The Three Basic Types of Three-Phase Motors Explained

Have you ever wondered what makes the world go round? In many factories, workshops, and big buildings, the answer is a three-phase motor. These powerful machines run everything from giant fans to the conveyor belts that move products. But not all motors are the same. Choosing the wrong one can be a costly mistake, leading to wasted energy and poor performance. This guide will simply explain the three basic types of three-phase motors so you can understand what makes each one special and which one is right for the job.

Table of Contents

- What Is a Three-Phase Motor Anyway?

- Type 1: The Workhorse Induction Motor

- What’s a Squirrel Cage Motor?

- What About the Wound Rotor Motor?

- Type 2: The Perfectly Timed Synchronous Motor

- How Does a Synchronous Motor Stay in Sync?

- Where Do You Use a Synchronous Motor?

- Type 3: What Are Special Purpose Motors?

- How Do I Choose the Right Motor?

- Why Motor Quality Matters

- Your Quick Guide to Three-Phase Motors

What Is a Three-Phase Motor Anyway?

Imagine you’re trying to push a merry-go-round. If it’s just you pushing, it can be jerky and hard to get started. Now, imagine you have two friends helping. You space yourselves out evenly and push one after the other. The ride becomes smooth and powerful. That’s the basic idea behind three-phase power.

A three-phase motor uses three separate waves of electricity that push in a perfect sequence. This creates a smooth, spinning force called a rotating magnetic field (RMF). This constant power makes these motors very strong and efficient. They don’t need special parts to get started, unlike some single-phase motors you might find in your home. That’s why they are the kings of the industrial world.

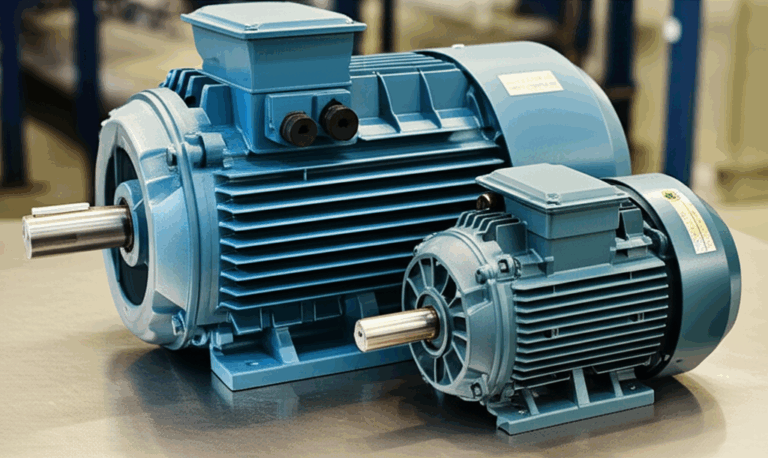

Type 1: The Workhorse Induction Motor

The most common type of three-phase motor is the induction motor. Think of it as the reliable pickup truck of the motor world. It’s tough, simple, and gets the job done without a lot of fuss. It’s also called an asynchronous motor, which is a fancy way of saying its moving part doesn’t spin at the exact same speed as the magnetic field.

Here’s how it works. The outside part of the motor, called the stator, has coils of wire. When three-phase power flows through these coils, it creates that rotating magnetic field we talked about. The inside part, called the rotor, is a solid chunk of metal. The magnetic field “induces” a current in the rotor, which creates another magnetic field. The rotor’s magnetic field tries to catch up to the stator’s field, which makes it spin!

The small difference in speed between the rotor and the magnetic field is called “slip”. This slip is actually necessary for the motor to create torque, which is its twisting power. There are two main kinds of induction motors.

What’s a Squirrel Cage Motor?

The squirrel cage induction motor (SCIM) is the most popular motor on the planet. Why the funny name? If you took the rotor out and stripped it down, it would look like one of those little cages that squirrels run in. It’s made of solid bars of metal connected at the ends by end rings. It’s incredibly simple and strong.

Problem: You need a motor that just works. It has to be tough enough to handle dust, bumps, and long hours without needing a lot of attention. Many motors have delicate parts that can break down, costing you time and money.

Agitate: Imagine your factory’s main conveyor belt stops working. Production grinds to a halt. You find out the motor failed because it was too complicated and a small part, like a brush, wore out. Now you’re facing expensive downtime, all because the motor wasn’t simple and reliable.

Solution: This is where the squirrel cage motor shines. It has no brushes or slip rings to wear out. Its tough rotor construction means it requires very little maintenance. You can install it and practically forget about it. It’s perfect for things that run all day long, like:

- Pumps to move water

- Fans for cooling and air circulation

- Compressors for air tools

- Conveyors in factories

- Grinders and other machine tools

These motors offer a great starting torque and are very cost-effective. For most general jobs, the squirrel cage motor is the perfect choice.

What About the Wound Rotor Motor?

The second type of induction motor is the wound rotor induction motor (WRIM), also called a slip-ring motor. This one is a bit more specialized. Unlike the solid bars in a squirrel cage rotor, the rotor in a WRIM has actual coils of wire, just like the stator. These wires are connected to slip rings and brushes on the outside of the motor.

Why add all this complexity? Because it gives you control. By connecting external resistors to the rotor through the slip rings, you can change the motor’s performance.

This is a huge advantage for certain jobs. A wound rotor motor can produce a very high starting torque while keeping the starting current low. This is important for moving very heavy loads from a dead stop without stressing the electrical system. You can also use the resistors to control the motor’s speed.

You’ll find these motors in heavy-duty applications like:

- Cranes and hoists that lift massive weights.

- Crushers in mines that break up big rocks.

- Rolling mills that shape steel.

- Elevators that need smooth starts.

However, the brushes and slip rings need more maintenance than a squirrel cage motor. As technology has improved, many of the jobs once done by wound rotor motors can now be done by a squirrel cage motor paired with a variable frequency drive (VFD). A VFD is an electronic device that controls the motor’s speed by changing the power going into it.

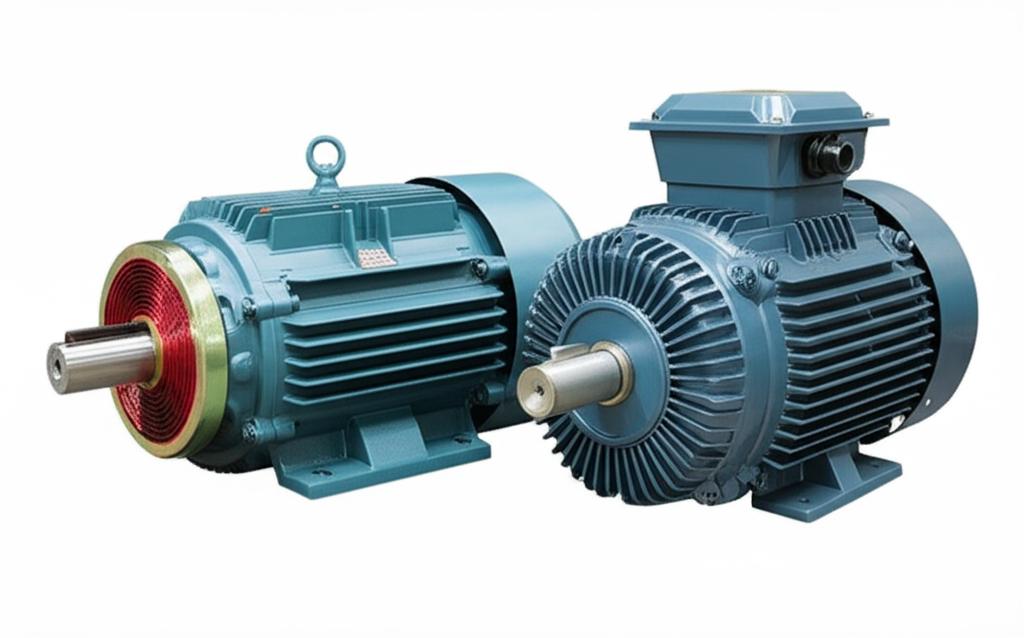

Type 2: The Perfectly Timed Synchronous Motor

Our second major type is the three-phase synchronous motor. If the induction motor is a pickup truck, the synchronous motor is a high-precision race car. The name “synchronous” tells you its secret: the rotor turns at the exact same speed—in sync—with the rotating magnetic field of the stator. There is no slip!

This is a big deal. In an induction motor, the speed can drop a little as you add more load. But a synchronous motor holds its speed perfectly steady, no matter what (as long as you don’t overload it).

How Does a Synchronous Motor Stay in Sync?

So how does it do this? A synchronous motor can’t create a magnetic field in its rotor through induction alone. It needs help. The rotor has its own magnetic field that is “on” all the time. This field is created in one of two ways:

Because the rotor is already a magnet, it “locks” onto the rotating magnetic field of the stator and is forced to spin at the exact same speed, known as synchronous speed. One downside is that these motors are not self-starting. They need a special starting method, like using damper windings (which act like a squirrel cage) or a VFD to get them up to speed before they can lock in.

Where Do You Use a Synchronous Motor?

You might be thinking this sounds complicated. It is, which is why these motors are more expensive. So, why use them?

Problem: Some industrial plants have a big problem with something called power factor. In simple terms, it means they are using electricity inefficiently. The power company doesn’t like this and often charges them extra fees. Also, some machines need a speed that never, ever changes, even by a tiny bit.

Agitate: Imagine your company getting an electricity bill that’s thousands of dollars higher than it should be, all because of penalties for bad power factor. Or picture a machine that makes delicate film or paper; if the motor speed varies even slightly, the entire product could be ruined, costing a fortune in wasted material.

Solution: This is the synchronous motor’s time to shine! By changing the amount of DC power sent to its rotor, you can change its power factor. You can run it in a way that actually cancels out the bad power factor from other machines in the plant. This is called power factor correction, and it can save a company a lot of money.

Because they run at a constant speed, they are perfect for:

- Large industrial fans, pumps, and compressors that need to run at one steady speed for peak efficiency.

- Machines that require exact timing, like in paper mills and textile factories.

- High-precision drives where speed cannot change.

They are also very efficient, especially in very large sizes (thousands of horsepower).

Type 3: What Are Special Purpose Motors?

Beyond the big two, there is a growing category of special motors designed for specific jobs. We already mentioned the Permanent Magnet Synchronous Motor (PMSM), which is becoming very popular. It’s super-efficient and offers great control. You can find them in electric cars and high-tech robots. The high-quality materials used in the core of a brushless DC motor allow for this incredible performance.

Other types include reluctance motors, which are very rugged and efficient, and stepper motors, which move in tiny, exact steps for things like 3D printers and CNC machines. These advanced motors are often controlled by smart electronics, pushing the boundaries of what’s possible.

How Do I Choose the Right Motor?

Now that you know the three basic types, how do you pick one? Here’s a quick comparison to help.

| Feature | Squirrel Cage Motor | Wound Rotor Motor | Synchronous Motor |

|---|---|---|---|

| Speed | Almost constant, but slips under load | Speed can be changed with resistors | Perfectly constant speed |

| Starting Power | Good | Very high | Low (needs help to start) |

| Cost | Low | Medium | High |

| Maintenance | Very Low | Medium (brushes need care) | Medium (brushes) or Low (PM) |

| Efficiency | Good to Excellent | Good | Very High to Excellent |

| Power Factor | Always lags | Always lags | Can be changed (leading or lagging) |

Think about your needs:

- For a simple, low-cost, reliable motor for a pump or fan, a squirrel cage motor is almost always the best answer.

- If you need to start a very heavy load smoothly, like a giant rock crusher, a wound rotor motor might be the ticket.

- If you need perfect speed or want to fix your plant’s power factor, you need a synchronous motor.

Why Motor Quality Matters

No matter which type of motor you choose, its performance comes down to the quality of its parts. The heart of any motor is its core, made of thin sheets of metal called laminations. The stator and rotor are both built from these stacks.

The quality of the high-quality stator laminations and the specially designed rotor laminations determines how efficient the motor will be. Poor-quality laminations waste electricity by turning it into heat instead of motion. This drives up your energy bills and can cause the motor to overheat and fail early.

That’s why at SinoLami, we focus on creating the best dependable motor core laminations. We use high-grade electrical steel to ensure our parts create strong magnetic fields with very low energy loss. When a motor is built with a great core, it runs cooler, lasts longer, and saves you money every minute it’s running. Choosing the right motor type is the first step. Ensuring it’s built with quality components is the secret to long-term success.

Your Quick Guide to Three-Phase Motors

Feeling more confident? Let’s wrap it up. Understanding these powerful machines doesn’t have to be hard.

Here are the key things to remember:

- Three-phase motors are the powerful workhorses of industry because they get smooth, efficient power.

- The Induction Motor is the most common type. The Squirrel Cage version is simple, cheap, and reliable for general use. The Wound Rotor version offers high starting torque and speed control for heavy-duty jobs.

- The Synchronous Motor is a high-precision machine. It runs at a perfect, constant speed and can be used to improve a factory’s power efficiency.

- Special Purpose Motors like PMSMs are pushing technology forward, offering amazing performance in things like electric vehicles and robotics.

- The quality of a motor starts at its core. High-quality laminations are essential for efficiency, reliability, and a long service life.

The next time you see a big piece of machinery humming away, you’ll know the secret behind its power. You’ll understand the difference between the simple workhorse and the precision racer, and you’ll be able to make a smart choice for any job that comes your way.

References:

- U.S. Department of Energy. (Various Reports). Motor Systems Efficiency.

- Grand View Research. (Market Analysis Reports). Global Industrial Electric Motor Market.

- NEMA Standards Publication. (2021). Motors and Generators. National Electrical Manufacturers Association.