The Unseen Powerhouse: Why AC Motors Are Indispensable to Modern Life and Industry

Table of Contents

- Introduction: The Silent Drivers I Keep Running Into

- What an AC Motor Is in Plain English

- How AC Motors Work: From Electromagnetic Induction to Torque

- Why AC Motors Win: Efficiency, Reliability, Versatility, Cost

- Types of AC Motors and Where They Shine

- Speed and Torque Control With VFDs

- Where AC Motors Power Our World

- Industrial and Manufacturing

- Commercial and Residential

- Transportation and Mobility

- Energy and Infrastructure

- Advanced and Specialized Technologies

- Energy Efficiency, Standards, and Regulations

- Materials, Design, and Durability Essentials

- Maintenance, Failures, and Predictive Analytics

- Economics and Societal Impact

- Environmental Impact and the Path to Sustainability

- Future Trends and Innovations

- What I Tell Clients Who Ask “Why AC Motors Matter”

- Conclusion

Introduction: The Silent Drivers I Keep Running Into

I have walked through factories that never sleep. I have toured data centers that hum like giant refrigerators stacked to the rafters. I have stood beneath wind turbines and felt the ground tremble when a pump station kicked on. Every time I do, the same realization hits me. Alternating current motors sit at the heart of it all.

As a market researcher, I study how and why technologies take root. AC motors keep showing up as the quiet champions. They convert electricity into motion with brutal efficiency. They tolerate harsh environments. They scale from a tiny fan to a megawatt compressor without breaking a sweat. They pair with modern controls like Variable Frequency Drives to deliver precise speed control and serious energy savings. That combination explains their dominance in industrial automation, HVAC, water treatment, electric vehicles, and beyond.

This is my practical guide to why AC motors are so important. I will share what I learned in the field and in the data. I will keep it simple and direct. You will walk away with a deep understanding of AC motor advantages, the role they play across sectors, the standards that shape them, and the trends that will keep them central to our world.

What an AC Motor Is in Plain English

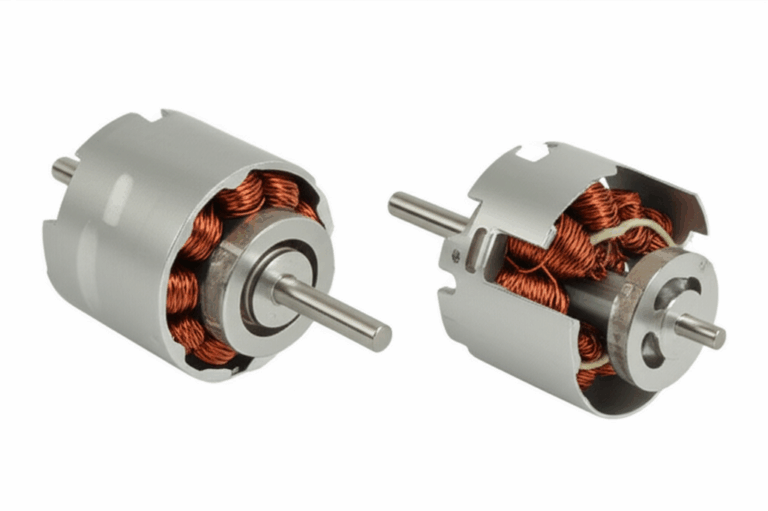

An AC motor turns electrical power into mechanical rotation using alternating current. That sounds abstract. Here is the simple version. The stator creates a rotating magnetic field. The rotor is pulled along by that field. The rotor turns the shaft. The shaft drives your pump, fan, conveyor, elevator, or car.

Two big families dominate:

- Induction motors. Workhorse machines. The stator’s rotating field induces current in the rotor which creates torque.

- Synchronous motors. The rotor locks to the rotating field at synchronous speed. Often uses permanent magnets or field windings. Great for high efficiency and power factor control.

You will also hear about three-phase and single-phase. Three-phase power feeds the industrial backbone because it delivers smooth torque and high efficiency. Single-phase motors serve homes and small commercial loads.

Nikola Tesla’s polyphase AC system set the stage for all of this. Westinghouse Electric backed the technology. General Electric, Siemens, and ABB took it to scale. Modern grids and factories stand on those shoulders.

How AC Motors Work: From Electromagnetic Induction to Torque

If you want the heart of the physics, you need only two ideas.

- Electromagnetic induction. Alternating current in the stator windings creates a rotating magnetic field. That field induces current in the rotor conductors which generate their own magnetic field. The two fields interact and the rotor turns. This is the core motor principle.

- Synchronous speed and slip. The stator field rotates at a speed set by line frequency and pole count. Induction motors run slightly below this speed. The difference is slip. That slip is where torque comes from.

Core parts matter.

- Stator. The stationary part. Laminated steel core with copper windings. The quality of the stator core lamination affects losses and heat.

- Rotor. The rotating part. Often a squirrel-cage conductor design buried in a laminated core. Precision in the rotor core lamination influences efficiency and torque.

- Windings and insulation. Decide current density, temperature class, and longevity.

- Bearings and cooling systems. Decide reliability under real loads.

Get those elements right and you get a motor that runs cool, efficient, and quiet. Cut corners and you pay with losses, heat, noise, and premature failure.

Why AC Motors Win: Efficiency, Reliability, Versatility, Cost

I have compared AC and DC solutions in dozens of projects. AC motors win most battles for five reasons.

- Efficiency and energy savings. Modern AC motors offer high efficiency across a broad range of sizes. Variable speed control trims waste. Less energy in means lower bills and fewer carbon emissions.

- Reliability and durability. Induction motors have no brushes or commutators. Fewer wear parts mean longer life. Synchronous designs offer stable operation and excellent power factor control. Both handle tough environments with proper enclosures.

- Versatility. You can find a motor for any job. Fractional horsepower for appliances. Multi-megawatt giants for compressors and pumps. Three-phase for industry. Single-phase for homes. Constant speed or variable speed. High or low torque. Indoor or outdoor. Explosive or corrosive atmospheres.

- Cost-effectiveness. Mass production and standardization drive costs down. Installation stays straightforward. Maintenance stays predictable. Total cost of ownership looks great over years of service.

- Scalability and power density. AC motors deliver serious power in compact footprints. That matters in data centers, EVs, and ships where space costs money.

That set of advantages explains why AC motor applications keep expanding. Once you see it, you cannot unsee it.

Types of AC Motors and Where They Shine

Here is how I bucket the landscape when I guide clients.

- Induction motors. The default in industrial machinery, pumps, fans, compressors, conveyors, cranes, and elevators. Rugged and economical. Easy to pair with VFDs for speed control.

- Synchronous motors. Great for high-efficiency operation and precise speed. Useful in large compressors, mills, and power factor correction roles. Permanent magnet synchronous motors appear in EVs and high-performance drives.

- Single-phase AC motors. Used in home appliances like refrigerators, washing machines, and air conditioners. Also small power tools and fans. Universal motors exist for portable tools. They can run on AC or DC and deliver high speed but need more maintenance.

- Three-phase AC motors. The industrial standard. Smooth torque and excellent efficiency. Critical for heavy duty equipment and manufacturing lines.

I often explain brushless DC (BLDC) motors as cousins. Many BLDC drives look like AC inverters that create a three-phase waveform for a permanent magnet rotor. In practice these motors behave like synchronous AC machines with electronic commutation. You see them in robotics, drones, appliances, and EV auxiliaries.

Speed and Torque Control With VFDs

Variable Frequency Drives changed the game. With a VFD you adjust frequency and voltage to control speed and torque. That allows:

- Precise process control in pumps, fans, extruders, mixers, and conveyors.

- Soft starts and stops that save mechanical components and reduce inrush current.

- Energy savings because you run only as fast as you need.

- Regenerative braking in some applications where energy feeds back to the DC bus or grid.

When I audit a facility, I always look at fans and pumps first. Variable speed saves the most there. Cutting fan speed a little slashes power due to cube-law physics. That is money in the bank with no loss in output when you have a margin.

Where AC Motors Power Our World

You feel their impact everywhere. Let me break it down.

Industrial and Manufacturing

- Automation and robotics. AC motors drive pick-and-place robots and servo axes in smart manufacturing cells.

- Material handling. Conveyor systems, cranes, hoists, and forklifts move goods nonstop.

- Pumps and compressors. Oil and gas, chemical plants, and water treatment facilities depend on them.

- Fans and blowers. Ventilation, dust collection, and process air. The HVAC backbone of plants.

- Mills, extruders, and mixers. Food processing, plastics, and pharmaceuticals rely on precise torque.

I remember walking a textile mill. You could not count the AC motors if you tried. Every frame, roller, and blower relied on consistent torque and controlled speed. Downtime would freeze the whole operation.

Commercial and Residential

- HVAC systems. Chillers, rooftop units, and building air handlers use AC motors to deliver comfort and air quality.

- Elevators and escalators. High starting torque with smooth control for passenger safety.

- Home appliances. Refrigerators, washing machines, fans, vacuum cleaners, and blenders run our daily lives.

- Power tools. Many rely on AC supply or inverter-based drives for portable convenience.

Transportation and Mobility

- Electric vehicles. Traction motors are often permanent magnet synchronous or induction designs. They deliver high torque at low speed and high efficiency on highways.

- Trains and trams. AC traction gives reliable power with regenerative braking for energy recovery.

- Marine propulsion. Electric and hybrid ships use AC drives for propulsion and thrusters.

I rode in an EV prototype once and the engineer grinned as he floored it. That instant torque comes from a well tuned AC drive. It never gets old.

Energy and Infrastructure

- Wind turbines and hydropower. Generators use AC machine principles to feed the grid.

- Power plant auxiliaries. Motors run feedwater pumps, cooling towers, and conveyors in thermal plants.

- Water and wastewater treatment. Pumps and agitators keep essential services running.

Advanced and Specialized Technologies

- Data centers. Motors run cooling systems and air handlers that protect servers.

- Medical equipment. Imaging systems, surgical tools, and lab analyzers use precise motor control.

- Aerospace and marine. AC machines handle actuators, environmental systems, and propulsion support.

- Mining. Heavy duty crushers and conveyors need rugged motors built for dust and shock.

- Food processing and packaging. Washdown-rated motors keep hygiene tight while lines run fast.

You see the same pattern over and over. AC motors provide the backbone for uptime and productivity.

Energy Efficiency, Standards, and Regulations

Efficiency matters because motors consume a large share of industrial electricity. Policy recognizes that reality. You will see three frameworks in most markets.

- IEC efficiency classes. IE1 to IE5 define performance tiers. IE3 and IE4 show up in most new industrial installations.

- NEMA classifications. NEMA Premium defines high-efficiency standards in North America.

- Government regulations. Departments of Energy set minimum efficiency performance standards for a wide range of motors. Utilities and research organizations like EPRI support programs that promote energy conservation.

Standards do not exist to make procurement harder. They exist to save energy at scale. You can meet those targets without pain using modern designs and materials. Pair that with VFDs and you push your system into the top tier of performance.

Materials, Design, and Durability Essentials

Great motors start with great materials and manufacturing. I have toured plants where you can smell the varnish on freshly impregnated windings. A few choices drive the final result.

- Electrical steel lamination quality. Thin laminations with low losses reduce heat. If you want a primer on why that matters, study electrical steel laminations.

- Stator and rotor laminations. Precision stamping and stacking reduce eddy currents and core losses. The build quality behind the stator core lamination and the rotor core lamination directly affects efficiency and torque ripple.

- Copper fill and winding design. Better fill factors and smart slot geometry lower resistance and heat.

- Insulation systems. Higher temperature classes extend life and allow more power density.

- Cooling methods. TEFC (totally enclosed fan cooled), open drip proof, water cooled, and air over designs serve different environments.

- Enclosure types and IP ratings. You match enclosures to dust, moisture, chemicals, or explosive atmospheres.

Motor design balances cost, efficiency, and durability. You can ask for a higher efficiency motor with premium laminations and better bearings. You will pay more upfront. You often make that back in energy savings and maintenance avoidance within a practical payback window.

Maintenance, Failures, and Predictive Analytics

I have asked maintenance teams what actually fails. The same culprits pop up.

- Bearings. Contamination, misalignment, and VFD-induced shaft currents can cause premature wear.

- Winding insulation. Thermal stress, overloads, and voltage spikes degrade insulation.

- Electrical issues. Voltage imbalance, harmonics, and poor power factor stress the motor.

- Mechanical issues. Misalignment, soft foot, and resonance cause vibration and damage.

You can fight back with best practices.

- Condition monitoring. Vibration analysis, thermography, and motor current signature analysis catch problems early.

- Predictive maintenance. IoT sensors stream data into analytics platforms that flag anomalies. You can schedule service before failure and avoid unplanned downtime.

- Power quality management. Proper grounding, filters for harmonics, and good cable practices matter with VFDs.

- Correct sizing. Oversized motors run inefficiently. Undersized motors run hot. Both die early.

I watched a plant cut unplanned downtime after moving to predictive maintenance on critical motors. Production stabilized. Overtime dropped. The case for smart monitoring pays for itself when lines run 24/7.

Economics and Societal Impact

The economic story speaks for itself.

- Reduced operating costs. Efficient motors and VFDs cut energy bills and demand charges.

- Lower total cost of ownership. Fewer failures. Less maintenance. Longer life.

- Standardization and availability. The global AC motor market offers interchangeable options that simplify procurement.

- Job creation. The AC motor industry supports manufacturing, service, system integration, and R&D across regions.

AC motors support entire supply chains. From electrical steel to copper windings to power electronics and control software. That stack creates high value jobs and steady demand for skilled labor and education in AC motor technology.

Environmental Impact and the Path to Sustainability

If you want to cut carbon emissions, you go after the big loads. Motors are big loads. Efficiency upgrades reduce energy consumption without slowing production. That hits the bottom line and climate goals at the same time.

- Energy conservation. High efficiency motors and optimized control reduce waste.

- Regenerative braking. Drives can push energy back into the system during decel in many applications.

- Renewable integration. Synchronous machines support grid stability and power factor correction. Electric drives help wind, hydro, and microgrids operate smoothly.

- Sustainable Development Goals. Cleaner industry and resilient infrastructure rely on efficient motors and smart control.

I have sat in meetings where sustainability leaders and maintenance heads finally saw eye to eye. AC motor upgrades gave both what they needed. Less energy use. Better uptime. No trade-off required.

Future Trends and Innovations

The future looks bright and busy.

- Higher efficiency classes. IE4 and IE5 machines become mainstream as materials and designs improve.

- Advanced power electronics. Wide bandgap semiconductors shrink drives and boost efficiency.

- Smart motors and IoT. Embedded sensors feed predictive systems for hands-off reliability.

- New materials. Better electrical steels, improved laminations, and advanced winding techniques push losses down and power density up.

- EV traction evolution. Permanent magnet synchronous and induction machines keep leapfrogging each other on cost, rare earth materials use, and performance.

- Microgrids and distributed generation. AC machines integrate with energy storage, solar, and wind to deliver grid resilience.

Research and development in motor control algorithms, materials science, and manufacturing methods will keep adding performance. I expect tighter integration with building management systems and industrial PLCs that optimize entire facilities in real time.

What I Tell Clients Who Ask “Why AC Motors Matter”

I like to summarize with five concrete points.

1) AC motors convert electricity to motion with high efficiency that you can improve further with VFDs.

2) They deliver reliability because they have simple, robust designs with fewer wear parts.

3) You can find a motor for every job from fractional horsepower to multi megawatt.

4) Standardization and mature supply chains keep costs reasonable and serviceable.

5) They underpin critical systems in manufacturing, HVAC, transport, water, energy, and healthcare which makes them essential to modern life.

If you need one actionable step, audit your largest fans and pumps. Look for oversized motors and fixed-speed drives. Then run the numbers on a high-efficiency motor and VFD retrofit. You will often find a compelling payback with lower noise and better control as a bonus.

Conclusion

AC motors are the unseen powerhouse of modern civilization. They sit behind the conveyor that feeds a packaging line. They cool the servers that stream your videos. They move the elevator you ride and the water you drink. They push ships through harbors and trains through tunnels. They deliver torque with efficiency and reliability that compounds across billions of operating hours.

I have watched AC motors quietly change facilities and balance sheets. I have seen upgrades that cut energy use without sacrificing throughput. I have seen maintenance teams sleep better because the drives tell them what needs attention before it fails. That is real progress.

The bottom line is simple. AC motors remain indispensable because they blend physics, practicality, and economics better than any alternative at scale. They make modern life possible. They will keep doing so as we push for smarter factories, cleaner grids, and more resilient infrastructure. When the world needs motion, AC motors answer the call.