Motor Laminations 101: How to Choose Materials and Processes for Efficiency, Cost, and Reliability

Every motor design lives or dies on its core. If you are wrestling with questions like “How does lamination thickness affect core loss at my operating frequency?” or “Should I spec NOES, cobalt iron, or a nanocrystalline option for a high-speed machine?” you are not alone. The lamination stack determines much of your motor’s efficiency, temperature rise, acoustic noise, and cost. The wrong choice adds watts of waste and months of delay. The right choice pays back in performance and reliability.

This guide acts like your on-call materials engineer. We’ll start with the problem you are trying to solve, explain the fundamentals in plain language, compare your options without spin, and give you a clear path to a confident decision.

In This Article

- Why Lamination Material Choice Is Critical

- Understanding Core Losses: Eddy Currents and Hysteresis

- Material Considerations: Selecting the Right Electrical Steel or Alloy

- Manufacturing and Assembly Processes: How They Shape Performance

- Which Application Is This For? Matching Materials and Processes to Use Cases

- Compliance, Testing, and Standards You Should Know

- Procurement and Cost Levers: Practical Tips for Engineers and Buyers

- FAQs

- Your Engineering Takeaway

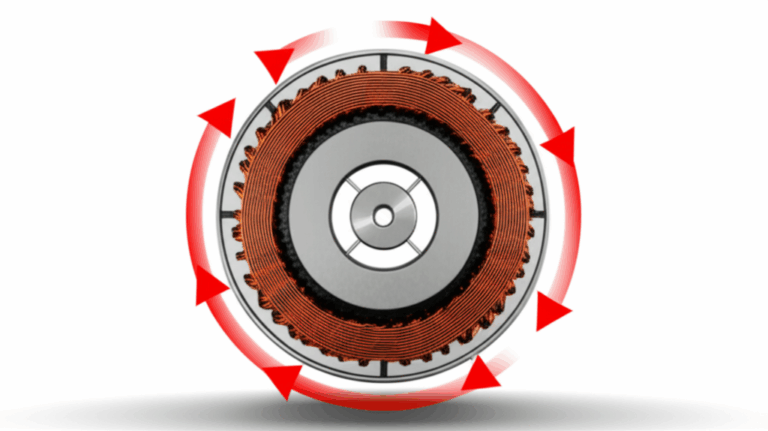

Why Lamination Material Choice Is Critical

Motor cores look simple. They are just stacks of thin steel sheets with slots and teeth. Yet those sheets act like the lungs of your machine. They breathe magnetic flux in and out every electrical cycle. You want that flux to move easily with minimal friction. In magnetic terms, friction shows up as loss and heat.

Here is what your lamination choice influences directly:

- Efficiency and heat rise: Core loss eats into your efficiency budget. Every watt of loss becomes heat you must remove.

- Torque density: Higher saturation flux density allows more torque per volume before the core saturates.

- Acoustic noise and vibration: Manufacturing stress and assembly methods can raise magnetostriction and acoustic emissions.

- Cost and lead time: Gauge, grade, and process complexity swing both material cost and throughput time.

If you remember only one rule from this section, make it this: select material and gauge around your peak operating flux density and electrical frequency, not around nameplate mechanical RPM alone. Electrical frequency scales with pole count. A 12-pole motor at 6,000 rpm sees 600 Hz. The lamination that looks fine at 50 Hz can run hot at 600 Hz.

For quick reference on common materials and gauges, many teams start by surveying available electrical steel laminations. You will see trade-offs between thickness, coating class, and loss curves across frequency.

Understanding Core Losses: Eddy Currents and Hysteresis

Let’s demystify the physics without drowning you in equations.

- Magnetic flux: Think of flux like water flowing through a sponge. Materials with high magnetic permeability let flux pass easily. Permeability is how “sponge-like” your core is to magnetic fields.

- B-H curve: This shows how much magnetic field (H) you need to push a certain flux density (B) through the material. The steeper and skinnier the loop, the less energy you waste per cycle.

- Coercivity: This is the field needed to bring the material back to zero flux after magnetization. Lower coercivity means lower hysteresis loss.

- Saturation flux density (Bs): This is where the sponge stops soaking up water. Push beyond Bs and your core stops helping, which drops torque fast and heats up the steel.

Two main core losses dominate in motor laminations:

1) Eddy current loss

- What it is: The changing magnetic field induces circulating currents in the steel. Those mini whirlpools burn energy as heat.

- Analogy: Picture eddies in a river behind a boulder. Big open water makes big eddies. Put in thin barriers and those eddies break into tiny harmless swirls.

- Why laminations help: We slice the core into thin, electrically insulated sheets. The insulation blocks currents from flowing in big loops. Eddy loss scales roughly with the square of lamination thickness and the square of frequency. Halve the thickness and you cut eddy loss about 4x at the same frequency and flux.

2) Hysteresis loss

- What it is: Energy you lose each time the material flips its magnetic direction. It’s the area inside the B-H loop. A narrower loop means less loss.

- What drives it: Material composition and processing primarily, along with stress state. Hysteresis loss rises roughly linearly with frequency and grows with flux density.

Other contributors:

- Excess or anomalous loss: Linked to domain wall motion and microstructural factors. You can treat it as the “miscellaneous” term that rises with both frequency and flux.

- Mechanical stress: Stamping, bending, welding, and clamping all add residual stress. Stress raises core loss and can raise noise due to magnetostriction.

- Temperature: Most steels see modest changes in loss with temperature. Design for operating temperature since that shifts both losses and saturation margins.

Bottom line: Thinner, higher-grade laminations reduce eddy loss at high frequency. Lower coercivity and clean processing reduce hysteresis loss. Good insulation between sheets and careful assembly keep circulating currents at bay.

Material Considerations: Selecting the Right Electrical Steel or Alloy

You have a wide range of soft magnetic materials. Your choice hinges on three factors: electrical frequency, target flux density, and cost tolerance. Let’s map the landscape.

Non-Oriented Electrical Steels (NOES), a.k.a. Silicon Steels (2%–3.2% Si)

This is the workhorse for motors. NOES offers balanced properties in all directions of the sheet plane, which matters for motors with rotating fields and teeth.

- Typical gauges: 0.50 mm down to 0.20 mm. EV traction and high-speed motors often go 0.20–0.27 mm.

- Pros:

- Good cost-performance trade-off for 50–1,000 Hz electrical frequency.

- Available in many loss grades with consistent coating classes.

- Well understood stamping behavior and stack factor.

- Cons:

- Saturation around 1.9–2.1 T. That limits torque density versus cobalt iron at the same cross section.

- Thinner gauges cost more and complicate stamping due to burr control and handling.

- When to choose: General industrial motors, pumps, fans, compressors, EV drive units, BLDC and PMSM machines that need low loss up to the low kHz range.

Tip: DO NOT assume 0.35 mm always beats 0.50 mm on loss. At lower frequencies, the performance gain might not justify the cost increase or the die changes. Model it first.

Grain-Oriented Electrical Steel (GOES), a.k.a. CRGO

Grain-oriented steel shines when the flux is mostly aligned with the rolling direction. That makes it ideal for transformers. Motors see flux that swings around teeth and yokes, so GOES benefits diminish in rotating machines.

- Pros:

- Very low loss in the grain direction at 50/60 Hz.

- Cons:

- Poor off-axis performance. Punching parts for motors spoils the benefit since flux paths rotate through teeth and back iron.

- When to choose: Transformer cores and certain static or quasi-static magnetic circuits. Not common in rotating motor cores.

Cobalt-Iron Alloys (FeCo, 48–50% Co)

If you chase power density and your budget can handle it, FeCo is your friend.

- Pros:

- High saturation flux density ~2.35–2.45 T. That enables smaller cores for the same torque.

- Good permeability at high fields.

- Cons:

- Expensive raw material. Processing requires care to avoid loss of properties.

- Can be more prone to work hardening and stamping wear.

- When to choose: High-speed, high-power-density aerospace machines, e-compressors, racing applications, motors that need aggressive downsizing at moderate frequencies.

Nickel-Iron Alloys (Permalloy family)

Great for sensors and low induction loss structures. Less common in standard motors that need high torque density. Saturation is lower than silicon steel, which limits peak torque.

- When to choose: Specialty low-field devices, magnetic shielding, or high sensitivity components rather than main motor cores.

Amorphous and Nanocrystalline Alloys

These materials deliver very low core loss at high frequency due to extremely thin ribbons and unique microstructure.

- Pros:

- Excellent loss performance in the kHz range.

- Cons:

- Ribbon form factor complicates typical radial-flux motor geometry.

- Brittle and difficult to stamp into standard tooth-slot shapes at scale.

- When to choose: Specialized topologies or axial-flux concepts that can use wound or laminated tape structures. Common in high-frequency transformers rather than mainstream radial-flux motors.

Soft Magnetic Composites (SMC)

Powder iron cores with an insulating binder allow 3D flux paths and near-net-shape molding.

- Pros:

- Isotropic magnetic properties in 3D. Great for complex flux paths and reduced eddy currents at higher frequency due to particle-level insulation.

- Good for segmented stators or axial-flux machines.

- Cons:

- Lower permeability and saturation than laminated steel. Losses can rise at lower frequencies compared to NOES.

- When to choose: 3D flux designs, integrated housings, or cost-driven shapes where traditional lamination stacks get too complex.

Lamination Gauge, Coatings, and Stack Factor

- Gauge: Thinner reduces eddy loss at high frequency. It also lowers mechanical stiffness during stamping and stacking. Expect higher cost and tighter handling rules for 0.20–0.27 mm.

- Coatings: Organic and inorganic coatings provide interlaminar insulation. They also influence punch life, bonding options, and corrosion behavior. Coating classes vary in electrical resistivity and thermal stability. Verify compatibility with your planned anneal or bonding process.

- Stack factor: This is the ratio of net magnetic steel height to the overall stack height. Thicker coatings and adhesive bonding lower stack factor. Design your magnetic cross section for realistic stack factors from your supplier, not idealized values.

If you need a quick walkthrough on parts that drive performance most, start with the stator since the teeth see high alternating fields. You can review typical constructions and trade-offs in a stator core lamination guide. Then cross check rotor constraints since rotor bridges and sleeves drive mechanical limits at speed. A good reference here is a rotor core lamination overview to spot common geometry pitfalls.

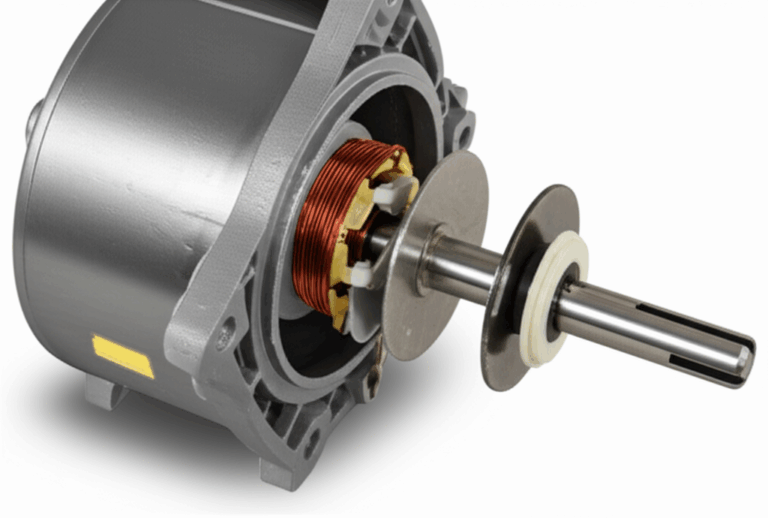

Manufacturing and Assembly Processes: How They Shape Performance

Material choice sets the ceiling. Manufacturing decides how close you get to it. Processes can either preserve the steel’s magnetic properties or ruin them with stress, burrs, and shorted laminations.

Profile Creation: Stamping vs Laser vs EDM vs Waterjet

- Progressive die stamping

- Best for high volume. Lowest cost per part after tooling.

- Controls burr with tuned clearance, sharp tooling, and frequent maintenance.

- Die wear and alignment drift can raise burr height. Burrs raise local loss and risk interlaminar shorts.

- Fine-blanking and vacuum heat treatment can improve edges and reduce stress.

- Laser cutting

- Excellent for prototyping and low volume. Handles intricate shapes without a die.

- Heat-affected zone (HAZ) and recast layer add local stress and raise loss near edges.

- Stress-relief anneal can recover some properties, though not always fully.

- Use optimized laser parameters and assist gas to minimize HAZ width.

- EDM (wire)

- Very accurate edges with minimal mechanical stress. Slower and costlier for volume.

- Surface recast can be an issue, yet often lower than laser HAZ on loss impact.

- Popular for precision prototypes and research.

- Waterjet

- No thermal stress. Slower, risk of edge roughness and taper. Less common for final production laminations.

Rule of thumb: Prototype with laser or EDM. Move to stamping for volume to control cost and repeatability. If you stay with laser for volume work, budget time for process tuning and post-cut anneals.

Stacking and Bonding Methods

- Interlocking (self-clinching tabs)

- Speeds stacking without external fasteners. No adhesives needed.

- Tabs distort local flux and can introduce stress. Usually minor if placed outside high-flux regions.

- Great for high-volume stator stacks.

- Welding

- Strong joints and simple fixturing. Beware that welds can short laminations.

- Place welds in low-flux regions. Use minimal heat input and spacing to reduce eddy paths and stress.

- Many traction cores limit welding or combine small spot welds with adhesive.

- Riveting or cleating

- Mechanical fastening without heat input. Adds localized stress and holes.

- Use with care near high-flux teeth or bridges.

- Adhesive bonding (backlack or post-stack resin)

- Excellent for minimizing interlaminar shorts and reducing vibration. Helps acoustic noise and mechanical rigidity.

- Lowers stack factor due to adhesive thickness. Requires cure cycles and clean processes.

- Backlack-coated steels bond during heat cycle without added liquid adhesive. Check coating class compatibility.

- Varnish impregnation

- Fills gaps and reduces vibration. Can improve heat transfer to housing.

- Not a substitute for proper interlaminar insulation. Choose varnish with suitable dielectric and thermal rating.

Burr Control and Edge Quality

Burrs matter. They create sharp edges that bridge insulation, which raises eddy currents between sheets. They also make winding insertion tougher and risk enamel damage.

- Set maximum burr height in drawings, typically 10–20% of lamination gauge for precision work, lower for high-frequency designs.

- Specify deburring if needed, yet remember that aggressive deburring can smear coatings and reduce insulation.

Stress Relief and Annealing

Forming and cutting introduce residual stress. Stress reduces permeability and increases loss.

- Stress-relief anneal can recover magnetic properties. Use process-specific recipes to avoid oxidation or coating damage.

- Do not assume annealing fixes all laser HAZ issues. Validate with test coupons.

Skew, Segmentation, and Assembly Impact

- Skewed slots reduce cogging torque and acoustic noise. They also complicate stamping and stacking. Segment skew is a common compromise.

- Segmented stators simplify winding insertion and allow higher slot fill with hairpins. Joints between segments need clean bonding to avoid magnetic discontinuities.

- Rotor bridges and sleeves require careful balance between mechanical strength at speed and magnetic performance. Thin bridges saturate, thick bridges cut torque density. Work with FEA early.

If your team builds BLDC machines for appliances or e-bikes, you will see many of these trade-offs in a compact form factor. A quick primer on geometries and stack strategies can help, like a bldc stator core overview.

Which Application Is This For? Matching Materials and Processes to Use Cases

Let’s turn general rules into concrete choices. Pick the profile that looks most like your project.

1) General Purpose Industrial Motors (Induction or PMSM, 50/60 Hz to a few hundred Hz)

- Material: NOES, common grades like M27–M36 equivalents. Gauge 0.35–0.50 mm.

- Process: Progressive die stamping with interlock or light welds. Varnish or light bonding if needed for noise.

- Why: You prioritize cost per kW, consistent performance, and robust supply. Thin gauges give modest gain at these frequencies, so they may not justify cost.

2) EV Traction and Hybrid Motors (PMSM/IPM, high pole count, 200–1,000+ Hz electrical)

- Material: NOES low-loss grades in 0.20–0.27 mm. Consider higher-silicon or premium grades tuned for mid to high frequency. Some programs test 6.5% Si steel for even lower losses, yet those sheets are brittle and tricky to stamp.

- Process: Progressive die with tight burr control. Adhesive bonding or backlack to reduce interlaminar shorts and noise. Limited, strategic welding if required.

- Why: High electrical frequency makes eddy loss the bully. Thinner gauges and clean stacking pay big dividends.

3) High-Speed Aerospace or E-Compressors (PMSM, 20k–120k rpm, moderate to high electrical frequency)

- Material: FeCo (cobalt iron) for high Bs and compact geometry. Gauge 0.10–0.20 mm if feasible.

- Process: Fine-blanking or laser with optimized parameters. Mandatory stress relief anneal. Adhesive bonding for rigidity and low vibration. Premium coatings for heat resistance.

- Why: You need torque density and thermal headroom. FeCo lets you push flux higher before saturation. The budget and quality system must support the complexity.

4) Axial-Flux or 3D-Flux Designs

- Material: Mix of thin NOES or SMC depending on flux path design. Some concepts use wound ribbon or specialty alloys.

- Process: Segmented elements or molded SMC parts. Emphasis on uniformity and magnetic continuity across joints.

- Why: The geometry dictates the material. You trade peak permeability for geometric freedom in 3D flux.

5) Small BLDC for Appliances, Tools, and E-Bikes

- Material: Cost-optimized NOES in 0.35–0.50 mm. Choose grades with acceptable losses at your electrical frequency.

- Process: Progressive die stamping with interlock. Consider varnish impregnation for noise control. Tight focus on burr limits to avoid enamel damage.

- Why: Cost per unit rules the roost. You still control loss by picking the right grade and clean manufacturing.

6) Transformer vs Motor Clarification

- Transformer cores use GOES or amorphous ribbons with flux aligned to rolling direction. Motor stators and rotors see rotating fields that punish GOES off-axis behavior.

- If a supplier offers CRGO for your motor core, ask for loss curves in rotating flux conditions. You will likely pivot back to NOES.

Compliance, Testing, and Standards You Should Know

Strong designs lean on strong standards. They avoid surprises in validation and production.

- Magnetic materials and loss testing

- IEC 60404 series covers test methods for magnetic properties. IEC 60404-2 describes ring methods. IEC 60404-3 covers single sheet testers for loss and permeability.

- ASTM A343/A343M includes methods for AC magnetic properties using ring specimens. ASTM A677 describes nonoriented electrical steel specifications.

- Motor efficiency testing

- IEEE Std 112 describes methods for motor testing and determining efficiency. This helps you see how core loss contributes to system performance.

- Quality systems and automotive

- ISO 9001 for quality management. IATF 16949 for automotive supply chains.

- PPAP and APQP processes for design validation and production readiness.

- Environmental and safety

- RoHS and REACH compliance for coatings and adhesives. UL recognition for insulation systems where applicable.

- Acoustic and NVH

- Many teams run modal and airborne noise tests on stators and completed motors. Lamination stress and bonding method show up clearly in NVH plots.

A quick yet important reminder. Ask for heat lot certificates, coating class data, and core loss curves at your actual operating induction and frequency. Not just at 1.0 T and 50/60 Hz. Mismatch here is a common source of late-stage heat rise surprises.

Procurement and Cost Levers: Practical Tips for Engineers and Buyers

Engineers design performance. Procurement makes it viable. Both roles can shift total cost and risk with a few smart moves.

- Choose gauge for frequency, not habit

- Thinner gauges cost more and hit die life. Use them where eddy loss justifies it. Model the savings and validate with test coupons.

- Optimize the lamination blank and nesting strategy

- Small geometry changes can raise sheet utilization a few percent. That pays back fast on large volumes.

- Balance die cost and production volume

- Progressive dies pay for themselves past a modest volume threshold. Laser and EDM suit prototypes and low volumes or complex shapes. Plan your transition early.

- Set realistic tolerances and burr limits

- Overly tight tolerances spike cost without improving performance. Align tolerances with actual functional needs. Specify burr limits that protect insulation and winding enamel.

- Decide stacking method with NVH in mind

- Adhesive bonded stacks reduce noise and vibration. They add process steps and lower stack factor. Interlocks save time and cost. Match the method to your product’s noise and cost targets.

- Consider segmentation for winding and yield

- Segmented stators improve slot fill and simplify winding, especially with hairpins. They raise assembly steps and require clean joints. Prototype early to confirm the true cost delta.

- Validate supplier capability

- Ask for sample stacks, loss measurements, and consistency data. Evaluate how they handle heat lot variations and coating classes. Review their corrective action history.

- Lock in your inbound inspection plan

- Measure stack height variation, burr height, coating continuity, and insulation resistance between laminations. Spot-check loss with ring or SST methods if you have capability or engage a test lab.

For teams new to lamination stacks across both stator and rotor, a broad overview of system-level trade-offs can help. You can scan an example portfolio under motor core laminations to align your design and purchasing decisions.

FAQs

- How does lamination thickness affect loss?

- Eddy current loss grows with the square of thickness and the square of electrical frequency. Thinner sheets cut eddy loss at the cost of higher material price and tougher stamping.

- What flux density should I target?

- Stay below saturation with margin. Many NOES designs operate near 1.4–1.7 T in teeth at peak. FeCo lets you push higher. Validate with FEA and prototype loss tests.

- Is laser cutting OK for production?

- Yes for low volume or complex shapes. You need a stress-relief anneal and tuned parameters to control HAZ. For high volume, stamping wins on cost and consistency.

- Should I bond, interlock, or weld my stacks?

- Bonding gives the best electrical isolation and NVH. Interlock is fast and cost effective. Welding is strong but can bridge laminations. Mix methods based on geometry and noise targets.

- Do coatings matter much?

- Yes. Coatings block interlaminar currents, influence punch life, and set bonding options. Choose coating classes that survive your thermal cycles.

- Can I use grain-oriented steel in a motor?

- It rarely pays off. Rotating flux punishes GOES off-axis performance. Use NOES for most rotating machines.

Your Engineering Takeaway

Let’s tie this together. Here is the short list you can take to your next design review or supplier call.

- Match gauge and grade to electrical frequency and target induction. Thinner steel cuts eddy loss at high frequency. It also raises cost and manufacturing difficulty.

- Control manufacturing stress. Your lamination is only as good as the cutting, stacking, and bonding behind it.

- Choose the stacking method to meet both NVH and cost goals. Bonding improves acoustics and interlaminar isolation. Interlocking speeds assembly. Welding needs careful placement.

- Test at operating induction and frequency. Lab curves at 50/60 Hz do not predict loss at 600–1,000 Hz.

- Align material and process to your application:

- Industrial motors: NOES 0.35–0.50 mm, stamped, interlocked.

- EV traction: NOES 0.20–0.27 mm, bonded stacks, tight burr control.

- High-speed aerospace: FeCo thin gauge, annealed, bonded.

- BLDC appliances: Cost-optimized NOES, stamped, focus on burr and enamel protection.

- Lock in supplier capability early. Review loss data, coating classes, burr control, and quality systems.

If you want a gut check on a specific stator or rotor geometry, send a simple package: your peak electrical frequency, target induction, lamination gauge, and intended stacking method. You will get sharper guidance in one call once those four bullets are on the table. That conversation usually saves weeks of back and forth.

Sources and standards for further reading:

- IEC 60404 series: Methods for the determination of magnetic properties of electrical steels, including ring and single-sheet test methods.

- ASTM A343/A343M: AC magnetic properties using ring specimens. ASTM A677: Specification for fully processed nonoriented electrical steel.

- IEEE Std 112: Standard Test Procedure for Polyphase Induction Motors and Generators.

- ISO 9001 and IATF 16949: Quality management systems relevant to motor core production.

- RoHS and REACH: Environmental compliance for coatings and adhesives.

Need a deeper dive on stator geometry, rotor bridges, or bonding options for your frequency band? Open your notebook and gather your operating points. Then reach out for a technical consultation. A 30-minute review with drawings and loss targets beats guesswork every time.