The Ultimate Guide to Motor Efficiency: Choosing the Most Energy-Efficient Motor for Your Needs

Every engineer, designer, and operations manager grapples with a fundamental challenge: how to squeeze every last bit of performance out of a system while keeping costs in check. When it comes to machinery, this challenge almost always leads back to the electric motor. If you’ve ever found yourself weighing the trade-offs between different motor technologies, trying to decipher efficiency ratings, and calculating the long-term cost implications, you’re in exactly the right place.

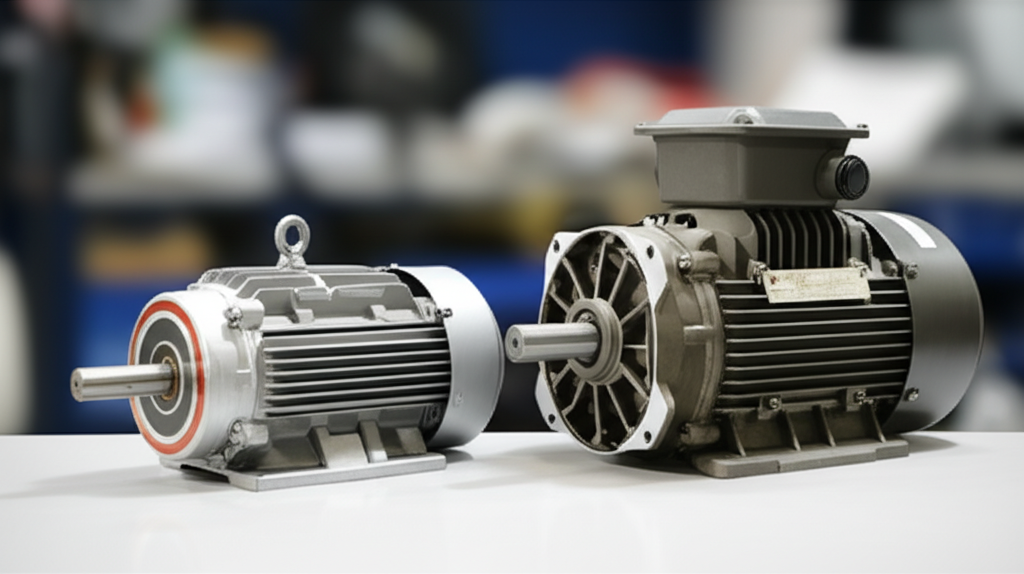

Electric motors are the unsung workhorses of our modern world, silently powering everything from industrial pumps to the drivetrain in your electric vehicle. But their widespread use comes with a hefty price tag—not just in initial cost, but in ongoing energy consumption. In fact, according to the International Energy Agency (IEA), electric motor systems account for nearly 70% of all industrial electricity use. That’s a staggering number.

This makes motor efficiency more than just a technical specification; it’s a critical factor for financial performance, operational reliability, and environmental sustainability. Choosing the right motor isn’t just about getting the job done; it’s about getting it done smartly. This guide will demystify the world of motor efficiency, breaking down the jargon and giving you the clarity to make informed decisions.

In This Article

- Understanding Motor Efficiency: The Basics

- Key Factors Influencing Motor Efficiency

- Comparing Motor Types by Efficiency: Which Motor is More Efficient?

- Motor Efficiency Standards and Classifications

- Choosing the Right High-Efficiency Motor for Your Application

- Maximizing Motor System Efficiency: Beyond the Motor Itself

- Conclusion: The Future of Efficient Motor Technology

Understanding Motor Efficiency: The Basics

Before we dive into a motor efficiency comparison, let’s get on the same page about what “efficiency” truly means in this context. It’s a simple concept at its core, but its implications are massive.

What is Motor Efficiency?

At its heart, motor efficiency is a straightforward ratio: it’s the measure of how well a motor converts electrical energy into useful mechanical work. The energy that isn’t converted into work doesn’t just vanish—it’s lost, primarily as heat.

The formula is simple:

Efficiency (%) = (Mechanical Power Output / Electrical Power Input) x 100

For example, if a motor draws 10 kilowatts (kW) of electrical power to produce 9 kW of mechanical power, its efficiency is 90%. The remaining 1 kW is lost as heat due to various factors like friction and electrical resistance within the motor’s components, which are built from motor core laminations.

Why High Efficiency is So Crucial

A few percentage points might not sound like much, but over the lifetime of a motor, the difference is enormous. Here’s why it’s a big deal:

- Massive Energy Cost Savings: The initial purchase price of an industrial motor often represents only 2-5% of its total cost of ownership (TCO). The other 95%+ is electricity. A 5% efficiency improvement on a continuously running 100 HP motor can save thousands of dollars per year in energy costs alone.

- Reduced Carbon Footprint: Less wasted energy means lower electricity consumption, which directly translates to a smaller environmental impact and helps your organization meet sustainability goals.

- Improved Reliability and Lifespan: Inefficiency generates heat. Excessive heat is the mortal enemy of a motor’s insulation and bearings. A more efficient motor runs cooler, which leads to a longer service life, less downtime, and reduced maintenance costs.

- Compliance with Regulations: Governments worldwide are implementing stricter Minimum Energy Performance Standards (MEPS). Choosing high-efficiency motors like those rated NEMA Premium or IE3 and above ensures you’re not just saving money but also staying compliant with current and future regulations.

Key Factors Influencing Motor Efficiency

You can’t just pick a motor type and assume you’ll get its nameplate efficiency. Real-world performance is a dynamic dance between several critical factors.

Comparing Motor Types by Efficiency: Which Motor is More Efficient?

Now for the main event. Here’s a head-to-head comparison of common motor types, from the highest efficiency contenders to the legacy workhorses.

A. Permanent Magnet Synchronous Motors (PMSM) / Brushless DC (BLDC) Motors

- Efficiency: Typically the champions of efficiency, reaching 90-98%.

- Why They’re So Efficient: The magic is in the rotor. Instead of inducing a current in the rotor windings (which creates heat and losses), PMSMs and BLDCs use powerful rare-earth or ferrite magnets. With no current flowing in the rotor, you eliminate a major source of energy loss. This results in fantastic power density (more power in a smaller package) and sustained high efficiency across a wide range of speeds and loads. They do, however, require an electronic controller (like a VFD) to operate. The design of the bldc stator core is critical for maximizing this efficiency.

- Best Applications: Electric vehicles (EVs), robotics, HVAC systems, servo applications, and any high-performance industrial drive where maximum efficiency and precision are paramount.

B. Synchronous Reluctance Motors (SynRM)

- Efficiency: Extremely high, often hitting 92-97% when paired with a VFD.

- Why They’re So Efficient: SynRMs are clever. Their rotor has no magnets and no windings—it’s essentially a specially shaped piece of steel. It works by aligning itself with the rotating magnetic field from the stator, a principle called reluctance. Because the rotor has no current and no magnets, its losses are incredibly low, rivaling and sometimes even exceeding IE4 and IE5 standards. They absolutely require a VFD to run. The unique design of the rotor core lamination is what allows this technology to function.

- Best Applications: Perfect for variable-torque applications like pumps, fans, compressors, and extruders, where they are almost always controlled by a VFD.

C. AC Induction Motors (ACIM)

The AC induction motor is the workhorse of industry—robust, reliable, and cost-effective. However, its efficiency varies dramatically depending on its design class. The core components, including the stator core lamination, determine its performance.

- IE1 (Standard Efficiency): 75-88%. These are legacy motors. While their initial cost is low, their high operating cost makes them a poor long-term investment. They are phased out in many parts of the world.

- IE2 (High Efficiency): 80-91%. An improvement over IE1, but now considered the baseline in many regions.

- IE3 (Premium Efficiency): 85-94%. This is the current mandatory standard in the U.S. (NEMA Premium), Europe, and many other regions for new motors. They use thicker copper windings, better quality steel laminations, and tighter manufacturing tolerances to significantly reduce losses compared to IE1/IE2.

- IE4 (Super Premium Efficiency): 89-96%. These motors offer the next step up, providing an additional 1-3% efficiency boost over IE3. The cumulative savings can be substantial in high-power or continuous-duty applications.

- IE5 (Ultra Premium Efficiency): 93-97%. This is the cutting edge, often incorporating SynRM or PMSM design principles into an induction motor frame to achieve the highest possible efficiency.

D. Brushed DC Motors

- Efficiency: Generally lower, ranging from 60-85%.

- Why They’re Less Efficient: The “brush.” These motors use carbon brushes and a mechanical commutator to deliver current to the rotor. This system creates friction, electrical sparks, and heat, all of which are sources of energy loss.

- Best Applications: Due to their simple control and high starting torque, they are still used in small appliances, toys, and older automotive applications, but they are rarely the choice for high-efficiency industrial systems.

Motor Efficiency Standards and Classifications

Navigating motor specifications can feel like alphabet soup. Luckily, global standards help create a level playing field for comparison.

A. IEC Efficiency Classes (International)

The International Electrotechnical Commission (IEC) defines the most widely adopted efficiency standards globally. The “IE” code makes it easy to see where a motor stands:

- IE1: Standard Efficiency

- IE2: High Efficiency

- IE3: Premium Efficiency (The current mandatory minimum in many major markets)

- IE4: Super Premium Efficiency

- IE5: Ultra-Premium Efficiency (Represents the most advanced, highest-efficiency technology available)

The trend is clear: regulations are continuously pushing manufacturers and users toward higher IE classes to drive down global energy consumption.

B. NEMA Premium Efficiency (North America)

In North America, the National Electrical Manufacturers Association (NEMA) sets the standards. The NEMA Premium® efficiency program is roughly harmonized with the IEC’s IE3 class. The U.S. Department of Energy (DOE) has made this the mandatory minimum efficiency level for most new motors sold in the country.

Choosing the Right High-Efficiency Motor for Your Application

Knowing which motor is technically the most efficient is only half the battle. The best choice is the one that’s most efficient for your specific job.

A. Analyze Your Application’s Needs

- Continuous vs. Intermittent Duty: For a motor that runs 24/7, even a small efficiency gain translates into huge savings. For a motor that runs for a few minutes per day, the higher initial cost of an IE4 or PMSM motor may not be justified.

- Constant vs. Variable Speed: If your load is constant, a high-efficiency ACIM might be perfect. If your load varies (like a fan that needs to adjust airflow), a PMSM or SynRM paired with a VFD is almost always the more efficient system.

- Power Requirements: Match the motor’s horsepower (HP) or kilowatt (kW) rating to the job.

B. Think in Terms of Total Cost of Ownership (TCO)

Don’t get fixated on the initial purchase price. The real cost of a motor is the sum of its purchase price and the electricity it consumes over its entire life.

Consider this: upgrading from an old IE1 motor to a new IE3 NEMA Premium motor might have a payback period of less than two years purely from energy savings. After that, the savings go straight to your bottom line. A quick energy savings calculation can often make a compelling business case for investing in a more efficient motor.

C. Ensure Proper Motor Sizing

This cannot be overstated. An oversized motor is an inefficient motor. Engineers sometimes specify a larger motor “just to be safe,” but this backfires on efficiency. A motor running at less than 50% of its rated load can be dramatically less efficient than at its 75-95% sweet spot. Always conduct a proper load analysis to ensure the motor is right-sized for the task.

Maximizing Motor System Efficiency: Beyond the Motor Itself

The motor is the heart of the system, but it doesn’t work in a vacuum. To achieve maximum energy savings, you have to look at the entire powertrain and its operation.

Conclusion: The Future of Efficient Motor Technology

So, which motor is more efficient?

If we’re talking pure technical capability, Permanent Magnet (PMSM/BLDC) and Synchronous Reluctance (SynRM) motors are the clear winners, regularly achieving efficiency levels that meet or exceed the highest IE5 standards. For general-purpose industrial applications, the modern AC Induction Motor at the IE3 (NEMA Premium) and IE4 levels represents a fantastic blend of efficiency, reliability, and value.

The most important takeaway, however, is that making an efficient choice goes beyond just picking a motor off a shelf. It’s about a holistic approach:

- Understanding the different technologies and their strengths.

- Selecting the right motor type and efficiency class for your specific application.

- Sizing the motor correctly to match the load profile.

- Optimizing the entire system with modern controls like VFDs and proactive maintenance.

The push for greater efficiency isn’t slowing down. As technology advances and energy regulations tighten, the shift towards smarter, more powerful, and incredibly efficient motor systems will only accelerate. By making informed decisions today, you’re not only cutting operational costs but also building a more sustainable and competitive future.