What Are Eddy Currents and How Do They Power Your World?

Have you ever wondered how a roller coaster stops so smoothly and safely without any screeching brakes? Or how airport security can spot a metal object in your bag without even opening it? It might seem like magic, but it’s actually a fascinating force of nature called an eddy current. Understanding this invisible power can feel like a big puzzle, but when you see how it works, you’ll find it’s part of countless things that make our lives safer, faster, and more efficient. Stick with me, and I’ll show you the incredible world of eddy currents in a way that’s easy to grasp.

Table of Contents

So, What Exactly Is an Eddy Current?

Let’s start with the basics. Imagine stirring a cup of water with a spoon. You create little whirlpools, right? An eddy current is kind of like that, but with electricity instead of water. When you move a magnet near a piece of metal, like aluminum or copper, it creates tiny, swirling currents of electricity inside that metal. This amazing trick is thanks to a science rule called Faraday’s Law of Induction.

But here’s the cool part. These little electrical whirlpools don’t just spin around doing nothing. They create their own tiny magnetic fields. And thanks to another rule called Lenz’s Law, these new magnetic fields push back against the original magnet. It’s like they’re saying, “Hey, stop changing things!” This pushing and pulling is what makes eddy currents so incredibly useful. We can use them to find problems, create heat, or even put the brakes on a speeding train. It all starts with a simple magnet and a piece of metal.

How Do We Use Eddy Currents to Keep Things Safe?

One of the most important jobs for eddy currents is finding tiny problems in metal parts before they become big, dangerous ones. This is called Non-Destructive Testing (NDT). Think about it: you can’t just cut open an airplane wing to see if it’s okay inside. That would wreck the wing! You need a way to check it without harming it. That’s where eddy current testing (ECT) comes in. It’s a superstar in the world of NDT techniques comparison.

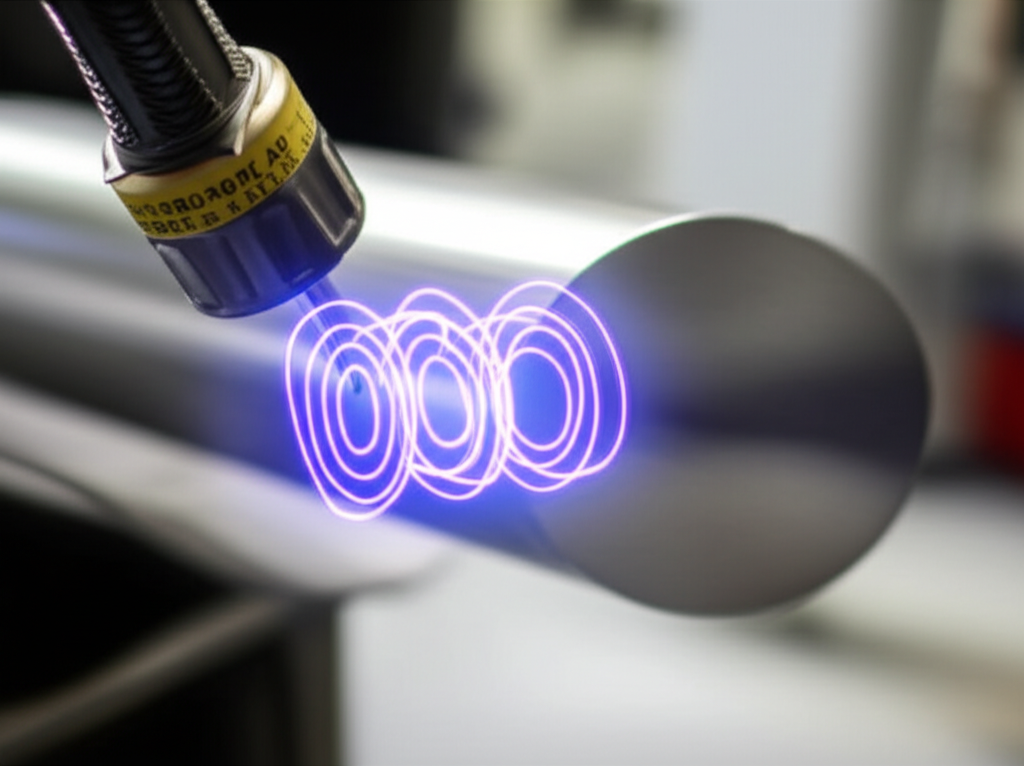

Imagine an engineer inspecting a critical part of a power plant. They’re worried about tiny cracks or material degradation that could cause a huge failure. It’s a massive headache because these flaws are often invisible. This is where the solution comes in. The engineer can use a special tool called an eddy current probe. This probe creates a magnetic field and sends those little eddy currents swirling through the metal. If the metal is perfect, the currents flow smoothly. But if there’s a crack, a spot of corrosion, or any other subsurface defects, it disrupts the flow. The probe detects this change and alerts the technician. This method is crucial for ensuring structural integrity in everything from bridges to roller coasters.

Can an Eddy Current Really Find a Crack I Can’t See?

Absolutely! This is where eddy current technology truly shines, especially in the aerospace industry and automotive industry. Imagine a giant airplane flying miles above the ground. Its parts are under a lot of stress, and a tiny crack could grow into a major problem. Pilots and passengers are counting on that plane being perfectly safe. The fear of a hidden flaw going unnoticed is a huge concern.

That’s why inspectors regularly use eddy current inspection equipment to scan the plane’s skin, wings, and even the tiny holes where rivets go. The probe can find a fatigue crack that’s smaller than a human hair. They do the same thing for high-performance car parts, railway wheel inspection, and pipeline inspection. By detecting these problems early, they prevent accidents and save lives. It’s a powerful tool for quality assurance and preventive maintenance. Many people don’t realize that this technology is a quiet guardian, working behind the scenes to keep us all safe.

Is Finding Flaws All Eddy Currents Can Do?

Finding cracks is a big deal, but eddy currents are far more versatile than that. They are also masters of material characterization. Have you ever wondered how a factory can be sure they’re using the right type of metal? A simple mix-up could be disastrous. For example, if the wrong aluminum alloy is used in an airplane wing, it might not be strong enough. This is a constant worry in manufacturing quality control.

Eddy currents solve this problem beautifully. Since different metals and alloys conduct electricity differently, an eddy current probe can instantly tell them apart. This is called conductivity measurement. It can even be used for heat treatment verification to make sure a metal part has been properly hardened. Technicians also use it for thickness measurement, checking how thick a layer of paint is or even measuring the wall thickness of a pipe to spot pitting or wear. For any part made of conductive materials, from simple sheets to complex stator core lamination, this technology is a go-to for checking quality without leaving a mark.

How Do Roller Coasters Stop So Smoothly?

If you’ve ever been on a modern roller coaster, you might have noticed how it glides to a smooth, silent stop at the end of the ride. There’s no squealing of brake pads. That’s the magic of electromagnetic braking, and it’s all thanks to eddy currents.

Here’s how it works: powerful magnets are placed along the track, and a metal fin is attached to the bottom of the roller coaster train. As the train zooms past the magnets, strong eddy currents are created in the fin. Remember Lenz’s Law? These currents create their own magnetic fields that push back against the magnets on the track. This creates a powerful braking force that slows the train down quickly and smoothly, all without any physical contact. There are no parts to wear out, which makes it incredibly reliable. This same principle is used in some high-speed trains and in devices called eddy current dynamometers, which are used to test engines.

Can You Really Cook with Magnets? The Magic of Induction Heating

Have you ever seen a modern stovetop that doesn’t get hot to the touch but can boil a pot of water in seconds? That’s induction heating, and you guessed it—it uses eddy currents! It’s a fantastic way to improve thermal efficiency and energy efficiency in the kitchen.

Underneath the glass surface of an induction cooktop is a powerful electromagnet. When you turn it on, this magnet creates a rapidly changing magnetic field. If you place a pot made of a magnetic material like cast iron or some types of stainless steel on the cooktop, this field generates strong eddy currents in the bottom of the pot. These swirling currents create a lot of heat directly in the pot itself, not on the cooktop surface. This is why the pot gets hot while the stovetop stays cool. This technology isn’t just for cooking; industries use massive induction furnaces for soldering, brazing, and even melting huge quantities of metal for forging.

Why Do Metal Detectors Beep at the Airport?

The beeping of a metal detector is a sound we all know. It’s a key part of our security applications. Whether you’re at the airport, a concert, or a courthouse, these devices are there to find hidden metal objects. The problem they solve is obvious: how to quickly check thousands of people for dangerous items without a physical search every time.

A metal detector works by sending out an alternating current (AC) through a coil probe, which creates a magnetic field. When you walk through, this magnetic field passes through you. If you’re not carrying any metal, nothing happens. But if you have a coin, keys, or something else made of metal in your pocket, that metal disrupts the magnetic field. The eddy currents created in the metal object create their own tiny opposing magnetic field. The detector’s receiver picks up on this change instantly and sounds the alarm. It’s a simple, effective, and non-contact way to keep places secure.

How Can We Sort Trash with Invisible Forces?

Recycling is incredibly important for our planet, but sorting different materials can be a huge, messy job. Think about a giant pile of mixed waste—how do you quickly pull out all the valuable aluminum cans? Doing it by hand is slow and expensive. This is where an eddy current separator comes to the rescue.

These amazing machines are a cornerstone of the recycling industry. Here’s the trick: waste moves along a conveyor belt that has a rapidly spinning magnetic rotor underneath it. As non-ferrous metals like aluminum cans pass over the spinning magnet, strong eddy currents are induced in them. This creates a powerful repelling force that literally flings the aluminum cans off the conveyor belt and into a separate collection bin. Other materials, like plastic and paper, aren’t affected and just fall off the end. This allows for the efficient and automated waste sorting and precious metal recovery that modern recycling depends on.

What Kind of Tools Do Experts Use for This?

To get the most out of eddy currents, you need some pretty sophisticated equipment. It’s not just a simple magnet on a stick. NDT technicians use advanced eddy current instrumentation to do their jobs. The main tool is a probe, which can come in many shapes and sizes. There are tiny pencil probes for inspecting a single fastener hole and larger encircling probes that a pipe or rod can pass through. The choice of probe types depends entirely on the job.

The signals from the probe are sent to a device with a screen that displays the information, often on what’s called an impedance plane display. An experienced technician can look at the squiggles and dots on the screen and understand exactly what’s happening inside the material. This signal interpretation requires a lot of training and skill, often leading to NDT certification. To ensure accuracy, technicians must use calibration standards—perfect pieces of metal with precisely made flaws—to set up their equipment before every inspection. Companies like Siemens, General Electric, and specialized firms like Olympus Corporation and Eddyfi Technologies are leaders in making this high-tech gear.

What’s Next for Eddy Current Technology?

The world of eddy currents is not standing still. Researchers and engineers are always coming up with new and better ways to use this technology. One of the most exciting developments is the eddy current array (ECA). Instead of using a single coil in a probe, an ECA probe has many coils arranged in a pattern. This allows it to scan a much wider area in a single pass, making inspections much faster. Imagine scanning an entire aircraft wing in a fraction of the time it used to take!

We’re also seeing more automated inspection systems. Robots and drones equipped with eddy current sensors can now inspect dangerous or hard-to-reach places, like the inside of a nuclear reactor’s steam generator tubes or the top of a giant storage tank. Furthermore, pulsed eddy current (PEC) and remote field eddy current (RFEC) techniques are pushing the boundaries, allowing inspectors to “see” deeper into materials and even inspect through coatings or insulation. By combining these advanced tools with artificial intelligence (AI) for better data acquisition and analysis, the future of eddy currents looks brighter than ever, promising even greater safety and efficiency for asset integrity management. These tools, along with a deeper understanding of the stator and rotor relationship in motors, continue to push engineering forward.

In Conclusion: Your World, Powered by Eddies

So, the next time you step onto a roller coaster, go through a security checkpoint, or even just cook on a modern stove, take a moment to think about the invisible forces at work. Eddy currents are a perfect example of how a simple principle of physics—electromagnetism—can be harnessed in countless brilliant ways.

- Safety First: From airplanes to bridges, eddy current testing is a silent guardian that finds tiny flaws before they become big disasters.

- Smooth and Strong: They provide powerful, wear-free braking for everything from high-speed trains to theme park rides.

- Hot in a Hurry: Induction heating uses eddy currents to cook our food and forge metal with incredible speed and efficiency.

- Clean and Green: They are essential for the recycling industry, automatically sorting metals to help protect our planet.

- Always Improving: With new technologies like array probes and AI, the applications for eddy currents will only continue to grow.

They are a testament to human ingenuity, turning a simple scientific curiosity into tools that shape and safeguard our modern world.