Unlocking Power: The Core Principle of Three-Phase Motor Operation

Of course. Here is the article written according to your instructions.

Table of Contents

- What is the Principle Operation of a Three-Phase Motor?

- Introduction: The Unsung Workhorse of Industry

- The Foundation: Three-Phase Power Explained (Briefly)

- Core Concept: The Rotating Magnetic Field

- Key Components and Their Roles

- Step-by-Step: How a Three-Phase Motor Operates

- Why Three-Phase Motors are Preferred: Advantages

- Common Applications of Three-Phase Motors

- Conclusion: The Enduring Legacy of AC Power

What is the Principle Operation of a Three-Phase Motor?

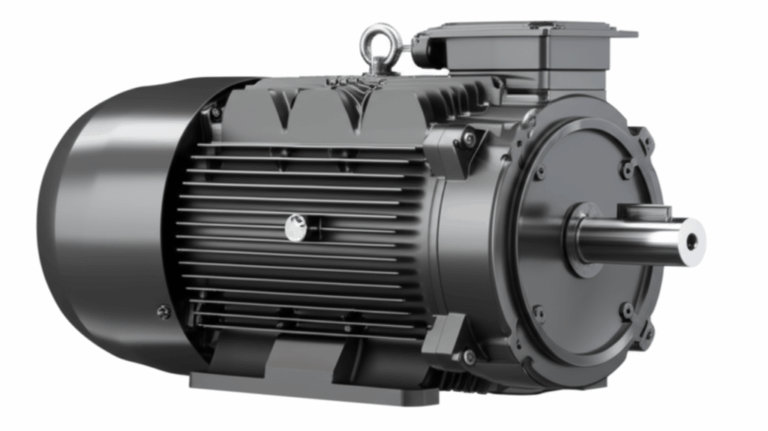

If you’ve ever stepped onto a factory floor, you’ve heard them. That steady, powerful hum is the sound of industry at work, and more often than not, it’s the sound of a three-phase induction motor. For years, I’ve worked with these machines, from tiny fractional horsepower units to giants that could power a small town. And what I’ve learned is that beneath their rugged iron exterior lies a principle of operation that is both elegant and brilliantly simple.

So, what is the principle operation of a three-phase motor?

At its heart, it’s all about a clever trick with magnets. The motor uses a three-phase AC power supply to create a rotating magnetic field in its stationary part. This rotating field then induces a current in the rotating part, creating another magnetic field. The interaction between these two magnetic fields generates the turning force, or torque, that makes the motor spin. It’s a beautiful dance of physics, all happening with no physical contact between the two main parts.

Let’s break down that magic. It’s a journey from the wall socket to the spinning shaft, and understanding it has been the foundation of my entire career.

Introduction: The Unsung Workhorse of Industry

Before we dive deep into the physics, let me tell you why this matters. The three-phase AC induction motor is arguably one of the most important inventions of the last 150 years. It’s the unsung workhorse behind nearly every major industry. Think about it: the pumps that bring you clean water, the conveyor belts that move your packages, the fans that ventilate massive buildings, and the machinery that builds your car—they all rely on these motors.

Why? Because they are incredibly reliable, efficient, and powerful. I’ve seen motors from the 1970s still running strong with just basic maintenance. Their simple construction, particularly the common “squirrel cage” design, means there are few parts to wear out.

It’s astonishing to think that these motors consume over 50% of the world’s total electricity and a staggering 70% of all electricity used by industry. That fact alone tells you how critical they are. Understanding how they work isn’t just an academic exercise; it’s the key to understanding modern industrial power, energy efficiency, and predictive maintenance.

The Foundation: Three-Phase Power Explained (Briefly)

To get how the motor works, you first need a basic grasp of the fuel it runs on: three-phase power. Don’t worry, you don’t need an electrical engineering degree for this.

Imagine you have three separate alternating current (AC) signals. In a standard single-phase outlet like you have at home, the voltage rises and falls in a single wave. It’s effective, but it delivers power in pulses.

Three-phase power is different. It consists of three AC signals, or “phases,” that are delivered on separate wires. The magic is that their waves are offset from each other. They each peak at a different time, precisely 120 degrees apart in their cycle.

Think of it like three people pedaling a single crankshaft. Instead of one person pushing down in bursts (single-phase), you have three people pushing in a smooth, continuous sequence. This results in a much smoother, more constant delivery of power. It’s this continuous, overlapping power delivery that is the secret ingredient for creating the motor’s core phenomenon.

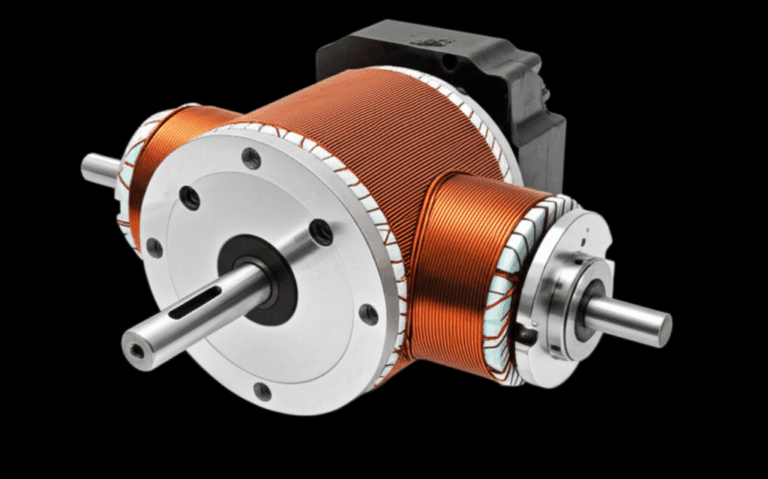

Core Concept: The Rotating Magnetic Field

This is it. The single most important concept in understanding a three-phase motor. If you get this, you’ve grasped 90% of the theory. The Rotating Magnetic Field (RMF) is what makes the whole thing go.

I remember when this concept finally clicked for me. I was an apprentice, and my mentor told me to stop thinking of it as electricity and start thinking of it as an invisible, spinning magnet inside the motor’s housing.

How a Rotating Magnetic Field is Created

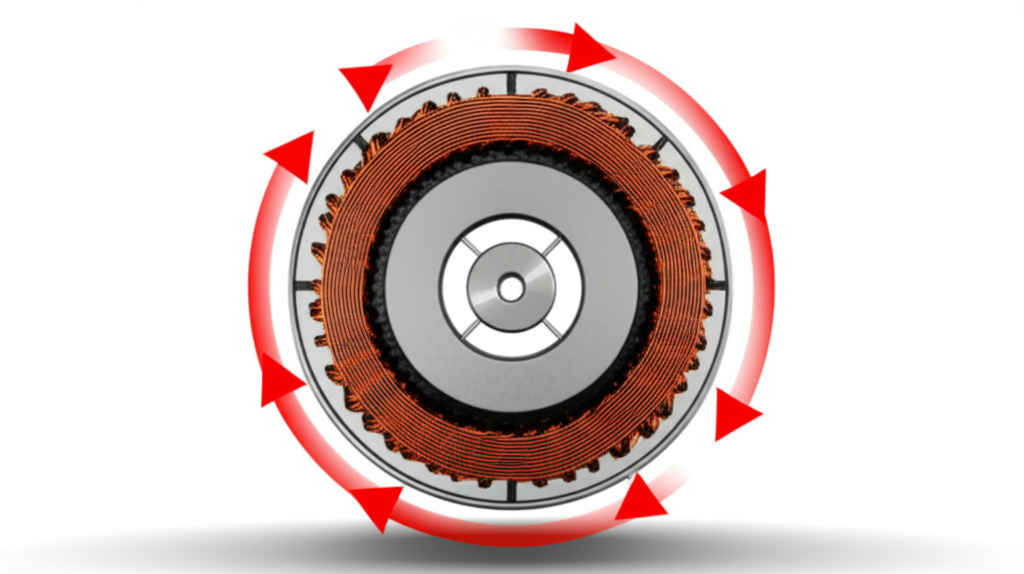

So, how do we create this invisible spinning magnet? It happens in the stator, the stationary part of the motor.

Inside the stator’s iron core are slots that hold coils of wire, known as the stator windings. These aren’t just one big coil; they are three separate sets of windings. Each set is connected to one of the three phases of our AC power supply.

Crucially, these three sets of windings are physically placed 120 degrees apart from each other around the circular stator frame. This physical arrangement perfectly mirrors the 120-degree electrical phase shift of the power supply.

Here’s what happens when you flip the switch:

Because the current in each winding is constantly rising and falling in this perfect sequence, the net magnetic field—the vector sum of all three—doesn’t just pulse on and off. Instead, it smoothly rotates around the inside of the stator at a fixed speed. This speed is called the synchronous speed, and it’s determined by the frequency of the AC power (e.g., 60 Hz in North America, 50 Hz elsewhere) and the number of magnetic poles designed into the windings.

That’s the trick! We’ve created a magnetic field that spins without a single moving part. It’s pure electro-magnetic genius, first conceived by visionaries like Nikola Tesla and Galileo Ferraris.

Key Components and Their Roles

A three-phase motor is surprisingly simple in its construction. I’ve taken apart and reassembled hundreds of them, and they generally boil down to just a few key parts. The relationship between the stator and rotor is the essence of its operation.

The Stator

As we just discussed, the stator is the stationary outer part. It’s a hollow cylinder made of a laminated iron core. Why laminated? It’s built from stacks of very thin steel plates, or what we call stator core lamination. This design is critical for reducing energy losses from swirling electrical currents called “eddy currents.” If the core were a solid block of iron, it would get incredibly hot and waste a ton of energy. Those windings carrying the three-phase AC power are carefully fitted into slots on the inner surface of the stator core.

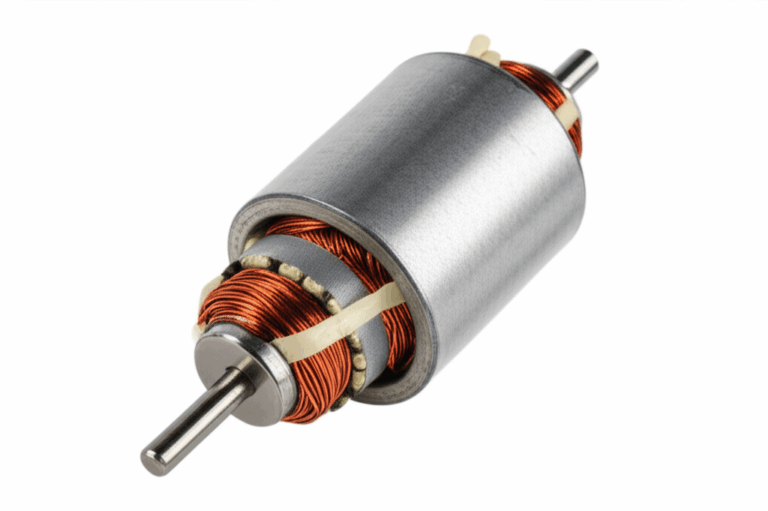

The Rotor

This is the part that rotates—the bit that does the actual work. It sits inside the stator but isn’t physically connected to it. There are two main types:

- Squirrel Cage Rotor: This is by far the most common type, found in probably 90% of induction motors. I love the name because it perfectly describes its appearance. It consists of heavy bars of copper or aluminum running along the length of the rotor, and these bars are short-circuited at both ends by conductive rings. It looks just like a hamster or squirrel cage. It’s simple, rugged, and incredibly reliable. The core itself is also laminated, much like the stator, to minimize energy losses. This kind of rotor core lamination is essential for efficiency.

- Wound Rotor: This type is less common and used for specific applications requiring very high starting torque or variable speed control (though Variable Frequency Drives, or VFDs, have largely replaced this need). Instead of shorted bars, it has actual windings like the stator, which are connected via slip rings and brushes to an external control circuit. I’ve mostly seen these on large cranes or heavy-duty crushing equipment.

The Air Gap

This might sound like nothing, but it’s one of the most critical parts of the motor’s design. The air gap is the tiny, precise clearance between the outer surface of the rotor and the inner surface of the stator. It has to be as small as possible—often less than a millimeter—because the magnetic field has to jump across this gap. A smaller gap means a stronger magnetic field and a more efficient motor. Any issues with the motor bearings can cause the rotor to rub against the stator, which is a catastrophic failure I’ve unfortunately witnessed a few times.

Step-by-Step: How a Three-Phase Motor Operates

Okay, we have our components and our rotating magnetic field (RMF). Now let’s put it all together. Here’s the sequence of events that happens in the blink of an eye when you power on the motor. It all comes down to a fundamental motor principle based on electromagnetism.

This difference in speed between the RMF (synchronous speed) and the actual rotor speed is called slip. Slip is absolutely essential for an induction motor to work. It’s this slight “slipping” behind that ensures the rotor bars are always cutting through the magnetic field, inducing current, and generating torque. The amount of slip increases as the load on the motor increases. A lightly loaded motor might have a slip of 1%, while a fully loaded motor might have a slip of 5%.

Why Three-Phase Motors are Preferred: Advantages

Working in the field, I quickly learned why engineers and technicians almost universally prefer three-phase motors for any serious industrial application. The advantages are just too compelling.

- Self-Starting: That rotating magnetic field means they are inherently self-starting. They don’t need special starter windings or capacitors like many single-phase motors do. You apply power, and they go.

- High Efficiency and Power Factor: They are far more efficient than their single-phase counterparts. Modern IE3 (Premium Efficiency) and IE4 (Super Premium Efficiency) motors can reach efficiencies of 95% or more. This is a huge deal when you remember that motors account for most of the industrial electricity bill. The financial payback for upgrading an old, inefficient motor is often just a couple of years.

- Robust Construction and Low Maintenance: The squirrel cage design, in particular, is a marvel of simplicity. There are no brushes or commutators to wear out. The only real maintenance items are the bearings, which can last for decades with proper lubrication. This reliability is the backbone of continuous manufacturing operations.

- Constant Speed Operation: They maintain a very steady speed even as the mechanical load changes, which is vital for applications like conveyor systems or machine tools.

- High Starting Torque: They produce powerful torque from a standstill, allowing them to get heavy loads moving without struggling.

Common Applications of Three-Phase Motors

Once you understand how they work, you start seeing them everywhere. My career has taken me from water treatment plants to automated warehouses, and these motors are the common thread.

- Pumps and Compressors: From small water pumps to massive air compressors for factory tools, three-phase motors provide the constant, reliable power needed.

- Conveyor Systems: The smooth, steady speed is perfect for moving goods along an assembly line or in a distribution center.

- HVAC Systems: Large commercial air conditioners, heaters, and ventilation fans rely on these motors to move huge volumes of air efficiently.

- Manufacturing Machinery: The power behind lathes, mills, grinders, and presses in a machine shop almost always comes from a three-phase motor.

- Industrial Fans and Blowers: Whether for cooling towers, exhaust systems, or material handling, these motors are the go-to choice.

Conclusion: The Enduring Legacy of AC Power

The principle behind the three-phase motor is a testament to the power of a great idea. It’s a dance of physics—a rotating magnetic field created by phased alternating currents inducing a secondary field in a rotor, which then gets dragged along for the ride. It’s elegant, efficient, and incredibly effective.

From my first days as an apprentice, fumbling with a multimeter, to my current role designing and maintaining complex automated systems, my respect for this simple machine has only grown. It is the quiet, reliable heart of the modern world. It doesn’t ask for much—just a clean power supply and a little grease for its bearings now and then. In return, it gives us the mechanical work that builds, moves, and powers our entire civilization. Understanding its fundamental principle isn’t just about passing a test; it’s about appreciating the invisible forces that shape our daily lives.