How to Test an Electric Motor with a Multimeter (Voltmeter Function) for Common Faults

Table of Contents

- Introduction: How to Test an Electric Motor with a Multimeter (Voltmeter Function) for Common Faults

- What will you learn today?

- Why should you test your motor?

- What tools do you need to test a motor?

- How do you stay safe every time?

- What should you check before any test?

- How do you test winding continuity with an ohmmeter?

- How do you check winding resistance balance?

- How do you test for a ground fault or weak insulation?

- How do you test a motor capacitor?

- What do the readings mean in real life?

- What common motor problems can you spot fast?

- When should you call a pro?

- How can you prevent the next failure?

- Why do motor cores and laminations matter so much?

- A quick case study from the field

- Data and statistics you can use

- References

- FAQ

- Key takeaways

You have a motor that will not start. Or it hums. Or it overheats. You want a clear way to test it with a multimeter. This guide shows you how to do safe electric motor troubleshooting with simple steps. You will learn where to place the test leads. You will see what number is good. You will know when to replace a capacitor. Then you will know when to call a pro. This is worth reading because it saves time and money. It also keeps you safe.

What will you learn today?

Let’s set the goal. You will learn how to test an electric motor with a digital multimeter. You will use the voltmeter and ohmmeter functions. You will run a motor winding test. You will do a continuity test. You will measure coil resistance. You will check insulation. You will test a capacitor. You will read results like a tech.

I will walk you through single-phase motor testing and three-phase motor testing. We will look at AC motor and DC motor checks. You will see how the multimeter helps with an HVAC motor test. We will also touch on fan motor, pump motor, compressor motor, and washing machine motor checks. You can do DIY motor testing. You can also know when you need professional motor testing.

Why should you test your motor?

Problem: a motor stops. It hums but does not turn. It trips a fuse. It trips a circuit breaker. It smells burned. You feel stuck. You do not know if the windings are good. You do not know if there is a short circuit or an open circuit. You do not know if the motor has a ground fault.

Agitate: you flip the switch again. Nothing. The HVAC is down. The pump is off. You worry about cost. You do not want a long wait. You do not want guesswork. You want fast answers.

Solution: a multimeter gives you fast answers. Use it to check winding integrity. Use it to read phase-to-phase resistance. Use it to check phase-to-ground resistance. Use it to spot resistance imbalance. A few tests tell you if the motor nameplate ratings match your readings. Then you decide to repair or replace. You avoid more damage. You avoid unsafe conditions.

What tools do you need to test a motor?

You do not need a lab. You need:

- A digital multimeter (DMM) with volts, Ohms, continuity, and capacitance

- Insulated screwdrivers and pliers

- Test leads in good shape

- Wire strippers and electrical tape if you need to clean a terminal

- Safety glasses and gloves

- Optional: a megohmmeter for insulation resistance test

- Optional: an analog multimeter if you like needle swing

- Optional: an ammeter to check current draw motor under load

You can also use a voltmeter to verify zero volts. You can use an ohmmeter motor test for the windings. You can read a multimeter display for expected motor readings. If you test a DC motor you may also do an armature test with a multimeter. If you test universal motors or brushed DC motors you may look at brushes and commutator too.

How do you stay safe every time?

Safety first. Lock it out. Tag it out. Use lockout/tagout (LOTO). Verify zero voltage with your voltmeter. Never touch live terminals. Avoid contact with live circuits. Follow NFPA 70E and OSHA safe electrical practices.

Discharge capacitors. A motor capacitor can hold charge. Use a resistor or proper tool to discharge. Keep one hand behind your back when you probe in tight spots. Wear PPE. Check your test leads. Do not use damaged leads. Do not guess. Be sure.

What should you check before any test?

Start with your eyes and nose. Look for scorch marks. Smell for burned out motor windings. Check the terminal box connections. Tighten loose wires. Read the motor nameplate data. Note voltage, phase, wire gauge, and expected amps. Note single-phase or three-phase. Note start and run terminals.

Spin the shaft. Check bearings and shaft for free movement. A stiff shaft points to bearings or shaft alignment check. Listen for scraping. You can spot rotor bar integrity issues in some cases. You can also see a broken fan blade or a blocked pump. Mechanical faults cause electrical trouble. Fix them first.

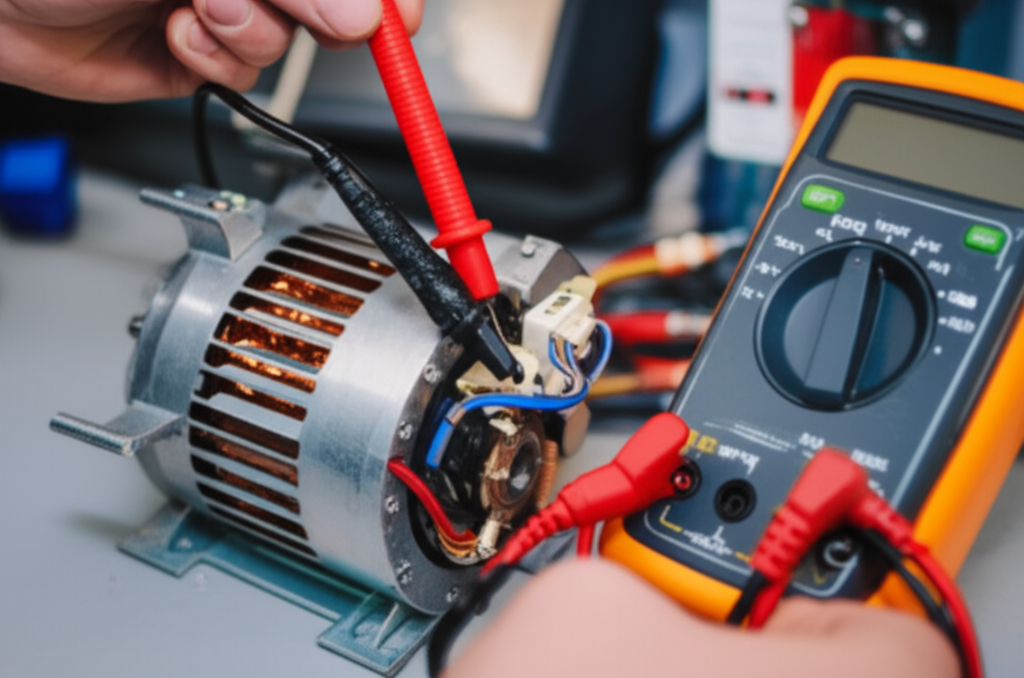

How do you test winding continuity with an ohmmeter?

Now we test winding continuity. Set your DMM to Ohms or continuity. Isolate the motor. Disconnect from the power supply, motor starter, and control circuit. For a three-phase motor, label T1, T2, T3. For a single-phase motor, find Start and Run. On a DC motor you will see armature and field.

Touch the leads to each winding pair:

- Three-phase: T1-T2, T2-T3, T3-T1

- Single-phase: Start-Run

- DC motor: armature segments as needed

Good: you see low, stable resistance. The value depends on motor size. A small fan motor may show 5 to 30 Ohms. A large industrial electric motor may show less than 1 Ohm. Bad open circuit: your meter shows OL or infinite resistance. That means open winding. Bad short circuit between turns will not always show here with a basic DMM. We will check balance next.

This ohmmeter motor test is the core of electric motor troubleshooting. It finds open circuit motor windings fast.

How do you check winding resistance balance?

Set the DMM to Ohms. Measure each pair on a three-phase motor: T1-T2, T2-T3, T3-T1. Write the numbers. Compare them.

Good: the readings match within about 5% to 10%. If one pair reads much lower you may have shorted windings. That causes overheating. It causes low torque. It can trip breakers. It can drop motor efficiency.

This winding resistance values balance check also applies to phase-to-phase resistance on larger motors. If you see resistance imbalance you can flag it for predictive maintenance motor review. If you maintain a fleet you can trend these numbers. That is dynamic motor analysis over time. It starts with static motor analysis today.

How do you test for a ground fault or weak insulation?

A ground fault means the winding touches the frame. That is unsafe. It can shock. It can trip a GFCI or breaker. We test it.

Set your DMM to Ohms. Place one lead on a winding terminal. Place the other on bare metal of the motor frame. Scrape for clean metal if you must. Good: OL or infinite. Bad ground fault: any measurable resistance. A DMM shows big problems. It may miss subtle issues.

Better: use a megohmmeter for motor insulation resistance. It sends higher test voltage. It reads in megaohms. Follow IEEE Std 43-2000 guidance. A common rule of thumb says at least 1 MΩ per kV plus 1 MΩ. For a 460 V motor that is about 1.46 MΩ. A megohmmeter gives a real insulation resistance test motor. You can also do dielectric strength test with other gear. You can also do partial discharge testing for advanced systems. Those are for a pro.

How do you test a motor capacitor?

Many single-phase motors use a start or run capacitor. A bad capacitor can cause motor humming but not turning. It can cause weak performance.

Discharge the capacitor. Remove the wires. Set your DMM to capacitance. Read in microfarads (µF). Compare to the label. Good: close to the value. Bad: much lower, much higher, or OL. Replace a bad motor capacitor. You can also test with resistance mode and watch the charging curve on an analog meter. A DMM with capacitance mode makes it easy.

This simple capacitor test fixes many HVAC and appliance motor repair jobs fast.

What do the readings mean in real life?

Let’s decode results with clear signs:

- OL on winding test: open winding. Motor will not start.

- Very low resistance between winding and frame: ground fault test failed. Unsafe to run.

- One winding pair much lower than the others: shorted winding. Motor overheats.

- Balanced winding resistance yet motor trips on start: check motor startup current and motor control circuit test.

- Good windings yet motor hums: test and replace a bad capacitor.

- Good readings yet motor runs hot: check voltage drop test motor. Check current draw motor under load with an ammeter.

You also check terminal box connections. You check the motor starter. You check the fuse. You check the circuit breaker size. You confirm the power supply matches the nameplate voltage and frequency. You confirm power factor correction is not off in your system.

What common motor problems can you spot fast?

Here are common failures and how your DMM helps:

- Motor not starting or humming: open winding, bad capacitor, or seized bearings.

- Tripping breakers: short to ground, shorted windings, or bad wiring.

- Overheating motor diagnosis: resistance imbalance, low voltage, high current, blocked air path.

- Burned out motor windings: low insulation readings, char smell, black varnish.

- Weak performance or low torque: partial shorts, wrong capacitor, wrong wiring diagram for motors.

You can test small electric motor units the same way. You can test an industrial electric motor with the same steps. You can test a brushless DC motor testing setup with caution since you need its controller. You can test brushed DC motor testing with armature continuity checks. You can test shaded pole motor testing and universal motor testing with simple Ohms checks. You can do synchronous motor diagnostics with more advanced gear. You can also do stepper motor testing and servo motor testing with a DMM for basic continuity. Many faults show up even at rest.

When should you call a pro?

A basic multimeter finds open windings. It finds shorts to ground. It finds resistance imbalance. It helps you identify motor faults. It handles 70% to 80% of electrical winding problems by static tests.

Some issues need more than a DMM. Subtle insulation breakdown calls for a megohmmeter or a surge comparison test. Rotor bar integrity calls for special tests. Core loss testing needs a lab. Infrared motor scanning can show hot spots while under load. Vibration analysis motor checks find bearing and alignment issues. Dynamic motor analysis under load shows deeper issues.

If you see water inside the terminal box you need a pro. If you have a large three-phase induction motor on a mission critical line you need a pro. If you work in a plant follow NEMA and IEC best practices. Hire a certified electrician or technician when in doubt.

How can you prevent the next failure?

Preventative motor maintenance works. It saves money. It reduces downtime. It extends motor lifespan. Build a simple plan:

- Clean the terminal box. Tighten terminal screws.

- Log resistance readings for each motor. Watch for drift.

- Do a regular insulation resistance test with a megohmmeter. Follow IEEE Std 43-2000.

- Check bearings. Listen and feel. Do a bearings test.

- Verify shaft alignment. Fix misalignment fast.

- Record voltage drop and current draw under load.

- Check motor shaft grounding where needed.

- Inspect the motor starter contacts.

- Check fuses and the circuit breaker rating.

- Read nameplate data. Match power supply.

Predictive maintenance motor plans cut costs by 15% to 30%. They reduce breakdowns by 30% to 50%. That is smart for any shop.

Why do motor cores and laminations matter so much?

Here is the big picture. Good motors start with good cores. The stator and the rotor hold stacked laminations. These laminations reduce core losses. They boost motor efficiency. They run cooler. They last longer.

If you build or repair motors you should care about lamination quality. The grade of steel matters. The cut and stack matter. The bonding matters. The slots and teeth matter for flux path. If you want better performance look at high quality stator core lamination. Pair it with quality rotor core lamination. When you need a full set for a new build you can source complete motor core laminations. The right electrical steel laminations improve motor health. They help with motor efficiency testing and real-world torque. They cut heating and core loss. That means longer life for windings and insulation.

Want a quick refresher on how these parts work together? Read this simple guide on stator and rotor. It shows how energy moves from the power supply to the shaft.

A quick case study from the field

I got a call about an HVAC system. The blower fan would not start. It only made a low hum. The tech had a multimeter. He followed HVAC motor test procedures. He set the DMM to Ohms. He ran a continuity test motor on the start and run windings. Readings looked fine. Next he tested the capacitor. It read far below the µF rating. He replaced it. The blower started at once.

Another day I saw a pump motor that tripped the breaker at start. It was a three-phase induction motor. I tested phase-to-phase resistance. One pair read much lower than the others. That pointed to shorted windings. The motor showed burnt varnish. We decided repair vs replace motor. The damage was deep. The cost of motor failure was high. We replaced it. We also checked shaft alignment and bearings. We logged nameplate data. We checked the motor control circuit. The fix stuck.

Data and statistics you can use

Here is a quick table with useful facts.

| Data Point | Description and Metric | Why it matters |

|---|---|---|

| Motor failure modes | Windings or stator faults about 30% to 38%. Bearings 40% to 50%. Rotor 5% to 10%. Other 10% to 15%. | Your DMM can find many winding faults. Check bearings too. |

| Detectability by static tests | About 70% to 80% of winding faults show in offline resistance and insulation tests. | Your DMM helps with most basic faults. |

| Winding resistance imbalance | More than 5% imbalance can show a winding issue. | Measure all pairs on three-phase motors. |

| Insulation resistance | Aim for at least 1 MΩ per kV plus 1 MΩ. | A megohmmeter gives accurate MΩ readings. |

| Capacitor failure rate | About 10% to 15% of single-phase motor failures are due to capacitors. | Test and replace bad capacitors. |

| Electrical accidents | About 5% to 10% of workplace deaths involve electrical hazards in the U.S. | Use LOTO and verify zero voltage. |

| Cost savings via PM | Predictive maintenance can cut costs by 15% to 30% and reduce breakdowns by 30% to 50%. | Plan regular checks. |

| DMM accuracy | Resistance accuracy about ±0.5% to ±1.5% for many DMMs. | Good enough for open, short, and balance checks. |

These numbers tie to sources like EPRI and IEEE motor studies, NEMA MG 1 guidance, IEEE Std 43-2000, OSHA, NFPA 70E, and maker specs from Fluke or Klein.

References

- IEEE Std 43-2000, Recommended Practice for Testing Insulation Resistance of Rotating Machinery

- NEMA MG 1, Motors and Generators, Section 20.37 on tolerances

- OSHA and NFPA 70E electrical safety guidance

- EPRI and IEEE motor failure surveys

- Fluke and Klein Tools DMM product specifications

- Maintenance Technology reports on predictive maintenance gains

FAQ

Q: Can I test a motor with only a voltmeter?

A: You can verify zero volts. You can check supply voltage. For motor winding tests you need the ohmmeter function. A multimeter gives both.

Q: What is a good reading for insulation to ground?

A: A DMM should show OL for basic safety. A megohmmeter should show high MΩ. Follow IEEE Std 43-2000.

Q: How do I test a universal motor?

A: Check continuity of the field and armature. Check brushes and commutator. Use the DMM for Ohms and continuity.

Q: Can I test under load?

A: Yes. You can check voltage drop test motor and current draw motor with an ammeter. Be careful. Live tests need training.

Q: Does a growler test help?

A: A growler test helps on DC armatures. It needs a special tool. Most DIY users do not have it.

Key takeaways

- Always disconnect power. Use LOTO. Verify zero volts with a voltmeter.

- Run a winding continuity test with your ohmmeter. OL means an open winding.

- Check resistance balance across phases. A big drop points to shorted windings.

- Test insulation to the frame. DMM shows gross faults. A megohmmeter shows true MΩ.

- Discharge and test capacitors. Many single-phase issues are bad capacitors.

- Match power supply to motor nameplate data. Check fuses and the circuit breaker.

- Inspect bearings and shaft. Fix alignment. Mechanical faults hurt the motor.

- Use predictive maintenance. Log resistance and IR readings. Watch for change.

- For deeper checks use surge comparison test, core loss testing, infrared motor scanning, vibration analysis motor, and dynamic motor analysis.

- Quality cores and laminations boost efficiency and life. Consider proven stator and rotor lamination sources when you build or repair.