Unlocking Power: Which Single Phase Motor Delivers the Highest Starting Torque?

Every engineer designing a machine, from a workshop air compressor to a heavy-duty conveyor system, eventually faces a critical question: will the motor have enough muscle to get the job done from a dead stop? If you’ve ever found yourself staring at a stalled motor under load or poring over spec sheets to decipher torque ratings, you’re in the right place. The challenge of overcoming inertia is a fundamental engineering problem, and choosing the right single-phase motor is often the key to solving it.

This guide is designed to be your expert consultant. We’ll break down the concept of starting torque, compare the heavy hitters in the single-phase motor world, and give you the knowledge to confidently select the perfect motor for your high-demand application.

What We’ll Cover

- Understanding Starting Torque: Why It Matters for Single-Phase Motors

- The King of Single-Phase Starting Torque: Capacitor-Start Motors

- Other Single-Phase Motor Types and Their Starting Torque Performance

- Comparative Analysis: Why Capacitor-Start Leads for Direct Single-Phase Applications

- Factors Influencing Single-Phase Motor Starting Torque

- Choosing the Right Single-Phase Motor Beyond Starting Torque

- Conclusion: Making the Best Motor Choice for Your Needs

Understanding Starting Torque: Why It Matters for Single-Phase Motors

So, what exactly is starting torque? In simple terms, starting torque (also known as locked-rotor torque or LRT) is the rotational force a motor can produce when it’s first energized and the rotor is at a standstill (0 RPM).

Think of it like trying to push a heavy car that’s parked. The initial, immense effort you need just to get the wheels to budge—that’s the real-world equivalent of starting torque. Once the car is rolling, it takes far less effort to keep it moving. Motors face the same challenge. Applications like compressors, which have to start against high pressure, or a fully loaded conveyor belt, require a massive initial “shove” to overcome static friction and inertia.

The core challenge for single-phase motors is that, by their nature, they don’t produce a true rotating magnetic field. A single winding fed by an AC power source creates a magnetic field that simply pulses back and forth. Imagine trying to spin a merry-go-round by just pushing and pulling it from one side—it would just shudder, not rotate. This is why single-phase motors need a “trick” or a special starting mechanism to get going. The effectiveness of this trick is what determines their starting torque.

The King of Single-Phase Starting Torque: Capacitor-Start Motors

When the job calls for serious grunt work, capacitor-start motors are the undisputed champions. They use a capacitor to create a significant phase shift in the current between the main and auxiliary windings, producing a powerful rotating magnetic field at startup. This design allows them to generate starting torques that are several times their full-load torque, making them ideal for tough applications.

There are two main heroes in this category:

Capacitor-Start Induction Run (CSIR) Motors

The CSIR motor is the workhorse for many demanding single-phase applications.

- Mechanism: It features two windings: a main (or run) winding and an auxiliary (or start) winding. In series with the start winding, there’s a start capacitor and a centrifugal switch. When you power it on, the capacitor gives the current in the start winding a “head start,” putting it out of phase with the current in the main winding. This phase difference creates a strong rotating magnetic field that yanks the rotor into motion. Once the motor reaches about 75% of its rated speed, the centrifugal switch physically disconnects the start winding and capacitor, and the motor continues to run efficiently on the main winding alone.

- Starting Torque Characteristics: CSIR motors are powerhouses at startup, typically producing a starting torque of 200% to 350% of their full-load running torque. This is more than enough to handle most hard-to-start loads.

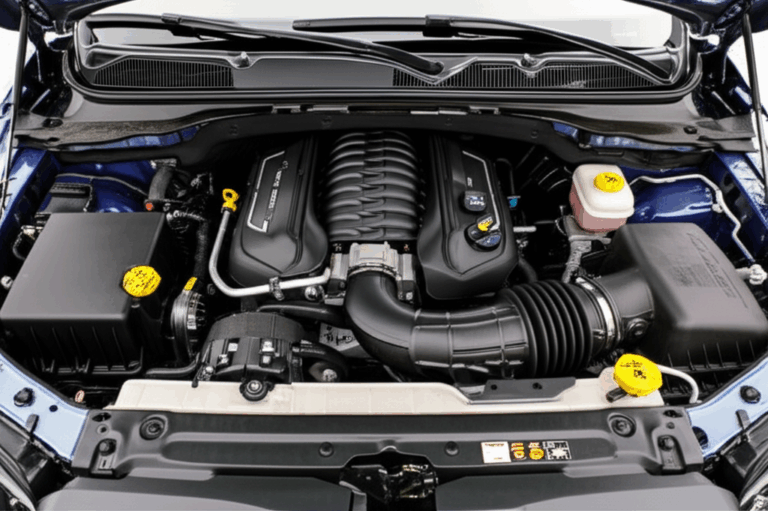

- Applications: You’ll find CSIR motors everywhere reliability is key. They drive refrigerator and air conditioner compressors, water pumps, large blowers, and conveyor systems.

Capacitor-Start Capacitor-Run (CSCR) Motors

If the CSIR is the workhorse, the CSCR is the premium, high-performance model. It takes everything good about the CSIR and makes it even better.

- Mechanism: A CSCR motor also has two windings and a start capacitor. However, it adds a second, smaller “run” capacitor that stays in the circuit with the auxiliary winding even after the start capacitor is disconnected by the centrifugal switch. This dual-capacitor system offers the best of both worlds. The large start capacitor provides a massive initial torque, while the run capacitor optimizes the phase angle during normal operation.

- Enhanced Performance: This design not only provides a slightly higher starting torque—often 250% to 400% of full-load torque—but also improves the motor’s running efficiency, power factor, and quietness. It essentially smooths out the motor’s performance across its entire operating range.

- Applications: Because of their superior performance and efficiency, CSCR motors are the go-to choice for the most demanding applications. This includes large commercial compressors, high-pressure pumps, and any high-inertia system where both starting power and running economy are critical. The robust construction of these motors often relies on high-quality motor core laminations to handle the high magnetic flux and ensure long-term durability.

Other Single-Phase Motor Types and Their Starting Torque Performance

While capacitor-start motors lead the pack, other types of single-phase motors serve different purposes, each with its own starting torque profile.

Split-Phase Induction Motors

The split-phase motor is the simpler, less powerful cousin of the capacitor-start motor.

- Mechanism: It also uses a start and run winding to create a phase shift. But instead of a capacitor, it relies on the different resistance and reactance of the two windings to create a small phase angle difference. The start winding is made of smaller wire, giving it higher resistance. This is a less effective way to create a rotating field compared to using a capacitor.

- Starting Torque Characteristics: Its starting torque is quite modest, typically ranging from 100% to 150% of its full-load torque. While better than nothing, it’s not suited for heavy loads.

- Applications: You’ll find split-phase motors in applications where the starting load is light, such as small fans, blowers, light-duty grinders, and some appliances like dishwashers.

Universal Motors

Universal motors are in a class of their own. They don’t operate on the induction principle but instead use brushes and a commutator, similar to a DC motor.

- Mechanism: The field and armature windings are connected in series. This design allows it to run on either AC or DC power (hence the name “universal”). Because the armature and field currents reverse in sync on AC power, the torque is always produced in the same direction.

- Starting Torque Characteristics: The starting torque of a universal motor is immense—often 300% to 600% or more of its rated torque. Their key characteristic is that torque is highest at zero speed and drops off rapidly as speed increases.

- Trade-offs: This incredible torque comes with downsides. Universal motors are noisy, produce electromagnetic interference (EMI), and their brushes wear out, requiring maintenance. They are also designed for very high speeds and are not typically used for continuous-duty applications that run at a constant, lower speed.

- Applications: They are perfect for applications that need a massive, short-burst of power and speed. Think power tools like drills and saws, vacuum cleaners, and kitchen blenders.

Shaded-Pole Motors

At the opposite end of the torque spectrum lies the shaded-pole motor.

- Mechanism: These are the simplest and cheapest AC motors. A portion of each stator pole is wrapped with a copper ring called a “shading coil.” This coil creates a slight lag in the magnetic field in that part of the pole, which is enough to produce a very weak rotating field effect.

- Starting Torque Characteristics: Their starting torque is extremely low, often less than 50% of their full-load torque. They can only start very light loads.

- Applications: Their low cost and simplicity make them suitable for very light-duty tasks like small cooling fans in electronics, timers, and small actuators in appliances.

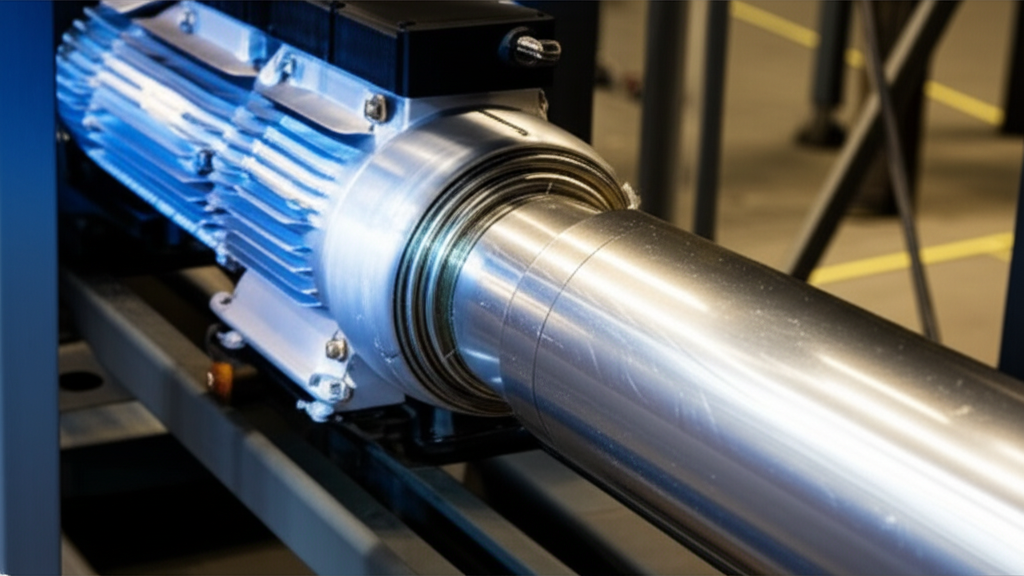

Permanent Magnet Synchronous Motors (PMSM) / Brushless DC (BLDC) Motors

Modern motors like PMSM and BLDC are a bit different. While they can operate on single-phase AC power, they don’t do it directly.

- Mechanism: These motors require an electronic drive or controller (like a Variable Frequency Drive, or VFD) to operate. The drive converts the incoming AC power to DC and then uses electronic switches to create a multi-phase AC waveform to precisely control the motor’s magnetic field.

- Starting Torque Characteristics: Because their operation is entirely controlled by electronics, their starting torque isn’t an inherent property but rather a programmable one. A properly configured drive can command a BLDC or PMSM to produce very high starting torque, often 200% to 400% of rated torque, with incredible precision and control from zero speed. The design of the bldc stator core is critical for achieving this high torque density efficiently.

- Applications: You see these advanced motor systems in modern high-efficiency appliances, HVAC systems (especially inverter-driven ones), robotics, and electric vehicles (though typically in three-phase configurations for higher power).

Comparative Analysis: Why Capacitor-Start Leads for Direct Single-Phase Applications

When you lay it all out, the picture becomes clear. For any application that connects directly to a single-phase AC line and needs to start a heavy load, the capacitor-start motor is the superior choice.

Here’s a direct comparison to put it all into perspective:

| Motor Type | Typical Starting Torque (% of Full-Load Torque) | Starting Current | Primary Mechanism for Starting | Typical Applications |

|---|---|---|---|---|

| CSCR Motor | 250-400% | High | Start & Run Capacitors | Large Compressors, HVAC, Industrial Pumps |

| CSIR Motor | 200-350% | High | Start Capacitor & Aux Winding | Compressors, Pumps, Refrigerators, Conveyors |

| Universal Motor | 300-600%+ | Very High | Series-wound field & armature | Power Tools, Vacuum Cleaners, Blenders |

| Split-Phase Motor | 100-150% | Very High | Resistance Start & Aux Winding | Small Fans, Blowers, Light-Duty Grinders |

| Shaded-Pole Motor | 25-75% | Low | Shading Coils | Small Appliance Fans, Timers, Toys |

| PMSM / BLDC Motor | Controlled (200-400%) | Controlled | Electronic Commutation | Modern Appliances, HVAC, Robotics |

As the table shows, while a Universal motor can produce higher peak torque, it’s designed for high-speed, intermittent use and comes with significant trade-offs in noise and maintenance. For the vast majority of industrial, commercial, and heavy residential applications that run continuously, the Capacitor-Start Capacitor-Run (CSCR) motor offers the best combination of high starting torque, excellent running efficiency, and reliability.

A case in point: a manufacturer of commercial refrigeration units was struggling with frequent starting failures in their compressors, which were powered by older split-phase motors. The motors simply couldn’t overcome the high initial pressure of the refrigerant. By upgrading to CSCR motors, they virtually eliminated startup failures, which extended the life of their compressors and improved overall system efficiency, proving the direct value of high starting torque.

Factors Influencing Single-Phase Motor Starting Torque

Even after selecting the right type of motor, a few external factors can impact its ability to start a load:

- Voltage Stability: A motor’s torque is proportional to the square of the applied voltage. This means even a small voltage drop (e.g., due to long or undersized wiring) can cause a significant reduction in starting torque. A 10% drop in voltage can result in a nearly 20% loss of torque!

- Load Characteristics: The nature of the load is critical. A high-inertia load, like a large flywheel or fan, requires sustained torque to accelerate. A high-friction load, like a compressor, requires high breakaway torque. Understanding your load’s profile is key.

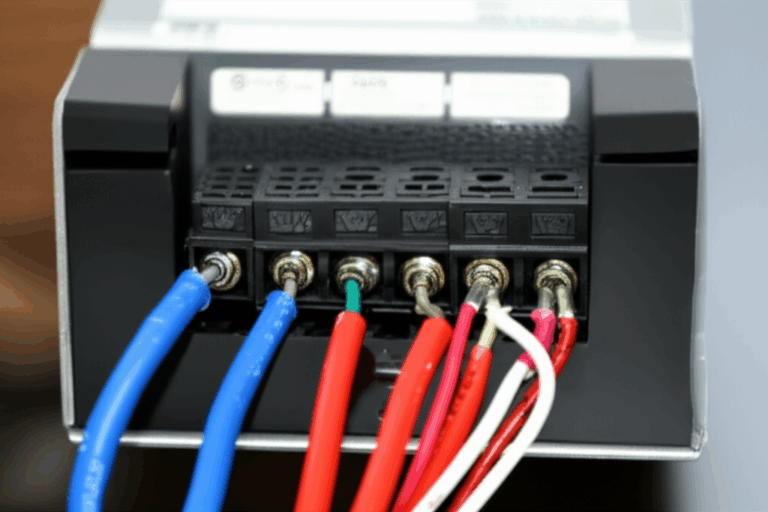

- Capacitor Selection: For CSIR and CSCR motors, the capacitor is the heart of the starting circuit. A failing or incorrectly sized capacitor will cripple the motor’s starting ability. The quality of the motor’s internal components, from the windings on the stator core lamination to the composition of the rotor, also plays a massive role in its overall performance.

Choosing the Right Single-Phase Motor Beyond Starting Torque

While starting torque is a vital specification, it’s not the only factor. A truly informed decision considers the entire picture:

- Full-Load Efficiency: How much electrical energy does the motor convert into useful work? A more efficient motor costs less to run over its lifetime. CSCR motors generally offer the best running efficiency.

- Power Factor: A measure of how effectively the motor uses current. CSCR motors with their run capacitor have a much better power factor than other induction motor types, which can be beneficial on electrical systems.

- Duty Cycle: Is the motor running continuously or intermittently? A universal motor is great for intermittent use, but would burn out quickly in a continuous-duty application where a CSIR or CSCR motor would thrive.

- Noise and Vibration: Universal motors are loud. For applications in quiet environments, a smooth-running induction motor like a CSCR is a far better choice.

- Maintenance: Brushless designs (CSIR, CSCR, Split-Phase, Shaded-Pole) are virtually maintenance-free. Universal motors require periodic brush replacement.

Conclusion: Making the Best Motor Choice for Your Needs

Navigating the world of single-phase motors can seem complex, but when it comes to raw starting power, the choice is clear.

Here are your key engineering takeaways:

- For the Highest Starting Torque: The Capacitor-Start Capacitor-Run (CSCR) motor is the top performer for most industrial and commercial applications, offering exceptional starting torque combined with excellent running efficiency. The Capacitor-Start Induction Run (CSIR) motor is a close second and a highly capable workhorse.

- For Extreme Speed & Intermittent Torque: If your application involves short bursts of extreme power and high speed, like a power tool, the Universal Motor is unmatched, but be prepared for noise and maintenance.

- For Light Loads: For simple, low-torque applications like small fans, a Split-Phase or Shaded-Pole motor offers a cost-effective solution.

- For Advanced Control: If you require precise speed and torque control, a BLDC or PMSM motor with an electronic drive is the modern solution, though it represents a complete system, not just a motor.

By understanding the fundamental “why” behind each motor’s performance, you can move beyond simply reading a spec sheet. You are now empowered to analyze your application’s unique demands—its inertia, its friction, its duty cycle—and select a motor that will not only start reliably every time but will also operate efficiently for years to come.