Unpacking Mud Motor Lifespan: Factors, Maintenance & Maximizing Durability in Drilling Operations

Have you ever wondered how long a mud motor should last? It’s a big question in the oil and gas industry. A failed motor can stop a huge drilling project right in its tracks. This can cost you a lot of time and a whole lot of money. This guide will explain what a mud motor’s life expectancy really is. I’ll show you what affects a motor’s life and how you can make it last longer. Reading this will help you avoid problems and save money on your next project.

Table of Contents

- What is a Mud Motor Anyway?

- So, What’s the Real Lifespan of a Mud Motor?

- What Things Can Shorten a Motor’s Life?

- How Can I Tell if My Mud Motor is Getting Tired?

- What Are the Secrets to Making Mud Motors Last Longer?

- How Does a Motor’s Lifespan Affect My Wallet?

- Why is a Strong Motor My Best Friend in Drilling?

- Conclusion: Smart Choices for a Longer Motor Life

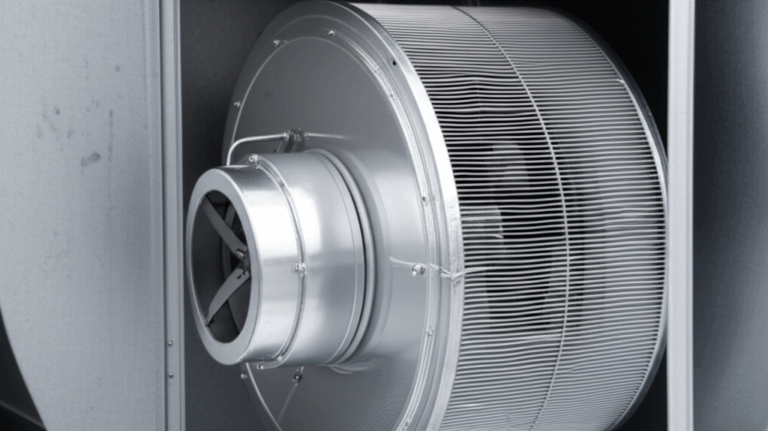

What is a Mud Motor Anyway?

Let’s start with the basics. Imagine you’re drilling a well thousands of feet into the earth. You can’t just drill straight down anymore. You need to turn and steer. A mud motor is the special tool that lets you do this. It’s like an engine for your drill bit but it’s powered by drilling fluid or “mud” not gasoline. This mud is pumped down the drill string from the drilling rig on the surface.

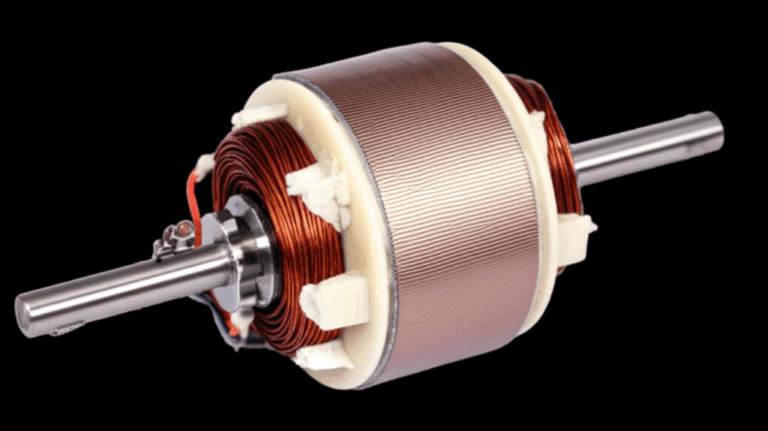

The motor sits right behind the drill bit in what we call the Bottom Hole Assembly (BHA). Inside the motor there are two key parts: a stator and a rotor. The stator is a tube with a special rubber lining that has a spiral shape. The rotor is a steel spiral that fits inside the stator. When the drilling mud flows through the motor it pushes the rotor causing it to spin. This spinning action turns the drill bit and chews through rock. To get a better look at these crucial parts, you can learn more about the relationship between the stator and rotor. Understanding how they work together is the first step in understanding the motor’s durability.

This amazing piece of oil and gas drilling technology is a type of Positive Displacement Motor (PDM). It allows for directional drilling and horizontal drilling which are key to reaching oil and gas reserves that aren’t straight below us. Without a reliable downhole motor we would be stuck with old-fashioned straight holes. So keeping this tool running is a very big deal for drilling efficiency optimization.

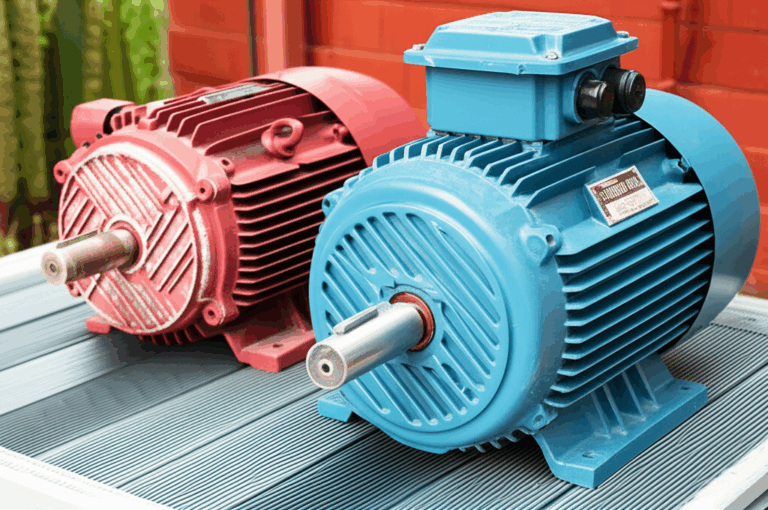

So, What’s the Real Lifespan of a Mud Motor?

This is the million-dollar question isn’t it? The simple answer is: there is no single number. Asking about a mud motor’s lifespan is like asking how long a car’s tires will last. The answer depends on the type of tire how you drive and the roads you drive on. The same is true for a downhole motor. The drilling motor service life can change a lot from one job to the next.

However I can give you some general numbers. For a standard motor in average conditions you might see an average mud motor run time of 100 to 300 hours. For a high-performance motor in a friendly environment you could get 500 hours or more. But in very tough or abusive conditions the PDM life expectancy could be less than 50 hours. It’s a huge range. A key thing to remember is that we often talk about the life of the “power section” which is the stator and rotor. The whole motor tool can last for years with proper care because you can rebuild the power section many times.

Think of it like this. The power section is the engine of your car. The car’s body can last for decades but you might need to rebuild the engine a few times. The Mean Time Between Failures (MTBF) is a metric we watch closely. A higher MTBF means the motor is more reliable. The goal of every drilling contractor and service company is to increase that number.

What Things Can Shorten a Motor’s Life?

You have a big project ahead of you. The plan is set and the crew is ready. The last thing you need is a surprise failure deep underground. This is a common problem: a motor gives out way too early. It makes you feel frustrated because every hour the rig isn’t drilling you’re losing thousands of dollars. It makes you wonder what went wrong. Several key factors can cause drilling operations wear and tear and dramatically reduce a motor’s life.

Here are the biggest culprits:

- The Ground Itself (Drilling Environment):

- Hot Temperatures: The deeper you drill the hotter it gets. High downhole temperature is a killer for the rubber elastomer inside the stator. It can make the rubber soft and weak.

- Gritty Rock: Drilling through hard abrasive rock like sandstone is like sandblasting the inside of your motor. This causes serious stator wear and rotor wear.

- Twists and Turns: A wellbore with a lot of sharp turns or doglegs puts extra stress on the motor’s drive shaft and bearing assembly.

- Nasty Chemicals: Some rock formations have nasty stuff like Hydrogen Sulfide (H2S). This gas can eat away at the motor’s parts.

- The Drilling Mud (Drilling Fluid Properties):

- Dirty Mud: If your drilling fluid has too many fine solids or rock cuttings it acts like liquid sandpaper inside the motor.

- Wrong Mud Mix: The type of mud you use matters. Some chemicals in the mud can harm the stator’s elastomer.

- Clogging Materials: Sometimes we add Lost Circulation Material (LCM) to the mud to plug cracks in the rock. But this LCM can also clog and damage the motor.

- How You Drill (Operational Parameters):

- Pushing Too Hard: Putting too much Weight on Bit (WOB) can over-stress the motor and cause it to fail early.

- Running Too Fast or Slow: Every motor has a sweet spot for its speed (RPM) and power (torque). Operating outside this range causes damage.

- Vibration and Shock: Bumpy drilling or using the wrong bit can create a lot of vibration. This shock can destroy the delicate bearing assembly lifespan.

- The Motor’s Build Quality:

- Not all motors are created equal. The quality of the parts matters. A well-built motor with a strong power section life expectancy starts with excellent materials. For example the quality of the stator core lamination is critical for performance. Likewise a poorly made rotor core lamination can lead to early failure. Choosing a motor from a good manufacturer with high-quality components is a smart investment.

How Can I Tell if My Mud Motor is Getting Tired?

Luckily a mud motor usually gives you some warning signs before it quits completely. If you know what to look for you can pull the motor out of the hole before it causes a major problem. Paying attention to these signs is a key part of failure prevention strategies for your motor.

Here are some clues that your mud motor is nearing the end of its run:

- It Loses Power: You’ll notice a drop in torque output. The drill bit just won’t cut as fast as it used to.

- It Needs More Push: The pressure gauge on the surface will show an increased pressure drop across motor. This means the motor is struggling to work and mud might be leaking past the rotor and stator.

- It Starts Shaking: You might see higher vibration levels on your Measurement While Drilling (MWD) tools. This could mean the bearings are worn out.

- It Gets Unpredictable: The motor might have trouble holding its direction or toolface which is a big headache for directional drilling.

If you see any of these signs it’s time to act. It’s much better to pull the motor out for an inspection than to wait for it to fail thousands of feet underground. Understanding any potential motor problem early is the best way to avoid costly downtime.

What Are the Secrets to Making Mud Motors Last Longer?

Now for the good news. You have the power to improve your mud motor lifespan. It’s not about luck; it’s about smart choices and good practices. By taking control of the process you can stop feeling helpless when a motor fails and start getting more hours out of every tool. This is the solution that saves your project and your budget.

Here are the best strategies to maximize your motor’s life and reliability:

By following these steps you can turn a motor from a potential liability into a reliable asset.

How Does a Motor’s Lifespan Affect My Wallet?

The connection between mud motor durability and drilling costs is huge. When a motor fails the costs add up much faster than you might think. It’s not just about the price of a new part.

Let’s look at the real economic impact:

| Cost Type | Description | Example Cost |

|---|---|---|

| Direct Costs | The price of repairing the motor or buying a new one. This includes mud motor repair costs and component replacement like a new power section or bearing assembly. | $20,000 – $100,000+ per motor |

| Indirect Costs (The Big One) | This is the cost of Non-Productive Time (NPT). When a motor fails you have to stop drilling pull the entire drill string out of the hole (which can take a day or more) replace the motor and run it all back in. All while the expensive drilling rig and crew are waiting. | $10,000 to over $1,000,000 per day |

As you can see the cost of mud motor failure is mostly in the downtime. The downtime costs drilling rig operations can easily be ten times the cost of the motor itself. This is why a slightly more expensive but much more reliable motor is often the cheaper choice in the long run. Extending a motor’s life directly reduces your operational costs drilling mud motor and improves your project’s bottom line. Better downhole equipment reliability means less risk and more profit.

Why is a Strong Motor My Best Friend in Drilling?

In the challenging world of drilling you need tools you can count on. A durable mud motor is more than just a piece of equipment; it’s your partner in reaching your target efficiently and safely. Think of it as an investment in success not just a cost on a spreadsheet.

When you invest in a high-quality motor and the practices to keep it healthy you are buying peace of mind. You are reducing the risk of that dreaded middle-of-the-night phone call about a failure. You are empowering your crew to drill with confidence knowing their tools won’t let them down. A longer mud motor lifespan leads to better drilling efficiency a lower cost per foot and a safer more predictable operation. It’s the foundation of a successful drilling program.

From the maintenance crew to the drilling engineer everyone plays a role in asset management drilling tools. By focusing on durability you are creating a culture of excellence that pays off on every single well you drill. The value of this reliability is priceless.

Conclusion: Smart Choices for a Longer Motor Life

We’ve covered a lot of ground. We learned that the life of a mud motor isn’t a fixed number. It’s a story written by the rocks you drill the mud you use and the choices you make every day on the rig. While a motor might only last 100 hours in a tough spot it can go for over 500 hours when everything is just right. The key is knowing you have a lot of control over that story.

By understanding the factors that cause wear and tear you can fight back. You can protect your investment avoid costly downtime and drill more efficiently than ever before.

Key Things to Remember:

- There is no magic number: A motor’s life ranges from under 50 to over 500 hours depending on conditions.

- Heat and grit are the enemies: High temperatures and abrasive rock are the biggest threats to a motor’s power section.

- Clean mud is happy mud: The quality and cleanliness of your drilling fluid directly impact motor life.

- Listen for warning signs: Pay attention to drops in power increased pressure and vibration to catch problems early.

- Prevention is the best cure: Smart motor selection smooth drilling practices and a good maintenance schedule are your best tools for extending motor life.

- Downtime is the real cost: The money lost during NPT is much greater than the cost of the motor itself. Investing in durability saves you money.