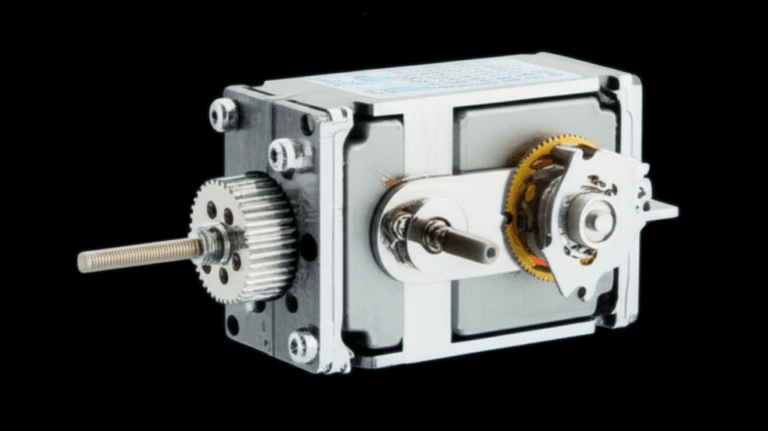

Your blower pulls air in and pushes it out. The Impeller Fan spins on a Motor Shaft. The Stator and Rotor inside the Electric Motor make the shaft spin when power flows. For a clear primer on how these parts interact see how the stator and rotor work together. Many blowers use single‑phase motors with a Run Capacitor to start and run the motor.

Quality inside the motor matters. The stator core lamination and rotor core lamination use electrical steel laminations to cut losses and keep heat low. You can learn more about high quality stator core lamination and matching rotor core lamination parts made from premium electrical steel laminations. Good laminations help with smooth starts and less heat which boosts life.

What symptoms do you see and what do they mean?

I like to match each symptom to likely causes. It makes diagnosing blower problems easy.

- Symptom: Blower Not Turning On (No Power) or “bounce house blower won’t start” or “power loss inflatable blower”

- Likely causes: circuit breaker tripped blower, GFI tripping blower, power cord damage blower, faulty switch inflatable, fuse blown blower motor, internal wiring check needed.

- Symptom: motor hums but no air

- Likely causes: failed run capacitor, impeller obstruction removal needed, frozen motor shaft, seized bearings.

- Symptom: blower not pushing enough air or weak airflow blower or motor spins slowly

- Likely causes: partially failed capacitor, air flow blockage blower or clogged air intake blower, worn out carbon brushes if it is a universal motor, motor winding damage.

- Symptom: blower motor overheated or blower motor getting hot then stops

- Likely causes: motor thermal overload trip, poor venting, debris (Foreign Objects), bad Thermal Overload Protector.

- Symptom: blower motor grinding noise or fixing a noisy blower

- Likely causes: bad bearings, impeller fan rub, loose mounts, motor vibration issues.

- Symptom: outdoor inflatable motor problems after rain

- Likely causes: moisture in motor, water damage blower motor, voltage fluctuations blower.

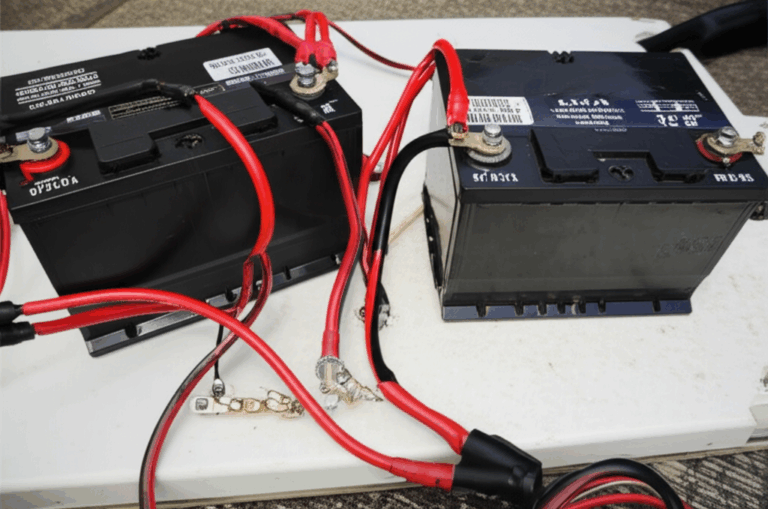

How do you do basic power checks?

Start simple. These checks fix a lot of calls fast.

- Test the outlet. Plug in a lamp. If it works you have power.

- Reset the GFCI and the Circuit Breaker. Do not ignore a GFCI that trips again. It may point to grounding issues blower or common electrical faults.

- Inspect the Power Cord end and the Extension Cord or Extension Cord Reel. Look for cuts. Look for heat marks.

- Check the On/Off Switch. A faulty switch inflatable blocks power.

- Look for a Fuse if your model has one.

- Use a Multimeter for a voltage test blower motor at the cord and switch. Use a Continuity Tester or Ohm Meter to do a continuity test blower wiring end to end.

If you see bad parts you can do finding replacement parts blower online. Many online blower repair resources show steps and parts. Read the User Manual for manual for blower motor steps and the blower motor diagram.

Why does the motor hum but not spin?

This one shows up all the time. The motor hums but the Impeller Fan sits still. The most common cause is a Run Capacitor that failed. The second cause is impeller obstruction removal needed due to Debris (Foreign Objects). Leaves. Grass. A small toy. I once pulled out a stick from a Holiday Inflatable blower that jammed the Fan Guard.

Sometimes the Motor Shaft gets tight. It can be a frozen motor shaft or seized Bearings (Motor). You might also find worn out carbon brushes if your unit uses Brushes (Carbon) with an Armature. Many blowers are induction style and have no brushes yet some holiday fans use universal motors.

How do you test and replace a run capacitor?

I treat this as the number one fix. Here is my fast path.

- Unplug the blower. Remove the Motor Housing cover. Take a photo for how to reassemble blower motor later.

- Discharge the Run Capacitor. Short it with a resistor or follow your User Manual. This is a key step in safety precautions electrical repair.

- Look at the capacitor. If it bulges or leaks you found the problem.

- Use a Multimeter with capacitance for testing a run capacitor. Compare to the capacitor value blower motor on the label in microfarads (uF) and VAC.

- Replace with a matching part. This is the core of capacitor replacement blower.

- Reconnect wires with Heat Shrink Tubing, Electrical Tape, and Cable Ties to secure.

This small part often restores full life. It solves many “motor hums but no air” cases. It also helps with weak airflow blower and motor stalling problem.

How do you clear debris and fix the impeller?

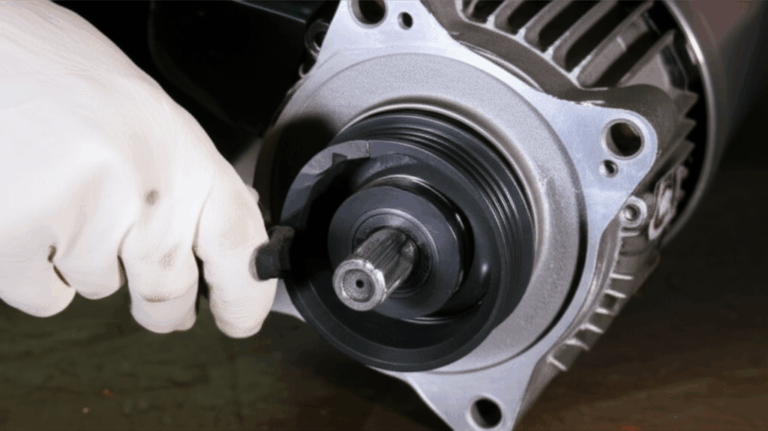

If air stalls you may have a clogged air intake blower. Do checking for debris in fan. Pop off the inlet screen. Clear leaves. Wipe dust. Use an Air Compressor to blow out the vents. Do not spin the motor with high air pressure for long.

Open the case for motor housing disassembly if needed. Remove the Impeller Fan carefully. Do impeller obstruction removal. Check Impeller Blades and Fan Guard for rub marks. If a blade cracked you can try fan blade repair or replace the wheel. Tighten screws to securing blower motor and housing. Set the gap so it does not rub.

How do you handle weak airflow or overheating?

Weak air means poor lift. You want that bounce back. Start with blockages. Clear the intake and outlet. Check the bag and tube for folds. Then check the capacitor again. A partially failed capacitor can run but slow.

If the case runs hot you might have poor venting. Clean dust. Set the blower on a hard pad. Keep grass away from the inlet. Look at the Thermal Overload Protector if it trips. You might need a new one. That is the motor thermal overload trip fix.

If you still have low air and the motor feels rough you may have bearing wear. Try how to lubricate blower motor with a light oil if the bearings have ports. If they do not you face replacing blower bearings. That is more work yet still possible.

What advanced checks can you try?

When basics fail you dig deeper. This is where troubleshooting AC blower motor gets real.

- Do an internal wiring check with your Multimeter. Test across windings with the Ohm Meter. Look for open or shorted paths.

- Check for motor winding damage. Burn smell. Dark coils.

- Inspect the Armature if you have a brushed motor. Do checking armature blower for wear lines.

- Consider replacing motor brushes if you see short Brushes (Carbon).

- Look for motor control board issues in models that have a small PCB. Many simple blowers do not have a board yet some do. Also check for an airflow sensor repair need if your model uses one.

- Repair small cracks with motor housing crack repair epoxy. Make sure mounts are tight to stop motor vibration issues.

If you suspect core issues in older units you may face mechanical failure blower fan. If the Stator or Rotor has damage you often replace the whole unit. Learn to identify motor type and read understanding motor schematics before you go too deep.

What tools and parts do you need?

I keep a small kit. It covers most jobs.

- Screwdriver Set: Phillips and flathead

- Needle-nose pliers

- Wire cutters/strippers

- Multimeter with voltage, continuity, capacitance

- Voltmeter, Ammeter, Ohm Meter attachments if needed

- Electrical Tape, Heat Shrink Tubing

- Cable Ties

- Lubricant (WD-40, silicone spray) for light jobs

- Safety Glasses, Work Gloves

- Replacement Parts: Run Capacitor, switches, Fuse, Bearings (Motor)

- Inflatable repair kit for small leaks in tubes

- Surge Protector

- Extension Cord rated for the Wattage (Motor) and Amperage (Motor)

You can find the best blower motor parts by reading the User Manual and understanding blower specs. Check motor rating and wattage. Match Voltage (Power Supply). When you shop, look for solid metal cores with good laminations. Better cores use quality steel. Learn how stator core lamination, rotor core lamination, and electrical steel laminations shape performance and heat. Good cores cut energy loss which extends life.

Should you repair or replace the blower?

Use a clear test. Price the part and your time. Compare to the cost of new blower motor and full unit price.

- Small repairs like capacitor replacement blower, faulty switch inflatable fixes, impeller obstruction removal, and cleaning blower motor are cheap and fast.

- Big issues like motor winding damage or a burned Stator and Rotor often cost more than a new unit. That is your repair vs replace blower choice.

- Check warranty information blower and customer support blower brand. Some makers like Blast Zone or B-Air can ship parts fast.

Factor in motor replacement cost inflatable, age, and safety. If the blower is near the end of life you may replace it. If it is young you can fix it.

How can you stop future blower failure?

A little care goes a long way. Use preventing blower failure steps.

- Do blower motor maintenance twice a season. Clean dust. Check screws. Look at the cord.

- Practice proper blower storage. Keep it dry. Use a bin. Avoid heat and sun. This helps with extending blower lifespan.

- Keep it off wet grass. You avoid moisture in motor and Water Damage.

- Do not kink the tube. Keep vents clear. You avoid air flow blockage blower.

- Use the right Extension Cord and avoid long runs. This cuts voltage fluctuations blower.

Case studies, numbers, and a clear action plan

I keep score. Here is what I see on the bench and in forums.

- Most “hums but no spin” problems come from the Run Capacitor. Many techs say 60 to 70% of these cases are fixed by a new cap.

- Debris (Foreign Objects) show up a lot in outdoor use. It is a quick DIY win.

- A clean blower can live 20 to 30% longer.

Now let me lay out your plan.

- Step 1: Safety first. Unplug. Dry area. Glasses on.

- Step 2: Outlet, GFCI, and Circuit Breaker checks.

- Step 3: Cord, switch, and Fuse checks.

- Step 4: Open case. Clear debris. Spin the Motor Shaft by hand to feel for drag.

- Step 5: Test and replace the Run Capacitor.

- Step 6: If needed check bearings, brushes, and windings.

- Step 7: Reassemble and test.

Quick fixes by symptom (table)

Here is a friendly troubleshooting guide inflatable table you can use.

| Failure Type / Symptom | Likelihood of Occurrence | Primary Cause(s) | Repair Action | Estimated DIY Cost (Parts Only) | Outcome / Success Rate (DIY) |

|---|---|---|---|---|---|

| No Power / Does not Turn On | High | Tripped GFCI/Breaker, Damaged Power Cord, Faulty On/Off Switch, Loose Wiring (Electrical), Fuse | Reset GFCI/Breaker, Replace Cord, Replace Switch, Reconnect/Solder Wiring | $0 – $25 | High |

| Motor Hums, No Spin | Very High | Failed Run Capacitor, Impeller Fan Obstruction, Seized Bearings | Replace Capacitor, Clear Debris, Lubricate/Replace Bearings | $5 – $30 | High to Moderate |

| Weak Airflow / Slow Spin | Moderate | Partially Failed Capacitor, Air Flow Blockage, Worn Windings | Replace Capacitor, Clear Blockages, Replace Motor if windings fail | $0 – $20 | High for simple causes |

| Overheating / Shuts Off | Moderate | Overload, Poor Vent, Debris, Faulty Thermal Overload Protector | Clean Vents, Replace Protector | $0 – $25 | Moderate |

| Grinding / Noise | Low | Bad Bearings, Impeller Rub, Loose Mounts | Replace Bearings, Reposition Impeller, Tighten Mounts | $0 – $30 | Moderate |

| Complete Motor Failure | Low | Prolonged Overload, Water Ingress, Severe Short | Replace Motor or Blower | $50 – $150+ | Low |

Do you need a pro and what about warranty?

Sometimes you hit a wall. If you see burnt windings or deep Water Damage call a professional blower repair service. They can test Amperage (Motor) draw with an Ammeter. They can spot causes of motor failure fast.

Check warranty information blower first. Reach customer support blower brand with your serial number. For a unit under warranty they may send a part or ask you to send the blower in. For out of warranty units you can shop Replacement Parts. If you need core parts learn to match motor rating and wattage and Voltage (Power Supply). You can also look up advanced motor core laminations options if you rebuild motors and want premium cores.

References

- Manufacturer User Manual for your model

- OSHA and local safety codes for electrical work

- Community repair forums with online blower repair resources

- Basic motor theory and understanding motor schematics

- Product pages for quality laminations and cores

FAQ

- What if my blower works then trips the GFCI?

- You may have grounding issues blower, moisture, or a leaking capacitor. Dry the unit. Test with a Multimeter. Replace suspect parts.

- Can I oil sealed bearings?

- If the bearings are sealed you usually replace them. Do replacing blower bearings when they grind or rumble.

- Do all blowers have brushes?

- No. Many use induction motors with no Brushes (Carbon). Some holiday fans use universal motors with brushes and an Armature.

- What if my blower has a control board?

- Some models use a small PCB. Look for motor control board issues if power reaches the board but not the motor.

Key takeaways

- Start safe. Unplug and use Safety Glasses and Work Gloves.

- Check power first. Outlet, GFCI, Circuit Breaker, Power Cord, On/Off Switch, Fuse.

- A bad Run Capacitor causes many “hum but no spin” cases.

- Clear blockages. Do cleaning blower motor and checking for debris in fan.

- For noise check bearings and rub spots. Fix motor vibration issues.

- Match parts to understanding blower specs and motor rating and wattage.

- Store it right. Dry and clean storage extends blower lifespan.

H2: What is inside your blower motor? Can you name the parts?

Let’s zoom in. A blower is simple at heart yet full of key parts.

- Electric Motor with Stator and Rotor

- Impeller Fan with strong Impeller Blades

- Motor Shaft joined to the fan

- Run Capacitor for start and run

- Thermal Overload Protector to stop heat damage

- Power Cord, On/Off Switch, and Fuse

- Motor Housing, Fan Guard, and sometimes an Air Filter (if applicable)

If you love to learn how the core works you will enjoy reading about stator core lamination and rotor core lamination and why they use electrical steel laminations to lower loss and heat. Better core stacks mean cooler runs which helps the Thermal Overload Protector stay quiet and keeps the blower strong.

H2: Can you diagnose the issue fast with a checklist?

I use a short diagnosing blower problems flow. It saves time when a Holiday Inflatable or inflatable waterslide blower repair pops up.

- “No power?” Think circuit breaker tripped blower, GFI tripping blower, power cord damage blower, faulty switch inflatable, fuse blown blower motor.

- “Hums only?” Think failed run capacitor, impeller obstruction removal, frozen motor shaft, seized bearings.

- “Weak air?” Think clogged air intake blower, air flow blockage blower, partially failed capacitor, worn motor bearings.

- “Overheats?” Think dust, blocked vents, motor thermal overload trip, bad Thermal Overload Protector.

For inflatable bounce house repair like a big Bounce House, these steps still apply. For small Holiday Inflatable fan repair the same flow fixes most calls.

H2: How do you open the blower and get to the parts?

Use how to open blower motor steps in the User Manual. Take out screws with your Screwdriver Set. Keep them in a cup. Lift the Motor Housing. Watch wires and the Fan Guard. Take a photo of wires so how to reassemble blower motor later is easy.

Set the parts on a clean towel. Do not lose the small clips. If you plan blower motor disassembly steps for bearing or brush work label each part.

H2: Are there special tests you should run with a meter?

Yes. Multimeter usage for blowers will save you hours.

- AC outlet test with Voltmeter

- Voltage test blower motor at switch and at the motor leads

- Continuity test blower wiring end to end with the Ohm Meter

- Testing a run capacitor in uF mode

- Ammeter clamp to read Amperage (Motor) draw under load

Use the readings to spot common electrical faults like open windings, short circuit blower motor, and weak capacitors. Readings far off from understanding blower specs mean a part has failed.

H2: What if you hear grinding or feel rough spin?

That rough feel is a clue. Try how to lubricate blower motor bearings if they are serviceable. If not do replacing blower bearings. You may need a puller and a small press. Keep parts clean. Do not bend the Motor Shaft.

Check the Impeller Fan for rub marks. A bent blade needs fan blade repair or a new wheel. Tighten mounts to cut motor vibration issues. Make sure you securing blower motor to the base.

H2: Can water cause motor failure?

Yes. Water Damage kills many blowers. Rain can slip in. Wet storage does harm. You will see rust. You will smell a burnt odor after power up.

Dry the unit well. Warm air helps. Check the Run Capacitor. Check the Thermal Overload Protector. Look for motor insulation breakdown and short circuit blower motor marks. If you see deep damage replace the motor or the whole blower.

H2: How do you pick parts that last longer?

Match the part first. Then choose quality. Read the label for Wattage (Motor) and Voltage (Power Supply). Pick a capacitor with the same capacitor value blower motor and equal or higher VAC rating.

For motor cores and rebuilds quality laminations matter. Better stator core lamination and rotor core lamination made from strong electrical steel laminations run cooler and waste less energy. That helps you avoid early heat stress and blower motor getting hot. It also protects the Thermal Overload Protector from nuisance trips.

H2: What about gardens, yards, and other uses?

I fix more than party blowers. A small garden blower repair uses the same steps. So do leaf air pumps and small Air Pump units. The core checks never change. Power first. Obstruction second. Capacitor third.

For holiday yard inflatable repair you often fight leaves and strings. Keep the inlet clear. For big inflatable waterslide blower repair watch long cords. They drop voltage. That makes motors hot. It can cause voltage fluctuations blower and slow spin.

H2: What if you are looking at brands and support?

Read your User Manual. Call customer support blower brand for parts. Manufacturer sites like Blast Zone or B-Air often have parts lists and help lines. Ask about lead time. Get warranty information blower in writing.

If they ask you to send the unit in ask for a quote. Compare motor replacement cost inflatable and cost of new blower motor with a new unit price. You now have the info to choose.

H2: Will a better cord and storage help?

Yes. A simple Surge Protector and a stout Extension Cord help a lot. Pick the right gauge for the run length that matches Amperage (Motor). Roll it on an Extension Cord Reel so you do not kink it.

Use proper blower storage. Wipe dust. Coil the cord loose. Keep it in a dry spot. I tape a small note with the test date so I keep blower motor maintenance on track.

H2: Full list of common issues you should check fast

This mini index makes sure you do not miss a step. Use it as a quick pass when you fix a blower.

- Troubleshooting AC blower motor

- electrical problem inflatable motor

- common reasons blower stops

- internal wiring check

- worn out carbon brushes

- motor shaft repair

- fuse blown blower motor

- grounding issues blower

- airflow sensor repair

- motor control board issues

- motor housing crack repair

- signs of motor wear

- understanding motor schematics

- how to reassemble blower motor

- finding replacement parts blower

- online blower repair resources

This little pass makes sure you cover every base when you work through your blower motor disassembly steps.

By the way, high quality cores and laminations help motors run cool and strong. If you like to go deeper into materials and design you can explore how the stator core lamination and rotor core lamination made from proven electrical steel laminations keep losses low which helps your blower start quick and stay cool.

References

- Manufacturer User Manuals for your specific blower model

- OSHA basic electrical safety guidelines

- Community electronics repair forums and capacitor testing guides

- NEC recommendations for outdoor extension cord use

- Brand support pages for Blast Zone and B-Air

Summary: most important things to remember

- Unplug first. Wear Safety Glasses and Work Gloves.

- Check outlet, GFCI, Circuit Breaker, Power Cord, On/Off Switch, and Fuse.

- Clear debris and fix air flow blockage blower before deeper work.

- Test and replace the Run Capacitor. It solves many “hums but no spin” cases.

- Lube or replace bearings if you hear grinding or feel drag.

- Watch heat. A hot case points to dust, a bad capacitor, or blocked vents.

- Store it dry. Use the right Extension Cord. Keep vents clear.

- Compare repair cost to a new unit. Check warranty information blower first.