Single-Phase vs. Three-Phase Motors: The Ultimate Comparison Guide

Of course, here’s an article that follows your guidelines.

When I first started tinkering with machinery, the difference between single-phase and three-phase motors felt like a foreign language. It wasn’t until I had to replace a motor in my workshop that I truly understood the importance of choosing the right one. This guide is a result of that hands-on experience and countless hours spent learning the ins and outs of these two common types of motors. I hope it helps you make an informed decision for your project.

Table of Contents

- What is Single-Phase Power?

- What is Three-Phase Power?

- Power Delivery and Torque

- Efficiency and Power Factor

- Motor Construction and Complexity

- Size, Weight, and Cost

- Starting Method

- Speed and Speed Control

- Maintenance and Longevity

- Single-Phase Motor Applications

- Three-Phase Motor Applications

- Advantages of Single-Phase Motors

- Disadvantages of Single-Phase Motors

- Advantages of Three-Phase Motors

- Disadvantages of Three-Phase Motors

Understanding Basic Electrical Phases

Before we dive into the motors themselves, let’s quickly touch on the power that drives them. The key difference lies in the number of alternating currents (AC) that power the motor.

What is Single-Phase Power?

If you’re in a typical home in North America, you’re using single-phase power. It’s the standard for residential applications. You can usually identify it by the three wires coming into your breaker box: two hot wires and a neutral. This setup provides 120V and 240V, which is perfect for your lights, appliances, and small power tools. Think of it like a single cyclist pedaling a bike; there’s a push, and then a coast, creating a pulsating power delivery.

What is Three-Phase Power?

Three-phase power is the workhorse of the industrial and commercial world. It consists of three separate AC signals, each out of phase with the others by 120 degrees. This provides a constant, smooth stream of power, much like three cyclists pedaling in sequence, so there’s always a push. This makes it ideal for running large, powerful motors efficiently. You’ll typically find voltages like 208V, 240V, or 480V in these systems.

Core Differences: Single-Phase vs. Three-Phase Motors

Now that we understand the power source, let’s see how that translates into the design and performance of the motors themselves.

Power Delivery and Torque

This is where the difference really becomes clear. A single-phase motor, because it runs on that pulsating power, doesn’t inherently create a rotating magnetic field. It needs a little help to get going, which is why you see things like start capacitors on them. Once it’s running, the torque it produces fluctuates.

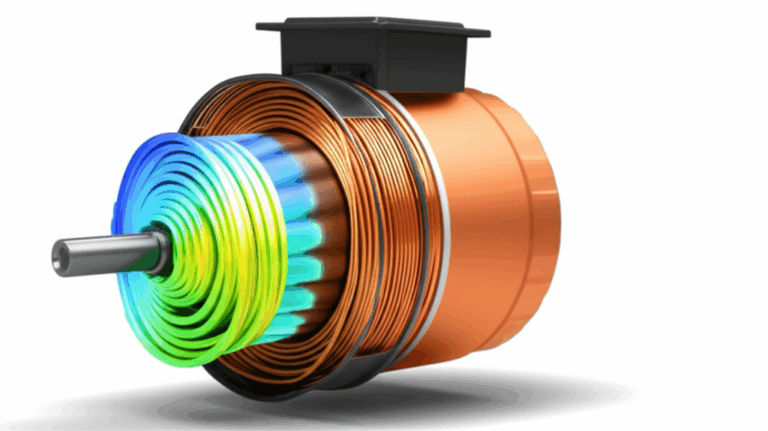

A three-phase motor, on the other hand, is a thing of beauty. The three-phase power supply naturally creates a rotating magnetic field inside the motor. This means it’s self-starting and delivers smooth, consistent torque throughout each rotation. For heavy-duty applications, this smooth delivery is a game-changer.

Efficiency and Power Factor

Efficiency is a big deal, especially when you’re paying the electricity bill. Three-phase motors are inherently more efficient than their single-phase counterparts. Because they deliver power more consistently, less energy is wasted. Over the lifetime of a motor, this can add up to significant savings.

The power factor is also generally better in three-phase motors. A good power factor means the motor is using the electricity it draws more effectively. A poor power factor, which is more common in single-phase motors, means you’re pulling more current from the grid than you’re actually using to do work.

Motor Construction and Complexity

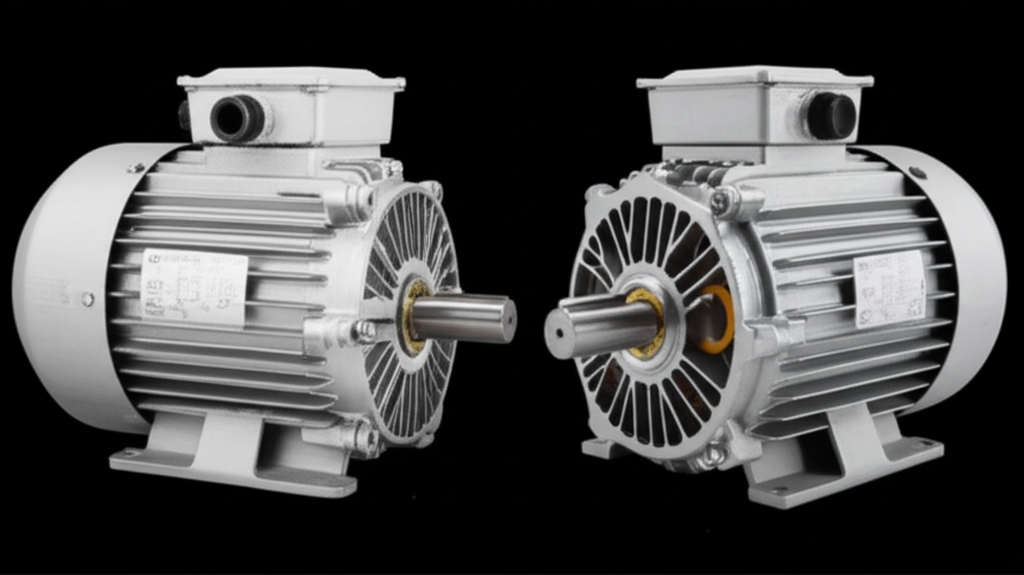

From the outside, they might look similar, but internally, they’re quite different.

- Single-phase motors need extra components to start. You’ll find start windings and often a capacitor to create a second, out-of-phase magnetic field to get the motor spinning. Once it’s up to speed, a centrifugal switch often disconnects this starting circuit. This adds complexity and more potential points of failure.

- Three-phase motors are elegantly simple in their construction. They have three sets of windings, one for each phase. The nature of the three-phase power supply eliminates the need for any special starting mechanism. This simple design contributes to their reliability and longevity. Both types rely on high-quality motor core laminations in their stator and rotor to manage the magnetic fields efficiently.

Size, Weight, and Cost

For a given horsepower rating, a three-phase motor will almost always be smaller, lighter, and more cost-effective than a single-phase motor. The simpler design and more efficient use of materials mean you get more power out of a smaller package.

However, the initial purchase price of a very small single-phase motor (under 1 horsepower) might be lower. But as the power requirements go up, the three-phase motor quickly becomes the more economical choice, not just in operating costs but also in upfront investment.

Performance Characteristics at a Glance

Let’s break down the key performance differences you’ll encounter.

Starting Method

- Single-Phase: Not self-starting. It relies on auxiliary windings and/or capacitors to create a temporary rotating magnetic field to overcome inertia. Common types include capacitor-start, split-phase, and shaded-pole motors.

- Three-Phase: Self-starting. The three-phase power supply creates a perfectly balanced rotating magnetic field from the moment it’s energized, providing excellent starting torque without any extra help.

Speed and Speed Control

For basic applications, both motor types will run at a speed determined by the frequency of the power supply (e.g., 60 Hz in North America) and the number of poles in the motor’s design.

However, when it comes to variable speed control, three-phase motors are the clear winner. They are perfectly suited for use with a Variable Frequency Drive (VFD), which allows you to precisely control the motor’s speed by altering the frequency of the power supplied to it. While you can find VFDs for single-phase motors, they are less common, more expensive, and generally less effective.

Maintenance and Longevity

Because three-phase motors have a simpler construction with fewer parts that can wear out (like starting switches and capacitors), they are generally more reliable and have a longer service life. The balanced power delivery also results in smoother operation and less vibration, which reduces wear and tear on the motor’s bearings and other components.

Applications: Where Each Motor Shines

Choosing the right motor really comes down to the job it needs to do and the power you have available.

Single-Phase Motor Applications

These are the everyday heroes of our homes and small businesses. Because they run on standard residential power, they are incredibly common. You’ll find them in:

- Household Appliances: Refrigerators, washing machines, dryers, fans, and blenders.

- Workshop Tools: Drill presses, small lathes, grinders, and air compressors.

- Light Commercial Equipment: Conveyor belts, pumps, and fans in smaller shops or offices.

Generally, single-phase motors are used for applications under 10 horsepower where a three-phase power supply isn’t available.

Three-Phase Motor Applications

When you need serious power and efficiency, you turn to three-phase motors. Their robust nature and powerful performance make them the standard in:

- Industrial Machinery: Large pumps, heavy-duty compressors, conveyor systems, and industrial fans.

- Manufacturing Equipment: Machine tools like lathes, mills, and grinders.

- Commercial HVAC Systems: Powering large air handlers and chillers in commercial buildings.

- Heavy-Duty Applications: Think cranes, elevators, and other equipment that requires high starting torque and smooth, continuous operation.

Key Advantages and Disadvantages

Let’s summarize the pros and cons to make the choice clearer.

Advantages of Single-Phase Motors

- Accessibility: Runs on standard household power.

- Lower Initial Cost (for small motors): More affordable for low-horsepower applications.

- Simple Wiring: The power connection itself is straightforward (live, neutral, ground).

Disadvantages of Single-Phase Motors

- Lower Efficiency: Consumes more power for the same output.

- Pulsating Torque: Can cause more vibration and noise.

- Limited Power: Not practical for applications above 10-15 horsepower.

- Requires Starting Mechanisms: Adds complexity and potential points of failure.

Advantages of Three-Phase Motors

- Higher Efficiency: Lower operating costs over the life of the motor.

- Smooth, Constant Torque: Less vibration and quieter operation.

- Higher Power Density: More power from a smaller, lighter package.

- Reliability: Simpler design with fewer parts to break.

- Self-Starting: No need for complex starting circuits.

Disadvantages of Three-Phase Motors

- Requires Three-Phase Power: Not typically available in residential settings.

- Higher Initial Cost (for small motors): Can be more expensive than a single-phase equivalent at lower power ratings.

- Complex Installation: Wiring and control systems (like motor starters) can be more involved.

Choosing the Right Motor: Factors to Consider

So, how do you decide? Ask yourself these questions:

FAQs about Single-Phase and Three-Phase Motors

Q: Can you convert a single-phase supply to three-phase for a motor?

A: Yes, you can! This is often done using a phase converter. There are two main types: static converters, which are simpler but can result in a power loss, and rotary converters, which use an idler motor to generate a true third phase and are much better for heavier loads. Variable Frequency Drives (VFDs) can also be used; some models are designed to take a single-phase input and produce a three-phase output to run a three-phase motor.

Q: Is a three-phase motor always better?

A: In terms of performance, efficiency, and power density, yes, three-phase motors are generally superior. However, “better” depends on the application. For a small home workshop compressor, a single-phase motor is perfectly adequate and more practical because it works with standard residential wiring.

Q: What is the maximum horsepower (HP) for a single-phase motor?

A: While there’s no hard technical limit, it’s rare to see single-phase motors rated above 10-15 HP. Beyond that, the current draw becomes very high, requiring extremely thick and expensive wiring. At that point, it’s far more practical and economical to use a three-phase system.

Conclusion: Making an Informed Decision

Choosing between a single-phase and a three-phase motor isn’t just about picking the more powerful option; it’s about matching the right tool for the job. For most home and light commercial applications, the convenience and availability of single-phase power make it the default choice. But for industrial settings, heavy machinery, or any application where efficiency and smooth, high-power performance are critical, the three-phase motor is the undisputed champion. By understanding the core differences in how they receive and use power, you can make a smart choice that will save you money, time, and headaches in the long run.