Unlocking Efficiency: A Deep Dive into Grain-Oriented Electrical Steel (GOES)

Of course, here is a detailed, long-form article based on the provided instructions and data.

When I first started in the electrical engineering field, I remember hearing terms like “grain-oriented electrical steel” or “GOES” thrown around. It sounded complex, and honestly, a bit intimidating. But as I’ve spent years working with transformers and power distribution systems, I’ve come to appreciate just how crucial this material is. It’s the unsung hero of our power grids, quietly working to make everything more efficient. Let me share what I’ve learned about it, why it matters, and how it’s different from other materials.

Table of Contents

- What Exactly is Grain-Oriented Electrical Steel?

- The Secret in the Structure: The Manufacturing Process

- From Raw Steel to a Specialized Alloy

- Rolling and Annealing: Forging the Path for Grains

- The Magic Step: Secondary Recrystallization

- The Finishing Touches: Insulation and Domain Refinement

- Why Does Grain Orientation Matter So Much?

- Anisotropy: The One-Way Street for Magnetism

- Lowering Core Losses: Reducing Wasted Energy

- High Permeability: The Superhighway for Magnetic Fields

- High Saturation Induction: Handling More Power

- Where Do We Use Grain-Oriented Electrical Steel?

- The Tangible Benefits of GOES in Our Power Grid

- GOES vs. Non-Oriented Steel: What’s the Difference?

- The Future of Power Relies on Materials Like GOES

What Exactly is Grain-Oriented Electrical Steel?

At its core, Grain-Oriented Electrical Steel (GOES) is a special type of silicon steel. It’s an iron alloy, usually containing about 3% silicon. This silicon content is important because it increases the electrical resistivity of the steel, which helps reduce energy losses caused by what we call “eddy currents.”

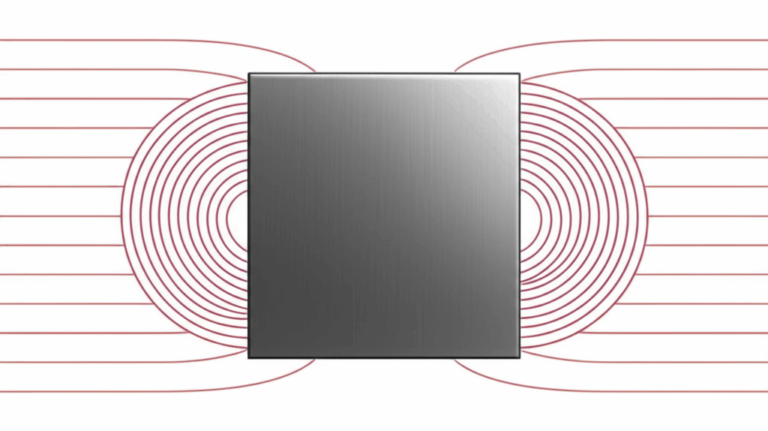

But the real magic of GOES isn’t just the silicon—it’s the grain. Imagine a piece of wood. It has a grain, and it’s much easier to split it along the grain than against it. Similarly, GOES is manufactured in a way that aligns the magnetic “grains” or crystals of the steel in a very specific direction. This process, called grain orientation, makes the steel exceptionally good at conducting magnetic flux along that direction.

This property is called magnetic anisotropy. Think of it like a highway system for magnetism. In GOES, you have a multi-lane superhighway where magnetic fields can travel with very little resistance in one direction. In other directions, it’s more like a bumpy country road. This is precisely what engineers want for certain applications, especially in power transformers.

The Secret in the Structure: The Manufacturing Process

The unique properties of GOES don’t happen by accident. It’s the result of a very precise and controlled manufacturing process. I remember being fascinated when I first learned about the steps involved because it’s a great example of how material science can create something with highly specialized characteristics.

From Raw Steel to a Specialized Alloy

It all starts with high-purity iron, which is then alloyed with a specific amount of silicon, typically around 3%. This mixture is melted down and cast into large slabs. This initial stage is crucial for ensuring the chemical composition is just right, as even small impurities can affect the final magnetic properties.

Rolling and Annealing: Forging the Path for Grains

Once you have the slab, the real transformation begins. The steel is first heated and then passed through massive rollers in a process called hot rolling. This reduces its thickness significantly and starts to align the crystal structure.

After hot rolling, the steel undergoes cold rolling. This is a critical step where the steel is rolled at room temperature, which further reduces its thickness and, most importantly, aligns the crystal grains in what is known as the “Goss texture.” This precise alignment is what gives GOES its unique directional magnetic properties. The cold rolling process builds up a lot of internal stress in the steel, which needs to be relieved in the next steps.

The Magic Step: Secondary Recrystallization

This is where the magic truly happens. After cold rolling, the steel is annealed (heated) again in a carefully controlled atmosphere. During this process, a phenomenon called secondary recrystallization occurs. A few select grains with the desired Goss orientation begin to grow rapidly, consuming the smaller, less ideally oriented grains around them.

To control this process, manufacturers add tiny particles called inhibitors, such as manganese sulfide (MnS) or aluminum nitride (AlN). These inhibitors act like pins, holding the boundaries of the smaller grains in place and preventing them from growing randomly. This allows the properly oriented Goss grains to dominate the structure. By the end of this step, almost all the grains in the steel are aligned in a single direction.

The Finishing Touches: Insulation and Domain Refinement

Finally, the steel sheets are coated with an insulating layer, often a type of glass film. When these sheets are stacked together to form a transformer core, this insulation prevents electrical currents (eddy currents) from flowing between the laminations, which would otherwise cause significant energy loss. This is a critical component of any electrical steel lamination.

For even higher performance, some grades of GOES undergo an additional process called domain refinement. This involves techniques like laser scribing or mechanical scratching to create stress lines on the surface. These lines refine the size of the magnetic domains within the steel, further reducing hysteresis loss—a type of energy loss that occurs when the magnetic field is reversed.

Why Does Grain Orientation Matter So Much?

So, why go through all that trouble to align the grains? Because the resulting properties make GOES incredibly efficient at its job.

Anisotropy: The One-Way Street for Magnetism

As I mentioned earlier, GOES is anisotropic, meaning its properties are direction-dependent. In the rolling direction (the direction the grains are aligned), the steel has very high magnetic permeability and very low magnetic reluctance. This means it can conduct magnetic flux with minimal energy loss, acting like a superhighway for magnetic fields. In other directions, its magnetic properties are significantly worse. This is perfect for applications like transformers, where the magnetic flux is designed to flow in a specific, predictable path.

Lowering Core Losses: Reducing Wasted Energy

One of the most important metrics for a transformer is its efficiency, which is largely determined by its core loss. Core loss is the energy that’s wasted and converted into heat within the transformer’s core as the magnetic field alternates. It’s made up of two main components:

Modern grades of GOES can have core losses as low as 0.8 watts per kilogram (W/kg) at a magnetic flux density of 1.7 Tesla and a frequency of 60 Hz. In contrast, non-oriented electrical steels might have losses three to four times higher under the same conditions.

High Permeability: The Superhighway for Magnetic Fields

Permeability is a measure of how easily a material can be magnetized. Think of it as the magnetic equivalent of electrical conductivity. Because the grains in GOES are aligned, it has exceptionally high permeability in the rolling direction. This means that a smaller magnetic field is needed to generate a large amount of magnetic flux. In practical terms, this allows engineers to build smaller, lighter, and more efficient transformers for the same power rating.

High Saturation Induction: Handling More Power

Saturation induction is the maximum magnetic field that a material can carry. GOES has a very high saturation point (around 2.03 Tesla). This high capacity allows transformers to be designed to operate at higher flux densities without becoming saturated and losing efficiency. The result is a more compact and cost-effective design.

Primary Applications of Grain-Oriented Electrical Steel

Given its unique properties, GOES is the material of choice for applications where high magnetic efficiency is paramount and the direction of the magnetic flux is predictable and controlled.

- Power Transformers: These are the large transformers you see in electrical substations. They step voltage up for long-distance transmission and then step it down for local distribution. Because they are energized 24/7, even a small improvement in efficiency leads to massive energy savings over their lifespan. GOES is the undisputed king here.

- Distribution Transformers: These are the smaller transformers you might see on utility poles or in green boxes in your neighborhood. They take the medium voltage from local lines and step it down to the level used in homes and businesses. Efficiency is just as critical here.

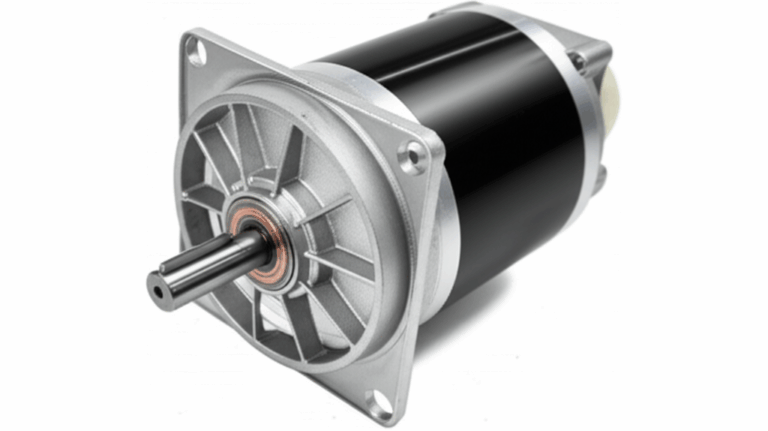

- Large Inductors and Chokes: In some high-power electronics and industrial applications, large inductors or chokes are needed. GOES is often used for their cores to minimize energy loss.

The Tangible Benefits of Utilizing GOES in Electrical Infrastructure

The impact of using GOES extends beyond just technical specifications. It has real-world benefits:

- Massive Energy Savings: The primary benefit is reduced energy loss. Globally, it’s estimated that core losses in transformers account for a significant percentage of all electricity generated. Using high-grade GOES can reduce these losses by up to 70-80% compared to standard steel, saving terawatt-hours of electricity every year.

- Reduced Environmental Impact: Less wasted energy means less fuel needs to be burned in power plants. This directly translates to lower emissions of greenhouse gases like carbon dioxide (CO2). A single high-efficiency transformer made with modern GOES can save hundreds of tons of CO2 over its operational life.

- Lower Operating Costs: For utility companies and large industrial users, the energy saved translates directly into lower electricity bills. The initial higher cost of a GOES transformer is quickly offset by these savings.

- Improved Grid Stability and Reliability: More efficient transformers generate less waste heat. This means they run cooler, which extends their lifespan and reduces the risk of failure, contributing to a more reliable power grid.

- More Compact and Lighter Equipment: The high magnetic performance of GOES allows for smaller core designs, which can be a significant advantage in applications where space and weight are concerns, such as in urban substations or wind turbines.

GOES vs. Non-Oriented (NGO) Electrical Steel: A Brief Comparison

It’s helpful to compare GOES with its counterpart, Non-Oriented (NGO) Electrical Steel. As the name suggests, the grains in NGO steel are randomly oriented. This means it has good magnetic properties in all directions (it’s isotropic), but not exceptional in any single direction.

| Feature | Grain-Oriented Electrical Steel (GOES) | Non-Oriented (NGO) Electrical Steel |

|---|---|---|

| Grain Structure | Aligned in one direction (Anisotropic) | Randomly oriented (Isotropic) |

| Primary Application | Transformers, Large Inductors | Electric Motors, Generators, Rotating Machinery |

| Core Loss | Very Low (e.g., 0.8 W/kg) | Higher (e.g., 2.5 W/kg) |

| Permeability | Very High (in the grain direction) | Moderate |

| Cost | Higher | Lower |

Because motors and generators have magnetic fields that are constantly rotating, they require a material that performs well in all directions. That’s where NGO steel shines. For a transformer, however, where the magnetic field follows a fixed path through the core, the directional superiority of GOES is exactly what’s needed. This specialized application is where you see components like a high-quality stator core lamination making a huge difference in motor efficiency.

Conclusion: Powering the Future with Intelligent Materials

Grain-Oriented Electrical Steel might seem like a niche topic, but it’s a cornerstone of our modern electrical infrastructure. It’s a perfect example of how materials science can lead to profound improvements in efficiency and sustainability. By carefully controlling the crystalline structure of a simple iron-silicon alloy, engineers have created a material that saves enormous amounts of energy every single day. As the world moves towards a more electrified and sustainable future, the role of advanced materials like GOES will only become more critical. It’s a silent hero, quietly working behind the scenes to power our world more efficiently.