Squirrel Cage vs. Wound Rotor Motors: A Comprehensive Comparison of Induction Motor Types

Every engineer, designer, and plant manager eventually faces the critical decision of selecting the right electric motor. It’s a choice that directly impacts performance, operational cost, and reliability. When you dive into the world of AC induction motors, you’ll quickly encounter two dominant yet fundamentally different designs: the squirrel cage motor and the wound rotor motor. On the surface, they might seem similar—both are workhorses of industry—but their internal construction dictates vastly different capabilities.

If you’ve ever found yourself weighing the trade-offs between starting torque, speed control, and budget, you’re in the right place. Choosing between these two isn’t just a technical detail; it’s a strategic decision. This guide is designed to act as your expert consultant, breaking down the engineering principles, comparing the pros and cons, and empowering you to select the ideal motor for your specific application with confidence.

What We’ll Cover

- The Heart of the Matter: Understanding Induction Motors

- What is a Squirrel Cage Induction Motor? The Industry Workhorse

- What is a Wound Rotor Induction Motor? The High-Torque Specialist

- Squirrel Cage vs. Wound Rotor: A Head-to-Head Comparison

- In-Depth Breakdown: Advantages and Disadvantages

- Applications: Choosing the Right Motor for the Job

- The Modern Game-Changer: The Impact of Variable Frequency Drives (VFDs)

- Your Engineering Takeaway: Making an Informed Motor Selection

The Heart of the Matter: Understanding Induction Motors

Before we pit these two motors against each other, let’s establish some common ground. Both squirrel cage and wound rotor motors are types of asynchronous induction motors. This means they operate on the principle of electromagnetic induction without needing any physical electrical connection to the rotor to create torque.

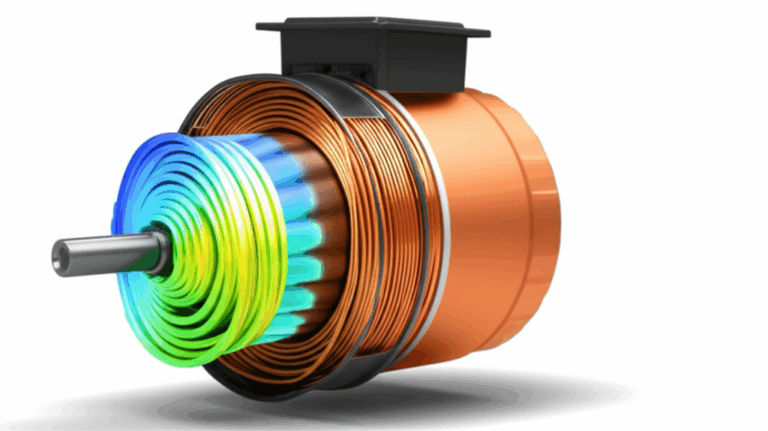

Here’s the simple version: the stator (the stationary part of the motor) has windings that, when energized with a three-phase AC supply, create a rotating magnetic field (RMF). This RMF sweeps past the conductors in the rotor (the rotating part), inducing a current within them. This induced current creates its own magnetic field, which interacts with the stator’s field, and voila—the rotor starts to spin, trying to “catch up” with the RMF. It never quite does, and that difference in speed, known as “slip,” is what makes torque generation possible.

While this core principle is the same for both, the entire story of their differences unfolds within the rotor’s design. How the rotor is constructed and whether you can interact with its electrical circuit is what separates the simple, rugged workhorse from the powerful, controllable specialist.

What is a Squirrel Cage Induction Motor? The Industry Workhorse

Chances are if you see an industrial motor, it’s a squirrel cage motor. They account for over 90% of all industrial motors for a reason: they are the epitome of simple, effective, and robust design.

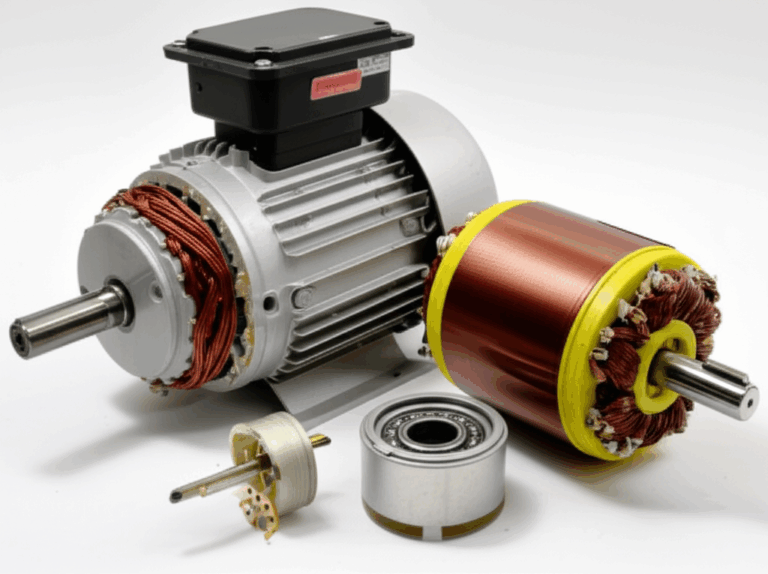

A Masterclass in Simplicity: Construction

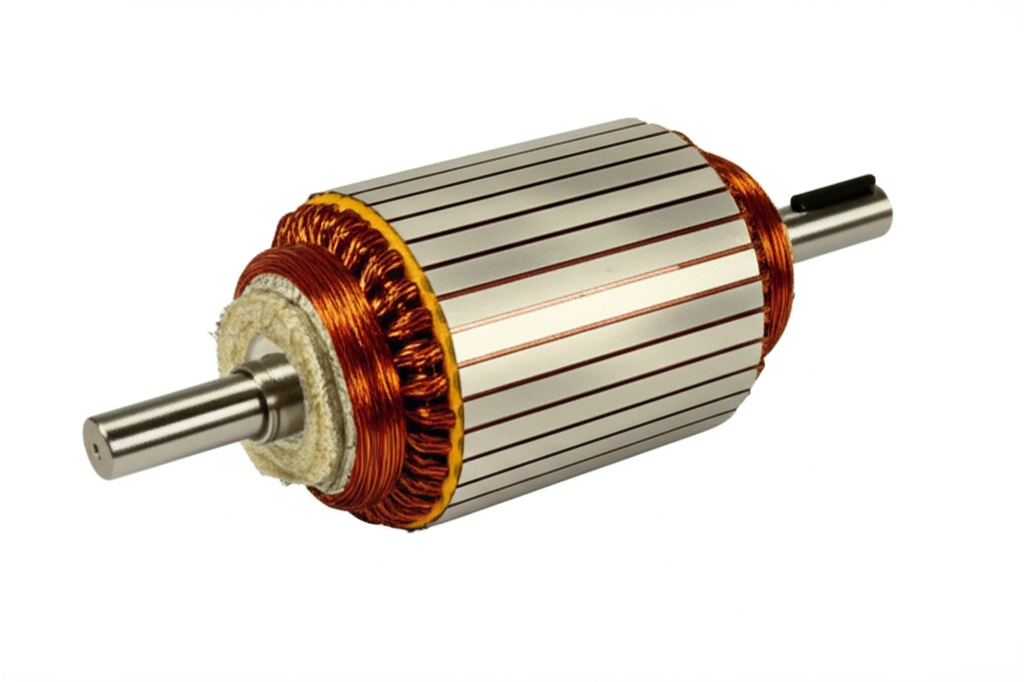

The genius of the squirrel cage motor lies in its rotor. Imagine a hamster wheel or, more historically, a “squirrel cage.” That’s precisely what the rotor looks like if you were to strip away the iron core. It’s made of a series of conductive bars—typically aluminum or copper—that run the length of the rotor and are short-circuited at either end by solid end rings. These bars are embedded within a laminated steel core, which serves to concentrate the magnetic field.

Crucially, the rotor is a self-contained, sealed unit. There are no external electrical connections, no windings in the traditional sense, and no parts designed to wear out other than the bearings. The interaction between the stator and rotor is purely magnetic, making it an incredibly durable piece of engineering.

How it Works: The Magic of Induction

When the stator’s RMF cuts across the rotor bars, it induces a large current in them. Because the bars are shorted by the end rings, this current circulates freely, creating a powerful magnetic field in the rotor. This field interacts with the stator’s field, producing strong torque and causing the motor to start and run. The motor’s characteristics, like starting torque and current, are fixed by the physical design—specifically, the shape and resistance of those rotor bars.

Key Characteristics at a Glance

- Construction: Extremely simple and robust.

- Maintenance: Virtually zero, aside from bearing lubrication.

- Cost: The lowest initial cost for its power rating.

- Reliability: Exceptionally high due to the lack of wearing parts like brushes.

- Control: Inherently a fixed-speed device, with its speed determined by the supply frequency and number of poles.

What is a Wound Rotor Induction Motor? The High-Torque Specialist

Now, let’s look at its more complex cousin, the wound rotor induction motor, often called a slip-ring motor. Where the squirrel cage is all about simplicity, the wound rotor is designed for control.

A More Complex Design: Construction

The stator of a wound rotor motor is identical to a squirrel cage motor’s. The difference, once again, is all in the rotor. Instead of simple bars, the wound rotor has a full three-phase winding, much like the stator itself. These windings are made of copper and are arranged in the rotor slots.

Here’s the key feature: the ends of these rotor windings aren’t short-circuited internally. Instead, they are brought out and connected to three insulated slip rings mounted on the motor shaft. Carbon brushes ride on these slip rings, providing a continuous electrical connection from the rotating rotor windings to an external stationary circuit. This external circuit is typically a bank of high-power variable resistors, often called a rheostat.

How it Works: Taking Control of the Rotor

That external connection is the wound rotor motor’s superpower. By adding external resistance to the rotor circuit during startup, you can fundamentally alter the motor’s performance characteristics.

According to the principles of induction motors, the maximum torque is independent of rotor resistance, but the slip at which that maximum torque occurs is directly proportional to the rotor resistance. By adding a lot of resistance at startup (when slip is 100%), you can shift the motor’s peak torque right to its starting point. This results in two incredible benefits:

As the motor speeds up, the external resistance is gradually reduced (either manually or automatically) until, at full speed, the slip rings are short-circuited, and the motor behaves much like a standard induction motor.

Key Characteristics at a Glance

- Construction: Complex, with windings, slip rings, and brushes.

- Maintenance: Higher due to the wear of brushes and slip rings.

- Cost: Significantly higher initial cost for the motor and its control gear.

- Control: Excellent control over starting torque, starting current, and (to an extent) operating speed.

Squirrel Cage vs. Wound Rotor: A Head-to-Head Comparison

Putting them side-by-side reveals how their design philosophies translate into real-world performance. The fundamental differences in their rotor core lamination and electrical connections create a stark contrast in capabilities.

Here’s a detailed breakdown:

| Feature/Metric | Squirrel Cage Induction Motor | Wound Rotor Induction Motor (Slip Ring) | Notes |

|---|---|---|---|

| Rotor Construction | Short-circuited conductive bars embedded in laminated core; no external connections. | Three-phase windings connected to slip rings and brushes, allowing external resistance. | The fundamental difference in design leads to all other variations. |

| Starting Torque | Moderate to Low (Typically 1.5 – 2.5 times full load torque) | High & Adjustable (Can be >3 times full load torque with external resistance) | Critical for applications requiring heavy load start-up (e.g., cranes, large mixers). |

| Starting Current | High (Typically 5 – 7 times full load current on DOL start) | Low & Controllable (Can be limited to 2 – 3 times full load current) | Reduces stress on the electrical grid, important for weak grids or sensitive equipment. |

| Speed Control | Limited inherently (Fixed speed with small slip); Excellent with VFDs. | Excellent inherently (By varying external rotor resistance; a traditional method). | VFDs have largely reduced the reliance on rotor resistance for speed control in new installations. |

| Efficiency | High (Typically 85-95% at full load) | Moderate (Typically 80-90%, lower with significant external resistance losses) | External resistance introduces energy loss as heat, especially during speed control. |

| Power Factor | Good (Typically 0.8 – 0.9 lagging at full load) | Moderate (Can be improved at starting, but often lower in operation) | Power factor correction can be a utility requirement and cost factor. |

| Maintenance | Very Low (No brushes/slip rings to wear; primary wear is bearings). | High (Regular inspection/replacement of brushes, slip rings, and mechanisms). | Increased complexity leads to higher operational expenses and potential downtime. |

| Robustness/Durability | Very High (Simple, fully enclosed rotor; suitable for harsh environments). | Moderate (Exposed slip rings and brushes are susceptible to dust, moisture, and wear). | Squirrel cage motors are the undisputed champions of reliability in harsh conditions. |

| Initial Cost | Lower (Simpler design, fewer components). | Higher (Due to complex rotor, slip rings, brushes, and specialized control gear). | The total system cost for a wound rotor motor is almost always higher. |

In-Depth Breakdown: Advantages and Disadvantages

Let’s move beyond the spec sheet and talk about what these differences mean for your project.

The Case for the Squirrel Cage Motor

Pros:

- Built Like a Tank: With a virtually indestructible rotor, these motors are incredibly robust and can handle harsh industrial environments with ease.

- Low Cost & Widely Available: Their simple design makes them cheaper to manufacture and readily available from countless suppliers in standard frame sizes.

- Minimal Maintenance: Forget about brush replacements or slip ring cleaning. Beyond greasing the bearings periodically, they are a true “fit and forget” solution.

- High Efficiency: With no external resistance losses, squirrel cage motors generally have higher efficiency and a better power factor during normal operation.

Cons:

- High Starting Current: A direct-on-line (DOL) start draws an enormous inrush current (5-7 times the rated current), which can cause voltage dips on your electrical network and stress components.

- Moderate Starting Torque: Standard designs have a fixed, moderate starting torque that may not be sufficient to get very heavy or high-inertia loads moving.

- No Inherent Speed Control: It’s a one-speed machine. To vary its speed, you absolutely need an external device like a Variable Frequency Drive (VFD).

The Case for the Wound Rotor Motor

Pros:

- Unmatched Starting Torque: This is its main claim to fame. By tuning the external resistance, you can achieve maximum torque at zero speed, allowing for smooth, powerful acceleration of the heaviest loads.

- Controlled, Low Starting Current: The ability to limit inrush current is a huge advantage, especially on weak power grids or when the motor is a significant portion of the total facility load.

- Smooth Acceleration: The gradual reduction of resistance provides exceptionally smooth and controlled acceleration, which is critical for applications like cranes or lifts where jerky movements are unacceptable.

- Traditional Speed Control: By leaving some resistance in the rotor circuit, you can achieve a degree of speed control, though this method is inefficient.

Cons:

- Complexity and Cost: The motor, with its slip rings and brushes, is more expensive. The external resistor bank and control gear add further to the initial cost and installation complexity.

- High Maintenance: Brushes wear down and create carbon dust. Slip rings can become scored or dirty. These components require regular inspection and replacement, leading to more downtime and higher operational costs.

- Lower Efficiency: Whenever you’re using the external resistors (either for starting or speed control), you’re converting electrical energy into wasted heat, which hurts overall efficiency.

- Less Robust: The exposed slip rings and brushes are vulnerable points, making them less suitable for very dusty, dirty, or corrosive environments compared to a fully enclosed squirrel cage motor.

Applications: Choosing the Right Motor for the Job

This is where the theory meets reality. The “best” motor is simply the one that’s right for the task at hand.

Where Squirrel Cage Motors Excel

Thanks to their simplicity and reliability, squirrel cage motors are the default choice for the vast majority of industrial applications. They are perfect for tasks with light-to-moderate starting loads that run at a constant speed. The quality and design of the motor core laminations are key to their efficiency in these roles.

- Pumps, Fans, and Blowers: These applications typically start with low loads and run continuously at a set speed.

- Compressors: While they can have higher starting torque requirements, many modern designs are well-suited for squirrel cage motors, often paired with soft starters.

- Conveyors: For most conveyor systems, a standard squirrel cage motor provides ample power.

- General Machinery: Lathes, drill presses, and countless other machine tools rely on the simple, dependable power of squirrel cage motors.

Where Wound Rotor Motors Remain Essential

Wound rotor motors thrive where high starting torque and low starting current are non-negotiable. They are specialists for the most demanding jobs.

- Cranes, Hoists, and Lifts: These require very high torque to lift heavy loads from a standstill and demand smooth, controlled acceleration.

- Crushers, Grinding Mills, and Cement Mills: These machines have enormous inertia. A wound rotor motor can provide the massive, sustained torque needed to get them turning without tripping the entire plant’s electrical protection.

- Heavy-Duty Conveyors: For large, heavily loaded conveyors, such as those used in mining.

- Traction Drives: Used in applications like trains or trams for controlled acceleration.

Case Study in Action: The Cement Ball Mill

Let’s consider a practical example. A cement plant needs a motor for a massive ball mill, a huge rotating drum filled with steel balls and raw material.

- The Challenge: The mill has extreme inertia. When full, it requires tremendous torque to overcome static friction and begin rotating. Furthermore, the plant is on a grid that has strict limits on how much current can be drawn during motor startup to prevent voltage sags that could affect other equipment.

- The Wound Rotor Solution: A large wound rotor motor is the classic, proven choice. By inserting maximum external resistance into the rotor circuit at startup, engineers can achieve 250-300% of the motor’s full-load torque while limiting the starting current to just 2-2.5 times the full-load current. This provides a powerful yet gentle start, protecting both the grid and the mill’s mechanical components. As the mill gets up to speed, the resistance is smoothly cut out.

- The Squirrel Cage Alternative? Could you use a giant squirrel cage motor with a VFD? Technically, yes. But for a multi-megawatt motor driving such a high-inertia load, the VFD would have to be incredibly large, complex, and expensive—potentially far more so than the wound rotor motor and its relatively simple resistance controller. In this specific, high-demand niche, the wound rotor often remains the more robust and cost-effective engineering solution.

The Modern Game-Changer: The Impact of Variable Frequency Drives (VFDs)

The rise of modern power electronics, specifically the VFD, has dramatically changed the motor selection landscape. A VFD controls a motor by varying the frequency and voltage of the power supplied to it, offering capabilities that were once impossible for standard squirrel cage motors.

By starting a motor at a very low frequency and voltage and ramping up, a VFD can provide a “soft start,” limiting the inrush current just like a wound rotor motor. It also allows for precise, highly efficient speed control across the motor’s entire operating range.

This has allowed squirrel cage motors to encroach on territory that once belonged exclusively to wound rotor motors. For many variable-speed applications or those needing a soft start, a squirrel cage motor paired with a VFD is now the preferred, more efficient, and lower-maintenance solution.

So, are wound rotor motors obsolete? Not quite. As our case study showed, for extremely high-power, high-inertia applications, the sheer cost of a VFD capable of handling the load can still make the traditional wound rotor motor a more viable option. They remain the undisputed specialists for the biggest, toughest jobs where their inherent starting characteristics provide a robust and proven solution.

Your Engineering Takeaway: Making an Informed Motor Selection

You now have the framework to navigate the choice between these two powerful induction motor types. The decision always comes back to the specific demands of your application.

Here are the key takeaways to guide your selection:

- It’s All About the Rotor: The simple, short-circuited rotor of a squirrel cage motor makes it reliable and cheap. The complex, accessible rotor of a wound rotor motor makes it controllable and powerful at startup. The quality of the materials, such as the electrical steel laminations, is critical to the performance of both.

- Prioritize Starting Conditions: Is your primary challenge starting a massive, high-inertia load? Or is your grid sensitive to high currents? If you answer yes to either, a wound rotor motor should be a serious contender. For everything else, a squirrel cage motor is likely the better starting point.

- Consider Total Cost of Ownership: Don’t just look at the initial price tag. A wound rotor motor costs more upfront and will continue to incur costs through higher maintenance and lower efficiency. A squirrel cage motor is cheaper to buy and run, but adding a large VFD can significantly increase the initial system cost.

- Embrace Modern Controls: For new installations requiring speed control or soft-starting, the combination of a squirrel cage motor and a VFD is the modern standard for most applications due to its efficiency and low maintenance.

- Respect the Niche: Don’t discount the wound rotor motor. In its niche of heavy industry—cranes, mills, and crushers—it remains an essential and often superior solution for providing brute-force starting torque with finesse.

By asking these questions and understanding the fundamental trade-offs, you can move beyond a simple spec sheet comparison and make a truly informed engineering decision that ensures your equipment runs efficiently, reliably, and cost-effectively for years to come.