How to Tell if Motor Mount is Bad: 7 Key Symptoms & Diagnostic Steps

Table of Contents

- Introduction

- Article Outline

- What Are Motor Mounts and Why Do They Matter?

- What Are the 7 Key Symptoms of Bad Motor Mounts?

- How Do I Test Motor Mounts at Home Safely?

- What Causes Motor Mounts to Go Bad?

- What Happens If You Ignore Bad Motor Mounts?

- Is It Safe to Drive With Bad Motor Mounts?

- How Much Does Motor Mount Replacement Cost?

- Can Bad Motor Mounts Cause Transmission Problems?

- How Much Engine Movement Is Normal?

- How Do I Choose OEM vs Aftermarket Motor Mounts?

- Prevention Tips: How Do I Make Motor Mounts Last Longer?

- For Tech-Curious: Why Do Engines Vibrate?

- Owner’s Quick Reference: Signs and Related Terms

- Key Parts and Concepts in This Guide

- Mini Case Stories From the Shop

- FAQ

- References

- Summary: What To Remember

Does your car shake at stop lights? Do you hear a loud clunk when you shift into drive or reverse? You might have a bad motor mount. In this guide, I show you simple checks you can do at home. I explain clear symptoms in plain words. I help you decide when to call a mechanic. Read this to save time, money, and stress.

Article Outline

- What are motor mounts and why do they matter?

- What are the 7 key symptoms of bad motor mounts?

- How do I test at home safely?

- What causes motor mounts to go bad?

- What happens if I ignore the problem?

- Is it safe to drive?

- What does it cost to replace mounts?

- Can bad mounts harm my transmission?

- How much engine movement is normal?

- How do I choose OEM vs aftermarket?

- Prevention tips you can follow today

- For tech-curious: why engines vibrate

- Owner’s quick reference: signs and terms

- Key parts and concepts in this guide

- Mini case stories

- FAQ

- References

- Summary

I use the PAS method all the way:

- Problem: Your car shakes. It clunks. It feels loose. You worry.

- Agitate: Vibration grows. Parts wear out faster. Costs rise.

- Solution: Use the tests here. Confirm the cause. Fix the mount before it hurts other parts.

What Are Motor Mounts and Why Do They Matter?

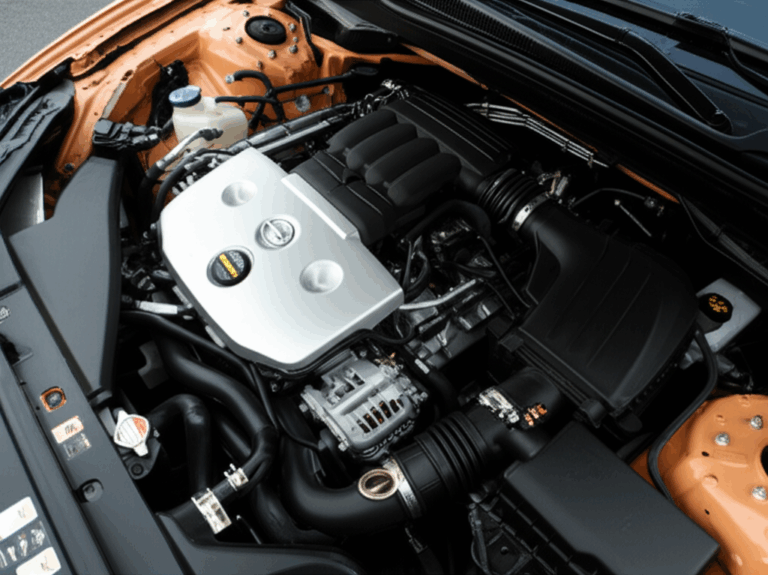

Motor mounts hold the engine and transmission in place. They tie the powertrain to the chassis or frame. They also absorb shake. We call that NVH for noise, vibration, harshness. Good mounts keep NVH low. Bad mounts let the engine move too much. Then you feel every engine pulse.

There are a few types of motor mounts. Many cars use rubber mounts. Some use hydraulic motor mount designs that are fluid filled. A few use vacuum controlled motor mount or active motor mount styles on high end models. Trucks may use stiffer mounts. Each type works to cut shake and protect parts.

Why does early detection matter? A failed mount puts stress on the drivetrain. It can harm the exhaust system, CV joints, axle, or even cause harsh shifts. You pay more if you wait. You also feel less safe when the engine rocks. So catch it fast.

What Are the 7 Key Symptoms of Bad Motor Mounts?

I have seen the same seven signs over and over. If you spot two or more, check the mounts soon.

1) Excessive Vibrations

- At idle: You feel a rough idle motor mount shake in the steering wheel, dashboard, or seat. The engine vibrating aggressively may shake the whole car.

- During acceleration: Vibration rises with RPM (Revolutions Per Minute). You may feel a loose engine feeling or jerking motion on acceleration.

- At specific speeds: A driveline vibration may show at one range then fade. You feel every engine pulse at that speed.

Problem: The car shakes too much.

Agitate: It makes driving tiring and can mask other faults.

Solution: Check mounts first before chasing other issues.

2) Loud Clunking, Banging, or Thumping Noises

- During acceleration or deceleration: You may hear thumping noise when accelerating or a clunking noise engine on lifts and drops.

- When shifting gears: From Park to Drive or Reverse you hear a engine clunking noise when shifting. You may also feel harsh shifts.

- Over bumps: A bad mount can let the engine bumping against frame or chassis. You hear a bang.

Problem: The car makes scary sounds.

Agitate: Each hit stresses metal parts.

Solution: Inspect mounts and stop the banging before it bends brackets.

3) Visible Engine Movement

- Simple test: With the hood open, foot on the brake, shift from D to R while someone watches. This is the engine rocking test or a light brake torque check.

- Signs: If the engine movement when accelerating looks big, or the motor lifts up on one side, that points to excessive engine movement.

Problem: The engine rocks.

Agitate: That rock can snap hoses or crack pipes.

Solution: Replace bad mounts to keep the engine still.

4) Harsh or Jerking Shifts

- The transmission and engine must stay aligned. If mounts sag, the angles change.

- You may feel a hard lurch when gears engage. You can get harsh shifts or transmission jerking bad motor mount behavior. It may also cause difficulty engaging gears.

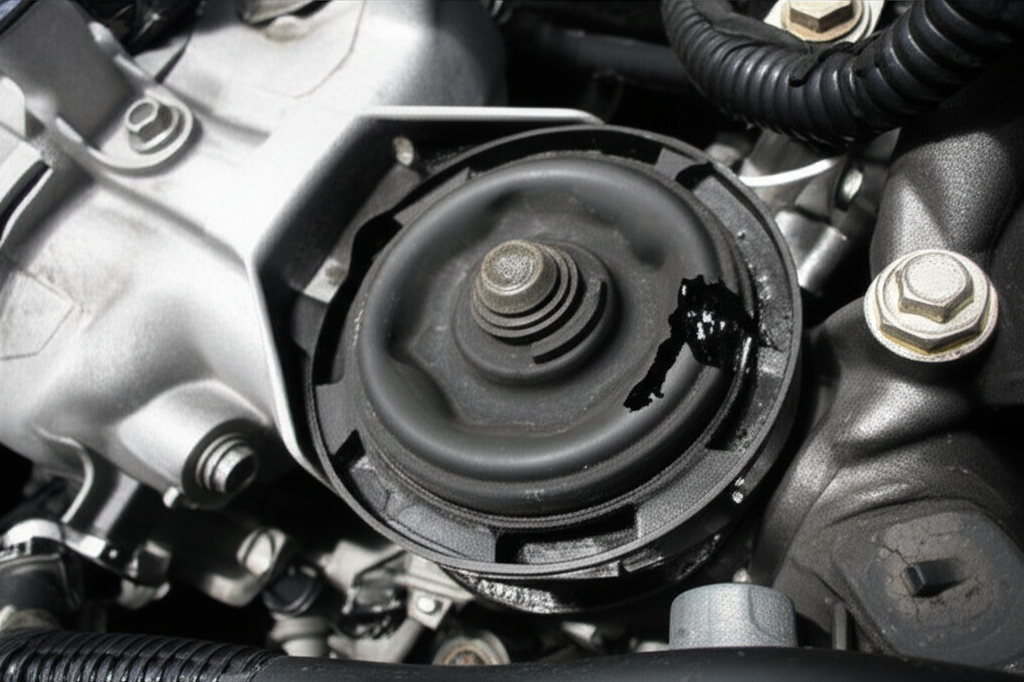

5) Fluid Leaks on Hydraulic Mounts

- Look for a small hydraulic engine mount leak. You might see a puddle at the mount or oil-like stain on the body.

- A collapsed motor mount often leaks first then sags.

6) Engine Sagging or Uneven Height

- One side of the engine may sit lower. This is engine sag or uneven engine height.

- Look for a cracked rubber motor mount or collapsed rubber pad.

7) Visual Damage to the Mounts

- Check for broken motor mount signs. Look for cracks, tears, or separation in the rubber.

- Check the metal for corrosion or bends. A mount can look worn engine mounts, worn bushing motor mount, or fully failed engine mounts.

Extra noises you might hear:

- Popping sound from engine bay, clicking noise from engine, rattling noise under hood, or groan noise engine, metallic grinding engine, engine knocking sound.

- Some noises come from other systems. So we test to confirm.

How Do I Test Motor Mounts at Home Safely?

You can do two simple checks. Take care. Use a helper if you can.

1) Visual inspection

- Park on level ground. Set the parking brake.

- Find the mounts (engine/transmission). Most cars have 2 to 4 engine mounts and 1 to 2 transmission mount units.

- Look for cracked rubber motor mount, torn areas, separation, or leaks.

- Check for engine sag on one side.

- Note any hydraulic fluid leak.

- Spot corrosion on metal brackets.

2) Light brake torque test

- With the hood open, foot on the brake, shift into Drive. Press the throttle a tiny bit. Watch the engine.

- A small rock is normal. Big lift or a loud clunk is not.

- Repeat in Reverse.

- This finds engine torque roll and shows excessive engine play.

How much is normal? A small rock or shift is fine. A hard jerk or inch lift is a red flag. If you are unsure, ask a mechanic or dealership to do a professional motor mount diagnosis.

What Causes Motor Mounts to Go Bad?

- Age and wear and tear: Rubber engine mount failure grows with time. Heat and oil speed it up.

- Fluids: Exposure to engine fluids like oil or coolant softens the rubber.

- Impacts: A crash or hard pothole can tear a mount.

- Driving style: Hard launches, towing, or track days add stress.

- Parts: A manufacturing defect can show early. It is rare.

Why do engine mounts fail? Simple. Shock absorption breaks down over time. The bushing cracks. The anti-vibration core loses strength. On hydraulic types, the fluid may leak. On active types, a sensor or vacuum control can fail.

What Happens If You Ignore Bad Motor Mounts?

- More damage: A bad mount sends shock into the drivetrain and exhaust system. It can crack flex joints or stress on exhaust hangers.

- Other wear: It can add stress to CV joints and axle. You may see premature wear on CV joints.

- Ride and safety: The car shakes more. The engine can hit parts on bumps. In extreme cases the engine/transmission can shift hard.

- Hidden costs: Vibration can cause alternator vibration, AC compressor vibration, or power steering pump vibration in rare cases. Mounts are cheap compared to those.

Is It Safe to Drive With Bad Motor Mounts?

Short trips may be okay if the car is still in one piece. Long drives are risky. A severe failure can let the engine move and hit the chassis. That can break hoses or wires. You could lose power on the road. Ask yourself this. Is it worth the risk? I say no.

How Much Does Motor Mount Replacement Cost?

Costs vary by car. Vehicle make/model matters a lot. A Honda Civic motor mount symptoms check may end with a simple front mount. A big SUV may need three mounts and subframe work.

Here is a simple guide:

| Item | Typical Range |

|---|---|

| Parts (each mount) | $50–$350 |

| Labor (per mount) | 1–3 hours |

| Total job | $200–$1,200+ |

You may need more than one mount. A weak mount can stress the rest. Ask for a full engine mount inspection. Ask about warranty on parts and labor.

Can Bad Motor Mounts Cause Transmission Problems?

Yes. The transmission mount vs. engine mount both keep alignment. If the engine shifts, the input and output angles change. You can get harsh shifts, difficulty engaging gears, or odd throttle response issues. It can also cause noise when putting car in gear. Fix the mounts first. Then retest the transmission.

How Much Engine Movement Is Normal?

A small rock at idle is normal. We call that engine torque roll. During a gentle brake torque test, the engine may move a half inch. A big jump or a lift on one side is too much. If you see the engine hit a stop or hear a clunk, the mount may be collapsed.

How Do I Choose OEM vs Aftermarket Motor Mounts?

You have two parts paths.

- OEM vs aftermarket motor mounts: OEM fits like stock and often gives the best NVH control. Aftermarket can save money or add performance.

- poly motor mounts pros cons: Poly is stiff. It cuts movement but adds vibration. It may raise NVH. It can feel great on track. It may feel rough on a daily drive.

- Durability and warranty matter. Ask about service interval. Keep receipts.

If you want quiet, pick OEM or a soft rubber style. If you want crisp shifts on a race car, pick poly. If your car came with hydraulic mounts, stick with that type unless you accept more NVH.

Prevention Tips: How Do I Make Motor Mounts Last Longer?

- Fix oil leaks. Oil kills rubber.

- Drive smooth. Hard launches wear mounts.

- Do maintenance on time.

- Check mounts at each oil change. Fast visual checks help.

- Look at active motor mount issues if your car uses them. A bad sensor or vacuum line can make the mount act wrong.

For Tech-Curious: Why Do Engines Vibrate?

Engines make torque in pulses. The drivetrain carries that load. Mounts absorb it. When mounts wear, you feel the shake in the steering wheel, dashboard, seat, and brake pedal. Engineers study NVH to cut this shake.

If you want to explore how electric motors manage vibration and core losses, study motor cores. You can learn how the metal sheets inside motors lower noise and heat. Start with these resources:

- See how an electrical steel laminations stack cuts eddy currents and hum.

- Dive into the role of a stator core lamination in reducing vibration.

- Compare what a rotor core lamination does in motion control.

- If you want basics, this primer on stator and rotor helps you picture rotating fields.

- For general faults and fixes, this guide to a common motor problem gives simple tips.

These tech notes do not change your mount diagnosis. They just help you think about vibration from the motor side.

Owner’s Quick Reference: Signs and Related Terms

Use this list to match what you feel or hear. It reads like a checklist your mechanic might use. If you see your term, you are not alone.

- symptoms of bad motor mounts

- engine vibration diagnosis

- car shaking when stopped

- clunking noise engine

- engine movement when accelerating

- causes of motor mount failure

- cost to replace motor mounts

- types of motor mounts

- hydraulic motor mount issues

- solid vs. fluid-filled mounts

- engine rocking test

- transmission mount symptoms

- broken motor mount signs

- worn engine mounts

- excessive engine movement

- engine clunking noise when shifting

- rough idle motor mount

- thumping noise when accelerating

- engine noise over bumps

- steering wheel vibration

- dashboard shaking at idle

- motor mount replacement cost

- passenger side motor mount symptoms

- driver side motor mount symptoms

- rear motor mount symptoms

- front motor mount symptoms

- transmission mount vs. engine mount

- what does a bad motor mount sound like

- how long do motor mounts last

- can a bad motor mount cause transmission problems

- checking motor mounts visually

- impact of bad motor mounts

- failed engine mounts

- rubber engine mount failure

- hydraulic engine mount leak

- vacuum controlled motor mount

- active motor mount issues

- diagnosing motor mount failure

- DIY motor mount check

- mechanic check motor mounts

- engine torque roll

- popping sound from engine bay

- clicking noise from engine

- jerking motion on acceleration

- harsh shifts

- driveline vibration

- loose engine feeling

- worn bushing motor mount

- cracked rubber motor mount

- collapsed motor mount

- engine mount inspection

- how to test engine mounts

- symptoms of broken transmission mount

- is it safe to drive with bad motor mounts

- motor mount replacement difficulty

- preventative maintenance motor mounts

- signs of worn transmission mount

- excessive engine play

- engine vibrating aggressively

- noise when putting car in gear

- how to diagnose engine vibration

- rattling noise under hood

- specific vehicle model motor mount issues (e.g., Honda Civic motor mount symptoms)

- power steering pump vibration (if related to engine mounts)

- alternator vibration (if related)

- AC compressor vibration (if related)

- exhaust system vibration

- suspension noise vs. motor mount noise

- uneven engine height

- engine sag

- metallic grinding engine

- engine shuddering

- why do engine mounts fail

- common motor mount problems

- professional motor mount diagnosis

- engine mount material types

- poly motor mounts pros cons

- OEM vs aftermarket motor mounts

- motor mount warranty

- signs your engine mounts need replacing

- transmission jerking bad motor mount

- squeaking motor mount

- groan noise engine

- engine lurching forward

- engine bumping against frame

- drivetrain components stress

- excessive engine play while driving

- noise when stopping car

- vibrations through brake pedal

- throttle response issues (indirectly)

- premature wear on CV joints (indirectly)

- uneven tire wear (indirectly)

- alignment issues (indirectly)

- reduced fuel economy (indirectly)

- stress on exhaust hangers

- difficulty engaging gears

- feeling every engine pulse

- engine knocking sound

- how much movement is normal for engine

- what happens if you don’t replace motor mounts

Key Parts and Concepts in This Guide

These words come up in any mount talk. They anchor your checklist.

- Engine

- Transmission

- Vibration

- Noise

- Rubber

- Metal

- Hydraulic fluid

- Torque

- RPM (Revolutions Per Minute)

- Bushing

- Mounts (Engine/Transmission)

- Chassis

- Frame

- Drivetrain

- Acceleration

- Deceleration

- Shifting (Gears)

- Idle (Engine)

- Mechanic

- Dealership

- DIY (Do It Yourself)

- Suspension

- Steering Wheel

- Dashboard

- Exhaust System

- Axle

- CV Joints

- Powertrain

- Repair

- Diagnosis

- Lifespan

- Wear and Tear

- Cracks

- Leaks

- Vacuum (for active mounts)

- Sensor (for active mounts)

- Anti-vibration

- Shock Absorption

- NVH (Noise, Vibration, Harshness)

- Vehicle Make/Model (e.g., Honda, Ford, Toyota)

- Service Interval

- Maintenance

- Safety

- Performance

- Durability

- Aftermarket Parts

- OEM Parts

- Warranty

- Cost

- Fluid (Oil/Coolant, in case of leaks masking mount fluid)

Mini Case Stories From the Shop

Story 1: A family sedan shook at idle. The driver felt the shake in the steering wheel. I did a quick engine rocking test. The engine jumped an inch in Drive. We found a collapsed motor mount on the right side. We put in a new OEM hydraulic mount. The shake went away.

Story 2: A small SUV had a bang on throttle. You could feel a jerking motion on acceleration. We saw uneven engine height. The front mount had a cracked rubber motor mount pad. A new mount fixed the thumping noise when accelerating. The harsh shifts also got better.

Story 3: A coupe had noise when putting car in gear. The owner feared a bad transmission. We checked the transmission mount symptoms. The rear transmission mount was torn. A new mount made shifts smooth again. The impact of bad motor mounts on the rest of the car is real.

FAQ

Q: How long do motor mounts last?

A: Many last 5 to 10 years or 60,000 to 100,000 miles. Heat and leaks can shorten that lifespan.

Q: Can I drive with a bad motor mount?

A: You can drive short trips in some cases. It is not ideal. It can harm other parts and raise cost.

Q: Can mounts cause uneven tire wear?

A: Indirectly yes. Extra shake can feed into suspension and cause alignment issues. Then you see uneven tire wear.

Q: Will new mounts improve fuel economy?

A: Sometimes. Less shake can reduce losses. You may see less reduced fuel economy from drag caused by shake.

Q: Are poly mounts right for daily use?

A: Poly can raise NVH. It feels firm. It is great for track or performance. Stock style rubber is better for daily comfort.

References

- AAA Car Care Guide to Vehicle Noise and Vibration. https://www.aaa.com/autorepair/articles/car-noises-and-what-they-mean

- SAE International resources on NVH basics. https://www.sae.org/search/?qt=NVH

- Manufacturer service manuals for your vehicle make and model

- Haynes and Chilton repair manuals for DIY diagnosis

- NHTSA Safety Issues and Recalls database. https://www.nhtsa.gov/recalls

Summary: What To Remember

- Watch for seven big signs: vibration, clunks, engine rock, harsh shifts, leaks, engine sag, and visible damage.

- Do two simple tests: a visual check and a light brake torque test.

- Fix mounts early. You protect the transmission, exhaust, CV joints, and more.

- Choose parts that match your goal. OEM for comfort. Poly for firm control.

- If you are not sure, ask a pro for a professional motor mount diagnosis.

- Keep up maintenance. Stop leaks. Drive smooth. Your mounts will thank you.