How to Tell if Your Blower Motor Is Bad: My Field-Tested Guide for HVAC and Cars

Table of contents

- The role of the blower motor in HVAC and cars

- Quick symptom check: is it the blower motor

- Primary symptoms in detail

- No airflow or weak airflow

- Unusual noises: squealing, grinding, clicking

- Inconsistent fan speeds or only works on one speed

- Burning smell or smoke

- Step-by-step DIY diagnostics

- Visual inspection

- Check fuses, breakers, and relays

- Resistor or control module checks

- Manual fan spin test

- Multimeter tests: voltage and continuity

- HVAC capacitor checks

- Distinguish motor failure from other issues

- Common causes of blower motor failure

- Costs, timelines, and what to expect

- When to call a professional

- Preventive maintenance and lifespan

- FAQs

- Final thoughts

I’ve diagnosed more blower motor problems than I can count. Some days I’m in a driveway chasing a car heater fan that won’t blow. Other days I’m kneeling next to a furnace that hums but refuses to push air. Different settings same core idea. When the blower quits your comfort goes with it. The good news is you can often narrow the problem fast with a few simple checks. I’ll show you how I do it step by step in plain English with real world examples.

The role of the blower motor in HVAC and cars

In a home HVAC system the blower motor pushes air across the evaporator coil in cooling season and over the heat exchanger in heating season. Then it sends that conditioned air through ductwork and out the vents. In a vehicle the blower motor pushes air through the heater core or across the evaporator inside the dash so the cabin gets warm or cool air.

Every time you ask for heat or AC the blower motor does the heavy lifting. No airflow or weak airflow turns comfort into frustration. That is why spotting the early signs of a bad blower motor matters. It prevents bigger problems like overheating a furnace or stressing an AC compressor.

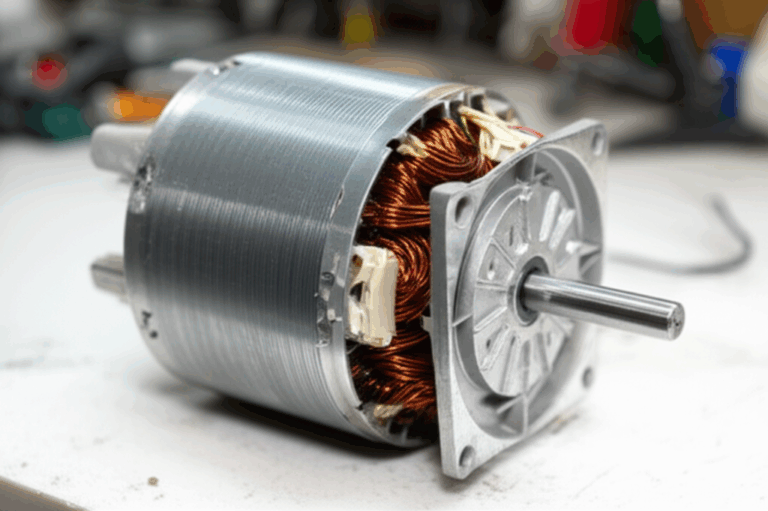

If you like to know how motors do their thing you can dig into the basics of the motor principle. Most blower motors spin a rotor inside a stator. Manufacturers build those parts with stacked laminations to reduce energy loss and heat. The stator core lamination and the rotor core lamination both matter since they shape the magnetic field and the efficiency of the motor. Those stacks are made from thin electrical steel sheets which is why you’ll sometimes see specs referring to electrical steel laminations.

Quick symptom check: is it the blower motor

When someone asks how to tell if the blower motor is bad I start with a short checklist. Match your symptoms to these common patterns.

- No air coming from vents even when the fan is set to high

- Fan works only on high or only on one speed

- Weak airflow from AC or heat even though the system runs

- Fan makes squealing grinding rattling clicking or humming noises

- Intermittent blower operation that cuts out randomly

- Burning smell from vents or visible smoke or sparks

- Furnace fan not cycling or HVAC fan not spinning when the thermostat calls for fan

- Car heater fan not working or car AC fan not blowing hard

If you see one or more of these I’d keep reading. You might have a bad blower motor a bad blower motor resistor or a power issue like a fuse relay or wiring fault.

Primary symptoms in detail

No airflow or weak airflow

When I flip the fan to high and get nothing I suspect one of three things. A dead blower motor. A failed control module or resistor. Or no power to the motor thanks to a fuse relay or wiring fault.

Weak airflow tells a different story. I think about a clogged cabin air filter in a car. I think about a blocked return or a dirty furnace filter in a home. Debris in the fan wheel will also choke airflow. If filters and vents look good and power checks out I lean back toward a weakening motor with worn bearings or failing windings.

Look for these clues:

- AC blows hot air with fan not working

- HVAC fan humming but not spinning

- Thermostat calling for fan but no air

Unusual noises: squealing, grinding, clicking

Noises talk. You just have to listen.

- Squealing or chirping usually points to worn bearings or a dry sleeve bearing. As bearings wear friction increases and the motor draws more current which can trip a breaker or blow a fuse.

- Grinding or rattling hints at debris in the squirrel cage fan or a cracked fan wheel. I’ve pulled pine needles leaves and even a toy dinosaur out of blower housings. Debris makes a racket and can overheat the motor.

- Clicking or ticking can mean something caught in the fan wheel or an internal motor issue. Intermittent clicking that gets faster with speed often points to a broken fin on the blower wheel.

When someone asks what a bad blower motor sounds like I say it depends. Squeal means bearings. Grind screams debris or damage. A heavy hum with no spin means the motor tries but can’t overcome drag or a bad start component.

Inconsistent fan speeds or only works on one speed

This symptom often points away from the motor itself and toward the blower motor resistor or the solid state control module on modern vehicles and variable speed HVAC systems.

- Fan only blows on high: Classic blower motor resistor failure in many cars. The high speed circuit bypasses the resistor so it still works while lower speeds do not.

- Fan does not respond to speed changes: Check the resistor or the control module. A bad control module can also cause intermittent operation.

- Intermittent operation: Look for a failing relay loose wiring a dying motor or an overheating resistor.

Burning smell or smoke

If I smell burning plastic or see smoke I shut the system off now. That smell can come from melting insulation on wires a short circuit a resistor pack overheating or a motor that is dragging and drawing too much current. In a furnace or residential air handler I also think about a bad HVAC run capacitor that forces the motor to labor which raises temperature.

Visible sparks or smoke are immediate safety concerns. Turn off the breaker for HVAC. Turn off the car and disconnect the battery if it is safe to do so.

Step-by-step DIY diagnostics

I start easy and move toward advanced tests. Take your time. Safety first.

Before you touch anything:

- For HVAC turn off the system at the thermostat then flip the breaker off. Confirm no power at the unit before you open panels.

- For vehicles park safely set the parking brake and disconnect the negative battery terminal if you will work on connectors or resistors.

Visual inspection

I begin with what I can see and reach.

- Check filters: A clogged furnace filter or cabin air filter can mimic a bad blower motor. Replace any filter that looks dirty or packed with dust.

- Inspect vent and return airflow paths: I’ve seen furniture pushed over a return grill. That kills airflow and stresses the motor.

- Look inside the blower housing: If accessible check the fan wheel also called the squirrel cage. Don’t force anything. You are checking for leaves mouse nests pet hair or debris in the blower motor wheel.

- Look for melted connectors or scorched plastic near the resistor pack. That is a dead giveaway for electrical overheating.

Check fuses, breakers, and relays

- HVAC: Verify the circuit breaker for the air handler or furnace. If it trips again right away something is shorting or the motor draws too much current. Some units have a service switch near the air handler. Make sure it is on.

- Vehicles: Check the fuse box for the blower motor fuse. You might also have a relay. The owner’s manual or the fuse box cover shows the location. If there is a similar relay nearby try swapping it to test. A bad relay can mimic a dead motor.

When I find a blown fuse I do not just replace it and call it done. I ask why it blew. Shorted wiring a seized motor or a resistor meltdown can pop fuses again.

Resistor or control module checks

- Cars with manual climate controls often use a blower motor resistor pack that sits in the airflow upstream of the fan. If the fan only works on high or only on certain speeds I pull the resistor and look for burnt spots cracked coils or melted plastic. If it looks cooked it probably is.

- Cars with automatic climate control and many HVAC systems use an electronic control module. When these fail the fan may surge not respond to speed commands or stay stuck at one speed. Visual inspection can show heat damage. You test it by checking inputs and outputs with a multimeter.

- HVAC variable speed systems use ECM or DC motors with a built in controller. If the motor does not spin yet has power at the module the control section may have failed.

Manual fan spin test

If the fan wheel is accessible and safe to reach I try a gentle spin by hand with the power off.

- It should turn freely and keep spinning a bit. If it feels gritty tight or stops quickly the bearings may be worn. A worn bearing can squeal and make the motor draw too much power.

- If it drags I also look for debris rubbing the housing. A blower wheel that has shifted on the shaft can scrape and bind.

Multimeter tests: voltage and continuity

If you are comfortable with a multimeter you can separate motor problems from power problems. Always disconnect power before unplugging connectors and testing resistance or continuity.

- Voltage test at the motor connector:

- HVAC: With power restored and a call for fan present check for correct voltage at the motor leads. If you see supply voltage and the motor does not spin the motor or its control is bad.

- Car: With the fan speed set to high check for battery voltage at the motor connector. No voltage means a fuse relay resistor or wiring issue upstream. Voltage present yet no spin points to a bad motor.

- Continuity test of motor windings:

- With power off and the connector unplugged measure resistance across the motor terminals. An open circuit means the windings are blown. Very low resistance plus a fuse that blows can suggest a shorted motor.

- Amperage or current draw:

- If you have a clamp meter check the motor current against spec. An old motor that draws too much current runs hot and trips protections. That is a sign of failing bearings or shorted turns.

Safety note: Always disconnect power before electrical testing. Don’t guess around live circuits.

HVAC capacitor checks

Many residential blower motors use a run capacitor. If the capacitor fails the motor hums yet does not start or it spins slowly and overheats. I’ve fixed no spin symptoms by replacing a weak capacitor more than once.

- Visual: A bulging or leaking capacitor is bad.

- Multimeter with capacitance: Measure the microfarads and compare to the rating on the label. Replace if it is out of tolerance.

- If you have to test in place keep your fingers off the terminals. Capacitors hold a charge. Discharge it safely with a resistor across the leads.

Extra notes for pros or brave DIYers

- Wiring diagram: I keep a diagram nearby. It helps me chase a blower motor electrical issue quickly. Look for the blower motor relay location and the resistor wiring path.

- Variable speed DC blower: These use a control module and a brushless motor. The diagnostic steps focus on inputs like power ground and the command signal. If those check out the module or motor is bad.

- Brush vs brushless: Older motors may have brushes that wear. Brush wear can cause intermittent operation and arcing noises.

Distinguish motor failure from other issues

When someone says the blower motor is bad I ask a few questions to avoid replacing the wrong part.

- Blower motor vs resistor: If the fan only works on high it is usually the resistor. If it does not work on any speed including high I test voltage at the motor then consider the motor.

- Blower motor vs clogged filter: Weak airflow with normal fan sound often points to a clogged filter or a blocked evaporator. Replace the filter first and check airflow again.

- Blower motor vs relay or fuse: If a fuse keeps blowing suspect a short or a seized motor. If the relay clicks but the motor does not spin check voltage at the motor.

- Blower motor vs control module: Weird speed behavior surging or no response to the fan switch can be a control module. Test inputs and outputs at the module.

- Blower motor vs HVAC run capacitor: Humming with no start that improves if you spin the wheel by hand points to a bad run capacitor on PSC motors.

I keep a simple rule. Verify power and ground at the motor. If power and ground are good yet the motor will not run the motor is bad.

Common causes of blower motor failure

Over time I see the same root causes repeat.

- Worn bearings: Bearings wear and start to squeal. Friction rises. The motor draws too much power and overheats.

- Electrical component failure: Resistors control modules relays and wiring faults account for many no fan or stuck speed problems. These often get misdiagnosed as bad motors.

- Debris ingestion: Leaves plastic bags pet hair and construction dust get pulled into the blower. Debris throws the blower wheel off balance and loads the motor.

- Overheating: Running with a clogged filter or blocked return bakes the motor. Long duty cycles on high speed can also push a weak motor over the edge.

- Age and wear: Motor windings and brushes degrade. Insulation dries out. Noise increases then the motor dies.

- Capacitor issues in HVAC: A weak run capacitor makes a good motor look bad. Always test or replace the capacitor during diagnosis.

If you are curious why motor cores are stacked in thin sheets that is to cut down eddy current losses which keeps heat in check and improves efficiency. That is where electrical steel laminations and good stator core lamination work help the motor last longer.

Costs, timelines, and what to expect

I do my best to set expectations because surprises make repairs feel worse.

- Residential HVAC blower motor replacement:

- Parts usually run from about $150 to $700. High efficiency or variable speed motors cost more.

- Labor often runs from about $200 to $600 depending on access and setup.

- The total can land anywhere from about $350 to $1300 or more.

- Automotive blower motor replacement:

- Parts range from about $80 to $300 for most vehicles.

- Labor ranges widely. A glove box drop is quick while a dash removal is not. Expect roughly $100 to $400.

- The total often lands between about $180 and $700 or more.

- Blower motor resistor replacement:

- Much cheaper than the motor. Parts and labor commonly fall between about $50 and $250.

DIY saves on labor if you are comfortable with the steps above. I still weigh the risk. If the job sits behind a dash that needs to come apart I quote it out. In a furnace the swap is usually straightforward yet you still need to match the motor size rotation and capacitor rating.

When to call a professional

I love a good DIY win. I also know where the line sits.

Call a pro when:

- You are not confident working around high voltage or vehicle wiring

- You find melted wires or signs of arcing

- You have a variable speed ECM motor with integrated electronics

- You smell burning or see smoke

- The blower sits in a tight spot that needs major disassembly

- You want a warranty on parts and labor

Pros bring specialized tools and experience. They can spot a bad control module vs a bad motor fast. I have seen plenty of “bad blower motor” calls turn out to be a blown fuse a seized blower wheel or a bad resistor.

Preventive maintenance and lifespan

A little maintenance goes a long way. Here is what I do for my own setups and what I advise customers.

- Replace filters on schedule. A clogged filter raises static pressure and forces the blower to work harder. That shortens its life.

- Keep returns and supply vents clear. A sofa blocking a return can double the load on the fan.

- Clean the blower wheel and housing. If you can safely access them a light vacuum helps. Debris on the wheel adds weight and causes vibration.

- Inspect the cabin air filter in your car. Replace it if it looks dirty or smells musty. Drivers often skip this simple fix.

- Listen for new noises. A squeal that comes and goes is your early warning signal.

- Check the HVAC run capacitor during seasonal service. Replace weak capacitors before they stress the motor.

How long does a blower motor last? I usually see residential blower motors run 10 to 15 years when maintained. Automotive blower motors often last 7 to 12 years. Usage heat and dust make a big difference.

FAQs

Q: Can I drive my car with a bad blower motor

A: You can if the motor simply does not blow. The engine will run fine but you lose defrost performance. That can become a safety issue in rain or cold since you need airflow across the windshield to clear fog. If the blower emits smoke or a burning smell do not drive until you inspect and fix it.

Q: How do I know if it is the blower motor or the resistor

A: If the fan only works on high the resistor is the prime suspect. If it does not work on any speed including high check for power at the motor connector. Power present with no spin points to the motor. No power points upstream to fuses relays resistors or modules.

Q: My HVAC fan hums but will not start. What does that mean

A: On many systems that means the run capacitor has failed. Replace the capacitor and try again. If it still hums the motor may have seized bearings or damaged windings.

Q: The fan runs yet airflow feels weak. Where do I start

A: Check filters first. Then check the blower wheel for debris. Make sure all supply and return vents are open. If the fan sounds normal after that the motor may be tired or the ductwork may be restricted.

Q: Is it expensive to fix a bad blower motor

A: It depends on access and motor type. Home systems tend to range between about $350 and $1300 all in. Cars often fall between about $180 and $700. Resistors and relays usually cost much less.

Q: Can I test a blower motor with a multimeter

A: Yes. Do a blower motor voltage test at the connector with the fan commanded on. Then do a continuity test across the motor windings with power disconnected. You can also check current draw with a clamp meter.

Q: Can a dirty air filter cause blower motor issues

A: Absolutely. A clogged filter restricts airflow which makes the motor work harder. That leads to overheating and early failure.

Q: What are the consequences of ignoring a failing blower motor

A: Expect higher energy use weak comfort and risk of collateral damage. A furnace can overheat. An AC coil can freeze due to low airflow. In a car you lose defrost which is a safety issue.

Q: What does a bad blower motor sound like

A: Squealing suggests bearings. Grinding suggests debris or a damaged wheel. A heavy hum with no spin suggests a bad capacitor or a seized motor.

Q: Is there anything I should know about motor construction that affects reliability

A: Motors use laminated cores to reduce losses and heat. Better laminations and design generally mean cooler operation and longer life. If you want a deeper dive into how laminations shape performance take a look at stator core lamination and rotor core lamination.

Final thoughts

When I diagnose blower issues I keep two goals in mind. Confirm the symptom and isolate the fault. I don’t guess. I start with filters and airflow. Then fuses relays and resistors. I spin the fan by hand. If needed I bring out the multimeter for voltage and continuity tests. Those steps tell me if I have a bad blower motor a control problem or just a clogged filter.

You can follow the same playbook at home or in your driveway. Take it step by step. Respect safety. If you ever feel out of your depth call a pro. A good technician will save time and protect your system. If you like to understand the why behind the fix the motor principle explains how voltage and magnetic fields become the spinning force that moves air. That little motor makes comfort possible so treat it well. Replace filters on time. Listen for change. Fix small issues before they become big ones. Your comfort and your wallet will thank you.

Internal links included: 4