Single Phase vs. Three Phase Motors: A Comprehensive Comparison

Have you ever tried to plug in a big, powerful tool and found it just won’t work? Or maybe you’ve noticed that some machines hum along smoothly while others seem to shake and rattle. The secret often lies in the type of electric motor being used. Choosing the wrong one is a fast way to waste money and time. This guide will simply explain the difference between single phase and three phase motors so you can make the right choice every time.

Table of Contents

- What Is a Single Phase Motor?

- And What About a Three Phase Motor?

- What’s the Big Deal with the Power Supply?

- How Do They Start Up? (The Starting Torque Secret)

- Which Motor is More Efficient and Saves Money?

- What About Cost and Size?

- Will It Shake, Rattle, and Roll? (Vibration & Noise)

- Where Do You Use Each Motor?

- Can I Run a Three-Phase Motor at Home?

- So, How Do I Choose the Right Motor?

- Frequently Asked Questions (FAQs)

- Key Takeaways

What Is a Single Phase Motor?

Let’s start with the motor you probably see every day. A single phase motor runs on single-phase power. This is the standard electricity you have in your home. Think about your wall outlets. That’s single-phase power. It uses one wave of alternating current (AC).

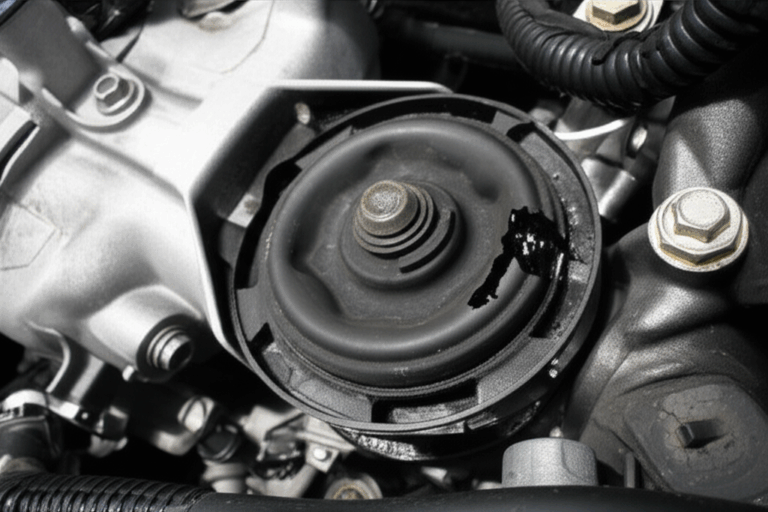

The big thing to know about single phase motors is that they are not self-starting motors. They need a little help to get going. This is why you often see a small, can-shaped part on them called a capacitor. This capacitor gives the motor an extra kick to start spinning. This is known as a capacitor start motor.

You’ll find these motors in all sorts of household items. They are perfect for light-duty jobs. We’re talking about fans, refrigerators, washing machines, and small tools like a drill press. Their horsepower ranges are usually low, often under 10 horsepower (HP). They are the go-to choice for most residential motor types.

And What About a Three Phase Motor?

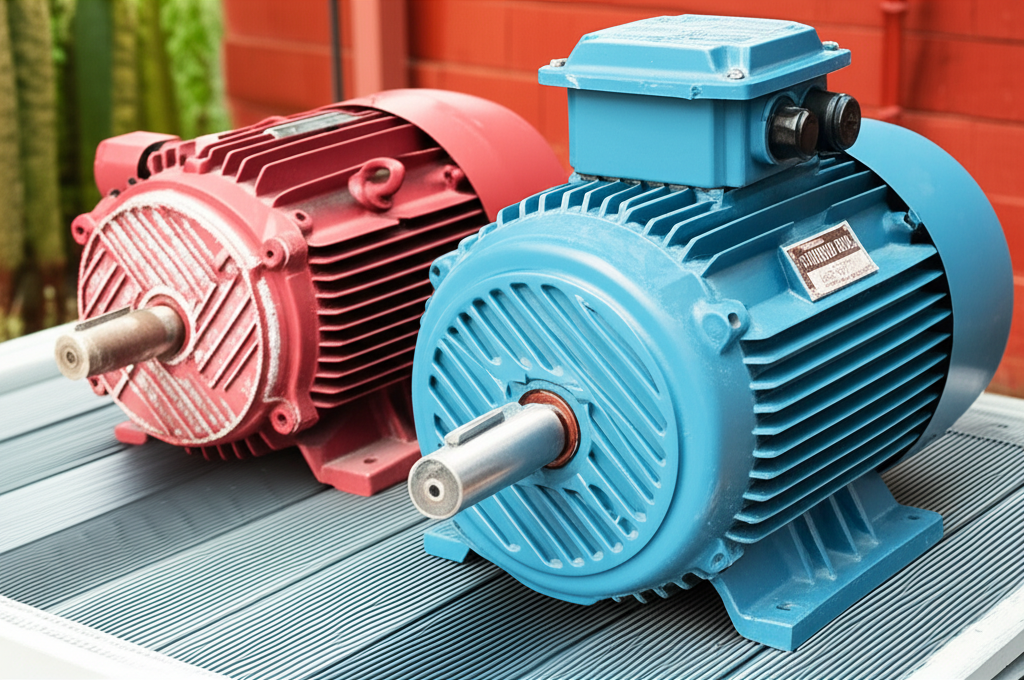

Now, let’s talk about the powerhouse. A three phase motor runs on three-phase power. Instead of one wave of electricity, it gets three separate waves. Each wave is timed perfectly after the other. This creates a steady, constant stream of power. You won’t find this type of power in most homes. It’s built for industrial motor types.

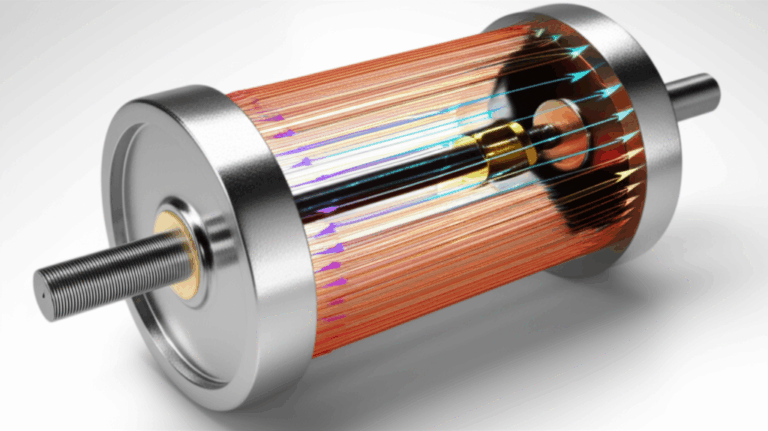

The best part about a three phase induction motor is that it’s self-starting. The three waves of power create a rotating magnetic field inside the motor. This field pulls the motor’s rotor around without any extra help. This makes it strong and reliable from the moment you turn it on.

These motors are the workhorses of industry. They power huge machines like compressors, large pumps, and conveyor belts. You’ll find them in factories, big commercial buildings, and on farms. Any heavy-duty machine that runs all day likely has a three phase motor. The design of the stator and rotor in these motors is built for this kind of tough work.

What’s the Big Deal with the Power Supply?

The power supply is the biggest difference. It’s like comparing a garden hose to a fire hose.

Problem: You have a job to do. Maybe it’s a small fan for your room or a giant pump for a factory. You need a motor that can handle the job without failing.

Agitate: If you pick a motor that doesn’t match your power supply, you’re in trouble. Imagine buying a powerful lathe motor for your workshop, only to find you can’t plug it in. Your project stops cold. Or, you use a small single phase motor for a heavy job. It will overheat, struggle, and burn out fast. This isn’t just a small headache; it’s a real motor problem that costs you time and money.

Solution: Understanding your power is the first step. Single-phase power is simple. It uses two or three wires and is found everywhere in homes. Three-phase power is more complex, using three or four wires. It delivers more power more smoothly. Knowing what power you have tells you which motor you can use right away.

| Power Supply Feature | Single Phase Motor | Three Phase Motor |

|---|---|---|

| AC Waveforms | 1 | 3 |

| Typical Wires | 2-3 (Live, Neutral, Ground) | 3-4 (3 Phases, Ground/Neutral) |

| Common Voltages | 120V, 240V | 208V, 230V, 460V |

| Found In | Homes, small shops | Factories, industrial sites |

How Do They Start Up? (The Starting Torque Secret)

Have you ever tried to push a heavy box? That first push is the hardest part. Motors feel the same way. The power to get started is called starting torque.

A single phase motor has a hard time starting on its own. Its power pushes and then pulls, but it doesn’t create a spinning motion at first. It’s like trying to spin a merry-go-round by just pushing in and out. It needs a sideways push. The starting capacitor gives it that push. Even with help, its torque is pulsating. This means it goes up and down with the single wave of AC power.

A three phase motor is a natural at starting. The three waves of power work together to create a smooth, spinning force from the very beginning. This rotating magnetic field gives it very high starting torque. It’s like having three friends push a merry-go-round one after another. It starts fast and spins smoothly. This smooth torque is a huge advantage for heavy loads.

Which Motor is More Efficient and Saves Money?

Efficiency is a big deal. An efficient motor does more work with less electricity. This saves you money on your power bill.

Problem: Your electricity bill is too high. You run machines all day, and the cost adds up. You need to find a way to cut down on energy use without slowing down your work.

Agitate: An inefficient motor is like a car with a leaky gas tank. You’re paying for energy that’s just being wasted as heat. Over a year, this can add up to hundreds or even thousands of dollars lost. That wasted energy also means the motor runs hotter, which can shorten its typical motor lifespan.

Solution: For pure efficiency, the three phase motor is the clear winner. Because it gets a constant supply of power, it runs more smoothly and wastes less energy. A typical three phase motor might be 85% to 95% efficient. A single phase motor doing the same job might only be 60% to 75% efficient. The better the parts, like high-quality stator core lamination, the more efficient the motor. Over its life, a three phase motor can easily pay for its higher initial cost through energy savings.

What About Cost and Size?

When you’re buying a motor, two things you’ll look at right away are the price and the size.

For small jobs, a single phase motor usually has a lower initial cost. They are simpler to build, so they are cheaper to buy. This makes them great for home appliances and small tools where you only need a little bit of power.

However, as you need more power, the tables turn. A 10 HP single phase motor would be huge, heavy, and very expensive. A 10 HP three phase motor is much smaller, lighter, and costs less per horsepower. So, three phase motors are a much better deal for bigger jobs.

Think of it this way: buying a scooter is cheaper than buying a truck. But if you need to haul heavy things, the truck is a much better value for the work it can do.

Will It Shake, Rattle, and Roll? (Vibration & Noise)

No one likes a noisy, shaky machine. The smoothness of a motor’s operation is important, especially for precise tools like a CNC machine.

The pulsating torque of a single phase motor causes more motor vibration. Because the power comes in one wave, the motor gets a “punch” of energy, then a brief pause, then another punch. This can cause the motor and the machine it’s attached to to shake. This also leads to a higher motor noise comparison.

Three phase motors are the opposite. Their smooth torque comes from the three overlapping waves of power. There are no pauses. This makes them run with very little vibration and noise. For machinery that needs to be precise or for places where noise is a concern, a three phase motor is a much better choice. The smoother operation also means less wear and tear on the machine’s parts over time.

Where Do You Use Each Motor?

The best way to understand the difference is to see where each motor is used. It all comes down to matching the motor to the job. The basic motor principle is to turn electricity into motion, but how much motion and how smoothly is key.

Single Phase Motor Applications:

- Residential: Your refrigerator, washing machine, and garage door opener all use single phase motors.

- Light Commercial: Office fans, small water pumps, and some HVAC units.

- Workshop Tools: Bench grinders, small drill presses, and bandsaws often use them.

- These are perfect for light-duty motor applications where you don’t need a ton of power.

Three Phase Motor Applications:

- Industrial Machinery: Large lathes, mills, and factory automation lines.

- Heavy-Duty Equipment: Big air compressors, commercial refrigeration, and elevators.

- Agricultural Equipment: Irrigation pumps, grain conveyors, and large ventilation fans.

- Anywhere you see heavy-duty motor applications that need constant, reliable power, you’ll find a three phase motor. They are the backbone of industrial machinery motors.

Can I Run a Three-Phase Motor at Home?

This is a common question. Let’s say you bought a great piece of industrial equipment for your garage workshop, but it has a three phase motor. Your house only has single-phase power. Are you out of luck?

Not necessarily. You have a few options.

While it’s possible, converting power adds cost and complexity. It’s often better to use a motor that matches your available power supply from the start.

So, How Do I Choose the Right Motor?

Choosing the right motor doesn’t have to be hard. Just ask yourself a few simple questions.

Problem: You’re standing in front of two motors. One is single phase, one is three phase. They look similar, but you know they are very different. You need to make the right call for your project or you’ll waste time and money.

Agitate: Choosing wrong can be a disaster. A motor that’s too weak will burn out. A motor that needs power you don’t have is just a heavy paperweight. A shaky, inefficient motor will drive you crazy and drive up your bills. You can’t afford a mistake.

Solution: Follow this simple checklist. By answering these questions, you’ll know exactly what you need.

- What power do I have? This is the most important question. If you only have single-phase power, your choice is simple unless you want to buy a converter.

- How much power do I need? For small jobs under 5-10 HP, a single phase motor is often fine. For bigger jobs, you need to go with three phase.

- What is the job? Is it a heavy, continuous load like a big pump, or something that runs for short periods like a small tool? Three phase motors are better for continuous, heavy work.

- How important is efficiency? If the motor will run a lot, the energy savings from a three phase motor will be a huge benefit.

- What is my budget? Think about both the initial cost and the long-term running cost. A cheaper motor might cost you more in electricity over time.

Making the right choice means your machine will run reliably, efficiently, and safely for years to come. High-quality parts from the start, like well-made rotor core lamination, ensure that no matter which type you choose, you get the best performance possible.

Frequently Asked Questions (FAQs)

Q: Can I run a three-phase motor on single-phase power?

A: Yes, but you need a special device called a phase converter or a Variable Frequency Drive (VFD) that is rated to do this. It adds extra cost and setup.

Q: Are three-phase motors always more expensive?

A: Not always. For very small motors (under 1 HP), a single phase motor might be cheaper. But as the horsepower goes up, three phase motors become much cheaper per horsepower.

Q: What’s the typical voltage for each?

A: For single phase in a home, it’s usually 120V or 240V. For three phase in an industrial setting, it’s often 208V, 230V, or 460V.

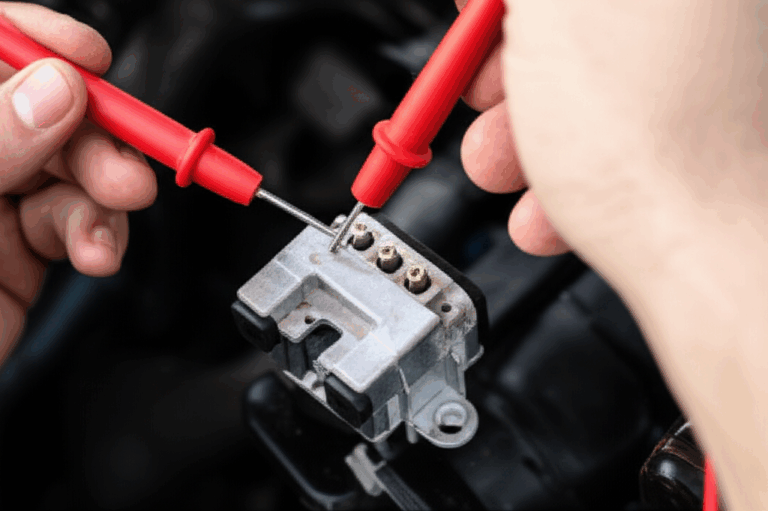

Q: How do I know if I have single or three-phase power?

A: The easiest way is to look at your electrical panel. A single-phase panel usually has two main “hot” wires coming in. A three-phase panel will have three. If you’re unsure, always ask a qualified electrician.

Key Takeaways

To make it simple, here are the most important things to remember:

- Single Phase Motors are for homes and light jobs. They run on standard house power but are less efficient and have a pulsating torque.

- Three Phase Motors are for industrial and heavy jobs. They need special three-phase power but are powerful, efficient, and run very smoothly.

- Power Supply is Key: Always check your available power before choosing a motor.

- Efficiency Saves Money: For motors that run often, a more efficient three phase motor will save you money in the long run.

- Torque Matters: Three phase motors provide smooth, constant torque, which is better for heavy loads and leads to less vibration.