How to Test Stator Windings: A Comprehensive DIY and Professional Guide

- Table of Contents

- Introduction

- What Is a Stator Winding and Why Test It?

- Are These Bad Stator Symptoms Showing Up?

- How Do You Stay Safe Before Any Electrical Test?

- What Tools Do You Need to Test a Stator?

- What Kinds of Stator Faults Should You Expect?

- How Do You Do a Quick Continuity Test?

- How Do You Measure Winding Resistance and Balance?

- How Do You Check for a Ground Fault?

- When Should You Use a Megohmmeter for an Insulation Resistance Test?

- How Do You Read and Combine All Results?

- What Should You Do If the Stator Fails the Tests?

- How Do You Prevent Future Stator Winding Failure?

- Real-World Data, Case Notes, and a Handy Table

- DIY or Professional Help: Which One Makes Sense?

- FAQ

- Key Takeaways

Testing your stator windings does not need to feel scary. I will walk you through it in plain steps. You will see what to do, what tools to use, how to stay safe, and how to read your numbers. You will save time. You will stop guesswork. You can fix a motor right the first time.

Problem. Your motor runs hot, slows down, or will not start. Your generator drops power. Your motorcycle has no spark or weak charging. You fear a bad stator winding.

Agitate. Downtime hurts. You lose work and money. A small fault can cook insulation and cause a short or a ground fault. That can lead to a bigger repair.

Solution. Test the stator windings with a multimeter and a megohmmeter. Use a clear flow. Use simple checks first. Then use advanced checks. I will show you every step. I will also share how better parts like quality stator core lamination and smooth motor core laminations help prevent winding failure.

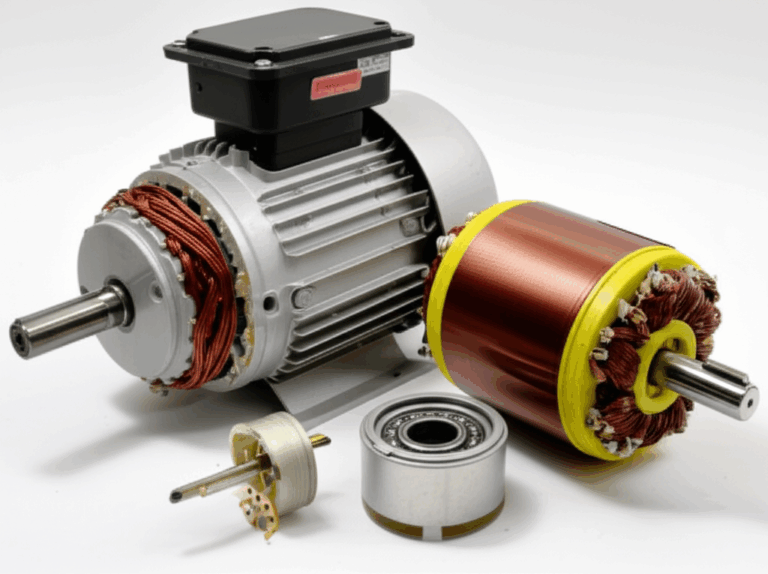

What Is a Stator Winding and Why Test It?

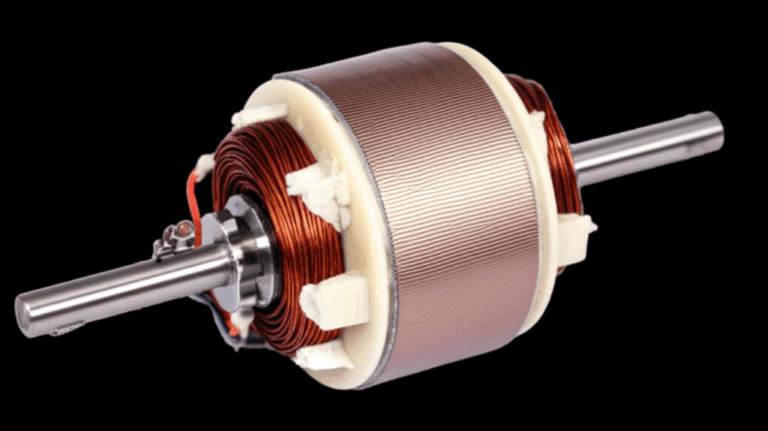

A stator is the still part of an AC motor, DC motor, alternator, generator, or magneto. The rotor spins inside. The stator winding is the copper coil that makes the magnetic field. It turns electrical energy into motion or makes power in a generator.

Why test it. Windings face heat, vibration, moisture, and dirt. The varnish can break down. A short circuit can form turn-to-turn. An open circuit can break the loop. A ground fault can push current to the frame. If you test early you catch small problems before you get smoke or a dead motor.

I learned this the hard way. Years ago my pump motor slowed and popped a breaker. I grabbed my digital multimeter and did a continuity test. The winding was open. A fast test saved the day. I swapped the stator and got the water back on.

Are These Bad Stator Symptoms Showing Up?

Watch for these signs in an AC motor or DC motor:

- Power loss under load

- Overheating motor causes hot housings or a hot smell

- Vibration motor issues that grow with time

- Unusual noise and hum

- Tripped breakers or blown fuses

- Bad stator symptoms like weak charging on a motorcycle or ATV

Engines tell on themselves too. No spark troubleshooting stator is common on small engine stator test jobs. Lawn mower stator test and marine engine charging system test steps look similar. Vehicle alternator fault finding often points to the stator in the alternator. E-bikes and an electric scooter may show dim lights or low range. Fans, pumps, power tools, refrigerator compressor, and HVAC motor loads can show slow starts or stalls. When in doubt test.

How Do You Stay Safe Before Any Electrical Test?

Electricity can bite. Take safety first.

- Disconnect power supply. Unplug. Remove the battery cable. Lock out a breaker.

- Use electrical safety lockout and tagout if the site needs it.

- Wear Personal Protective Equipment (PPE) like insulated gloves and safety glasses.

- Discharge capacitors before you touch leads.

- Work in a dry area. Moisture ingress motor faults get worse when you add wet hands.

- Follow the service manual and wiring diagram if you have them.

I also keep my workbench neat. I label test leads. I use good light. Little habits stop big mistakes.

What Tools Do You Need to Test a Stator?

You can do a lot with a simple kit.

- A Digital Multimeter (DMM) with Ohms and continuity

- An Ohmmeter function for low resistance numbers

- A Megohmmeter for insulation resistance test motor checks

- Alligator clip test leads to free your hands

- A continuity tester for quick beeps

- A growler test motor tool if you work on armatures and some stators

- Surge comparison test motor gear and partial discharge test windings tools for deeper pro work

- A service manual or specs for acceptable resistance values motor wide

- Basic hand tools to access the stator plate and electrical connector

Brand matters. Fluke and Megger make solid testers. They last and give you stable readings.

What Kinds of Stator Faults Should You Expect?

You will see three big fault types.

- Open circuit. The winding breaks and current stops. A continuity test will not beep. The DMM shows OL or infinite resistance.

- Short circuit. The insulation breaks down turn-to-turn or phase-to-phase. Current takes a shortcut. Resistance drops lower than normal.

- Ground fault. Current leaks from a coil to the core or frame. The fault goes phase-to-ground.

Insulation resistance test motor checks catch weak varnish and contamination motor failure risks. Heat damage motor windings and varnish damage stator often follow long overloads. Moisture ingress motor and dirt speed up insulation breakdown causes. Wear and tear motor windings, manufacturing defects motor, or quality control motor testing misses can all play a role.

Better materials help. Tight stacks and smooth edges reduce hot spots. Quality electrical steel laminations guide the magnetic field and cut core losses. That keeps the winding cooler which helps it live longer.

How Do You Do a Quick Continuity Test?

Start simple. A continuity test finds open circuits fast.

- Set your multimeter to continuity. The speaker icon shows it. If not, set it to the lowest Ohms range.

- Touch the probes across the ends of each winding or each phase. On a three-phase stator check U-V, V-W, and W-U in pairs. On a single-phase motor you may check start and run windings.

- A good winding beeps or shows low resistance like 0.1 to 5 Ohms. A bad open circuit shows no beep and OL.

This step takes seconds. It can save you from pulling a motor apart for nothing. I always do this first on a motorcycle stator testing job or an ATV stator diagnostics job.

How Do You Measure Winding Resistance and Balance?

Next you check the resistance more closely. You look for a short circuit stator windings fault and for balance.

- Set the DMM to Ohms. Use auto range or a low range.

- For a three-phase motor measure U-V, V-W, W-U. For single-phase measure the start and run coils as shown in the wiring diagram motor stator.

- Write down each reading. Compare them.

What is good. Readings close to spec and uniform across phases. Keep phase-to-phase resistance motor numbers within 5 to 10 percent of each other. What is bad. A reading that is near zero suggests a direct short. A big mismatch over 10 percent shows imbalance.

This method works on AC motor stator diagnostics and DC motor stator troubleshooting. It also helps on alternator stator testing procedure as you compare the three-phase outputs. You can build a stator resistance chart for your shop so you spot odd values fast.

Use Ohm’s Law too. V = I × R. If the resistance is lower than it should be then the current will rise at a fixed voltage. High current makes heat. Heat cooks insulation. That is why a low reading is a red flag.

How Do You Check for a Ground Fault?

A ground fault test looks for a leak from a winding to the frame.

- Set your DMM to continuity or a high Ohms range like 20 MΩ.

- Put one probe on a winding lead. Put the other on a clean bare spot on the stator core or motor case.

- A good stator shows no beep and OL. A bad stator shows a beep or any measurable resistance.

Do this with the stator leads isolated from the rest of the circuit. That keeps the rectifier or voltage regulator and any filter capacitors out of the path. In vehicles you may also do a rectifier diode test for stator and a voltage regulator testing check if charging is weak.

When Should You Use a Megohmmeter for an Insulation Resistance Test?

A megohmmeter sends DC at a higher test voltage like 500 V or 1000 V. It measures insulation health in Megaohms.

- Use it when the motor matters. Industrial machinery, compressors, HVAC systems, and pump motors often need this.

- Select the right test voltage for the rated motor voltage as per IEEE or the manufacturer.

- Test phase-to-ground. Test phase-to-phase on a three-phase motor.

What number is good. A practical rule is more than 1 MΩ is a minimum for motors in service. New motors often measure over 100 MΩ. IEEE Std 43 gives guidance. One common rule of thumb says IR in MΩ should be at least kV + 1 where kV is the rated motor voltage in kilovolts at 40°C. Higher is better.

If you see a drop from your baseline you may have moisture, dirt, or insulation breakdown. Dry the motor if needed. Clean it. Test again. You can also try a polarization index test if you have time.

How Do You Read and Combine All Results?

Do not read any single test in a vacuum. Put them together.

- Continuity test: catches open circuit faults.

- Resistance test: finds short circuits and phase imbalance.

- Ground fault test: finds phase-to-ground faults.

- Megohmmeter test: shows insulation health and trends.

Here is a quick table you can use.

| Test | Good Result | Bad Result | Fault Type |

|---|---|---|---|

| Continuity | Beep or low Ohms | No beep or OL | Open circuit |

| Resistance balance | Phases within 5–10% | >10% mismatch or near zero | Short or imbalance |

| Ground fault | OL to frame | Any measurable path | Ground fault |

| Insulation resistance | High MΩ and stable | Low MΩ or dropping | Insulation breakdown |

If two tests point to the same fault you likely have your answer. For example a very low resistance reading and a ground path means a shorted coil that also touches the frame. If the resistance looks fine yet IR is low you might have wet windings or contamination.

What Should You Do If the Stator Fails the Tests?

Problem. Your stator fails. The motor is down. Work stops.

Agitate. The longer you wait the more you lose. A failed winding can hurt bearings and the rotor. Overheating can warp parts.

Solution. Choose the right fix.

- Replace the stator on small motors or machines. It is often cheaper and faster than a rewind.

- For large or special motors a professional rewind can save cost. A rewind can run 40 to 70 percent of a new motor. Replacement of a small unit may cost less.

Also fix the root cause. Check cooling and ventilation. Clean ducts and filters. Look for voltage issues and overloads. Address vibration. Track operating temperature and electrical current. Moisture and contamination are common causes so seal and protect as needed.

If you build or spec motors you can boost life with better cores. Precision rotor core lamination and tight stator core lamination stacks reduce stray losses. That means less heat in the windings. Less heat means longer life.

How Do You Prevent Future Stator Winding Failure?

I like simple habits that pay off.

- Regular cleaning and debris removal

- Ensure proper cooling and ventilation

- Monitor temperature with sensor technology motors like RTDs or thermal imaging motor scans

- Track vibration analysis motor data and correct imbalance or misalignment

- Keep a diagnostic flow chart motor plan and record your values

- Do predictive maintenance motors. Use condition monitoring electric motors and motor circuit analysis (MCA). Even online motor testing works when you cannot stop the line. Save records in your asset management motor system and use predictive analytics motor tools to spot trends.

If the application is harsh consider sealed housings. If the duty is heavy look at larger frames. Always use specs and service manual motor testing methods from the maker.

Real-World Data, Case Notes, and a Handy Table

Let us ground this in data. In many plants bearing related failures make up 40 to 50 percent. Stator related issues often sit around 30 to 40 percent. Rotor related failures are lower. Early detection cuts unplanned downtime by a lot and helps you plan repairs.

Here is an at-a-glance table you can use in the shop.

| Topic | What to Remember | Field Tip |

|---|---|---|

| Typical winding resistance ranges | Small motors 0.5–20 Ω per phase. Medium 0.05–1 Ω. Large <0.05 Ω. Always check specs. | Warm copper changes resistance so note temperature. |

| IR standards | IEEE guidance. Aim high. In service >1 MΩ is a common floor. New motors often >100 MΩ. | Record baseline when new. Watch for big drops. |

| Test effectiveness | Continuity finds opens. Balance finds shorts. Ground test finds leaks. Megohmmeter finds weak insulation. | Combine results for the full picture. |

I once helped an HVAC team with a big compressor motor. Insulation resistance dropped at a routine check. We planned a change during a slow week and saved a rush fee. That simple test paid for itself.

DIY or Professional Help: Which One Makes Sense?

You can handle many tests if you follow steps and stay safe. A DIY motor repair can solve small engine stator test issues and simple shop motors. Power tool motor test jobs often take minutes. Fan motor winding test steps are quick too.

Call a pro when the motor is large or critical. Industrial machinery and compressor motor diagnostics often need surge comparison, partial discharge, and MCA. A pro shop may use a growler test motor tool, a high-end megohmmeter, and thermal imaging. They will give you a clear report with specifications motor windings and interpretation of test results motor.

If you repair or build motors for EVs or drones you might also look at a BLDC stack. A well made bldc stator core supports high efficiency and smooth torque. That reduces heat in the windings and helps with motor efficiency issues and performance issues electric motor wide.

FAQ

Q: Can I test a stator on the bike or should I remove it

A: You can do basic checks in place. Do continuity, resistance, and ground tests with the stator leads unplugged. For an insulation test remove the stator or isolate it fully.

Q: What about an alternator in a car

A: You can test alternator stator resistance between phases and check for a ground fault. Also test the rectifier diode and the voltage regulator for a full charging system fault finding path.

Q: Do I need a megohmmeter

A: For home and small jobs a DMM is fine. For industrial work get a megohmmeter. It finds early insulation problems you cannot see with a DMM.

Q: Does a DC motor stator test differ

A: The steps look the same. Check continuity, resistance, and ground. Some DC machines use a different coil layout so follow the wiring diagram.

Q: What if readings drift as I test

A: Temperature and contact pressure can change small values. Use alligator clips. Let the motor sit at room temp when you can. Clean terminals.

References

- IEEE Std 43. IEEE Recommended Practice for Testing Insulation Resistance of Rotating Machinery

- NEMA MG 1. Motors and Generators

- EPRI and industry reliability studies on motor failure modes

- Manufacturer service manuals and wiring diagrams for specific motors

- Fluke and Megger user guides for DMM and IR testing

Key Takeaways

- Test the stator winding with a plan. Start simple then go deeper.

- Use a digital multimeter for continuity test stator coil checks, ohmmeter stator test steps, and ground fault stator test checks.

- Use a megohmmeter insulation resistance test motor step for deeper health checks.

- Compare numbers to specifications motor windings and keep phase-to-phase resistance motor readings balanced.

- Fix root causes. Heat, moisture, and dirt drive insulation breakdown causes.

- Use condition monitoring electric motors and predictive maintenance motors to catch faults early.

- Quality cores matter. Choose tight, clean motor core laminations and smooth stator core lamination plus well matched rotor core lamination to lower heat and protect windings.

- Keep PPE handy. Follow electrical safety lockout and discharge capacitors before tests.

- Build a simple diagnostic flow chart motor path and a stator resistance chart for your shop.

- Document each test. Use asset management motor tools and predictive analytics motor methods to spot trends early.

Additional Notes that Help You Use This Guide Right Now:

- For single-phase motor testing check both start and run windings. Many starter motor winding test jobs also include checking the armature and brushes.

- For three-phase motor winding test work write down all three pairs. Keep them within 5 to 10 percent.

- In a generator stator testing or alternator stator testing procedure always isolate phase-to-phase and phase-to-ground paths.

- AC and DC tests share the same core ideas yet component layouts differ. A magneto on a small engine ties into the ignition coil primary secondary test path so follow the service manual motor testing steps.

- When you see varnish damage stator, heat damage motor windings, or contamination motor failure signs consider replacement. It is often faster than a rewind on small units.

- For better materials and build quality look for precise electrical steel laminations that reduce core losses and help windings run cooler.

Detailed Checklist of What You Did Today:

- You gathered measurement tools motor diagnostics like a DMM, a megohmmeter, and alligator clips.

- You followed safety precautions electrical testing with PPE.

- You did continuity, resistance, and ground checks.

- You measured insulation resistance with proper test voltage.

- You reviewed acceptable resistance values motor and used manufacturer data.

- You read common motor problems and found the true cause.

- You planned preventative maintenance motors steps like cleaning, ventilation, thermal imaging motor scans, vibration analysis motor checks, lubricant analysis motor related, online motor testing for live checks, and offline motor testing during shutdowns.

- You used a troubleshooting guide motor windings and a diagnostic flow chart motor to keep things clear.

- You used measurement tools motor diagnostics from trusted brands like Fluke and Megger.

- You confirmed your results with interpretation of test results motor standards and decided on replacement vs professional motor diagnostics or a rewind.

With these steps you can test a stator winding today. You can read your results with confidence. You can keep your machines running strong yet safe.