What Are Eddy Currents? A Comprehensive Guide to Their Principles, Applications, and Impact

Have you ever wondered how a roller coaster stops so smoothly without a screech? Or how a metal detector finds a lost coin on the beach? The answer is a fascinating and invisible force of nature called an eddy current. They are like tiny, powerful whirlpools of electricity that can heat metal, create brakes, and even see through solid objects. This guide will uncover the secrets of these amazing currents, showing you how they work and why they are one of the most useful tools in modern technology.

Table of Contents

- What Exactly is an Eddy Current?

- How Do Eddy Currents Actually Get Created?

- What Makes an Eddy Current Stronger or Weaker?

- How Do We Use Eddy Currents to Keep Us Safe?

- Can Eddy Currents Cook My Food? (Yes, They Can!)

- How Do Eddy Currents Stop a Speeding Train?

- What Are the Good and Bad Sides of Eddy Currents?

- Why Do Motors and Transformers Get Hot and Waste Power?

- How Do We Tame Unwanted Eddy Currents?

- The Amazing Future of This Invisible Force

What Exactly is an Eddy Current?

Imagine stirring a cup of water with a spoon. You see little whirlpools, or eddies, spinning in the water. Now, picture something similar happening with electricity inside a piece of metal. That’s basically an eddy current!

An eddy current is a loop of electrical current that forms inside a conductor, like a piece of copper or aluminum. But instead of water, these are loops of moving electrons. They are also known as Foucault currents, named after the scientist who discovered them.

These currents don’t just appear out of nowhere. They are created when a conductor is exposed to a changing magnetic field. Think of it as a special kind of dance between magnetism and electricity. This relationship is a cornerstone of physics, explained by something called Faraday’s Law of Induction.

How Do Eddy Currents Actually Get Created?

So, what does it take to get these electrical whirlpools spinning? The magic ingredient is change. You need a magnetic field that is changing its strength or position relative to a metal object. This process is called electromagnetic induction.

There are a few ways to make this happen:

No matter how you do it, the result is the same: the changing magnetic flux (the amount of magnetic field passing through a surface) creates an electrical force, pushing electrons to swirl around in loops. And as Lenz’s Law tells us, these eddy currents create their own magnetic field that always pushes back, opposing the original change that created them. It’s like nature trying to keep things in balance.

What Makes an Eddy Current Stronger or Weaker?

Not all eddy currents are created equal. Some are barely there, while others can be powerful enough to melt steel. Several factors determine just how strong these currents become.

- Strength of the Magnetic Field: A stronger magnet or a more powerful electrical coil will create stronger eddy currents. More magnetic muscle means more push on the electrons.

- Speed of Change: The faster the magnetic field changes, the stronger the eddy currents. This means moving the magnet faster or, in an AC system, increasing the frequency of the current. This is why high-frequency induction is so effective for heating.

- Electrical Conductivity: Materials that conduct electricity well, like copper and aluminum, will have much stronger eddy currents than materials that don’t. It’s easier for the electrons to get moving in a good conductor.

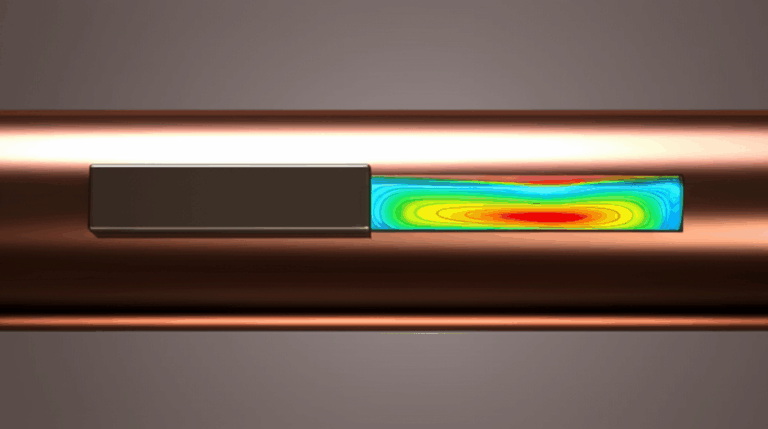

- Material Thickness: A thicker piece of metal provides more room for larger eddy currents to form, making them stronger. However, there’s a catch called the skin effect, where at very high frequencies, the currents tend to stay near the surface of the conductor.

Understanding these factors allows engineers at companies like Siemens and ABB to design systems that either maximize eddy currents for useful tasks or minimize them to prevent problems.

How Do We Use Eddy Currents to Keep Us Safe?

Imagine being responsible for the safety of an airplane. You know that a tiny, invisible crack in a critical part could lead to a disaster. But how can you find it without taking the whole plane apart? This is a huge problem in the aerospace industry and many others. It would be a nightmare to miss something so small yet so dangerous.

This is where eddy current testing (ECT) comes to the rescue. It’s a brilliant form of non-destructive testing (NDT) that uses eddy currents as a superpower to see inside metals. An inspector uses a special tool called an eddy current probe, which contains a coil of wire with an AC current running through it.

When the probe is brought near a metal part, like a wing spar on a Boeing or Airbus plane, it creates a smooth, predictable pattern of eddy currents in the metal. The testing equipment, made by experts like Olympus or GE Inspection Technologies, measures this pattern.

But if there’s a surface defect or a hidden crack, it disrupts the flow of the eddy currents. It’s like a rock in a stream—the water has to flow around it. The equipment immediately detects this change in the electrical whirlpools, alerting the inspector to a potential problem long before it becomes a catastrophe. This technology is essential for ensuring safety in everything from power generation equipment to oil and gas pipelines.

Can Eddy Currents Cook My Food? (Yes, They Can!)

Have you ever seen an induction cooktop? They look sleek and modern, with a smooth glass surface. You can put your hand right next to a boiling pot and feel no heat at all. How is this possible? The answer, once again, is eddy currents!

The problem with old-fashioned stoves is that they waste a lot of energy. A gas flame or a glowing electric coil heats the air, the stovetop, and everything around the pot before it even starts heating your food. This inefficiency costs you money and makes your kitchen hot.

Induction cooktops provide a brilliant solution. Underneath the glass surface is a powerful coil of copper wire. When you turn on the burner, an alternating current flows through this coil, creating a rapidly changing magnetic field.

This magnetic field does nothing to the glass top, which is why it stays cool. But as soon as you place a pot made of a ferromagnetic material (like cast iron or stainless steel) on top, the magic happens. The magnetic field induces massive eddy currents inside the base of the pot. These swirling currents cause Joule heating—also known as resistive heating—which is essentially heat generated by electrical friction. The pot itself becomes the source of heat, cooking your food directly and efficiently. It’s a perfect example of using eddy currents for a specific, powerful purpose.

How Do Eddy Currents Stop a Speeding Train?

Bringing a massive, heavy train or a lightning-fast roller coaster to a smooth, safe stop is a huge engineering challenge. Traditional friction brakes, with pads that clamp down on wheels, can wear out, overheat, and even fail under extreme stress. They create dust, noise, and require constant maintenance.

This is where magnetic braking systems offer a cleaner, safer, and more reliable solution. Instead of physical contact, these brakes use the power of eddy currents.

Here’s how it works: powerful electromagnets are attached to the train or roller coaster car, and a thick, conductive rail (often made of aluminum or copper) is fixed to the track. When it’s time to brake, electricity is sent to the magnets. As the train moves, these strong magnetic fields pass over the conductive rail.

This relative motion induces enormous eddy currents within the rail. According to Lenz’s Law, these eddy currents create their own magnetic field that opposes the motion that created them. This creates a powerful drag force—a form of eddy current damping—that slows the train down smoothly and silently, without any parts ever touching or wearing out. This is why you feel that gentle, consistent braking force at the end of a modern roller coaster ride instead of a sudden jerk. It’s a powerful demonstration of the Lorentz force at work.

What Are the Good and Bad Sides of Eddy Currents?

Like any powerful tool, eddy currents have both amazing benefits and some significant drawbacks. Understanding both sides is key to using them effectively.

| Advantages | Disadvantages |

|---|---|

| Non-Contact Operation: Perfect for braking, sensing, and testing without physical wear and tear. | Energy Losses: They generate unwanted heat in motors and transformers, wasting electricity. |

| High Speed & Precision: Can heat metals in seconds and detect tiny flaws with incredible accuracy. | Skin Effect: At high frequencies, currents stay near the surface, limiting their depth. |

| Clean & Efficient: Induction heating and magnetic braking produce no smoke, dust, or waste products. | Material Limitation: Only work with conductive materials; they’re useless on plastic or ceramic. |

| Detects Hidden Flaws: Advanced techniques can find subsurface flaws that aren’t visible. | Sensitivity Issues: In testing, results can be affected by the distance from the surface (lift-off). |

Why Do Motors and Transformers Get Hot and Waste Power?

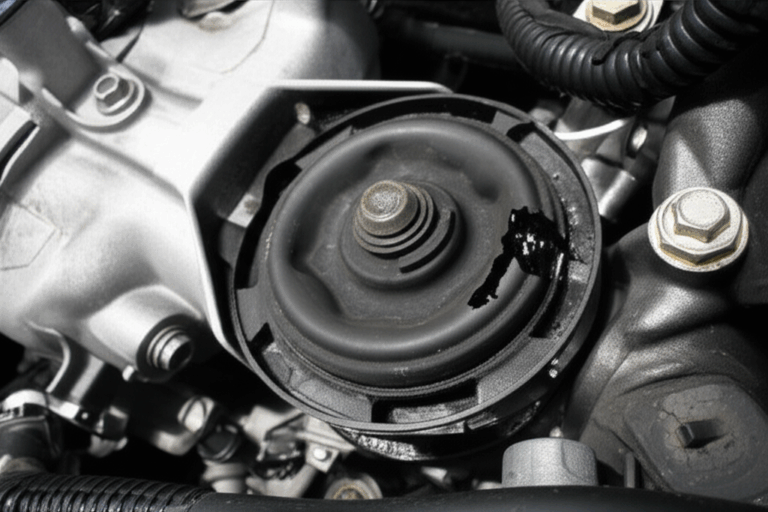

While eddy currents can be incredibly useful, they can also be a massive headache. If you’ve ever felt a power adapter for your laptop or a large motor get warm, you’ve experienced the downside of eddy currents. This heat represents wasted energy, and in large industrial equipment, it can be a huge problem.

In devices like electric motors and transformers, powerful, changing magnetic fields are essential for their operation. These devices have cores made of iron to concentrate the magnetic field lines. The problem is that iron is a conductor. So, as these powerful magnetic fields change, they induce unwanted eddy currents inside the iron core itself.

These swirling currents do nothing to help the motor turn or the transformer transfer power. All they do is generate heat through Joule heating, just like in an induction cooktop. This heat represents a direct loss of energy, reducing the efficiency of the device. A motor that loses 10% of its energy to heat is a motor that costs 10% more to run. For large industrial motors or the transformers that power our cities, this wasted energy can add up to millions of dollars and contribute to unnecessary carbon emissions. The challenge for engineers is to keep the helpful magnetic fields while getting rid of the wasteful eddy currents.

How Do We Tame Unwanted Eddy Currents?

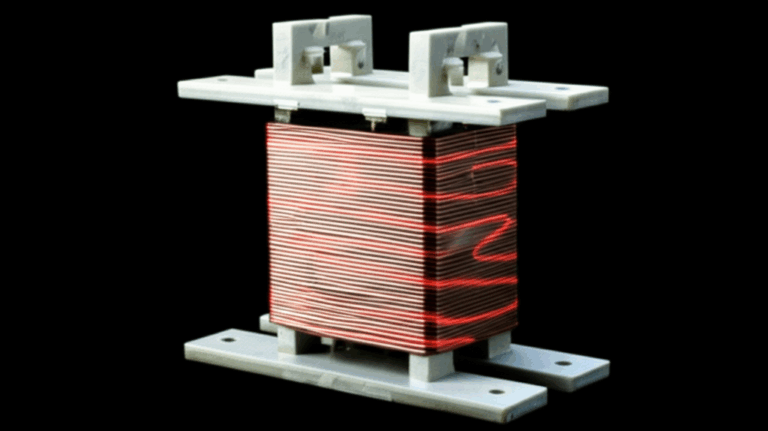

So, how do you solve the problem of energy-wasting eddy currents? You can’t just get rid of the iron core, because it’s crucial for the device to work. The solution, developed over a century ago, is elegantly simple: you slice it up.

Instead of using a solid block of iron, engineers build cores from many thin sheets of electrical steel, each one insulated from the next with a thin layer of varnish or oxide. This construction is called a laminated core. By dividing the core into these thin slices, you break up the path for large eddy currents. They can still form, but only as tiny, weak whirlpools within each individual lamination.

These smaller currents generate far less heat, dramatically reducing energy loss. This is why if you look closely at a disassembled motor or a large transformer lamination core, you’ll see it’s made of hundreds of these stacked plates. Companies that specialize in high-quality motor core laminations are essential to the efficiency of the modern world, helping build everything from tiny drone motors to massive power plant generators. Using high-grade materials like silicon steel laminations further reduces losses, ensuring that as much electrical energy as possible is used for work, not wasted as heat. This simple but brilliant innovation is one of the most important in the history of electrical engineering.

The Amazing Future of This Invisible Force

From cooking our food to stopping roller coasters and inspecting critical parts of airplanes, eddy currents are a powerful and versatile phenomenon. They are a perfect example of how a deep understanding of physics, from Maxwell’s equations to Faraday’s Law, can be harnessed to solve real-world problems.

The technology continues to evolve. Eddy current array (ECA) probes now use multiple coils to create a detailed, 2D map of a surface in a single pass, making inspections faster and more accurate than ever. New techniques like pulsed eddy current (PEC) are allowing inspectors to “see” through insulation and coatings. And in the world of recycling, powerful eddy current separators use magnetic fields to literally fling aluminum cans and other non-ferrous metals out of a stream of mixed waste, making recycling more efficient.

As our world becomes more reliant on electricity and advanced materials, the role of eddy currents in technology, from Maglev trains to sensitive vibration monitoring systems, will only continue to grow. This invisible force is all around us, working silently to make our lives safer, more efficient, and more technologically advanced.

Key Takeaways to Remember:

- What they are: Eddy currents are loops of electrical current created in a conductor by a changing magnetic field.

- How they work: They are governed by Faraday’s Law of Induction and Lenz’s Law.

- Good uses: They are vital for non-destructive testing (NDT), induction heating, magnetic braking, and metal detectors.

- Bad effects: They cause energy loss and unwanted heating in transformers, motors, and generators.

- How to control them: Unwanted eddy currents are minimized by using laminated cores made of thin, insulated sheets of electrical steel.