How to Measure Motor Efficiency: A Practical Guide to Uncover Energy Savings

Are your energy bills creeping up? It feels like you’re paying more and more for electricity, but you’re not sure why. A big, hidden cause could be your electric motors. They power almost everything in a factory or large building, and if they are not efficient, they are just wasting your money. This guide will show you, step by step, how to find out if your motors are wasting energy. You’ll learn simple ways to measure their efficiency and find huge opportunities for energy savings.

Table of Contents

- What is Motor Efficiency Anyway?

- Why Should I Bother Measuring It?

- What are the Main Ways to Measure Efficiency?

- What Tools Do I Need for the Job?

- How Do I Measure Efficiency in My Facility? (A Simple Guide)

- My Motor’s Efficiency is Low. What’s Wrong?

- How Can I Make My Motors More Efficient?

- Should I Repair or Replace an Old Motor?

- Sinolami: The Heart of an Efficient Motor

- Key Takeaways to Remember

What is Motor Efficiency Anyway?

Think of a motor like a bucket you use to carry water. If you pour 10 gallons of water in, but only 9 gallons make it to the destination because of a leak, your bucket is 90% efficient. An electric motor works the same way. It takes in electrical power and turns it into mechanical power to do work, like spinning a fan or a pump.

Motor efficiency is just a number that tells us how good the motor is at changing electricity into useful work. The formula is simple:

Efficiency (%) = (Output Power / Input Power) x 100

But no motor is perfect. Some energy is always lost. This lost energy turns into heat. These losses are the “leaks” in our bucket. There are a few main types of losses in electric motors:

- Copper Losses: This is heat created by electricity moving through the copper wires inside the motor’s core parts, the stator and rotor.

- Core Losses: The metal heart of the motor, called the core, also loses energy as it magnetizes and demagnetizes. This is where the quality of the stator core lamination becomes very important. Better materials mean fewer losses.

- Friction and Windage Losses: This is just like it sounds. The motor’s bearings cause friction, and the cooling fan inside creates air resistance (windage).

- Stray Load Losses: These are the small, miscellaneous losses that are harder to measure. Think of them as tiny, hard-to-find leaks.

Why Should I Bother Measuring It?

You might be thinking, “This sounds complicated. Why should I care?” The answer is simple: money. Electric motors use a huge amount of electricity. In fact, studies from the U.S. Department of Energy show they can account for over 60% of all industrial electricity use. That’s a massive slice of your energy bill.

When a motor is inefficient, it’s like leaving a window open while the air conditioning is on. You’re paying for energy that is just turning into wasted heat. Imagine you have a 100 horsepower (HP) motor that runs all day. If you improve its efficiency by just a few percentage points, you could save thousands of dollars per year on that one motor alone. Now, multiply that by all the motors in your facility. The economic benefits add up fast.

Beyond the energy savings, measuring and improving motor efficiency helps your business in other ways. An efficient motor runs cooler, which means it will last longer and need fewer repairs. This improves reliability and cuts down on surprise breakdowns. It also reduces your company’s carbon footprint, which is great for the environment. Measuring efficiency is the first step in a good predictive maintenance program.

What are the Main Ways to Measure Efficiency?

Okay, so you’re convinced. But how do you actually do it? There are two main methods for measuring motor efficiency.

1. The Direct Method (Input-Output)

This is the most accurate way, but it’s usually done in a lab. For this method, you measure the electrical power going into the motor and the mechanical power coming out of the shaft at the same time. You need special equipment like a dynamometer, which acts like a treadmill for the motor, to measure the output torque and speed.

- Pros: Very accurate. It’s the gold standard.

- Cons: Expensive and almost impossible to do on a motor that’s already installed and running equipment in your factory.

2. The Indirect Method (Sum of Losses)

This is the practical choice for most people. It’s also called the “in-situ” method because you can do it while the motor is in place. Instead of measuring the output power directly, you measure the input power and then calculate all the losses we talked about earlier (copper, core, etc.). Then you subtract the losses from the input power to find the output power.

- Pros: Much easier to do in a real-world setting. You don’t have to disconnect the motor from its load.

- Cons: Not quite as accurate as the direct method because you have to estimate some of the losses. However, it’s still very useful for finding problem motors.

Standards like IEEE 112 (Method B) and IEC 60034-2-1 provide detailed steps for using this method.

What Tools Do I Need for the Job?

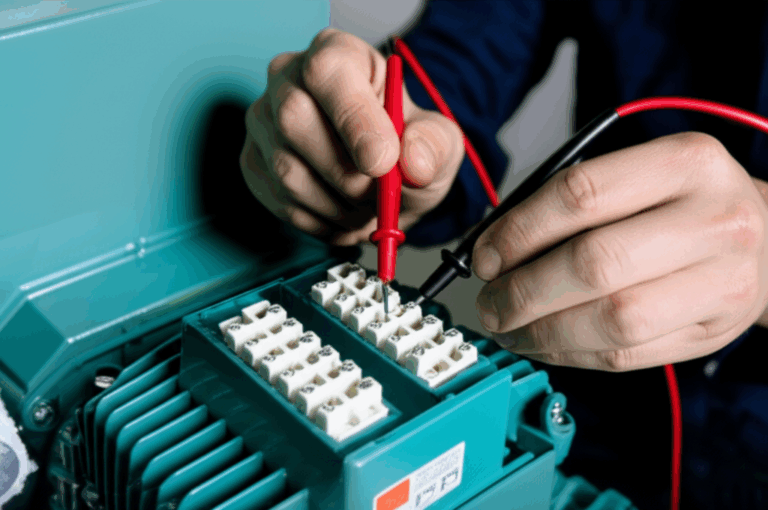

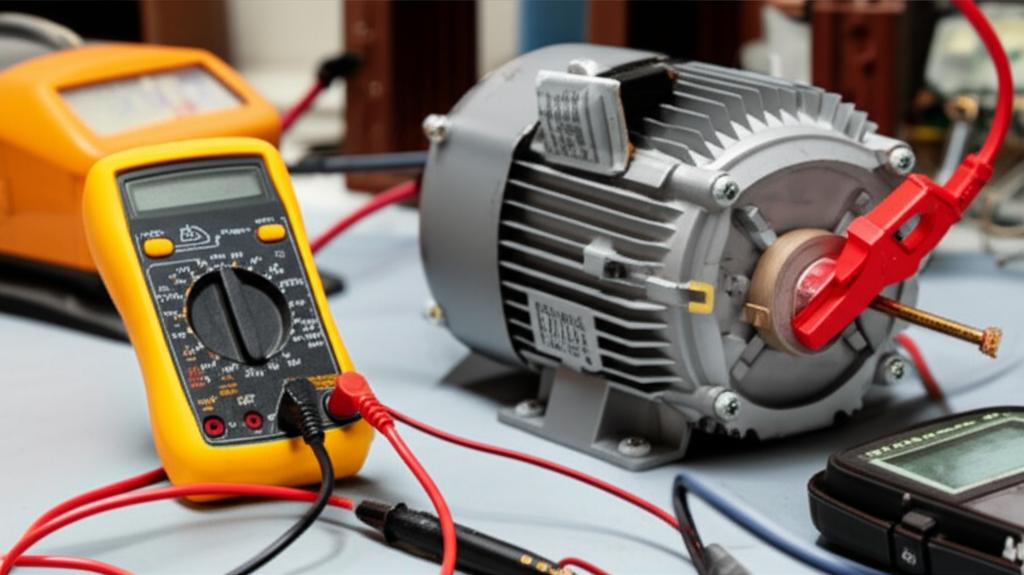

You don’t need a whole laboratory, but you do need a few key pieces of motor efficiency testing equipment.

| Tool | What It Does | Why You Need It |

|---|---|---|

| Power Analyzer | Measures electrical power accurately. | It tells you the exact input power the motor is using, including voltage, current, and power factor. |

| True RMS Clamp Meter | A simpler tool that clamps around a wire. | Good for quick checks of current and voltage. Some can also measure power. |

| Digital Tachometer | Measures the speed of the motor shaft (RPM). | You need to know how fast the motor is spinning to understand its performance. |

| Digital Multimeter | Measures voltage and resistance. | Useful for checking the motor’s winding resistance to calculate copper losses. |

| Infrared Thermometer | Measures temperature without touching. | A motor that’s too hot is a sign of inefficiency. |

A data logger is also helpful if you want to monitor the motor’s performance over a longer period to understand its load profile.

How Do I Measure Efficiency in My Facility? (A Simple Guide)

Let’s walk through a practical, step-by-step motor efficiency calculation using the indirect method.

Step 1: Be Safe!

Before you do anything, follow all safety rules. This includes proper Lockout/Tagout (LOTO) procedures if you need to attach any sensors directly. Safety first, always.

Step 2: Gather Nameplate Data

Look at the motor’s nameplate. Write down its rated horsepower (HP) or kilowatts (kW), voltage, full-load current (amps), and full-load speed (RPM). This tells you what the motor should be doing.

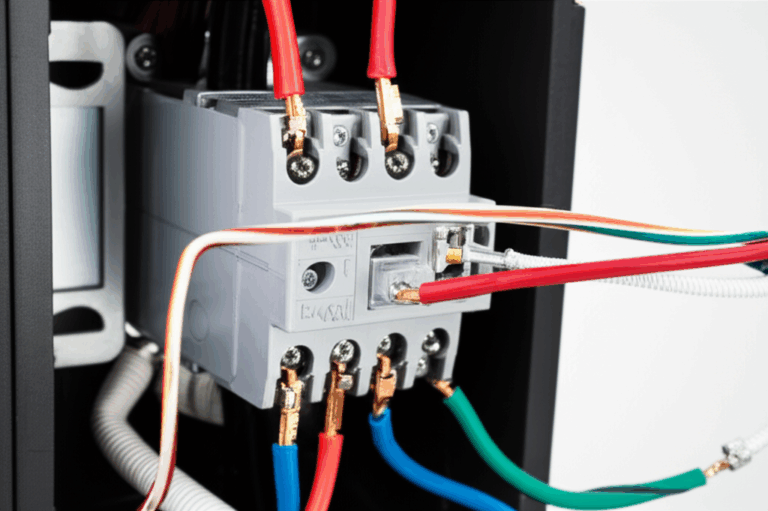

Step 3: Measure the Electrical Input Power (P_in)

With the motor running under its normal load, use your power analyzer or clamp meter to measure the voltage (V) and current (A) for all three phases. Also, get the power factor (PF). The formula for three-phase power is:

Input Power (kW) = (Voltage x Current x Power Factor x 1.732) / 1000

Step 4: Estimate the Losses

This is the trickiest part of the indirect method.

- Copper Losses: You can calculate these if you measure the resistance of the stator windings with your multimeter when the motor is off and cool. The formula is P_copper = 3 x (Current)² x Resistance.

- Core, Friction, and Windage Losses: These are often found by doing a no-load motor testing. This means running the motor when it is disconnected from its load. The power it draws is just enough to overcome these fixed losses. If you can’t do that, you can use standard values from charts provided by organizations like the Department of Energy.

- Stray Load Losses: These are usually estimated as a small percentage (around 1-2%) of the motor’s output power.

Step 5: Calculate the Efficiency

Now you have all the pieces. First, find the output power:

Output Power = Input Power – Total Losses

Then, use the efficiency formula:

Efficiency (%) = (Output Power / Input Power) x 100

Compare this number to the efficiency listed on the nameplate. If your measured efficiency is much lower, you may have a problem.

My Motor’s Efficiency is Low. What’s Wrong?

So you did the test and the result isn’t great. Don’t worry. This is the first step to fixing the problem. A low efficiency reading is often a symptom of a deeper motor problem. Here are some common causes:

- Incorrect Sizing: A motor is most efficient when it’s running between 75% and 100% of its full load. If you have a huge motor doing a tiny job (under-loading), its efficiency will be terrible. This is a very common issue.

- Poor Power Quality: Your motor needs clean, stable power. Problems like voltage imbalance (where the voltage in the three phases isn’t equal) or harmonics (distortions in the electrical signal) can create extra heat and waste a lot of energy.

- Aging and Wear: Over time, bearings wear out, and insulation on the windings can break down. This increases friction and electrical losses.

- Poor Maintenance: A motor that isn’t regularly lubricated and cleaned will run hotter and less efficiently. A simple motor maintenance best practice is to keep it clean and listen for unusual noises from the bearings.

How Can I Make My Motors More Efficient?

Once you’ve identified an inefficient motor, you have several ways to improve the situation. These motor efficiency improvement strategies can have a big impact.

Should I Repair or Replace an Old Motor?

When an old motor fails, you have a choice: repair it or replace it. For many years, people would just rewind the motor. However, rewinding motor efficiency can be a gamble.

A high-quality rewind from a good shop can maintain most of the motor’s original efficiency. But a bad rewind can easily reduce efficiency by a few percentage points. That might not sound like much, but over the motor’s life, that lost efficiency will cost you far more in electricity than the cost of a new motor.

A good rule of thumb is to look at the life cycle cost. This includes the purchase price, repair costs, and the cost of electricity over its entire life. More often than not, buying a new NEMA Premium efficient motor is the smarter financial decision in the long run, especially for motors that run many hours per year.

Sinolami: The Heart of an Efficient Motor

A motor’s efficiency isn’t magic. It’s the result of smart design and high-quality materials. At the very core of every great electric motor are the laminations—thin sheets of steel that make up the stator and rotor. The quality of these components has a direct impact on core losses, one of the biggest enemies of efficiency.

At Sinolami, we specialize in manufacturing precision motor core laminations from the best electrical steel. Our products are engineered to minimize energy loss, reduce heat, and help motor manufacturers build the most efficient motors on the market, from standard induction motors to advanced permanent magnet designs. By focusing on the quality of the core, we help create motors that save you money and protect the environment.

Key Takeaways to Remember

Measuring motor efficiency is a powerful way to cut costs and improve your operations. Here are the most important things to remember:

- Efficiency is a big deal. Motors use a lot of electricity, and even small improvements can lead to huge savings.

- You can measure it yourself. The indirect method (sum of losses) is a practical way to test motors in your facility.

- You need the right tools. A power analyzer, clamp meter, and tachometer are essential for getting good measurements.

- Low efficiency has a cause. It’s usually due to improper sizing, poor power quality, or motor age.

- You can fix it. Strategies like installing VFDs and upgrading to NEMA Premium motors offer a great return on investment.

- Think long-term. When a motor fails, replacing it with a new high-efficiency model is often cheaper than a rewind when you consider the life cycle cost.