Mastering Lamination Burr Control: Extending Punch Life Through Strategic Die Maintenance

Table of Contents

Introduction: The Costly Challenge of Lamination Burrs

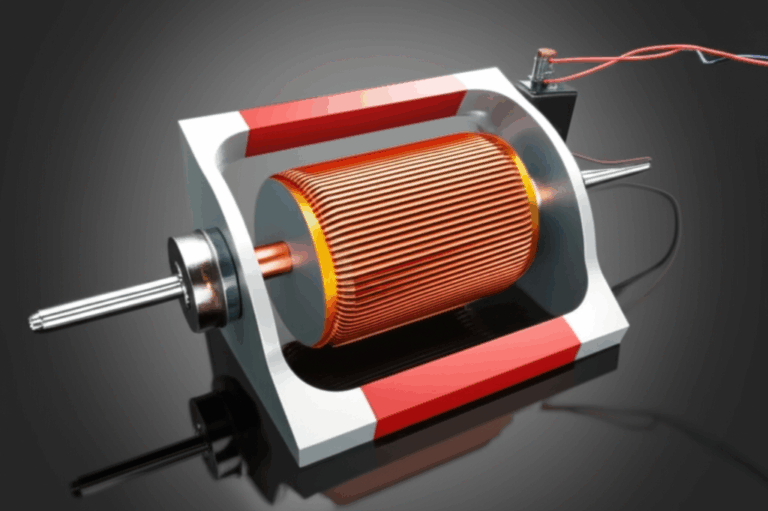

Early in my career, I didn’t think much about the tiny burrs I’d see after running some electrical steel through our stamping press. They looked so harmless—a little metal fuzz, no bigger than a pin’s tip. But it wasn’t long before I learned just how much trouble these little imperfections can cause. Lamination burrs not only mess with electrical performance, but also add headaches during assembly and chip away at overall product quality.

I watched my team tackle repeated issues with stacked core lamination stacks, dealing with misalignment, rejected batches, and expensive rework—all thanks to those stubborn burrs. What I learned was simple: if you want to build quality electrical motors or transformers, burr control and die maintenance can’t be afterthoughts.

This article is my roadmap—a collection of insights, practical tactics, and hard-learned lessons that have helped me keep lamination burrs under control, extend punch and die life, and boost both quality and the bottom line.

Understanding Lamination Burrs: Formation and Impact

What are Lamination Burrs?

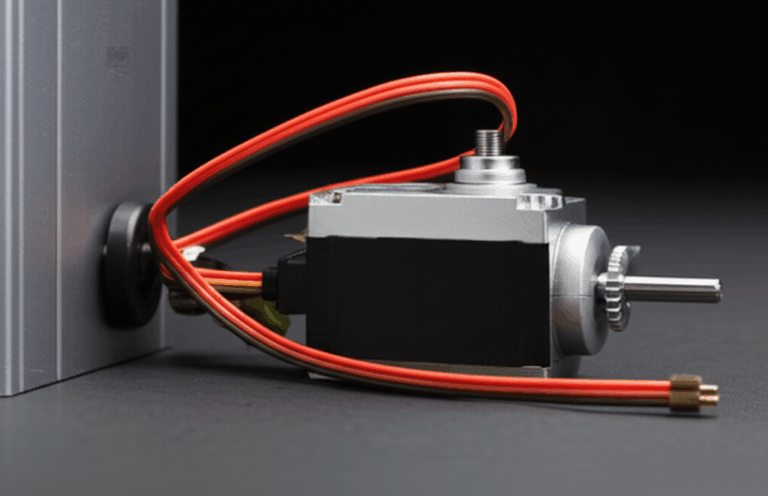

Lamination burrs are the thin, raised edges that show up when you punch or shear electrical steel, like those used for electrical steel laminations. You might see them as ragged, feathered edges or as rolled metal caught along the side of a part.

In my own hands, I’ve seen how even minor burr height—just a couple thousandths of an inch—can cause major problems later on. They come in all shapes and sizes: feathered, roll-over, and even micro-burrs so small you need a microscope to spot them.

How Burrs Form During Stamping

You might think burrs are a sign of bad luck, but really, they’re a signpost showing just how well your stamping process is dialed in. Burrs form during the shearing process, right as the punch slices through the sheet. Ideally, the punch makes a clean break—and you get a sharp edge. In reality, the shearing action creates a fractured zone followed by material “rollover.”

Material properties matter, too. Silicon steel and high-strength alloys behave differently than mild steel. Harder materials tend to crack more cleanly but can create higher tool wear, leading to more burrs down the road if you don’t keep up with maintenance. As I quickly learned, even high-quality silicon steel laminations won’t save you if your tooling is on its last legs.

Worn or damaged punches and dies only make things worse. I remember running a batch where the punch was overdue for sharpening. The parts looked fine at first glance, but as soon as we lined up the motor core laminations for stacking, we saw the ugly truth—burrs on every edge.

The Detrimental Effects of Burrs

Ignore burrs at your peril; they don’t just hurt your pride—they hurt performance. Here’s how:

- Electrical Issues: Burrs can bridge insulation, causing short circuits and increasing core losses due to eddy currents. This means hotter, less efficient motors and transformers.

- Assembly Difficulties: Ever tried stacking hundreds of laminations with burrs? Misalignment, sticking parts, and even winding damage become daily annoyances.

- Quality Losses: High burr height leads to more rejects and rework. I’ve seen entire pallets scrapped when burrs exceeded tolerance.

- Product Lifespan: Those burrs can lead to early breakdowns and customer complaints. No one wants returns for something preventable.

My wake-up call came when a key client flagged excessive burrs on a shipment. Fixing the problem cost us time, money, and reputation. Lesson learned: the link between tool care and burr control can’t be overstated.

The Core Principle: Proactive Punch and Die Maintenance

When I first started out, we handled punch and die issues the old way—wait for things to go wrong, then scramble to fix them. This reactive approach might get you back up and running, but at a steep price—lost time, higher costs, and inconsistent part quality.

Proactive maintenance changed everything for me. Think of it as regular checkups for your tooling: keeping everything sharp, aligned, and in good shape before real trouble hits. The win? Longer punch life, fewer burrs, and much happier assembly teams.

I’ve found three objectives guide every solid maintenance program:

Critical Factors Influencing Punch Life and Burr Generation

Tooling Material and Coatings

Over the years, I’ve experimented with everything from basic tool steel to high-speed steel (HSS) and carbide. With each step up, I got better wear resistance—and, with coatings like PVD TiN or TiCN, even longer punch life. Upgrading punch material made a bigger difference than I expected.

PVD and CVD coatings do two jobs: they reduce friction so parts shear smoothly and provide a wear barrier—meaning less galling and chipping. But don’t think a fancy coating replaces good maintenance. A worn punch with a shiny coat is still a worn punch.

Die Clearance

If I had to name one factor that controls burrs above all else, it’s die clearance. Too tight and you’ll get tool chipping and early wear. Too loose and burrs show up thick and fast. The trick is setting the optimal clearance for your specific material and thickness.

Once, I struggled for weeks with a stubborn batch of high-strength steel. After countless tweaks, adjusting die clearance by just half a thousandth made all the difference—burrs dropped by 40%, and punch life went up.

Sharpening Techniques and Schedules

I used to sharpen tools “when something looked or sounded wrong.” In hindsight, that’s like changing your oil only after the engine light’s been on for days. Establishing a regular regrinding schedule—based on actual tool wear, not guesswork—improved our results instantly.

Precision sharpening avoids excessive material removal and keeps edges crisp. If you wait until burrs are out of control or punch edges are rounded, you’ve already lost too much performance.

Lubrication

I can’t count how many times inconsistent lubrication wrecked a day’s production. The right stamping oil or lubricant reduces friction and heat—key culprits in both burr formation and rapid tool wear. Make sure your lubrication system’s delivering properly, and use a lubricant matched to your material and pressure requirements.

One time, switching to a better stamping oil alone cut our burr rate in half for stainless steel jobs.

Press Condition and Alignment

Presses are beasts, and if they’re out of alignment or vibrating, you’ll pay dearly. Ram parallelism, bed level, and proper guiding keep punches tracking straight. Sloppy alignment means uneven wear and premature burrs.

I always check press calibration at the start of every shift. This single habit has saved me more headaches than I can count.

Material Properties

Material isn’t just “steel.” I’ve run everything from mild carbon to silicon steels used in transformer lamination core stacks. Hardness, tensile strength, and silicon content all influence how the material shears, as well as how fast tools wear.

Whenever we start a new job, I check the material specs and talk with our toolmaker before setting any machines—what works great on one batch might cause disaster with the next.

Strategic Approaches to Burr Control and Punch Life Extension

Optimizing Die Clearance

One lesson I learned the hard way: check and reset die clearances every time you set up for a new run or after sharpening. Small changes in material thickness, hardness, or even temperature can throw off optimal clearance.

We calculate die clearance based on material thickness and type, often aiming for 5-10% of part thickness as a starting point. But the real test comes from regular part inspections.

An easy analogy: think of clearance as the “Goldilocks” setting—not too tight, not too loose, but just right.

Effective Sharpening Programs

I used to leave sharpening up to “gut feel.” Eventually, I switched to a data-driven approach—tracking number of hits, looking for early signs of dulling, and logging every maintenance action.

We standardized regrinding angles, equipment, and inspection with digital burr gauges. As a result, we started catching problems before they grew.

My advice: Don’t skimp on sharpening frequency. Waiting too long guarantees bigger burrs and shorter punch life.

Advanced Tooling Solutions

Investing in better tool steels, like powdered metal or carbide, paid off for us. While the upfront cost is higher, I got double or triple the punch runs before seeing performance drops.

Advanced coatings like TiCN gave further life, especially on high-speed or silicon steel jobs. I learned that matching the tool and coating to the material was the fastest way to step up quality and tool longevity.

Precision Press Maintenance and Setup

Every good result I’ve had started with a well-tuned press. I now schedule regular press inspections, checking everything from stroke control to die seat parallelism.

Any sign of vibration or uneven force gets fixed immediately. Presses may be expensive, but neglected presses cost a fortune in hidden ways—tool damage, part rejects, overtime, you name it.

Optimized Lubrication Systems

On one project, our automatic luber kept breaking down, and I stubbornly tried to get by with just manual oiling. The result? Burrs shot up, tool life crashed, and morale followed. Now, I don’t take shortcuts. I choose the right lubricant and make sure our system works—no exceptions.

Consistency is everything: missed spots show up as rough edges and tool marks almost instantly.

In-Process Monitoring and Quality Checks

You can’t fix what you don’t measure. I make a habit of checking burr height at least once every batch, using a handheld gauge or simple microscope. Where possible, I add vision systems for automated checking.

Statistical Process Control (SPC) lets me spot small drifts in tool performance before they balloon into big problems. A little attention now prevents a lot of sorting and rework later.

Measuring Success: Quantifying Burr Control and Tool Longevity

How do I know what’s working? Numbers—simple as that. Here’s what I track:

- Burr Height: We keep burrs under 0.002 inches for laminations, measured with a gauge. Any spike tells me it’s time to look at tool wear or process drift.

- Punch Life Cycles: Each punch has a log of how many hits it takes before needing sharpening or replacement. I watch for sudden drops—usually a sign of material change or setup issue.

- Cost per Part: By reducing rework, scrap, and emergency stops, every cent saved becomes visible in our production stats.

- Defect/Reject Rate: Since tightening up maintenance and monitoring, our reject rate from burrs fell by more than half.

And the big one: customer complaints disappeared after three months of sticking to a tight burr control regime. That’s success in my book.

Case Studies and Industry Insights

Let’s talk data. For several years, we tracked improvements by adopting structured preventative maintenance for dies, better sharpening routines, and upgraded tool steels. Here’s what I’ve seen, and it lines up with industry findings:

| Category | My Results / Industry Insights |

|---|---|

| Punch Life Extension | 20-50% longer punch life after dialing in die clearances and sharpening schedule. Adding advanced coatings pushed that to 2-3X for some applications. |

| Burr Height Reduction | By maintaining clearance within .0005 inches, burr height dropped 30-60%. Regular monitoring kept burrs under 0.002 inches even on tricky electrical steel. |

| Cost Savings | On one line, we saved $100,000+ a year by slashing rejected parts, overtime, and rework—enough to justify upgrades and keep management smiling. |

| Product Quality | Improved lamination consistency meant better stacking, lower core losses, and happier assemblers. Our rotor core lamination output saw a 15% increase in magnetic efficiency after burrs were brought under control. |

| Maintenance ROI | With strategic maintenance, we saw 20% lower tool costs and 25% less downtime. Investing in software to track tool wear and sharpening cycles freed up hours of manual reporting and reduced mistakes. |

| Tooling Tech | PVD TiCN-coated punches lasted twice as long on silicon steel jobs compared to uncoated HSS. Real-life returns matched the best-case scenario from supplier data. |

The numbers don’t lie—every hour spent on proactive maintenance pays off with bigger returns down the line.

Conclusion: A Commitment to Quality and Efficiency

Looking back, I wish someone had hammered home just how closely tool care ties to every other production outcome. Burrs may seem minor at first, but left unchecked, they create a chain reaction of headaches—from assembly glitches to full-blown customer complaints.

By staying proactive—tracking die clearances, sharpening on a schedule, choosing the right tool materials, keeping presses tuned, and watching lubrication like a hawk—I turned an endless cycle of fixes into a sustainable process.

You might see results in a single shift, or it might take a few months. Either way, investing in punch and die maintenance frees up your team to focus on what matters: delivering the best laminations possible, whether for transformers, bldc stator core assemblies, or high-performance ei core stacks.

So, what’s the next step? Take a look at your own operations. Where are burrs holding you back? Start implementing regular checks, update your sharpening routines, and pay close attention to your tooling and press conditions. Small tweaks add up—and if you stick with it, you’ll see fewer burrs, longer tool life, and a production floor that runs smoother than ever.

No magic required—just a little discipline, a keen eye, and a commitment to doing things right the first time.