Motor Laminations: A Practical Guide to Material, Thickness, and Manufacturing Choices That Drive Motor Efficiency and Cost

Every design engineer faces the same tough trade-off. You need higher motor efficiency and power density, yet you have to watch cost, lead time, and risk. Much of that battle happens in the steel stack. Lamination material, thickness, coating, and how you cut and assemble the stack can swing core losses by double-digit percentages. That means hotter stators and rotors, more copper loss, lower torque, and sometimes a noisy machine that fails a customer test.

If you have asked yourself questions like “How thin should I go for high-speed BLDC?” or “Will laser cutting hurt my losses?” or “Which coating gives me enough interlam resistance without delamination?” you are in the right place. I will break down the physics in plain English. Then I will map the options and show how to choose a stack that fits your application and your business constraints.

In short, you will leave with a clear plan you can take to your supplier and your team.

In This Article

- Why Lamination Choice Is Critical

- The Engineering Fundamentals: What’s Really Going On?

- Material Considerations: From Silicon Steels to Cobalt Alloys

- Manufacturing and Assembly Processes: Stamping, Laser Cutting, and More

- Which Application Is This For? Picking a Best-Fit Stack for Your Motor

- Design Decisions and Trade-offs: A Step-by-Step Selection Playbook

- Quality, Standards, and What to Ask Your Supplier

- Common Pitfalls and How to Avoid Them

- Cost Drivers and How to Reduce Them Without Sacrificing Performance

- Your Engineering Takeaway

Why Lamination Choice Is Critical

Let’s name the problem. You need to minimize core losses and hit your torque-speed targets at a cost that your business can live with. Core losses split into two big buckets. Hysteresis loss and eddy current loss. They rise when magnetic flux swings faster or harder. They turn into heat. That heat erodes efficiency and stresses insulation and bearings. It can also push you into larger housings, bigger heatsinks, or more expensive magnet grades to compensate.

Lamination choices hit the problem at the source. Thinner laminations cut eddy currents. Better material reduces hysteresis. Proper coatings block interlam shorts and keep your stack cool and quiet. Smart cutting and stacking preserve magnetic properties and reduce mechanical runout. Every choice moves both performance and cost. You balance that at the design stage, not at the test stand after you already bought tooling.

The Engineering Fundamentals: What’s Really Going On?

Let’s keep the physics simple and useful. Three concepts do most of the work in motor cores: eddy currents, hysteresis, and magnetic permeability and saturation.

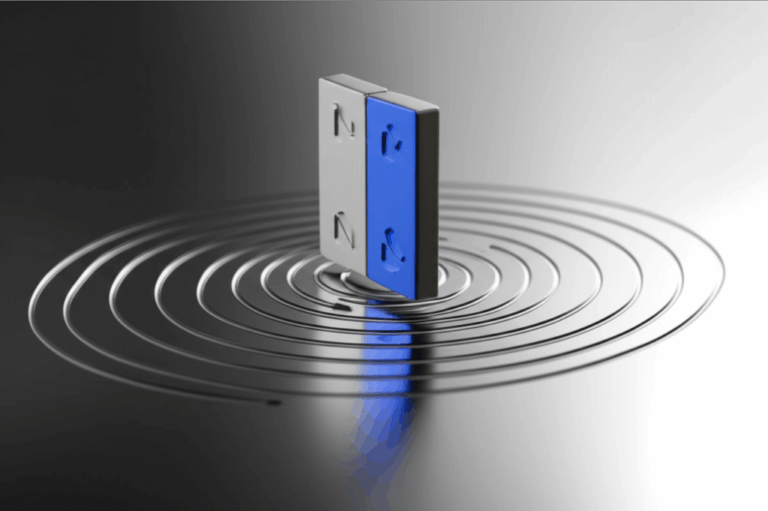

Eddy Currents: The “Whirlpools” That Waste Power

Picture a river full of whirlpools. Eddy currents act like those little vortices, but in steel. A changing magnetic field induces circulating currents inside the lamination. Those currents burn energy as heat. Thinner laminations split one big whirlpool into many small ones. Each smaller loop loses less energy since the loss scales roughly with the square of thickness. That simple t^2 relationship makes thickness a primary lever when frequency goes up. If you double the thickness, you can see roughly four times the eddy current loss at the same frequency and flux density.

Two more knobs matter:

- Resistivity of the steel and the coating between laminations. Higher resistivity chokes current loops.

- Frequency. Higher electrical frequency grows eddy currents fast.

So you attack eddy currents with thin laminations and good interlam insulation. If you run at high electrical frequency, that choice is not optional.

Hysteresis: Energy Lost Every Cycle

Hysteresis loss comes from the energy needed to flip the direction of magnetization every cycle. The B-H curve tells the story. You push the material up and down the curve as the field swings. Coercivity is the material’s resistance to being demagnetized. Lower coercivity means lower hysteresis loss.

Hysteresis loss grows with frequency and with the area inside the B-H loop. It also depends on flux density. You can reduce it by selecting a steel with low coercivity and by avoiding unnecessary over-excitation. That often means choosing a material with good permeability and keeping induction levels realistic for your application.

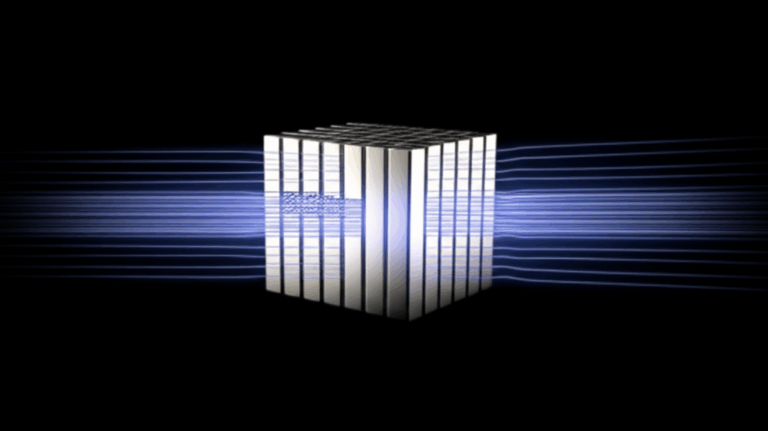

Permeability and Saturation: How Much Flux Can You Carry?

Magnetic permeability is the steel’s ability to carry flux. Think of it like a sponge that soaks up field lines. High permeability gives you more flux for the same magnetizing effort. That helps torque production and reduces current. Saturation sets the ceiling. Push flux density too high and you hit a wall where more magnetizing force produces little extra flux. That leads to rapid loss growth and heat. Cobalt-iron alloys raise the saturation ceiling but at a steep price.

Heat, Noise, and Mechanical Factors

Heat follows loss. More core loss warms the laminations, the copper, and the magnets. The system will complain. You might see thermal runaway at high speed. You might hear more audible noise since magnetic forces vibrate the stack. Assembly choices matter here. Bonded stacks often damp vibration better than welded stacks. Burrs and interlam shorts can create hot spots and extra noise.

Material Considerations: From Silicon Steels to Cobalt Alloys

You have a menu of lamination materials. Each brings strengths and trade-offs. Start with application frequency, flux density, and cost targets. Then pick a class of material that supports those targets with margin.

Nonoriented Silicon Steel (CRNGO): The Workhorse for Motors

Nonoriented electrical steel dominates motor cores. It offers balanced magnetic properties in all directions. That suits rotating machines.

Typical lamination thickness ranges from about 0.1 mm to 0.65 mm. Choose thinner gauges for higher frequencies. Many industrial motors use 0.35 mm or 0.5 mm as practical midpoints. High-speed BLDC and PMSM designs often drop to thinner gauges to control eddy currents. You pay more for thinner steel and you might face lower throughput and higher scrap in manufacturing. Still, thin wins when frequency rises.

Properties to watch:

- Core loss at your target induction and frequency

- Permeability and B-H curve shape

- Yield strength and hardness that affect punching quality

- Coating type and interlam resistance

Standards you can reference:

- ASTM A677 covers nonoriented electrical steel fully processed types

- IEC 60404 series covers magnetic property measurements

You can learn more about the base products many suppliers offer under the umbrella of electrical steel laminations.

Grain-Oriented Silicon Steel (CRGO): Great for Transformers, Not for Motors

Grain-oriented steel shines along the rolling direction and stumbles off-axis. That anisotropy helps transformers, not rotating machines. Motors demand good properties in all directions since the flux rotates. Use CRGO for transformers and chokes. Avoid it for rotors and stators in most motors.

Cobalt-Iron Alloys: High Saturation for Power-Dense Machines

Cobalt-iron (Co-Fe) alloys offer very high saturation induction and good strength at temperature. That helps traction motors, aerospace actuators, and compact, high-power designs that run hot or at high speed. The price is high. Machining can be tough. You want to avoid unnecessary HAZ and residual stress. Use Co-Fe when torque density and temperature margin justify the cost.

Nickel-Iron Alloys: High Permeability for Specialty Cases

Nickel-iron alloys like 50% or 80% Ni-Fe provide very high permeability and very low coercivity. They shine in low-induction applications that need ultra-low loss or precise magnetic behavior. Motors rarely need this class for the entire stack due to cost and saturation limits. You might reserve Ni-Fe for sensing components or magnetic shields rather than the main torque-producing laminations.

Lamination Coatings and Interlam Resistance

The coating between laminations matters. Its job is to prevent shorts between plates and to keep eddy currents in check. Coatings range from inorganic phosphate-based films to organic varnishes. They differ in:

- Electrical resistance

- Maximum temperature

- Chemical compatibility with bonding adhesives

- Weldability and paint adhesion

- Stack friction for interlocking

A practical rule: specify an interlam resistance target that matches your frequency and loss goals. Then check coating class and bonding compatibility during trials. Do not assume that a coating that works for stamping will bond well without surface prep. Test peel strength and loss before you lock the spec.

Manufacturing and Assembly Processes: Stamping, Laser Cutting, and More

Your cutting and stacking route shapes magnetic performance and cost. This is where the rubber meets the road.

Progressive Die Stamping: The High-Volume Workhorse

Progressive die stamping sets the bar for cycle time and piece-to-piece repeatability in volume. You amortize tooling cost over long runs. You also get tight burr control and strong positional accuracy when the tool is well built and maintained.

Pros:

- Lowest unit cost in volume

- High throughput and repeatability

- Tight burr control when the die is tuned

Cons:

- High upfront tooling cost and lead time

- Less flexible for frequent design changes

- Tool wear can increase burr and degrade edges without maintenance

Design tips for stamping:

- Use generous fillets at slot root and tooth tips

- Keep tolerances tight where it matters but avoid over-tolerancing that drives tool cost

- Call out a maximum burr height on the print

- Ask for die maintenance plans when runs are long

Laser Cutting: Fast Iteration and Complex Geometry

Laser cutting enables rapid prototyping and low-volume builds. You can try new slot shapes, skew strategies, and vent patterns without investing in tooling. The trade-off lies in the heat-affected zone and potential edge hardening. That can increase loss if you skip proper process control.

Pros:

- No tooling cost

- Fast design iteration

- Complex geometry with ease

Cons:

- Heat-affected zone can raise core loss

- Burr and recast issues if parameters are off

- Slower cycle times than stamping for volume

How to get good results:

- Use nitrogen assist to limit oxidation when possible

- Tune power and speed to minimize HAZ

- Consider a light post-process such as micro-deburr or stress relief when compatible with material and coating

- Validate core loss on laser-cut coupons at your target frequency and induction

Wire EDM and Waterjet: Niche but Valuable

Wire EDM delivers exquisite precision and a cool edge. It takes time and costs more. You might use it for critical prototypes or small medical or aerospace parts where accuracy beats throughput. Waterjet avoids a thermal HAZ but can leave a rougher edge. Both methods typically serve small runs or special cases.

Managing Burrs and Edge Quality

Burrs matter. They can breach the coating and short laminations in the stack. They can also interfere with proper stacking and cause variation in the lamination factor. Specify a burr height limit and a measurement method. Discuss deburring options and understand how they change cost and throughput.

Stack Assembly Methods: Interlocking, Bonding, Welding, and Mechanical Fasteners

- Interlocking: Tabs formed in the stamping step snap plates together. Think LEGO bricks that hold without extra parts. It saves time and avoids heat input from welding. It can add a small amount of distortion if tab patterns are not symmetric. It offers a clean path for stator core lamination and rotor core lamination stacks in many industrial motors.

- Bonding: Adhesive bonding creates a solid, damped stack with excellent interlam insulation. It can lower audible noise and sometimes core loss compared to welded stacks. You must validate adhesive temperature rating and compatibility with coating and varnish.

- Welding (spot or TIG): Welding secures stacks well but can introduce HAZ and residual stress. You often see welded rotors or stators where mechanical robustness is critical. Keep weld size and location away from high flux regions when possible. Validate loss impact.

- Rivets or pins: Mechanical fasteners avoid heat input. They create through-holes that may affect flux if not placed thoughtfully. Use them for prototypes or where assembly flow benefits from simple fixtures.

Stress Relief and Annealing Considerations

Semi-processed steels need a final anneal after punching to restore magnetic properties. Fully processed steels arrive with final magnetic texture and do not want a high-temperature anneal that damages coatings. If you must anneal a fully processed stack, understand the coating limits and potential loss of insulation. Check manufacturer data and test stacked cores after anneal since theory alone will not tell the whole story.

Which Application Is This For? Picking a Best-Fit Stack for Your Motor

One size never fits all. Anchor your choice to operating frequency, flux density, torque density, and production volume.

High-Speed BLDC and PMSM Drives

- Profile: Electrical frequency often in the hundreds of hertz or higher. Tight thermal budgets. NVH sensitivity in consumer products or e-mobility.

- What helps: Thin nonoriented silicon steel. Strong interlam insulation. Bonded stacks for damping and loss control. Laser for prototypes then stamping when you lock geometry. Consider skew to reduce cogging but check its effect on back-EMF and losses.

- Watch-outs: Laser HAZ can hide. Validate losses with Epstein or single-sheet tests on cut coupons. Keep magnet temperature within grade limits since copper and core heat add up at speed.

Industrial Induction Motors

- Profile: 50 or 60 Hz electrical frequency with modest harmonics. Long life and high reliability. Cost sensitivity.

- What helps: Mid-range thickness like 0.35 to 0.5 mm works well at line frequency. Progressive die stamping for volume. Interlocking or welding based on assembly and noise goals.

- Watch-outs: Over-specifying thickness raises cost with little gain at line frequency. Focus on burr limits, lamination factor, and consistent coil insertion damage control.

Automotive Traction Motors

- Profile: Wide speed range, high torque density, aggressive thermal cycle, strict quality standards.

- What helps: Thinner NOES or Co-Fe for high saturation and strong field weakening. Bonded stacks for NVH and loss. Tight control of coating and adhesive. Full APQP and traceability.

- Watch-outs: Weld HAZ in critical flux paths. Adhesive compatibility with ATF or coolant in e-axles. Tight rotor runout and balance under overspeed conditions.

Small Fractional Horsepower Motors

- Profile: Cost dominates. Volumes can be high. Electrical frequency depends on control strategy.

- What helps: Cost-optimized NOES at thickness that matches frequency. Interlocking for simple assembly. Tooling that supports high yield.

- Watch-outs: Tolerance creep over long runs. Coating selection that supports varnish impregnation without delamination.

Aerospace and Defense Actuators

- Profile: High reliability, strict weight limits, often high speed and temperature.

- What helps: Co-Fe for high saturation and thermal strength. Wire EDM or optimized laser for prototypes. Bonded stacks for vibration and noise.

- Watch-outs: Detail the inspection plan. Measure magnetic properties on production coupons. Track every lot with robust documentation.

Design Decisions and Trade-offs: A Step-by-Step Selection Playbook

Let’s convert all that into a clear workflow.

1) Define Electromagnetic Targets

- Electrical frequency range under worst-case operating conditions

- Peak and RMS flux density targets in stator teeth and back iron and in the rotor

- Efficiency target and allowable core-loss budget at key operating points

- Thermal limits on copper, steel, and magnets

Use quick analytical models or FEA to see how induction moves through the core at load and speed. Mark the hotspots. Those set the material challenge.

2) Pair Frequency With Thickness

- Low frequency (50/60 Hz with limited harmonics): mid-thickness NOES is often enough

- Medium frequency (100–600 Hz): thinner NOES pays off

- High frequency (kHz region in some drives or switched reluctance designs): go very thin and consider alternative materials, but validate cost and manufacturability

Remember the t^2 behavior of eddy current loss. That simple rule of thumb keeps you honest.

3) Choose a Material Class That Hits Hysteresis and Saturation Targets

- Standard NOES for most motors

- Lower-loss NOES grades for premium efficiency or high speed

- Co-Fe where torque density or elevated temperature demands a higher saturation ceiling

- Specialty Ni-Fe if an auxiliary magnetic function requires it

Keep the B-H curve and coercivity in view. Hysteresis loss matters at every frequency.

4) Lock a Coating Strategy and Interlam Resistance Target

- Set an interlam resistance requirement that reflects your frequency and loss budget

- Confirm adhesive bonding compatibility or weldability with the coating

- Validate temperature class in the context of your worst-case thermal environment

5) Select a Manufacturing Path That Matches Volume and Risk

- Prototype fast with laser or EDM

- Shift to progressive die stamping once the geometry is stable and volumes justify tooling

- Specify burr height, lamination factor, and inspection methods on the print

- Choose a stack assembly method that supports your NVH, loss, and mechanical goals

6) Prove It With Coupons and Stacks

- Test single-sheet or Epstein samples cut by your chosen process at your target induction and frequency per IEC 60404 methods

- Build a short stack and measure temperature rise, noise, and iron loss at speed

- Update your model with measured loss data and re-check copper sizing and thermal margins

7) Close the Loop With Supply Chain

- Lock alternates for material grade and thickness to manage availability

- Confirm coil width compatibility with your lamination nest to boost yield

- Agree on quality documentation and change control before SOP

Quality, Standards, and What to Ask Your Supplier

Strong motors start with solid specs and controls. You set the bar with standards and a clear RFQ.

Material Specs and Standards That Matter

- ASTM A677 for fully processed nonoriented electrical steel

- ASTM A876 for grain-oriented electrical steel (transformer-grade, included here for completeness)

- IEC 60404 series for magnetic property measurement methods

- ISO 9001 for quality systems

- IATF 16949 for automotive quality management when relevant

Use the standard designations as a reference point then add your application-specific targets.

Measuring Core Loss and Permeability

Ask for:

- Core loss data at your frequency and induction, measured per IEC 60404 methods

- B-H curve snapshots that include your operating induction range

- Interlam resistance measurements and coating class details

- Coupon data that reflects the actual cutting process you will use

Production Controls and Traceability

- Burr height inspections with a defined method and frequency

- Lamination factor measurements on sample stacks

- Coating integrity checks after stamping or laser cutting

- First article inspection that includes dimensional and magnetic data

- Lot traceability from steel to finished stack

RFQ Checklist You Can Use Today

- Material class and allowable alternates

- Lamination thickness and tolerance

- Coating type and minimum interlam resistance

- Maximum burr height and edge quality requirements

- Cutting process (stamping, laser, EDM) and any post-process

- Stack assembly method and any bonding or weld limits

- Lamination factor target and measurement method

- Core loss target at defined induction and frequency for process-representative coupons

- NVH targets if applicable

- Required certifications and standards compliance

- Packaging and handling requirements to protect coating and flatness

If you want a quick reference while you scope options, see the overview on motor core laminations.

Common Pitfalls and How to Avoid Them

- Using grain-oriented steel in a motor: You will get anisotropic behavior and unexpected loss. Stick with nonoriented for rotating machines.

- Overheating edges during laser cutting: You will see a HAZ that raises loss. Tune parameters and validate with tests. Consider nitrogen assist.

- Ignoring burr height: Burrs can short laminations and raise loss. Specify limits and check them often.

- Welding in high-flux regions: Welds can degrade magnetic performance. Place welds carefully or choose bonding if loss budgets are tight.

- Coating mismatch with adhesive: Some coatings resist bonding. Vet adhesive compatibility in prototype builds.

- Over-specifying thin gauges at low frequency: You will pay more and see little gain. Match thickness to frequency.

- Skipping coupon tests: Vendor datasheets use idealized conditions. Your cutting and stacking path changes properties. Test your process.

Cost Drivers and How to Reduce Them Without Sacrificing Performance

- Tooling: Progressive dies cost money. Wait to tool until the design settles. Use laser or EDM to iterate.

- Material thickness: Thinner gauges cost more and cut slower. Use the thinnest gauge that materially reduces loss at your frequency.

- Nesting and scrap: Optimize lamination nests for coil width and yield. Small changes can save serious steel cost at volume.

- Burr and post-processing: Better dies reduce burr then you skip expensive deburr steps. Prevent the problem rather than grinding it away.

- Assembly method: Interlocking often reduces secondary operations. Bonding increases material cost but can cut NVH fixes later.

- QA frequency: Smart sampling plans keep quality high without drowning the line in inspection time.

Your Engineering Takeaway

Here is the short list you can pin to your wall:

- Match lamination thickness to electrical frequency since eddy current loss scales with thickness squared

- Choose low-coercivity material to reduce hysteresis loss at your target induction

- Use strong interlam insulation and validate bonding or welding compatibility

- Prototype with laser or EDM but test process-representative coupons for loss and interlam resistance

- Move to progressive die stamping for volume to cut unit cost and improve repeatability

- Pick a stack assembly method that supports NVH and thermal goals while respecting flux paths

- Lock standards, inspection methods, and change control in the RFQ so production stays on track

If you are aligning a new design and want to sanity check your stator or rotor approach, review the basics of stator core lamination and rotor core lamination. You can also explore the broader field of electrical steel laminations to compare material classes and coatings.

Want a second set of eyes on your stack-up and specs? Share your frequency targets, induction levels, and a draft RFQ with your lamination partner. Ask for process-representative coupon data and a proposal that covers material options, thickness trade-offs, coating choices, and assembly routes. You will make a clean decision with fewer prototypes and a faster path to a cool, quiet, and efficient machine.