What Are Brushless Motors? The Ultimate Guide to BLDC Technology

Table of Contents

- Introduction: Unveiling the Brushless Motor

- What is a brushless motor

- Why brushless motors are gaining popularity

- How Brushless Motors Work: The Principles of Operation

- Core components: stator, rotor, ESC

- Electronic commutation

- Sensored vs sensorless control

- Trapezoidal vs sinusoidal control and FOC

- Inrunner vs outrunner designs

- Brushless vs Brushed Motors: A Head-to-Head Comparison

- Mechanism and component differences

- Advantages of brushless motors

- Disadvantages and tradeoffs

- When I still pick brushed

- Types of Brushless Motors

- BLDC motors

- PMSM motors

- Key Design Concepts You’ll See in Spec Sheets

- Three-phase windings, magnetic circuit, air gap

- Torque production, cogging torque, vibration

- Losses: copper, iron, hysteresis, eddy currents

- Laminations, materials, and core construction

- Cooling, housing, bearings, and sealing

- EMI, insulation, and reliability

- Common Applications of Brushless Motors

- Consumer electronics

- Power tools

- Automotive and transportation

- Industrial and robotics

- Data, Trends, and What the Numbers Say

- How I Choose a Brushless Motor and ESC

- Sizing, voltage, current draw

- Winding configurations

- Sensored vs sensorless decisions

- ESC features that matter

- Maintenance, Failure Modes, and Diagnostics

- The Future: Why Brushless Dominates

- Conclusion: The Brushless Revolution

Introduction: Unveiling the Brushless Motor

I still remember the first time I swapped a brushed motor out of my RC car for a brushless setup. The car felt like it grew wings. It ran cooler, pulled harder out of corners, and the battery lasted longer. That experience lit a fire. I wanted to know why this “brushless” thing felt so different.

If you’re asking “what are brushless motors” you’re in the right place. I’ll walk you through how they work, why they’re better in many cases, and where you’ll find them. I’ll share what I’ve learned from drones to power tools to EVs. No fluff. Just practical insights with examples you can picture.

What is a brushless motor

A brushless motor is an electric motor with permanent magnets on the rotor and electromagnets on the stator. It doesn’t use brushes or a commutator. Instead it relies on electronic commutation from a controller called an ESC. That switch from mechanical to electronic switching changes almost everything. Efficiency goes up. Maintenance drops. Control gets precise.

You’ll see two main families under the brushless umbrella:

- BLDC (Brushless DC) motors that often use trapezoidal control

- PMSM (Permanent Magnet Synchronous Motors) that often use sinusoidal control and Field Oriented Control for smooth torque

Both are “brushless” in the sense that they eliminate brushes and use an external controller.

Why brushless motors are gaining popularity

Three reasons sold me early on:

- They waste less energy. Less friction. Less heat. Higher motor efficiency is the name of the game.

- They last longer. No brushes means no brush wear and minimal sparking. Bearings become the main lifetime limit.

- They offer better power-to-weight ratios. You get more power density in a smaller, lighter package.

That combo wins in drones, EVs, power tools, HVAC, robotics, and appliances. As electronics get cheaper the cost gap keeps shrinking, so adoption keeps climbing.

How Brushless Motors Work: The Principles of Operation

When I build a brushless system I picture three parts working together: the stator, the rotor, and the ESC. The ESC feeds the stator coils a timed, rotating magnetic field. The rotor’s permanent magnets chase that field. Spin happens. The magic is in the timing.

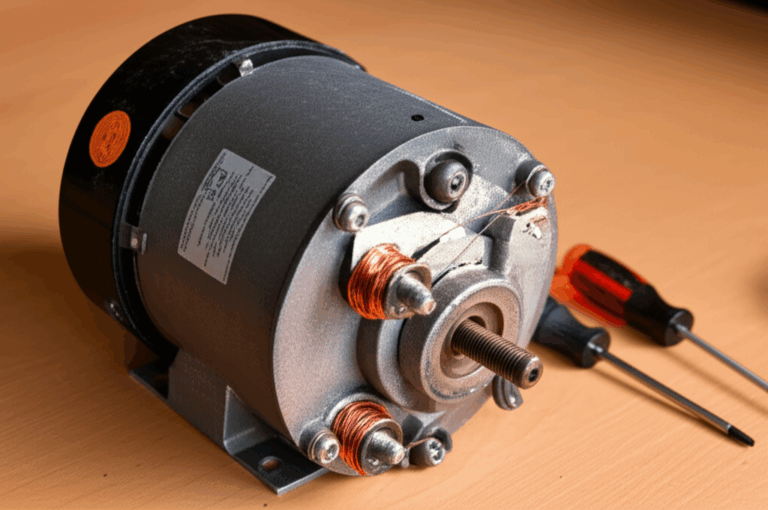

Core components: stator, rotor, ESC

- Stator: The stationary part with windings. The windings become electromagnets when energized with current. If you want a deeper primer, I like to point people to this simple breakdown of the stator and rotor.

- Rotor: The rotating part with permanent magnets. The magnets can be inside a rotor core or on the surface depending on torque and speed goals.

- ESC (Electronic Speed Controller): The “brain” that performs electronic commutation. It switches current between phases, sets torque and speed, and implements protection. Modern ESCs use PWM, microcontrollers, and sensor feedback to do this precisely.

Electronic commutation

In a brushed motor mechanical brushes switch current through the armature. In a brushless motor the ESC switches current between stator phases. It creates a rotating magnetic field that “pulls” the rotor around. No brush friction. No brush arcing. No commutator wear. The ESC’s job is to align the stator’s field with the rotor’s magnetic poles at the right angle and the right time.

That timing angle matters because it defines torque production and efficiency. Get the angle wrong and you waste energy or produce ripple. Get it right and you squeeze out quiet, smooth power.

Sensored vs sensorless control

I’ve used both. Each has pros and cons.

- Sensored BLDC: Hall effect sensors read rotor position directly. Starts are smooth. Low-speed torque is predictable. Power tools and robotics often go sensored because stalls and direction control matter.

- Sensorless BLDC: The ESC infers rotor position from back EMF (the voltage induced in unused phases). Sensorless setups run great at medium to high speeds. They are simpler and cheaper. Drones love them. They can struggle at zero speed starts or under heavy load.

Some controllers blend the two or estimate well enough that starts feel almost sensored. Good firmware makes a world of difference.

Trapezoidal vs sinusoidal control and FOC

I’ll keep this simple because the names sound more intimidating than they feel in practice.

- Trapezoidal control: The ESC applies voltage in steps that look like trapezoids. It’s common in BLDC drives. It’s efficient and simple, yet it can introduce torque ripple and a bit more acoustic noise.

- Sinusoidal control: The ESC drives the phases with smooth sine waves. It reduces torque ripple and noise. It pairs well with PMSM designs.

- Field Oriented Control (FOC): This is the big leagues. The ESC transforms the three-phase currents into a rotating reference frame. It controls magnetic flux and torque components independently. You get precise torque control, higher efficiency across a wider speed range, and quieter operation. I use FOC when I care about smoothness under varying loads.

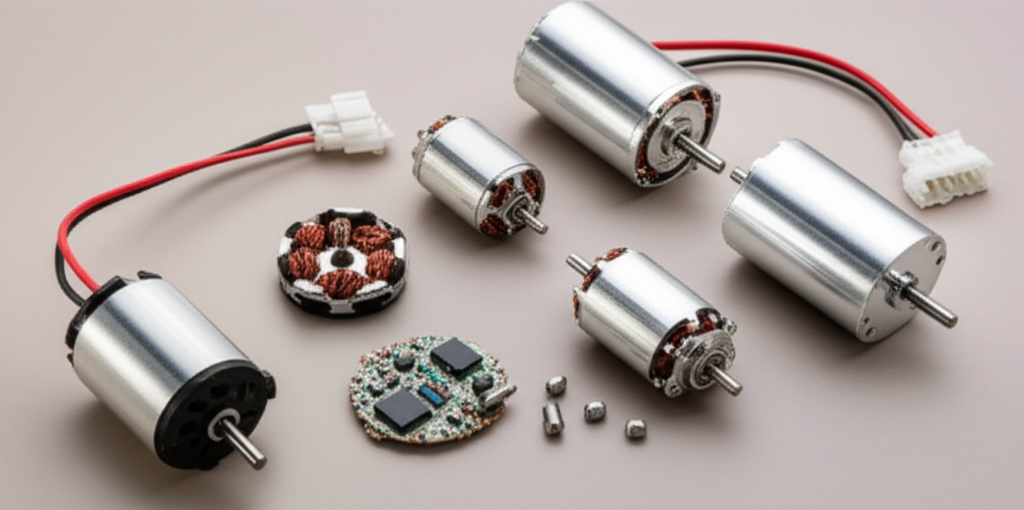

Inrunner vs outrunner designs

If you’ve held a drone motor you’ve likely held an outrunner. The can spins on the outside with the magnets attached to it. Outrunners produce higher torque at lower RPM which is perfect for direct-drive props. Inrunners hide the rotor inside the stator. They spin faster with lower torque which suits geared systems, pumps, and high RPM fans.

In short:

- Inrunner: Rotor inside, high RPM, lower torque, good for gearboxes or tiny fans.

- Outrunner: Rotor outside, lower RPM, higher torque, great for drones and direct-drive applications.

Brushless vs Brushed Motors: A Head-to-Head Comparison

I used brushed motors for years in small projects. They still have a place. Yet once you understand the tradeoffs you’ll see why brushless motors took over so many fields.

Mechanism and component differences

- Brushed: Brushes, commutator, sparking, carbon dust, mechanical commutation.

- Brushless: No brushes, ESC for commutation, permanent magnets in rotor, cleaner operation.

That single difference removes a friction point and a failure mode. It also hands control over to software which opens the door to smarter features.

Advantages of brushless motors

- Higher efficiency: Typical brushless systems deliver roughly 85–90% efficiency and some designs push beyond that in sweet spots. Brushed often sits around 75–80%.

- Longer lifespan and durability: No brushes to replace. Bearings become the wear item. I’ve seen brushless motors run for tens of thousands of hours in fans and pumps.

- Lower maintenance: No brush replacement. No commutator resurfacing. Less dust.

- Greater power-to-weight ratio: You get more output per gram. This matters in drones, EVs, and handheld power tools.

- Quieter operation: No brush-on-commutator chatter. Sinusoidal control cuts noise even more.

- Better speed and torque control: The ESC can manage torque limits, speed ramps, and precise positioning.

- Reduced EMI: No brush arcing. Better for electronics-dense environments and medical devices.

Disadvantages and tradeoffs

- Higher upfront cost: The ESC adds complexity and cost. Prices keep dropping as ESCs and semiconductors scale which softens the blow each year.

- Control complexity: You need the right ESC and the right settings. Sensorless starts under heavy load can be tricky. FOC setup requires tuning.

When I still pick brushed

I still choose brushed in these cases:

- Rock-bottom cost with simple on/off control

- Very low-speed positioning without a dedicated controller

- Environments where a cheap disposable motor makes sense

Even then I weigh the maintenance pain against the simplicity.

Types of Brushless Motors

Let’s separate the labels you’ll see in catalogs and spec sheets.

- Brushless DC (BLDC): Often trapezoidal back EMF and commutation. Efficient and common in appliances, fans, drones, RC cars, and industrial gear.

- Permanent Magnet Synchronous Motors (PMSM): Often sinusoidal back EMF with FOC. Smoother torque and better acoustic behavior at the cost of more sophisticated control. EVs love PMSM for that reason.

Some products use the terms loosely. I focus on the control method and back EMF shape more than the label because that affects noise, torque ripple, and efficiency.

Key Design Concepts You’ll See in Spec Sheets

This is the practical stuff that helps you read between the lines.

Three-phase windings, magnetic circuit, and air gap

Most brushless motors use three-phase windings. The windings create the rotating magnetic field that drags the rotor around. The magnetic circuit routes that field through the stator teeth, across the air gap, through the rotor core and magnets, and back again. The air gap sets the coupling strength. Smaller gaps boost torque density yet make manufacturing and alignment more demanding.

Torque production, cogging torque, and vibration

Torque comes from the interaction of the stator field with the rotor magnets. The exact winding layout, slot count, and magnet pole count shape the torque curve. Cogging torque appears when the rotor magnets prefer certain stator tooth positions due to magnetic reluctance. You feel it as a notchiness at low speed. Designers fight cogging with skewed stator slots, fractional slot windings, and careful magnet shaping.

Vibration follows torque ripple. Sinusoidal control and FOC help smooth it. Good mechanical design matters too because poor balance and loose housings amplify vibration.

Losses: copper, iron, hysteresis, eddy currents

Losses fall into a few buckets:

- Copper loss: I²R in the windings. Thicker wire and better cooling help. So does FOC when it optimizes current.

- Iron loss: Magnetizing and demagnetizing the core causes hysteresis loss. Rapid changes induce eddy currents which waste energy as heat. Designers reduce these with thin laminations and the right electrical steel.

- Mechanical loss: Bearings and air friction.

In practice you feel these as heat. If a motor runs hot at light load it likely suffers from iron loss at that speed. If it runs hot under heavy load you’re losing power in copper.

Laminations, materials, and core construction

Here’s where quality parts shine. The stator and rotor cores use laminated electrical steel to cut eddy currents. Thin sheets get stacked with insulation between them so eddy current loops stay tiny. That reduces iron loss and boosts efficiency. When I’ve spec’d motors for quiet, efficient operation I’ve paid close attention to lamination thickness and grade.

If you want a practical look at how stator cores get built the choice of stator core lamination directly affects iron loss and torque density. The same applies to the rotor. Good rotor core lamination choices keep eddy currents low without weakening the magnetic circuit. If you’re comparing suppliers at a higher level, understanding the landscape of motor core laminations helps you ask better questions about thickness, stacking factor, and material grade.

I care about stacking factor because it defines how much steel actually ends up in the magnetic path versus insulation. Better stacking factor means better flux carrying capacity for the same size. For the steel itself you’ll see silicon steel and other electrical steels chosen to balance loss and cost. Lower loss grades help at high speeds where eddy currents spike.

Cooling, housing, bearings, and sealing

Heat is the silent killer. Here’s how I plan for it:

- Cooling methods: Natural convection, forced air, or liquid cooling depending on power. Outrunners often rely on airflow from the prop or fan they drive. Inrunners may sit on finned housings or water jackets in high performance setups.

- Housing: Aluminum housings pull heat away fast. Plastic housings insulate and may trap heat.

- Bearings: Good bearings define lifespan. Ball bearings are common. Ceramic hybrids can push performance but cost more. Clean environments extend life so sealing and dust control matter.

- Sealing and environmental resistance: If the motor faces dust, moisture, or chemicals I look for IP-rated housings and proper seals. That protects windings and bearings.

EMI, insulation, and reliability

Brushless motors cut brush arcing which slashes EMI. The ESC still switches high current fast which can inject noise into nearby circuits. Shielding, good cable layout, and proper grounding help. Insulation types on windings protect against voltage spikes from PWM switching. I watch for proper insulation class if the motor runs hot because insulation breakdown shortens life. Predictive maintenance practices and vibration analysis catch issues early in industrial settings.

Common Applications of Brushless Motors

I bump into brushless motors everywhere now. Here are the places I see most.

Consumer electronics

- Drones and RC vehicles: High torque density and low weight-to-power ratio make brushless essential. Quadcopter flight control needs precise torque and quick response which brushless delivers.

- Vacuum cleaners: Dyson made high-speed BLDC motors a household talking point. They run quietly, save energy, and pack power in a small package.

- Washing machines: Direct-drive drum motors cut belts and boost reliability with smooth torque.

- Computer fans and hard drives: Quiet, reliable, and efficient. That combo keeps your gear cool and your office sane.

Power tools

Cordless drills, impact drivers, circular saws, and grinders now ship with brushless motors in many pro lines from Makita, DeWalt, Bosch, Milwaukee, and others. You get:

- More torque per charge

- Less heat during sustained work

- Longer tool life with fewer service intervals

Once I moved to a brushless drill I noticed longer runtime and a cooler grip after back-to-back holes.

Automotive and transportation

- Electric vehicles and hybrids: PMSM motors dominate EV propulsion because they deliver high efficiency with smooth torque. Assist systems like electric power steering also rely on BLDC motors for precise control.

- E-bikes and scooters: Compact brushless hub motors or mid-drives keep rides quiet and responsive.

Industrial and robotics

- Industrial automation: Robotics arms and actuators need precise torque control and reliability. BLDC and PMSM motors paired with FOC and encoders hit both marks.

- HVAC systems and pumps: Variable speed BLDC drives slash energy use and improve comfort. Fan and pump curves benefit from efficient partial-load operation.

- Medical devices: Quiet operation with low EMI is critical in clinical settings.

Data, Trends, and What the Numbers Say

I don’t pick tech because it sounds fancy. I look at results. Here’s what I’ve seen repeatedly across projects and industry reports:

- Efficiency: Brushless motors often deliver 85–90% efficiency in typical operating ranges and some designs go higher at their sweet spots. Brushed motors tend to land around 75–80%.

- Lifespan: Brushless motors routinely run for tens of thousands of hours. Bearings become the life limiter rather than brushes or commutators.

- Power-to-weight ratio: BLDC and PMSM motors can deliver two to three times the power-to-weight of similar brushed motors. That’s why drones fly longer and EVs accelerate harder without ballooning in size.

- Market momentum: Industry estimates placed the global BLDC market in the low twenty billions of USD in 2023 with a healthy growth rate through 2030. You can feel that trend in tool aisles and EV sales.

- Adoption patterns: EVs, drones, and premium appliances have largely standardized on brushless. Professional-grade power tools have shifted as well because users demand runtime, torque, and reliability.

Numbers don’t tell the whole story, yet they explain why your next appliance, tool, or vehicle will likely use a brushless drive.

How I Choose a Brushless Motor and ESC

When I match a motor to a job I start with the load and the power source. Then I work my way through the details.

Sizing, voltage, and current draw

- Power and torque: Define the torque and speed you need at the shaft. Decide if you’ll go direct drive or add a gearbox. Outrunners shine in direct drive. Inrunners pair well with gear reduction.

- Voltage: Match motor and ESC voltage to your battery or supply rails. Higher voltage often means lower current for the same power which reduces copper loss and heat.

- Current draw: Look at continuous and peak current. Check the ESC’s continuous and burst ratings. Leave headroom so the system handles transients without tripping or overheating.

Winding configurations

You’ll see winding terms like Wye (Y) and Delta. The difference shows up in Kv (RPM per volt), torque constant, and current draw. Y windings typically deliver more torque per amp at lower speed. Delta favors higher speed for the same voltage. Manufacturers often publish Kv ratings which help estimate no-load RPM. Real-world RPM will be lower under load.

Sensored vs sensorless decisions

- Sensored: I choose sensored when I need smooth starts under load, precise low-speed control, or reliable direction control. Power tools and robotics applications benefit.

- Sensorless: I go sensorless for drones, fans, and high-speed applications where starts are light and the cost and complexity of sensors add little value.

ESC features that matter

- Control method: Choose trapezoidal, sinusoidal, or FOC based on your noise, smoothness, and efficiency goals.

- Protection: Overcurrent, overtemperature, and undervoltage lockout save parts. Soft-start reduces mechanical stress.

- Interface: PWM, analog, CAN, or other fieldbus options. Industrial drives often play in CAN or Ethernet-based ecosystems.

- Tuning: FOC requires current loop tuning and sometimes observer tuning. Good tools make this painless. I look for autotuning or presets that match common motor sizes.

If you build your own ESC, pay attention to gate drive layout, shunt placement, and dead time. Hardware matters as much as firmware when you chase low EMI and low loss.

Maintenance, Failure Modes, and Diagnostics

Brushless doesn’t mean maintenance-free forever. I keep an eye on a few usual suspects.

- Bearings: The most common wear item. Listen for noise. Watch for heat. Vibration analysis can flag bearing wear before failure.

- Overheating: Prolonged overload or insufficient cooling cooks windings and demagnetizes magnets. If a motor runs too hot consider a higher voltage system, better cooling, or a larger motor.

- Insulation breakdown: Spikes from switching and heat age the insulation. Good ESC filtering and proper insulation class help.

- EMI and wiring faults: Poor cable routing or loose connectors cause intermittent faults. Shielded cables and solid grounds prevent weird behavior.

- Diagnostics and predictive maintenance: Back EMF analysis, current signatures, and thermal monitoring reveal problems early. I value ESCs that log faults and temperatures.

When a motor vibrates more than usual I check for:

- Bent shaft or damaged prop/gear

- Debris inside an outrunner can

- Loose housing or cracked mount

- Demagnetization or uneven magnet spacing in rare cases

Fix the root cause fast because vibration shortens bearing life.

The Future: Why Brushless Dominates

Every year I see brushless tech push into new corners:

- Higher power density: Better magnets, improved electrical steel, and smarter cooling raise torque density without a size penalty.

- Cheaper, smarter controllers: Semiconductors keep improving so FOC controllers cost less and deliver more features. That narrows the cost gap with brushed systems.

- Sustainability: Higher efficiency means lower energy bills and less waste heat. Longer life means less maintenance waste.

- Better materials: Advanced laminations, better magnet adhesives, and improved insulation systems push reliability.

As a result brushless motors show up in places they never did before. From compact medical pumps to quiet HVAC drives to high-speed lab centrifuges. The trend looks one-way.

Conclusion: The Brushless Revolution

When I switched that first RC car to brushless the difference felt obvious. I have kept seeing the same pattern in drones, power tools, EVs, and factory floors. Brushless motors trade a simple mechanical commutator for smart electronics. That trade unlocks efficiency, performance, precision, and life. You control torque cleanly. You cut maintenance. You scale from tiny computer fans to multi-megawatt traction drives with the same core principles.

If you remember nothing else, remember this:

- Brushless motors replace brushes with an ESC. That single change boosts efficiency and control.

- BLDC and PMSM live under the brushless umbrella. Trapezoidal, sinusoidal, and FOC control shape noise and smoothness.

- Design details matter. The air gap, winding layout, and quality of laminations shape torque, loss, and heat. If you want to dig deeper into materials and stacking approaches for cores, broader choices in motor core laminations will give you helpful context.

- Pick sensored for smooth starts under load. Pick sensorless for simple high-speed work.

- Keep heat in check. Bearings define life.

Brushless motors are not just a trend. They are the new normal for efficient electric power. Once you use them a while you wonder why you ever accepted the sparks, dust, and drag of brushes.