Unlocking Superior Performance: Why 3-Phase Motors Are More Efficient

Every design engineer, facility manager, and procurement specialist eventually faces a critical decision point: choosing the right electric motor. This choice ripples through a project, impacting everything from upfront cost and physical footprint to long-term operational expenses and reliability. If you’ve found yourself weighing the trade-offs between single-phase and three-phase motors, particularly asking, “Are 3-phase motors really more efficient?”, you’re asking the right question. The answer is not just a simple “yes”—it’s a gateway to understanding a more robust, reliable, and cost-effective approach to powering the modern world.

You’re not just selecting a component; you’re making a long-term investment in performance and sustainability. Let’s break down the engineering principles behind this choice to empower you to make the most informed decision for your application.

In This Article

- The Fundamental Difference: Single-Phase vs. Three-Phase Power

- Key Reasons for Three-Phase Motor Efficiency

- Beyond Efficiency: Additional Advantages of 3-Phase Motors

- Where Three-Phase Motors Excel: Common Applications

- When Are Single-Phase Motors Preferred? (Contextualizing Efficiency)

- Real-World Impact: Energy Savings and ROI

- Your Engineering Takeaway: The Empowering Conclusion

Are 3-Phase Motors More Efficient? (The Definitive Answer)

Yes, absolutely. For nearly all commercial and industrial applications, three-phase motors are significantly more efficient than their single-phase counterparts. This isn’t a minor difference; it’s a fundamental advantage rooted in the very nature of three-phase power. The superiority comes from a combination of constant power delivery, a more elegant electrical design, and inherently balanced loads that reduce energy waste at every stage of operation.

While a single-phase motor is perfect for your home’s washing machine or a small workshop drill, a three-phase motor is the undisputed workhorse of industry for a reason. Let’s explore the physics and practical benefits that make this true.

The Fundamental Difference: Single-Phase vs. Three-Phase Power

To understand why a 3-phase motor is more efficient, you first have to grasp the difference in the “fuel” they run on.

Single-Phase Power: This is the standard power you find in your home. It operates on a single alternating current (AC) sine wave. Picture a simple wave that rises to a peak, falls to zero, drops to a valley, and returns to zero. This cycle means the power delivered is pulsating. At the zero-crossing points, there is literally no power being delivered for a split second. For a motor, this pulsating delivery results in uneven torque and vibration. It’s like trying to pedal a bicycle with only one leg—you can do it but it’s jerky and inefficient.

Three-Phase Power: Now, imagine three of those sine waves, perfectly synchronized but offset from each other by 120 degrees. When one wave is at its zero point, the other two are still delivering substantial power. The result is a continuous, smooth, and constant stream of power. There are no dips to zero. It’s like pedaling that same bicycle with three legs, each one pushing in perfect sequence. This constant power delivery is the secret sauce behind the efficiency and smooth operation of three-phase motors.

This fundamental difference in power delivery is the foundation for all the other advantages that follow.

Key Reasons for Three-Phase Motor Efficiency

The superior design of three-phase motors capitalizes on the smooth power delivery to minimize the three main enemies of efficiency: electrical losses, mechanical losses, and thermal losses.

Constant Power Delivery & Smoother Torque

Because the power supply never drops to zero, a three-phase motor produces a constant and uniform torque on its output shaft. This smooth rotational force is a game-changer.

- Reduced Vibration: The pulsating torque of a single-phase motor causes mechanical vibrations. Vibration is wasted energy and also leads to increased wear and tear on bearings, couplings, and the machinery the motor is driving. Less vibration means a longer service life and lower maintenance costs.

- Lower Noise: The mechanical chatter caused by fluctuating torque makes single-phase motors inherently noisier. The quiet hum of a three-phase motor is a direct result of its smoother operation.

- No Wasted Energy on Pulsations: The motor doesn’t have to constantly overcome the dips in power, leading to more of the input electricity being converted directly into useful work. The core

motor principleis simply executed more effectively.

Superior Power Factor

Power factor is a measure of how effectively an electrical device converts the current supplied by the grid into useful work. A power factor of 1.0 is perfect; anything less means you’re drawing more current from the grid than you’re actually using, leading to waste in the electrical system and potentially higher utility bills.

- Single-Phase Motors: Often have a poor power factor, typically ranging from 0.5 to 0.7. This is partly due to the auxiliary windings and capacitors they need just to get started.

- Three-Phase Motors: Naturally operate with a much better power factor, usually between 0.8 and 0.9 at full load. This means they draw less reactive power from the grid, reducing the overall current required to do the same amount of work. For a large industrial facility with hundreds of motors, improving the power factor can lead to substantial savings on electricity costs.

Optimized Design and Reduced Losses

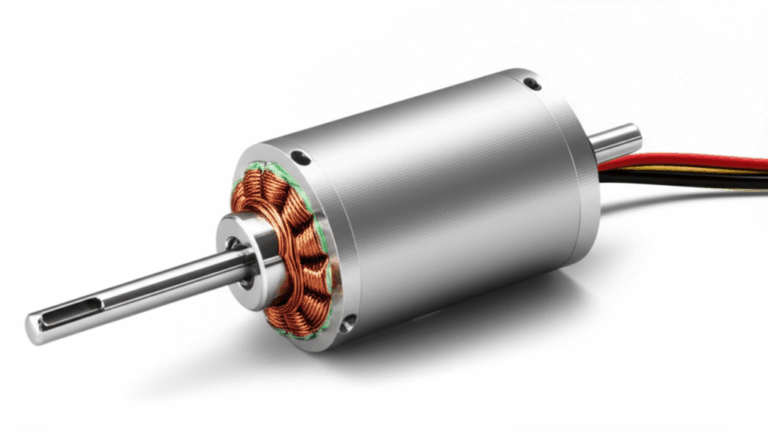

The physical construction of a three-phase motor is simpler and more efficient than a comparable single-phase motor. This design elegance translates directly into lower energy losses.

Copper Losses (I²R Losses)

These are resistive heating losses that occur as current flows through the copper windings in the motor. The formula for this loss is I²R (current squared times resistance). For the same horsepower rating, a three-phase motor can deliver that power with lower current per phase. Lower current means exponentially lower I²R losses, which means less energy is wasted as heat. This is a huge factor in overall efficiency. The quality of the electrical steel laminations used in the core also plays a major role in managing the magnetic field and minimizing these losses.

Core Losses

Core losses (or iron losses) occur within the steel core of the motor and are caused by the rapidly changing magnetic field. They are divided into two types:

The balanced, rotating magnetic field in a three-phase motor is more uniform than the pulsating field in a single-phase motor. This more stable magnetic environment reduces both hysteresis and eddy current losses in the core.

Self-Starting Nature

Most single-phase induction motors are not self-starting. They require an auxiliary starting mechanism, like a start winding or a capacitor, to create an initial rotating magnetic field. These components add complexity, are potential points of failure, and are often inefficient. In contrast, a three-phase motor is inherently self-starting due to the phase-shifted nature of its power supply. This eliminates the need for inefficient starting components, making the design simpler, more reliable, and more efficient from the get-go.

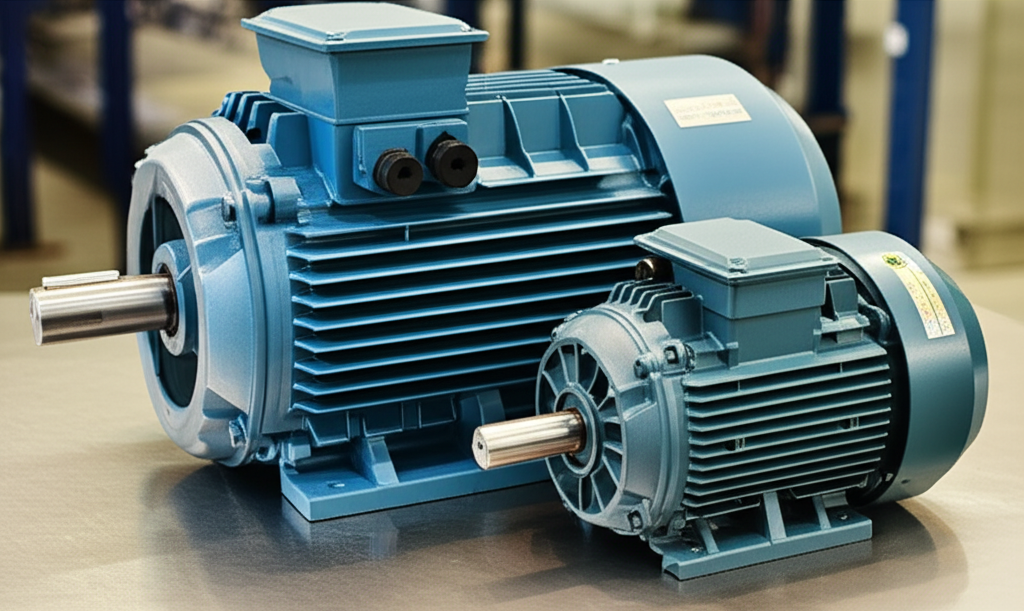

Better Power-to-Weight Ratio

For a given horsepower rating, a three-phase motor is almost always smaller and lighter than a single-phase motor. This means it requires less material (copper, steel) to build, making it more resource-efficient. For engineers and designers, this translates to more compact machine designs and easier integration into tight spaces.

Beyond Efficiency: Additional Advantages of 3-Phase Motors

While energy efficiency is often the main driver, the benefits of choosing a three-phase motor extend far beyond just lower electricity bills.

- Reliability & Durability: The simpler design (no centrifugal switches, start capacitors, or auxiliary windings) and reduced vibration lead to a significantly longer operational life and greater reliability. There are simply fewer parts to fail.

- Higher Starting Torque: Three-phase motors provide powerful starting torque, making them ideal for starting heavy, demanding loads like loaded conveyors, large pumps, and industrial compressors.

- Scalability: Three-phase power is the global standard for high-power applications. These motors are readily available in a massive range of sizes, from fractional horsepower to thousands of horsepower, without a significant drop-off in efficiency at larger scales.

- Compatibility with Variable Frequency Drives (VFDs): This is a massive advantage in modern industry. VFDs allow for precise control over a motor’s speed. By matching the motor’s speed to the exact load requirement—instead of running it at full speed all the time—VFDs can unlock staggering energy savings, often in the range of 30-50% for fan and pump applications. Three-phase induction motors are perfectly suited for VFD control.

Where Three-Phase Motors Excel: Common Applications

You’ll find three-phase motors running the machinery that forms the backbone of our economy. Their combination of efficiency, power, and reliability makes them the only logical choice for:

- Industrial Manufacturing: Powering pumps, compressors, fans, conveyor belts, machine tools, and heavy machinery.

- Commercial HVAC Systems: Driving large air handlers, chillers, and cooling tower fans in office buildings, hospitals, and data centers.

- Large-Scale Refrigeration: Used in industrial freezers and cold storage warehouses.

- Agricultural Machinery: Operating irrigation pumps, grain elevators, and ventilation fans.

- Water and Wastewater Treatment Plants: Driving the massive pumps and aerators needed for municipal services.

In any application that requires more than about 5-7.5 horsepower and runs for significant periods, the efficiency gains and reliability of a three-phase motor will almost always justify the initial setup cost.

When Are Single-Phase Motors Preferred? (Contextualizing Efficiency)

Despite the clear advantages of three-phase power, single-phase motors still have an important role to play. They are the practical choice in specific scenarios:

- Low Power Requirements: For most residential and small commercial applications under 5 horsepower (e.g., home appliances, power tools, garage door openers), the efficiency difference is less significant in dollar terms, and the simplicity of using standard wall power is a huge benefit.

- When 3-Phase Power is Unavailable: The biggest barrier is infrastructure. Most residential areas and small businesses are only supplied with single-phase power. The cost of running a new three-phase service from the utility can be prohibitively expensive, making single-phase the only viable option.

- Cost-Sensitive, Intermittent Use: For a tool that is only used for a few minutes a day in a small workshop, the upfront cost savings of a single-phase motor will likely outweigh any potential long-term energy savings.

Real-World Impact: Energy Savings and ROI

The difference in efficiency isn’t just an abstract percentage; it translates into tangible financial savings. Let’s look at a practical example.

Consider a 10 horsepower (HP) motor running two shifts a day (4,000 hours/year) with electricity costing $0.12/kWh.

- Single-Phase Motor (75% efficient):

- (10 HP 0.746 kW/HP 4,000 hrs * $0.12/kWh) / 0.75 = $4,774 per year

- Three-Phase NEMA Premium Motor (91.7% efficient):

- (10 HP 0.746 kW/HP 4,000 hrs * $0.12/kWh) / 0.917 = $3,908 per year

That’s an annual saving of $866 for a single 10 HP motor.

Now, imagine a manufacturing plant with 50 such motors. The savings quickly escalate to over $43,000 per year. This is why government bodies and industry standards organizations like NEMA (National Electrical Manufacturers Association) and the IEC (International Electrotechnical Commission) have pushed for higher efficiency standards, such as NEMA Premium and IEC IE3/IE4.

The return on investment (ROI) for upgrading from an older, standard-efficiency motor to a new premium-efficiency three-phase motor is often just 1-3 years. With utility rebates, which are common for these upgrades, the payback period can be even shorter. The choice isn’t just about being “green”; it’s a sound financial decision. The core assembly of these high-efficiency motors, from the stator and rotor to the windings, is engineered to minimize these exact losses.

Your Engineering Takeaway: The Empowering Conclusion

So, are 3-phase motors more efficient? The answer is an emphatic yes. For any application demanding power, reliability, and long-term cost-effectiveness, the three-phase motor is the superior engineering choice.

Let’s summarize the key takeaways:

- Fundamental Advantage: Three-phase power delivers a constant, smooth stream of energy, unlike the pulsating power of single-phase.

- Higher Efficiency: This results in smoother torque, less vibration, a better power factor, and optimized electrical and magnetic designs that dramatically reduce energy losses.

- Greater Reliability: With a simpler construction and fewer points of failure, three-phase motors offer a longer service life and lower maintenance requirements.

- Superior Performance: They deliver higher starting torque and are perfectly suited for speed control with Variable Frequency Drives (VFDs), unlocking even greater efficiency.

- Clear Financial Benefit: The significant reduction in energy consumption leads to a rapid return on investment, making them the most cost-effective choice for industrial and commercial use.

Choosing the right motor is a critical decision that impacts your design, your budget, and your carbon footprint. By understanding the fundamental principles that make three-phase motors more efficient, you are empowered to specify a solution that delivers superior performance and value for years to come.