How to Fix Low Compression in a Motor

Low compression steals power. It makes your car hard to start. It wastes fuel. In this guide I show you how to spot it fast and fix it right. I also share costs, tools, and simple steps you can do today. If you want your engine strong again you are in the right place.

Table of Contents

- What Is Engine Compression and Why It Matters

- What Are the Engine Low Compression Symptoms

- How to Test Engine Compression

- What Is a Leak-Down Test and How to Use It

- What Causes Low Engine Compression

- Can Low Compression Be Fixed Without Rebuilding

- Step-by-Step Low Compression Repair

- DIY vs Pro: Tools, Time, and Cost

- How to Prevent Low Engine Compression

- Diesel vs Gasoline: What Is Different

- Starter Motors, Alternators, and Laminations

- FAQs

- References

- Key Takeaways

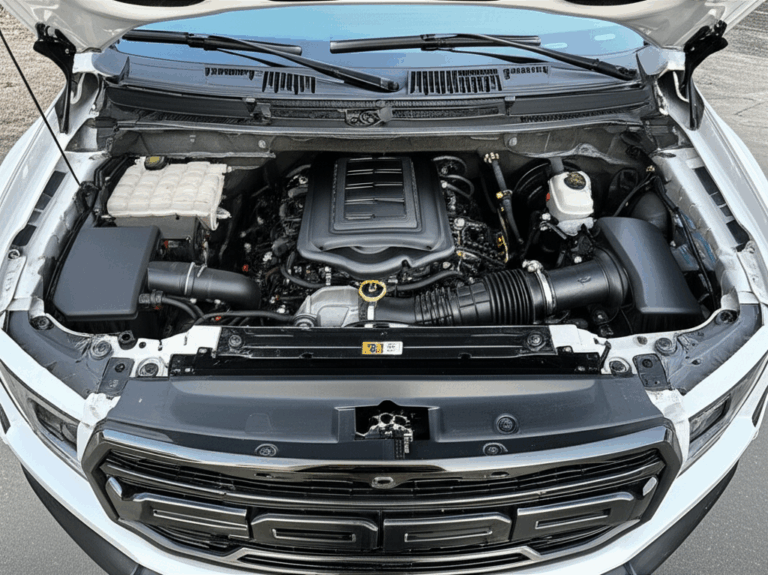

What Is Engine Compression and Why It Matters

Problem: Your engine feels weak. You press the gas and not much happens. That can be low compression.

Agitate: Low compression kills power and it hurts fuel economy. It can cause misfires. It can even stop the engine from starting.

Solution: Learn how engine compression works. Then test it. Then fix it. I will show you how.

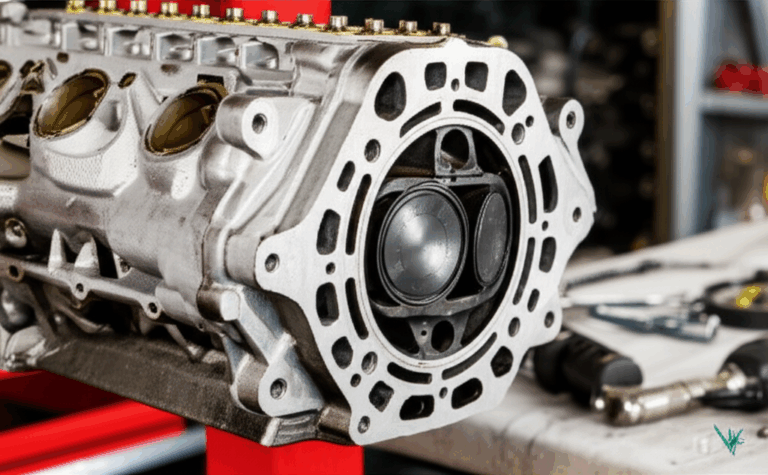

In simple words, compression squeezes air and fuel in the cylinders. The pistons go up. The mix gets tight. A spark plug lights it. Boom. Power. Good compression keeps that boom strong. Bad compression means the air leaks past piston rings, valves, or the head gasket. That hurts engine performance and can shorten engine lifespan.

You also hear about compression ratio importance. A higher ratio can boost power. It also can raise stress. Your engine maker sets the right ratio. Follow that spec.

What Are the Engine Low Compression Symptoms

I look for engine low compression symptoms like these:

- Hard starts or the engine won’t start low compression

- A rough idle and misfiring engine low compression

- Reduced power and acceleration

- Poor fuel economy low compression

- Engine knocking low compression or other noise

- Oil consumption low compression and smoke from exhaust low compression that looks blue or white

- A Check Engine Light for misfire codes

You may also smell fuel. You may see a drop in vacuum on an engine vacuum test low compression check. You may feel a stumble. If one hole is low you feel a shake. If all are low the engine feels lazy.

How to Test Engine Compression

Problem: You suspect low compression. You need proof.

Agitate: Guessing costs time. You might replace parts that are not bad. You may spend money twice.

Solution: Run a compression test. It is simple. It is the first win.

Tools you need: a compression tester (tool). A basic set runs cheap. You also need a ratchet and a spark plug socket. On diesel you use a special adapter.

Dry test steps:

What is acceptable engine compression? Check your engine compression specification lookup in the service manual. Most gas engines show 120 to 200 PSI. The average engine compression PSI varies by model. The key is how even they are. What is minimum compression difference? Keep each cylinder within 10 to 15% of the highest. If one is low you found the bad hole.

Now do a wet test. Add a teaspoon of oil to the low hole. People ask how much oil to add for wet test. A teaspoon is fine. Crank again. If the number jumps a lot your worn piston rings diagnosis is likely. If it does not change much the leak is at the valves or head gasket. That is the wet compression test vs dry trick.

What Is a Leak-Down Test and How to Use It

A compression leakage test tells you where the air goes. A leak-down tester (tool) sends air into the cylinder at top dead center.

How to use a leak-down tester:

Now listen. If you hear hissing in the intake manifold the intake valves leak. If you hear it in the exhaust system the exhaust valves leak. If it rushes out the oil filler you have engine blow-by past piston rings or piston lands. If bubbles show in the engine coolant you may have a blown head gasket, a cracked cylinder head, or engine block damage low compression.

This test helps with identifying which cylinder has low compression and spotting the common low compression issues. It also shows the difference between compression and leak down test.

What Causes Low Engine Compression

You asked what causes low compression in one cylinder. You asked what causes uneven compression. Here are the big ones.

- Worn or damaged piston rings: Rings can wear, stick, or break. A engine flush for sticky piston rings can free them if mild. Bad wear needs a tear down. High engine blow-by and blue smoke point here. You can also see symptoms of worn piston lands.

- Faulty valves or valve seats: A burnt valve, bent valve, or worn valve seats leak. You can hear a hiss in the intake or tailpipe on a leak-down test. A backfire hints at an exhaust valve. Yes can exhaust valve issues cause low compression. They can.

- Blown or leaking head gasket: Overheat the engine and the head gasket can fail. Then you get white smoke. Coolant loss. Milk in the oil. These are signs of blown head gasket low compression.

- Damaged cylinder head or engine block: A cracked cylinder head repair or warped head may be needed after a big overheat. Cylinder wall damage repair may need a sleeve if walls are scuffed or cylinder bore out of round. You may need a cylinder liner. People ask can a cylinder liner cause low compression. It can if it is worn or not sealed.

- Timing issues: A slipped timing belt or timing chain can hold valves open. So can a bad timing chain cause low compression. Yes. It can bend valves. It can also cause camshaft wear low compression when things go wrong. You can also have fixing lifter problems low compression if a lifter collapses and a valve does not open right.

- Other: Worn camshaft/lifters, valve spring issues, bent connecting rods, fuel injector issues low compression from wash down, spark plug condition low compression that hides the real cause, pre-ignition damage, and carbon buildup that scrubs ring seal.

You can also see low compression after engine overhaul if ring end gaps are wrong or the hone is off. You may wonder why is my new engine losing compression. Bad break in or wrong oil can be at fault. That is the importance of proper engine break-in.

Can Low Compression Be Fixed Without Rebuilding

This is a big one. Can low compression be fixed without rebuilding. Sometimes yes.

Cheapest way to fix low compression:

- Free sticky rings with an engine flush for sticky piston rings.

- Try using engine oil additives for compression. Pick a best compression restorer additive if your rings are stuck not worn.

- Set the engine valve adjustment low compression if your engine has adjustable valves.

- Fix small timing belt low compression fix issues before they get worse.

But if parts are worn or broken you need to fix them. That means a top end (engine) job or a bottom end (engine) job. It may mean an engine rebuild for low compression or engine reconditioning low compression. It may even mean engine remanufacturing or engine replacement. You also ask can low compression be fixed without rebuilding. If the cause is mild then yes. If not then no.

Step-by-Step Low Compression Repair

I use the PAS framework in the shop. We name the problem. We show the pain to agitate action. Then we offer the solution.

Repair Worn Piston Rings

Problem: The leak-down test points to the crankcase. The wet test jumps. You have worn or damaged piston rings.

Agitate: Oil use climbs. Power drops. The catalytic converter can clog from oil. Emissions go up. That is the impact of low compression on emissions.

Solution:

- Try a flush and a drive if rings stick. This is a short fix.

- If not, pull the engine. Inspect cylinders. Use cylinder wall honing if walls are smooth and in spec. Replace piston rings from an engine rebuild kit. Check torque specifications for connecting rods and crankshaft bolts. If walls are scuffed use how to fix scuffed cylinder walls steps or a sleeve. If the bore is out of round then fixing cylinder bore out of round may be needed at a machine shop.

Address Valve-Related Issues

Problem: You have a burnt valve or a seat that leaks.

Agitate: A single low compression cylinder fix is needed. You hear a pop in the tailpipe. The idle shakes.

Solution:

- Do a valve adjustment if needed. You can fix minor lash issues. You can also how to check valve clearances low compression with feeler gauges.

- Replace valve seals if you see oil at start and overrun. People ask about valve seal replacement cost. We cover cost soon.

- Pull the cylinder head. Do a valve grinding/replacement. Cut valve seats. Check valve guides. You can be replacing valve guides low compression if they are worn. Also check valve spring height and fix valve spring issues low compression.

Replace a Blown Head Gasket

Problem: You see white smoke and coolant loss. The test shows air into the coolant.

Agitate: Overheating warps heads. Oil mixes with coolant. Bearings suffer. That makes the bottom end engine problems low compression even worse.

Solution:

- Pull the head. Clean the block and head. Check the head for warp and cracks. Use dye or pressure test. Fix small cracks with a weld if safe or replace the head.

- Install a new head gasket. Follow the torque specifications and the proper sequence. Replace gaskets as needed. This is head gasket repair for low compression done right.

Fix Timing and Valvetrain Issues

Problem: The engine is out of time or the camshaft is worn or a lifter collapsed.

Agitate: Valves hit pistons on some engines. That bends valves. That adds cost.

Solution:

- Inspect and replace the timing belt/chain and the guides. People ask timing belt low compression fix and the answer is fix timing first. Then test again.

- Check camshaft wear low compression. Replace the camshaft and lifters if lobes are flat. That means fixing collapsed lifters low compression too.

Repair Cylinder Head and Block Damage

Problem: The head is cracked or the block is damaged.

Agitate: Coolant in oil ruins bearings. Oil in coolant ruins hoses. The leaks never stop until you fix the root.

Solution:

- You can try a weld on a small head crack. A good machine shop can tell you if it is safe.

- Replace the cylinder head if the damage is bad.

- Sleeve the block if needed. That means a cylinder liner. In severe cases do an engine overhaul or engine replacement.

Special Notes

- Check the PCV valve if you have blow-by. A stuck PCV can raise pressure and push oil past seals.

- Check the fuel injectors for wash down. Fuel injector issues low compression come from too much fuel that strips oil off walls.

- Check spark plug condition low compression. The plugs can tell a story about each cylinder.

DIY vs Pro: Tools, Time, and Cost

You can do many checks at home. DIY low compression repair makes sense for tests and simple parts. For deep work use a mechanic/technician you trust. Here is a guide.

Tools You Need

- Compression tester

- Leak-down tester

- Torque wrench

- Basic hand tools

- Straight edge and feeler gauges

- Shop air if you do leak-down

- Optional: engine hoist for pulls

- Other tools for engine compression repair as needed

Cost and Outcomes

| Component/Issue Causing Low Compression | Likelihood/Prevalence | Typical Symptoms | Common Fix/Repair | Estimated Repair Cost (Parts + Labor) | Durability/Success Rate After Fix | Notes/Data Source |

|---|---|---|---|---|---|---|

| Worn/Stuck Piston Rings | Very High (30-40%) | Oil use, blue smoke, blow-by, power loss | Flush minor or piston ring replacement with hone | $1,500 – $4,000+ | High if cylinders are good | Repair manuals and engine rebuilders |

| Burnt/Bent Valves | High (20-30%) | Misfires, power loss, backfiring | Valve replacement and seat grind | $1,000 – $3,500+ | High | Machine shop data |

| Blown Head Gasket | High (15-25%) | Overheating, white smoke, coolant loss | Head gasket replacement and head check | $800 – $2,500+ | High if head is good | Consumer quotes and shop guides |

| Warped/Cracked Cylinder Head | Moderate (10-15%) | Persistent low compression, leaks | Head repair or replacement | $1,500 – $4,500+ | High | Engine rebuilding associations |

| Worn Valve Guides/Seals | Moderate (5-10%) | Oil use, smoke, carbon buildup | Guide and seal replacement | $800 – $2,000+ | High | Repair manuals |

| Worn Camshaft/Lifters | Moderate (5-10%) | Ticking, power loss, misfires | Camshaft and lifter replacement | $1,200 – $3,000+ | High | OEM data and forums |

| Damaged Cylinder Walls | Low (2-5%) | Severe oil use and blow-by | Re-bore or sleeve or replace engine | $2,500 – $7,000+ | High if pro built | Specialized shops |

| Timing Issues (Belt/Chain) | Low (1-3%) | No start and bent valves | Timing parts and valve repair | $500 – $2,000 belt only | High | OEM intervals |

People ask how much does engine compression test cost. A shop may charge $75 to $200. A leak-down test can add more. Professional low compression repair cost depends on parts, labor, and your car.

Will you need to replace engine due to low compression. If the fix costs over half the car value you may replace or buy a reman engine. You can ask about the cost of engine remanufacturing for low compression and compare. You can also ask for engine reconditioning low compression quotes.

How to Prevent Low Engine Compression

You can save money with simple habits.

- Do regular oil changes on time. Use the right engine oil grade. Many use synthetic oil for low compression engines because it resists breakdown. It will not fix wear. It can help protect parts.

- Watch the engine coolant level. Fix leaks. Avoid engine overheating low compression damage.

- Warm the engine before you push it. Avoid lugging in high gear. That is proper driving habits.

- Keep up with best practices for engine maintenance. Replace filters. Use good fuel injectors and spark plugs.

- Run a regular compression check if you tow or track. It is cheap. It gives you a baseline.

- Keep the PCV valve clean to cut blow-by pressure.

- Fix common causes of oil leaks low compression early so oil stays where it belongs.

You want the benefits of high compression like power and efficiency. You do not want the risks of hot spots. Follow the engine dynamics set by the maker. If you mod the engine watch for impacts of pre-ignition on compression and detonation.

Diesel vs Gasoline: What Is Different

A diesel engine low compression fix follows the same plan. The tests use different adapters. Diesel compression runs much higher. Always use the right tester. Glow plugs come out for the test.

A gasoline engine low compression repair uses the steps you saw above. Gas engines use a spark to light the mix. Diesels use heat. The compression ratio is key for both.

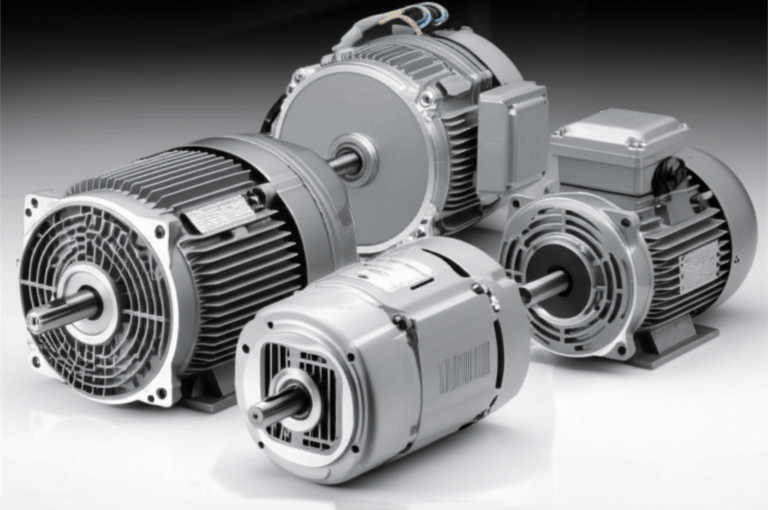

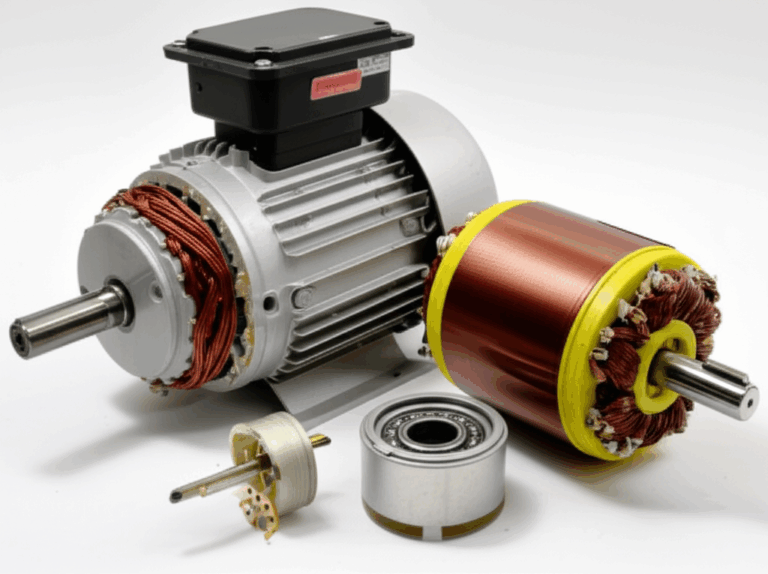

Starter Motors, Alternators, and Laminations

One quick note. We spoke about engines a lot. Cars also use electric motors in starters and pumps. If you service or build motors then the iron and steel inside matters. The quality of the motor core laminations can change heat, noise, and life. A starter has a stator and rotor. If you want a primer read this clear guide on stator and rotor. Good stator core lamination and rotor core lamination reduce losses and boost output. You can learn more about stator core lamination and rotor core lamination from specialists who make them for industry use.

Why bring this up here. Because some misfires and slow cranking look like compression loss when the starter turns too slow. A healthy starter helps you test compression right. It spins the engine fast so every PSI reads true.

FAQs

Q: What are the consequences of low engine compression

A: You get hard starts, misfires, bad power, rich fuel trims, and poor MPG. The catalytic converter can fail from oil. You can overheat. The engine can die.

Q: How long can you drive with low compression

A: Not long without risk. A weak hole can wash down and score a wall. That makes a small problem a big one. This is one of the real risks of ignoring low compression.

Q: What is the cheapest way to fix low compression

A: Free sticky rings with a flush and a compression restorer additive. Set valve lash. Fix small leaks. These work only on mild cases. Worn parts need real repairs.

Q: What if compression is too high

A: That can mean heavy carbon buildup or the wrong parts. Clean the carbon. Check the head and gasket thickness and the compression ratio.

Q: When should I find a reliable mechanic for low compression

A: If you need head work, ring jobs, timing set service, or machine work. You can test at home. You can do light fixes. Big jobs need a mechanic/technician with experience.

Q: Does engine age change compression

A: Yes. The impact of engine age on compression is real. Wear grows. Seals harden. Regular care slows it.

Q: How do I improve engine compression

A: Fix leaks. Use the right oil. Keep parts in spec. Do good engine break-in on rebuilds. That is how to improve engine compression for the long run.

Q: What happens if you drive with a bad valve

A: You can burn it more. You can damage the seat. You can lose a lot of power. Stop and fix it.

Q: Do I need an engine tear down low compression

A: You may. If the leak is in rings, walls, or rod shape then yes. That is an engine tear down low compression case.

Q: Why do I have low compression after head replacement

A: The head may be too short after a heavy cut. The timing may be off. The valves may not seat. These are real causes of low compression after head replacement.

References

- OEM service manuals and torque data for your vehicle make and model

- ASE and I-CAR training materials on engine diagnostics

- AAA consumer guidance on repair decisions and DIY limits

- Automotive machine shop best practices for valve and cylinder work

- Engine rebuilders association publications on honing and ring seating

- Consumer publications on typical repair costs by job type

PAS in Action: A Short Case

Problem: A customer came in with poor power and a shake. They feared the worst.

Agitate: The truck could not tow the small boat. Fuel costs jumped. Family trips stalled.

Solution: We ran a dry and wet compression test. One hole was down. The wet test jumped. We added a flush and a short drive. Compression rose into spec. We planned a ring job in six months. The truck towed just fine on the next trip.

Company Information and How We Help

I have turned wrenches for years. My team follows clear steps. We explain each test before we do it. We use OEM parts when needed and high grade aftermarket parts when they make sense. We share photos of the engine bay and parts like the head gasket, pistons, valves, valve guides, valve seats, pushrods, lifters, camshaft, connecting rods, crankshaft, and the engine block. We share torque specifications. We stand by our work.

We carry engine rebuild kit options. We can do engine overhaul and engine reconditioning. We also install OEM parts and test with the right tools. If you work on electric motors too we can point you to trusted makers of laminations and steel cores. We want to be your guide from test to road test.

Understanding Compression Test Results

Let’s tie it all up.

- If one cylinder is low you likely have a valve or ring issue in that hole.

- If two next to each other are low think head gasket.

- If all are low think timing or wear.

- If the wet test adds PSI then rings. If it does not then valves or head gasket.

Use data. Make the call. That is understanding compression test results like a pro.

Extra Checks Most People Miss

- Check PCV valve and lines to control engine blow-by.

- Inspect plugs. A clean wet plug can show a coolant leak. A black oily plug can show oil use.

- Scan the engine management system (ECU) for fuel trims. Rich trims can come from low compression.

- Check intake manifold gaskets and exhaust system for leaks that confuse tests.

- Confirm fuel injector issues low compression are not the first cause. Replace or clean if needed.

- Verify spark plug condition low compression is not masking a dead hole.

Time, Value, and Next Steps

Think about cost to reseal engine for low compression vs value. Ask for a full quote. Ask about piston ring replacement cost, valve seal replacement cost, and head gasket repair for low compression. Ask about options like engine remanufacturing, engine replacement, or a used engine. Pick the path that fits your budget and your car’s life.

If you keep the car long term a bottom end engine problems low compression rebuild can be wise. If the car is near the end then a small fix or sale can be fair. It is your call.

Final Thought on Safety and Emissions

Low compression raises emissions. It can foul the catalytic converter. It can dump raw fuel. Fix it early. You will save fuel. You will breathe cleaner air. Your engine will thank you.

Key Takeaways

- Low compression hurts power and MPG. It also can stop starts.

- Test first. Do a dry test and a wet test. Then do a leak-down test.

- Use the PAS plan. Name the problem. Feel the pain. Pick the solution.

- Rings, valves, head gaskets, and timing cause most issues.

- Small fixes help mild cases. Worn parts need real repairs.

- Match the job to your budget and the car’s value.

- Keep oil and coolant fresh. Avoid heat. Check PCV. That prevents many failures.

- Common phrases to remember for your notes:

- causes of low engine compression

- step-by-step low compression repair

- diagnosing engine compression loss

- preventing low engine compression

- when to replace engine due to low compression

- Use good parts and follow torque specs. That keeps the top end and bottom end tight.

- If you also work with electric motors make sure the laminations are high grade so starters and pumps run strong.