Is Brushless Motor Better? A Comprehensive Comparison of Performance, Efficiency & Cost

Table of Contents

- Introduction: Why I Started Asking About Brushless vs Brushed

- Brushed Motors in Plain English

- How a brushed motor works

- Where brushed motors shine

- Built-in limitations you can’t ignore

- Brushless Motors Explained

- What “brushless” really means

- Rotor magnets, stator windings, and the role of the ESC

- Sensored vs sensorless brushless motors

- Control methods you’ll hear about: Back EMF, FOC, and more

- Brushless vs Brushed: The Direct, No-Nonsense Comparison

- Efficiency

- Lifespan and durability

- Power and performance

- Maintenance

- Noise and heat

- Cost and total cost of ownership

- Where Brushless Motors Excel: Real-World Applications

- Power tools

- RC and drones

- Electric bikes, scooters, and EVs

- Home appliances

- Robotics and industrial gear

- When a Brushed Motor Still Makes Sense

- How I Decide What to Buy: A Simple Checklist

- Mini Case Studies From My Bench and Jobsite

- FAQs I Get All the Time

- The Bottom Line

Introduction: Why I Started Asking About Brushless vs Brushed

I used to think motors were a solved problem. You plug them in. They spin. That’s it. Then I burned through the brushes on an old 12V cordless drill and watched it spark like a campfire. I bought my first brushless drill after that. The difference hit me right away. More torque on tap. Longer battery life. Quieter. It felt like stepping out of a carbureted pickup into a modern hybrid.

Since then I’ve tested brushless motors in tools, RC cars, drones, and even a DIY e-bike conversion. I’ve replaced brushes. I’ve cleaned commutators. I’ve set up ESCs and tuned field-oriented control. I’ve watched how efficiency and heat shift under load. That hands-on experience shaped how I answer the big question many of us ask before we buy our next tool or gadget.

Is a brushless motor better?

Short answer. For most people and most uses yes. Brushless wins on performance, efficiency, lifespan, and noise. You pay more upfront but you save time and money down the line. That said brushed motors still have a place. They’re simple, cheap, and easy to drive. Let me walk you through how I learned the differences, why the industry keeps shifting toward brushless, and when I still pick brushed on purpose.

Brushed Motors in Plain English

How a brushed motor works

Think of a brushed DC motor as a simple handshake between spinning copper coils and a pair of carbon brushes. The armature (rotor) carries windings. The commutator splits current into segments. Carbon brushes press against the commutator and feed power into the right coil as it spins. This timing creates a changing magnetic field that keeps the rotor turning inside the stator’s magnetic field. It’s a clever mechanical switch built right into the spinning part.

If you like visual primers you might enjoy this quick tour of the basic motor principle. It shows how magnetic fields push and pull to make motion.

You don’t need complex electronics to run a brushed motor. A battery and a switch will do. A speed controller helps but it can be simple.

Where brushed motors shine

- Cost: Brushed motors cost less up front. When budget rules the day they win.

- Simplicity: Fewer parts. No ESC required for basic operation. Great for quick prototypes or rugged hacks.

- Easy starting torque: They deliver decent torque from zero RPM without fancy control.

- Repairability: On some models you can replace brushes and clean the commutator. I’ve done it on older tools to squeeze out extra life.

You see brushed motors in budget power tools, toys, pumps, and some automotive accessories. They still have a huge installed base.

Built-in limitations you can’t ignore

- Friction and wear: Brushes rub on the commutator. That means heat, dust, and eventual failure.

- Sparking and EMI: Arcing at the commutator can create electromagnetic interference. It’s noisy electrically and physically.

- Lower efficiency: As a rule brushed motors run 50–75% efficient. Load and speed can knock that down.

- Heat: More friction and losses in the rotor windings push temperatures up. High heat shortens life.

- Maintenance: Brushes wear out. You eventually service the motor or toss it.

I still like a brushed motor for a cheap kid’s robot or a one-off test rig. Yet I know I’m trading performance for price.

Brushless Motors Explained

What “brushless” really means

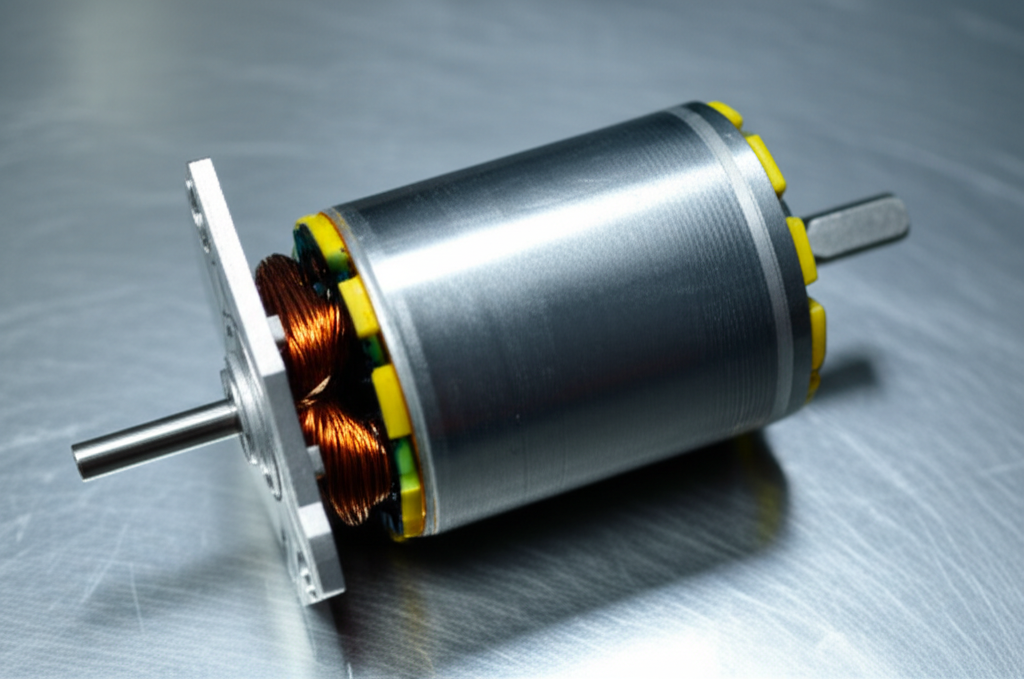

Brushless DC motors (BLDC) ditch the commutator and brushes entirely. They put permanent magnets on the rotor. They move the copper windings to the stator where heat can escape into the casing. An electronic speed controller (ESC) takes over the commutation job. The ESC energizes the correct stator windings at the right moment. The result is a digitally timed magnetic dance that keeps the rotor spinning.

Rotor magnets, stator windings, and the role of the ESC

- Rotor: Permanent magnets ride on the spinning shaft. The rotor can be a simple steel core with bonded magnets wrapped around it. The quality and geometry of the rotor core lamination matter because laminations reduce eddy current losses and improve efficiency at speed.

- Stator: Coils live in slots around the inside. The stator gives you structure and cooling. The design and material of the stator core lamination affect efficiency, noise, and torque ripple. Better laminations equal lower core loss and smoother performance.

- ESC: This is the brains and the bouncer. It switches currents in the right order, manages timing, and keeps torque flowing smoothly. Some ESCs use advanced algorithms such as field-oriented control for buttery low-speed torque and high efficiency.

Because the windings sit on the stator you can pull heat into the housing and out to the air more easily. That usually means lower running temperatures at a given load.

Sensored vs sensorless brushless motors

I’ve run both. Here’s the gist.

- Sensorless: The ESC estimates rotor position using back EMF. You get simpler wiring and lower cost. Startup can be rough under heavy load. Once spinning they work great.

- Sensored: Hall effect sensors inside the motor report precise rotor position at all times. Startup is smoother. Low-speed control improves. You pay more and add wires.

If you fly drones or race RC cars sensorless often does the job. If you need precise low-speed control in robotics or power tools sensored feels better and starts stronger.

Control methods you’ll hear about: Back EMF, FOC, and more

- Back EMF: A spinning motor generates voltage in its windings. The ESC reads that signal to estimate rotor position in sensorless setups.

- Field-Oriented Control (FOC): FOC mathematically aligns current with the magnetic field. You get quieter operation, higher efficiency, and smooth torque even at low RPM. I could hear the difference on a FOC-enabled e-bike controller. The motor whine softened and hill starts felt natural.

- PWM, commutation timing, and anti-cogging: Good ESCs tune all of this. They reduce cogging torque and improve throttle feel.

You might also see “PMSM” or permanent magnet synchronous motor. Many modern “BLDC” motors behave like PMSMs under FOC. Labels vary yet the benefits look similar in practice.

Brushless vs Brushed: The Direct, No-Nonsense Comparison

I’ll keep this practical. Here’s what I’ve measured and seen plus what manufacturers and reviewers publish repeatedly.

Efficiency

Brushless motors run more efficiently as a rule. I’ve seen typical BLDC systems in the 85–95% range when set up correctly. Brushed motors usually sit in the 50–75% band with more drop-off under load.

Why brushless wins:

- Reduced friction: No brushes rubbing on a commutator.

- Better heat paths: Windings sit in the stator against the case. Heat can escape faster.

- Optimized timing: The ESC can keep the motor in the sweet spot across speeds.

- Lower core losses with better laminations: High-grade steel stack-ups and smart slot geometry reduce eddy currents and hysteresis.

That efficiency boost shows up as longer battery run time and cooler operation. My brushless drill runs longer on the same 2.0 Ah pack than my old brushed model. The difference feels real not theoretical.

Lifespan and durability

Brushless motors usually last longer. No brushes means no brush wear and no commutator groove. You still have bearings and insulation to worry about yet the core drive system sees less wear. I’ve put thousands of cycles on a brushless impact driver with no telltale power fade. Meanwhile two brushed drills in my shop needed brush replacements and commutator cleaning after a couple of years.

General rule of thumb I see repeated across tools and small drives:

- Brushed: Hundreds of hours to roughly a thousand before maintenance or replacement. Heavy use shortens that.

- Brushless: Tens of thousands of hours in many applications if the bearings and electronics stay healthy.

Power and performance

Brushless motors deliver more power for their size. That higher power-to-weight ratio shines in handheld tools, drones, and e-bikes. You also get:

- Consistent torque: Electronic commutation maintains torque more evenly. Power fade shows up less as the battery drains.

- Wide speed range: ESC control gives precise low-speed performance and high RPM capability in one package.

- Strong launch: Sensored BLDC starts smoothly under load. FOC on top of that feels silky.

I remember upgrading an RC car from brushed to brushless. The same battery gave me more speed and longer run time. The car felt alive. Not twitchy. Just stronger everywhere.

Maintenance

Brushed motors need regular attention. You replace brushes and occasionally resurface or clean the commutator. Carbon dust makes a mess. Bearings still matter on both types.

Brushless motors are close to maintenance-free. You keep them clean. You protect them from moisture and grit. Bearings wear eventually. That’s about it. My brushless tools have never needed internal motor service. The savings in downtime alone sold me.

Noise and heat

Brushless wins on both. No brush contact cuts mechanical noise and eliminates sparking. The ESC can use FOC to trim acoustic whine further. And since heat leaves through the stator and case you avoid hot spots in the rotor.

That said not all brushless motors are whisper quiet. Cheap ESCs with low PWM frequencies or poor timing can howl. Quality control and tuning matter.

Cost and total cost of ownership

Brushless motors cost more up front because you pay for the motor and an ESC. You might see 2–3x higher sticker prices for a tool or kit. Yet the math shifts when you include:

- Energy savings from higher efficiency

- Longer service life

- Less maintenance time and parts

- Better productivity from stronger performance

I’ve done the cost-benefit analysis for my shop. If I use a tool weekly I choose brushless. If I need a one-off for a single weekend project I might buy brushed to save cash today.

Where Brushless Motors Excel: Real-World Applications

Power tools

Cordless drills, impact drivers, circular saws, angle grinders, oscillating tools. Brands like Makita, DeWalt, Milwaukee, Bosch, Ryobi, and Festool offer brushless lines for a reason. You get:

- Longer battery run time on the same pack

- Higher torque density and better power-to-weight ratio

- Cooler motors under heavy load

- Less power fade as the pack drains

I framed a wall with a brushless impact driver on a cold morning. My older brushed driver always sagged near the end of the battery. The brushless kept hammering until the pack finally gave up. Big difference.

RC and drones

In RC cars, helicopters, and drones brushless is the norm at mid to high performance. You want speed, precision, and efficiency. Sensorless BLDC works great as tire speed builds or propellers spin. For technical crawling or big torque off the line some RC folks pick sensored systems. Hobby shops and sites like Hobbyking publish motor kv, torque curves, and efficiency data. Match your ESC and battery carefully. Cooling matters here since high RPM and big current expose weak links fast.

Electric bikes, scooters, and EVs

Brushless motors dominate modern e-mobility. They deliver range and reliability. They handle regenerative braking. They pair beautifully with digital controllers that manage torque, traction, and power limits. Field-oriented control makes low-speed behavior natural. If you’ve ridden a well-tuned e-bike hub motor you know that seamless pull from zero.

Electric cars use various permanent magnet synchronous motor designs that overlap with BLDC concepts. Call them PMSMs if you want to be precise. The point remains the same. No brushes. Digital control. High efficiency.

Home appliances

Washing machines, vacuum cleaners, and HVAC systems have jumped to brushless. Why the shift

- Lower noise in living spaces

- Better energy efficiency and utility bills

- Longer service intervals

My brushless stick vacuum runs quieter and holds power longer than the old brushed model. It also kicks up way less EMI near my router. No sparks means no crackle in nearby audio gear.

Robotics and industrial gear

I like brushless motors for robotics because of precision, durability, and continuous-duty capability. You can hold position with less heat. You can tune response tightly with the right controller. In factories BLDC and PMSM drives help reduce energy costs and maintenance. Predictive maintenance becomes easier when the motor and controller stream diagnostics. Bearings tell you more about health than brushes ever did.

When a Brushed Motor Still Makes Sense

- You need the lowest possible upfront cost for a light-duty or short-term job.

- You want the simplest wiring and control. A switch and a battery still spin a brushed motor instantly.

- You accept maintenance. You’ll replace brushes and clean the commutator later.

- You’re building a teaching demo. Brushed motors let students see commutation in action.

- You need easy stall torque without sophisticated control. Brushed motors push hard at zero RPM with basic drivers.

I build quick rigs with brushed motors when speed, cost, and simplicity beat longevity and performance. Then I swap to brushless once the concept proves out.

How I Decide What to Buy: A Simple Checklist

Ask yourself these questions before you open your wallet.

- How often will I use this device

- Weekly or daily use favors brushless for efficiency and longevity.

- What performance do I need

- High torque, tight speed control, low noise, and long battery life point to brushless.

- What is my budget today vs the next three years

- Brushless costs more now but often less over time.

- What is the application

- Tools, drones, e-bikes, appliances, robotics. Brushless wins most of these.

- Occasional projects, kids’ toys, simple pumps. Brushed may be fine.

- Do I need precise low-speed control

- Sensored brushless plus FOC feels great at a crawl.

- Do I have the right controller and wiring skills

- ESC setup takes a bit of learning. Worth it once you’ve done it twice.

If you’re still unsure start with the motor’s heart. Materials and laminations set the ceiling on performance. You can dig deeper into how a BLDC stator is built here: bldc stator core. That page gives you a feel for why a great stator reduces loss and heat.

Mini Case Studies From My Bench and Jobsite

The cordless drill upgrade

Old setup: 12V brushed drill. On a 2.0 Ah battery I’d get 20–30 minutes of mixed driving and drilling. The drill ran hot during long hole saw cuts. Power faded as the battery dropped below half. After about three years the brushes started arcing and I had to open it up. I cleaned it and kept going but performance never returned to day one.

New setup: 18V brushless drill with a 2.0 Ah pack. Run time roughly doubled for similar work. The tool felt stronger at the same battery level. It stayed cooler too. I never had to service the motor. I also noticed the noise level dropped. Not silent yet less whine and no brush crackle. If you compare user reviews the pattern repeats across brands like DeWalt, Makita, Milwaukee, Bosch, and Ryobi.

The RC car swap

I replaced a budget brushed can motor with a mid-range brushless system. Same voltage. Same vehicle. The brushless setup pulled harder and kept speed longer thanks to efficiency. I ran two battery packs back-to-back and the motor barely felt warm. The brushed motor would get toasty after one pack. As a bonus I could tune throttle curves and braking with the ESC software. That control made the car easier to handle on tight tracks.

The e-bike hill test

A geared hub motor with FOC climbed a hill near my house at a steady cadence. No surging. No cogging feel. I swapped to a sensorless controller for a few rides as a test. Startup under load felt rougher. Once rolling it matched fine. Sensored plus FOC just felt better at low speed in traffic. That is worth the extra wires to me.

FAQs I Get All the Time

Is a brushless motor more efficient

- Yes in most cases. I see 85–95% for many BLDC systems versus 50–75% for brushed. Setup, load, and quality change the exact number. The gap stays big.

Do brushless motors last longer

- Yes because they don’t have brushes or a commutator to wear. Bearings and insulation still matter. Keep them cool and clean they run for years.

Are brushless motors quieter

- Usually. No brush rubbing means less mechanical noise and no sparking. Good controllers lower PWM whine as well.

Do brushless motors use less battery

- Yes for the same work you tend to see longer run time. Efficiency wins here.

Why are brushless motors more expensive

- The motor design is more advanced and you need an ESC. Volume keeps pushing prices down. Mid-range tools and appliances now offer brushless at reasonable prices.

What’s the difference between sensored and sensorless brushless

- Sensorless relies on back EMF to detect rotor position. Lower cost and fewer wires, yet rougher starts under heavy load.

- Sensored uses Hall effect sensors. Smoother at low speed and better startup torque. Great for tools and robotics.

Are brushed motors obsolete

- Not at all. They remain useful when cost and simplicity beat performance and longevity.

What about cogging torque

- That lumpy feel at very low speed often comes from slotting and magnet interaction. Stator design and control algorithms reduce it. If cogging bothers you look for motors with skewed slots and controllers with anti-cogging features.

Does material quality really matter

- Absolutely. The stack of thin laminations inside the stator and rotor limits core losses and heat. If you want a deeper look at the materials that reduce loss this overview of stator core lamination is helpful. You can also see how the rotor core lamination shapes performance and efficiency.

What’s PMSM and how does it relate to BLDC

- Permanent magnet synchronous motors operate similarly to BLDC under FOC. Labels blur in practice. Both use permanent magnets on the rotor and electronically controlled stator windings. You get the same headline benefits—efficiency, torque density, and precise control.

How do ESCs keep everything cool and controlled

- They manage commutation timing, limit current, and use PWM to modulate power. Advanced ESCs implement field-oriented control for smooth torque at all speeds. Many add thermal protection and soft-start features so the system lives longer.

The Bottom Line

After years of using and testing both types I can say this with confidence. Brushless motors are better for most modern applications. They run more efficiently. They last longer. They deliver higher power-to-weight and better control. They make less noise and heat. You will pay more at the checkout screen yet you often spend less over the life of the machine.

That does not erase the value of brushed motors. If you need something cheap and simple for light use brushed still makes sense. I still keep a few brushed motors on hand for experiments and quick tools.

If you want a simple rule of thumb use this. If you will use the device often or demand strong performance pick brushless. If your project is occasional and cost is the top priority pick brushed.

One last tip from my bench. When you compare motors look beyond the label. The internal metal stack-ups matter because they set the ceiling for efficiency and heat. If you want to see how BLDC cores get built from the inside out this page on bldc stator core offers a clear view. If you’re just getting started and want a quick refresher on the basics of how motors make torque this primer on the motor principle keeps it simple.

With that you have the full picture. You know how both designs work. You know where each one fits. Pick the motor that matches your real-world needs not just the buzzwords. Then go build something that spins.