How to Reset Your Blower Motor: A Comprehensive Troubleshooting Guide (Car & Home HVAC)

Table of Contents

- Introduction: What “resetting” a blower motor really means

- Safety first: Precautions you do not skip

- How I reset or revive a blower motor step by step

- Check the fuse or circuit breaker

- Inspect the blower motor relay

- Examine the blower motor resistor or control module

- Power cycle the system

- Look for thermal overload protection

- Deeper diagnostics if the quick reset does not work

- Multimeter checks you can trust

- Wiring harness and ground checks

- Fan speed control problems and resistor logic

- Capacitors, ECM modules, and variable speed motors

- HVAC control board and thermostat checks

- Real‑world examples from my garage and my furnace room

- When to call a professional

- Preventative maintenance that keeps the air moving

- Quick troubleshooting checklists

- FAQs

- Conclusion: Get your airflow back without guesswork

Introduction: What “resetting” a blower motor really means

When my blower motor quits, I do what you probably do. I look for a reset button. Sometimes I find one. Most of the time I do not. That is the truth. “Reset” in the blower world usually means one of three things:

- Power cycling the system to clear a temporary glitch.

- Resetting a tripped breaker or a motor’s thermal overload.

- Fixing the reason the protection tripped in the first place.

Whether it is a car HVAC blower or a home furnace fan, the symptoms feel the same. No air coming from the vents. The heater fan not working on a cold morning. The car AC fan not blowing on a hot day. Sometimes the fan works only on high speed. Sometimes it runs intermittently or clicks and stalls. I have seen all of it in my driveway and in my basement.

In this guide I will show you what has worked for me. I will cover fuses, relays, resistors, control modules, and basic HVAC blower fan troubleshooting. I will walk you through a safe reset for both automotive and home systems. Then I will show you what to do if the simple stuff fails. I keep it simple. I start with the cheapest and fastest checks. Then I move deeper only if needed.

A quick note before we dive in. People often assume low refrigerant or a bad AC condenser fan causes the blower to stop. That is a different circuit. The blower moves air across the heater core and evaporator coil. Refrigerant level, the condenser unit, or a frozen evaporator coil can cause poor cooling. They do not usually make the interior fan go dead. If the fan is dead, focus on power flow to the blower motor first.

Safety first: Precautions you do not skip

Electricity does not care how handy you feel today. Respect it.

- For cars:

- Turn the ignition off. Remove the key.

- Disconnect the negative terminal of the car battery if you will unplug connectors or handle wiring. That protects you and it protects the climate control panel and the HVAC control module.

- For home HVAC:

- Turn off the main breaker feeding the furnace or air handler. Do not trust the wall switch alone.

- Verify power is off at the unit.

- Use the right tools:

- A multimeter that reads DC and AC voltage, ohms, and amperage.

- A fuse puller and spare fuses of the correct amperage.

- Insulated screwdriver. Nut drivers or a socket set.

- Flashlight and gloves. Eye protection helps when you work under the dash or inside a furnace compartment.

- Understand the risks:

- Electrical shock. Short circuits. Spinning fan blades.

- A blower motor can start suddenly while you test. Keep fingers clear.

I like to say it out loud before I start. Power off. Hands clear. Test once. Test twice.

How I reset or revive a blower motor step by step

I use the same flow in a car or a home HVAC system. Power must reach the blower motor through protection and control. I chase that path in order.

Check the fuse or circuit breaker

This fixes more “dead fan” calls than anything else. Fuses and breakers protect the circuit. They also “reset” a lot of problems by forcing you to find a short or an overload.

- Locate:

- Car: You usually have a fuse panel under the dashboard and one under the hood. Look for labels like “blower motor,” “HVAC,” “heater,” or “AC.” The owner’s manual or the fuse panel diagram will point you to the blower motor fuse location.

- Home: Go to the main electrical panel. Look for the breaker feeding the furnace or air handler. Some systems have a service switch and a cartridge fuse near the unit.

- Identify and inspect:

- Car blade fuses show a tiny metal filament. If it is broken or blackened, it is blown.

- Home breakers show a tripped position. Move them fully off then back on to reset.

- Action:

- Replace a blown fuse with the correct amperage only. Do not upsize the fuse.

- Reset a tripped breaker once. If it trips again, stop. You may have a short circuit or a seized blower motor drawing too much current.

Quick tip. If a car fuse blows immediately, unplug the blower motor and try again with a new fuse. If the new fuse holds with the motor unplugged, the motor may be shorted or stuck. If the fuse still blows, look for a shorted wiring harness or a failed blower motor resistor.

Inspect the blower motor relay

Relays handle heavy current without burning up the dashboard switch or the climate control panel. They fail more often than you think.

- Locate:

- Car: The blower motor relay often sits in the engine bay fuse box or under the dash near the HVAC harness.

- Home: Some furnaces have a fan relay on the control board or as a separate cube relay.

- Test:

- If the relay matches another one nearby, swap it briefly with a known good twin like a horn relay. If the blower wakes up, replace the relay.

- You can also check for click and coil resistance with a multimeter.

- Action:

- Replace a suspect relay. They are inexpensive compared to the time you spend chasing intermittent blower motor operation.

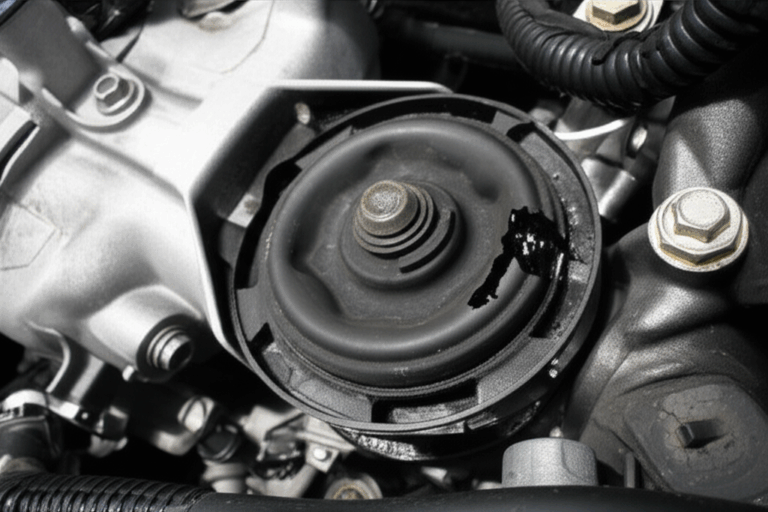

Examine the blower motor resistor or control module

This part controls fan speeds. In many cars with manual controls, the resistor drops voltage to give you speed 1 through 3. High speed bypasses the resistor. If your fan only works on high speed, the resistor is the number one suspect. If none of the speeds work, it can still be the resistor or the control module in automatic climate systems.

- Locate:

- Car: Usually near the blower motor behind the glove box or under the dash. Two screws and one harness plug hold it.

- Home HVAC: Variable speed blowers use an ECM control module that mounts on the motor or in the air handler. Single speed AC motors use a fan relay and a capacitor rather than a resistor.

- Inspect:

- Look for burnt spots, melted connectors, or corrosion. A resistor that overheats leaves a brown mark and a smell you will not forget.

- Action:

- Replacement is the fix. You do not reset a failed resistor. You swap it. For ECM modules, you may try a power cycle. If it still acts up, the module or the motor may need replacement.

Power cycle the system

Here is the “reset” most people look for. It clears temporary glitches in control modules and climate control units.

- Vehicle:

- Disconnect the negative battery terminal for 5 to 10 minutes. Reconnect. Start the car and test the blower. This can reset the HVAC control module and clear a stuck state in the climate control panel.

- Home HVAC:

- Turn off the breaker feeding the furnace or air handler for 5 to 10 minutes. Turn it back on. Some systems also have a small reset button on the control board. Follow the manufacturer’s instructions if present.

I have had cars regain all fan speeds after a battery reset. I have also had furnaces respond after a control board power cycle. It will not cure a dead motor. It can clear a software burp.

Look for thermal overload protection

Many motors protect themselves with a thermal overload protector or a resettable fuse inside or on the housing. If the blower overheats, it stops until it cools.

- Locate:

- Home HVAC motors sometimes have a small button on the motor shell. Not all do. Many internal protectors reset automatically once the motor cools.

- Action:

- Let the motor cool for 30 minutes. Press the reset if present. If it runs again then trips later, find the cause. A clogged air filter, a blocked return, a dirty squirrel cage fan, or a failing bearing will cook a blower motor.

- Underlying cause:

- Do not just reset and walk away. Overheating repeats if you do not fix airflow or a mechanical bind.

Deeper diagnostics if the quick reset does not work

When the fuse and relay check out and a power cycle does nothing, I grab a multimeter. The next steps tell you if you have a no power issue, a bad ground, a failed resistor, or a worn out blower motor.

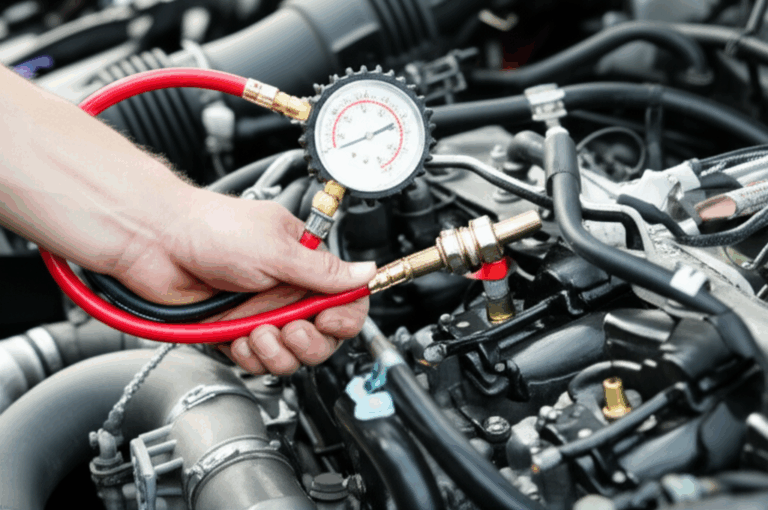

Multimeter checks you can trust

- Verify power at the motor connector:

- Car DC motor: With the fan switch on high, back‑probe the blower motor positive wire. You should see battery voltage. If you do not, work upstream. Check the blower motor fuse, the relay output, and the blower motor resistor input.

- Home AC motor: With the thermostat set to fan ON, check for 120 VAC or 240 VAC at the motor leads depending on your system. If power is missing at the motor, suspect the fan relay or the control board.

- Check ground:

- Many blower motor failures trace to a poor ground. Use a voltage drop test from the blower ground wire to the chassis ground in a car. Anything over 0.2 V on the ground side under load tells you the ground path is dirty. Clean the ground connection.

- Amp draw:

- A blower motor that pulls too many amps will blow fuses. Compare measured draw to spec if you have it. If not, compare to a known good similar vehicle or look for a pattern like fuse blows on high only which often means high amp draw from a worn motor or a restricted fan.

Wiring harness and ground checks

I have found loose connectors and corroded pins more times than I can count. Wiggle test the harness while the blower runs. If it cuts out, inspect the connector for heat damage. Clean or replace as needed.

- Look for:

- Melted blower motor connector.

- Burnt resistor plug.

- Chafed wires under the dash or near the blower housing.

- Ground eyelets on a rusty body panel. Remove the bolt. Clean to bright metal. Reinstall tight.

Fan speed control problems and resistor logic

If the fan only works on high, the resistor or the resistor wiring is the classic failure. If no speed works, test the resistor input.

- How I test:

- With the connector unplugged, measure resistor coil resistance with ohms. Open circuits mean failed coils. Some designs use a solid state control module for variable speed. Those require voltage checks rather than ohms.

- Bypass as a diagnostic only:

- You can briefly bypass the resistor to feed full power to the blower to prove the motor works. Do not leave it that way. You will overheat the wiring and you will lose speed control.

Capacitors, ECM modules, and variable speed motors

Home HVAC blowers vary by design.

- PSC motors:

- Many older furnaces use permanent split capacitor motors. A bad run capacitor can make the motor hum then stall. If you nudge the squirrel cage and it starts, suspect the capacitor. Test with a capacitance meter or swap with a known good capacitor of the same microfarad rating and voltage.

- ECM variable speed motors:

- Newer systems use ECM or variable speed blower motors. They run on a control module that decides fan speed. These are efficient and smooth. They are also more complex. You can power cycle the system. If the motor still fails to respond to the thermostat command, the ECM module may be at fault. Some models store HVAC diagnostic codes on the control board as blinking LEDs. Check for code charts inside the furnace door.

- Automotive climate control modules:

- Many vehicles use a blower motor control module instead of a simple resistor. People call it a final stage unit in European cars. If the fan surges or cuts out randomly, this module often fails. Replacement fixes it.

HVAC control board and thermostat checks

When the blower does nothing in a home system, make sure the thermostat is calling for fan.

- Thermostat and low voltage:

- Set the thermostat to FAN ON. If the fan still does not run, jump the G terminal to R at the control board. If the blower runs, the thermostat or the thermostat wiring is suspect. If it does not, the fan relay or the control board may be faulty.

- Furnace limit switch reset:

- Some furnaces lock the blower when the limit switch trips due to overheating. Let the unit cool. Reset the limit switch if it has a manual reset. Then find out why it overheated. A clogged filter is a common cause.

Real‑world examples from my garage and my furnace room

Two stories stick with me. They taught me to start simple and to trust the meter, not my gut.

- The car that only blew on high:

- My friend’s sedan had a heater fan not working on speeds 1 through 3. High worked fine. I pulled the glove box and found the blower motor resistor mounted with two screws near the blower. The connector was melted. The resistor coils were cooked. I replaced the resistor and the pigtail. I cleaned the blower motor ground. I replaced the cabin air filter which was clogged. All speeds came back. Lesson learned. Fan only works on high speed means the resistor failed or the connector burned due to heat.

- The furnace that ran for five minutes then quit:

- My own furnace fan would start, run five minutes, then stop. The house sat quiet for fifteen minutes. Then it would try again. I checked the air filter. It was dirty. I cleaned the squirrel cage. It was packed with dust. I measured amp draw. It ran high. I found the motor’s thermal overload protector was cycling. I replaced the filter. I cleaned the blower wheel and the evaporator coil. The motor cooled down and stopped tripping. It still sounded rough so I scheduled a blower motor replacement before winter.

When to call a professional

I love DIY. I also know my limits.

- Call a professional automotive technician when:

- You have no power at the blower motor but the fuses and relays check out. The issue may sit in the climate control unit or the wiring harness inside the dash. Dashboard removal for blower motor service is no picnic.

- Your vehicle uses a complex HVAC control module tied to the ECU. Some cars need scan tool access for diagnostic trouble codes in the climate system. An OBD‑II scanner that reads body modules helps, not just a basic engine code reader.

- Call an HVAC technician when:

- The furnace control board shows fault codes you cannot clear. The blower motor is a variable speed ECM unit with a failed module. You suspect low voltage thermostat wiring faults you cannot trace. The blower motor capacitor tests good and the motor still will not start.

- You feel uncomfortable around high voltage. That is a smart decision.

Professional diagnosis costs real money. I have seen diagnostic fees in the 80 to 150 dollar range for both auto and home service. You can save by doing the initial checks yourself. Fuse, relay, power, ground, and filter checks take 15 to 30 minutes. That quick work solves a huge chunk of blower complaints.

Preventative maintenance that keeps the air moving

A blower motor lives longer with clean airflow and good electrical connections.

- Change filters on time:

- Car cabin air filter. Replace it every 12 months or 12,000 to 15,000 miles in dusty areas. A clogged filter restricts airflow and increases amp draw.

- Home HVAC air filter. Follow the schedule for your filter type. Check monthly during heavy use.

- Keep vents clear:

- Do not block returns with furniture or rugs. Give supply vents room to breathe.

- Clean the blower wheel:

- Dust caked on a squirrel cage fan throws it out of balance. It adds load and noise. Clean with a soft brush and vacuum. Take care not to bend the blades.

- Listen for noise:

- Clicking, scraping, or ball bearing noise tells you the motor is on borrowed time. Some older motors allowed lubrication. Most modern motors have sealed bearings and you replace them when they get noisy.

- Inspect wiring:

- Check connectors for heat damage. Verify the blower ground wire stays tight. Look for signs of corrosion.

Quick troubleshooting checklists

When the fan is dead:

- Car:

- Check the blower motor fuse.

- Swap the blower motor relay.

- Verify power and ground at the motor connector.

- Bypass the resistor briefly to test the motor.

- Disconnect the battery to power cycle the HVAC module.

- Home:

- Reset the breaker. Check the service switch.

- Set thermostat to FAN ON. Jump R to G at the board.

- Test the blower capacitor in PSC systems.

- Power cycle the furnace control board.

- Press the motor’s thermal overload reset if present.

When the fan only works on high:

- Car:

- Replace the blower motor resistor and repair the connector if it is burnt.

- Home:

- Not common with PSC motors. Check the fan relay or the control board if speeds are commanded by an ECM and only high runs.

When the fan runs constantly and will not turn off:

- Car:

- A stuck blower motor relay or a shorted control module can feed power all the time. Pull the relay to stop it. Replace the relay or module.

- Home:

- A stuck fan relay on the control board or a thermostat issue can hold G energized. Remove the thermostat. If the fan still runs, the board or relay is stuck.

When the fan runs intermittently:

- Car:

- Wiggle test the blower motor connector and the resistor harness. A loose connection or corroded ground is common.

- Home:

- Overheating motor trips a thermal overload. Fix airflow. Check amp draw. Replace the motor if needed.

FAQs

- Is there a blower motor reset button in cars?

- Usually no. Resets in cars mean pulling the HVAC fuse or disconnecting the battery to reset the climate control. The blower motor itself does not have a reset button in most vehicles.

- Why does my blower stop after a few minutes?

- Thermal overload. Overheating due to a clogged filter, a dirty blower wheel, restricted returns, or a failing motor can trip the protector. Fix the cause and the symptom goes away.

- Can I lubricate my blower motor?

- Most modern blower motors in cars and in furnaces use sealed bearings. They are not serviceable. Older designs had oil ports. If yours does not have ports, you replace the motor rather than lubricate it.

- Can the ECU or an OBD‑II code cause a blower to stop?

- The engine control unit does not control the cabin blower directly. Some vehicles store HVAC DTCs in the body control module or the climate control unit. A capable scan tool helps. A basic code reader may not see those codes.

- What about the AC contactor or the condenser fan outside?

- Those affect the cooling side. They do not stop the indoor blower from turning. Focus on the blower circuit if the problem is no air movement.

A quick peek under the hood: how a blower motor works

I find it easier to troubleshoot when I remember what is spinning inside. A blower motor is simply a motor that turns a fan. In many designs you will find a stator and a rotor stacked with thin magnetic plates. If you want a refresher on the components inside a motor, this explainer on stator and rotor spells out the basics. The working idea is simple and beautiful. Electricity creates magnetic fields that push and pull the rotor around. The air rides the blades and rushes through your vents.

That is the motor principle in action. Designers build the core from thin steel sheets called laminations. They cut losses in the iron and keep the motor efficient. If you like the hardware side, you can read more about the role of motor core laminations in reducing eddy currents and improving performance. These laminations use specialized alloys. The steel matters because the motor lives in a hot space, the current pulses, and you want the motor to run cool and quiet. Many manufacturers use advanced electrical steel laminations for exactly that reason.

None of this theory fixes a dead fuse. It does explain why a motor that overheats or runs out of balance starts to draw more current and then trips protection. Form follows physics.

Cost, time, and what usually fixes it first

I like to set expectations. Based on years of wrenching in driveways and basements, here is what I see most often.

- Fuses and circuit breakers create 30 to 40 percent of the “no air” calls. They are cheap and fast to fix.

- Blower motor resistors and control modules create another 25 to 35 percent. Fans that only work on high speed live here.

- Relays sit around 10 to 15 percent. They fail, especially when loads run high.

- The motor itself fails 15 to 20 percent of the time. Motors wear out and seize. Bearings get noisy. Brushes in DC motors wear down in cars.

- A basic round of checks takes 15 to 30 minutes if you have a multimeter and a flashlight.

- Parts costs for DIY fuse or relay replacement sit in the 5 to 30 dollar range. A resistor or control module costs more. A new blower motor costs the most.

These ranges match what I see hands‑on. They also line up with common repair trends. The point is simple. Start with the easy wins. Reset the breaker. Swap the relay. Test the resistor. Measure voltage. You will solve most problems without touching the dashboard core.

Putting it all together: a step‑by‑step script you can follow

- Symptom: Blower motor not working, no air coming from vents.

- Step 1: Check the fuse or breaker. Replace or reset once. Do not upsize.

- Step 2: Swap the blower motor relay with a known good identical relay. Replace if the blower wakes up.

- Step 3: Power cycle the system. Battery off for cars. Breaker off for home HVAC.

- Step 4: Inspect the blower motor resistor or control module. Replace if burnt or open. If only high works, prioritize this step.

- Step 5: Verify power and ground at the motor connector with a multimeter. If power and ground are present and the motor does nothing, the motor is bad.

- Step 6: For home PSC motors, test the blower motor capacitor. Replace if out of spec.

- Step 7: If the motor starts then stops, look for thermal overload. Fix airflow and amp draw issues.

- Symptom: Intermittent blower motor operation.

- Wiggle test connectors and the wiring harness. Clean ground connections. Check the relay socket for heat.

- Inspect the resistor harness. Replace cooked plugs. Consider a new blower motor if amp draw spikes.

- Symptom: Fan will not turn off.

- Pull the relay. If the fan stops, the relay stuck closed. Replace it.

- If the fan keeps running in a home system with the thermostat removed, the control board fan relay is stuck.

Final thoughts and a little encouragement

I have seen people freeze in place when a fan stops. They imagine a massive bill or a dashboard on the garage floor. Start small. Think in terms of power flow. Power leaves the battery or breaker. It passes through electrical circuit protection, switches, relays, resistors or modules, and finally lands on the blower motor. Somewhere along that path the chain broke. Your job is to find the break.

If you follow the order in this guide, you will save time. You will protect yourself. You will fix a lot of “blower motor not working” problems with a reset or a simple part. When the problem runs deeper, you will know it with confidence. That knowledge helps when you do bring in a pro. You can describe your tests. You will avoid paying to have the same fuses checked twice.

Conclusion: Get your airflow back without guesswork

Here is the recap I use on my own jobs.

- Reset means power cycle, breaker reset, or thermal overload reset. True reset buttons are rare.

- Start with fuses, relays, and clear power‑and‑ground checks. Replace the blower motor resistor when only high speed works. Clean the clogged cabin air filter before it cooks the new part.

- Use a multimeter. Confirm voltage at the motor connector. Do a voltage drop test on the ground. Test the blower motor capacitor in PSC systems.

- If the blower still fails after a clean round of checks, you probably have a failed blower motor or a control module. At that point a professional diagnosis makes sense.

You can do this. Go step by step. Stay safe and methodical. The air will be back on before your coffee cools.

Internal link self‑check: I included 4 unique internal links, each used once. They are:

- https://nfdyzyo.top/stator-and-rotor/

- https://nfdyzyo.top/motor-principle/

- https://sinolami.com/motor-core-laminations/

- https://sinolami.com/electrical-steel-laminations/