What Are Energy Efficient Motors? Your Comprehensive Guide to Savings & Sustainability

Have you ever looked at your company’s power bill and felt a little shock? A huge chunk of that bill comes from electric motors. They are the hidden workhorses in our world, running everything from fans to factory machines. The problem is, older motors are like leaky buckets, wasting tons of energy and money. This guide will show you how a special kind of motor, the energy-efficient motor, can fix that leak. You’ll learn how they save you a fortune, help the planet, and make your business run smoother than ever before.

Table of Contents

- What’s the Big Deal with Energy Efficient Motors?

- How Do These Motors Actually Save Energy?

- What Do All These Codes Mean? (IE3, IE4, NEMA Premium)

- What Are the Real-World Benefits for Me?

- Are There Different Kinds of Efficient Motors?

- What is a Variable Frequency Drive (VFD)?

- Where Can I Use These Super Motors?

- How Do I Choose the Right Motor?

- Can’t I Just Rewind My Old Motor Instead of Replacing It?

- Your Next Step to a Smarter, Greener Future

What’s the Big Deal with Energy Efficient Motors?

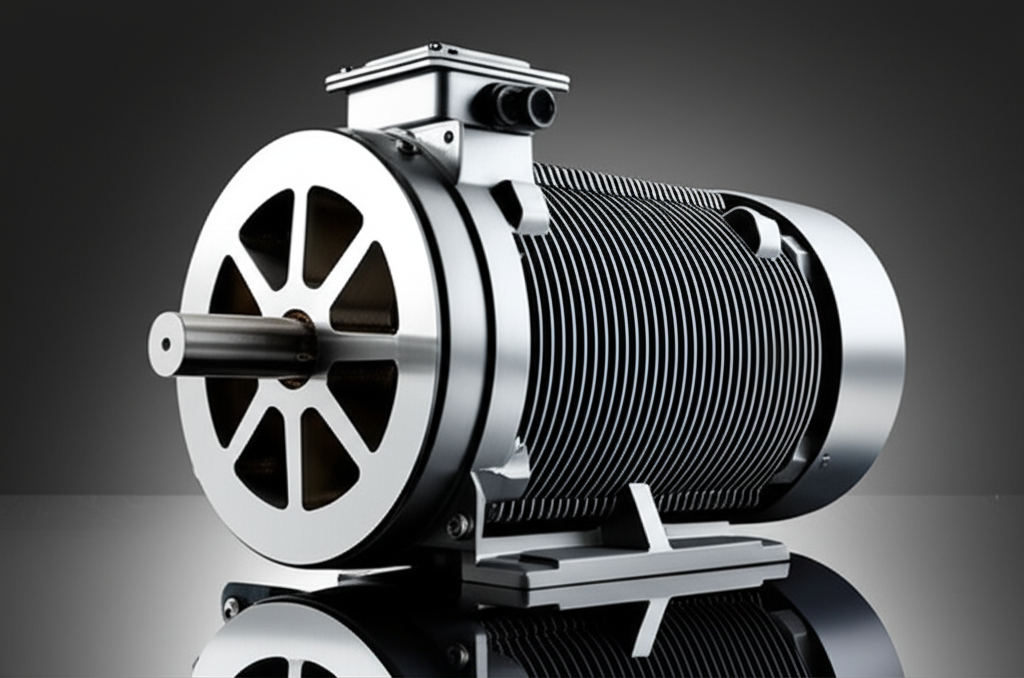

So, what is an energy-efficient motor? Think of it this way. A regular, standard motor does a job but wastes a lot of electricity as heat. You can feel it when you touch an old motor; it’s hot! An energy-efficient motor is designed to do the same job but with much less waste. It turns more electricity into useful work and less into useless heat.

This is a huge deal. Why? Because experts at the International Energy Agency (IEA) say that electric motors use almost half of all the electricity in the world! In factories and big buildings, that number is even higher. When so much power is being used, even a small improvement in efficiency can lead to giant savings. Using high-efficiency motors is one of the easiest ways for a business to reduce operating costs and lower its carbon footprint. It’s a simple change that makes a massive difference.

How Do These Motors Actually Save Energy?

You might be wondering what makes these motors so special. It’s not magic; it’s just smarter design and better materials. Imagine trying to run a race wearing heavy boots. You’d get tired and waste a lot of energy. A standard motor is like that runner. An energy-efficient motor is like a runner with lightweight, high-tech shoes. It’s built to win the race against energy waste.

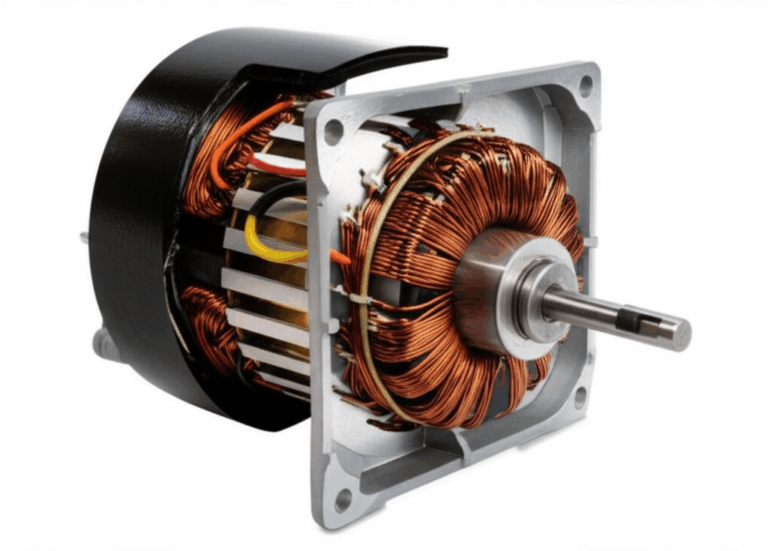

Engineers at companies like Siemens, ABB, and WEG have made key improvements. First, they use higher-quality materials. This includes thinner, better-grade steel for the stator core lamination, which reduces energy loss from magnetism. They also pack in more copper wires, making it easier for electricity to flow. This lowers electrical resistance, kind of like turning a narrow pipe into a wide one so more water can get through easily.

Second, the design itself is better. The parts are made with incredible precision. The tiny air gap between the spinning part (the rotor) and the stationary part (the stator) is optimized. Better bearings are used to reduce friction, and a smarter fan design reduces the energy needed to cool the motor. All these small changes add up to big energy consumption reduction. They are simply built to lose less energy to heat, friction, and electrical resistance.

What Do All These Codes Mean? (IE3, IE4, NEMA Premium)

When you start looking at motors, you’ll see codes like IE3, IE4, or NEMA Premium Efficiency. It sounds confusing, but it’s actually simple. These are just like energy ratings for your refrigerator or TV. They tell you how efficient the motor is. A higher number is better.

The most common system in the world comes from the IEC (International Electrotechnical Commission). They have different efficiency classes:

- IE1 (Standard Efficiency): This is the baseline, the old-school motor.

- IE2 (High Efficiency): Better than IE1, but now considered old technology in many places.

- IE3 (Premium Efficiency): This is the new standard in many countries, including those following the EU Ecodesign Directive. It offers great savings.

- IE4 (Super Premium Efficiency): Even better than IE3. These motors provide excellent performance and faster payback.

- IE5 (Ultra Premium Efficiency): The best of the best! These often use advanced technology like Permanent Magnet Synchronous Motors (PMSM) to reach incredible efficiency levels.

In North America, you’ll often see the NEMA (National Electrical Manufacturers Association) rating. Their “NEMA Premium” class is very similar to the IEC’s IE3 class. The important thing to know is that governments all over the world, including the U.S. Department of Energy (DOE), have created motor regulations that require new motors to meet these high standards.

Here’s a simple way to think about it for a common 20 HP motor:

| Efficiency Class | What it Means | Typical Efficiency |

|---|---|---|

| IE1 | Standard (Old) | ~88% |

| IE2 | High | ~90% |

| IE3 / NEMA Premium | Premium (Good Choice!) | ~91.5% |

| IE4 | Super Premium | ~93% |

| IE5 | Ultra Premium (Best) | ~94.5% |

That small difference of a few percentage points saves thousands of dollars over the motor’s life.

What Are the Real-World Benefits for Me?

This is the most important question, right? It’s great that these motors are fancy, but what’s in it for you? The benefits are huge and fall into three main areas.

First is the most obvious: significant energy cost savings. Switching to an IE3 motor can cut that motor’s energy use by 3-10%. That might not sound like much, but for a motor that runs all day, every day, the savings add up fast. Most companies find that the motor payback period is just 1 to 3 years. After that, it’s pure profit! When you look at the Total Cost of Ownership (TCO), the small extra price for an efficient motor is tiny compared to the lifetime of energy savings. For example, a wastewater plant swapped its old pump motors for IE3 motors and cut its electricity use by 38%. That saved them $95,000 a year!

Second, you’ll see a big environmental impact reduction. Using less electricity means your local power plant burns less fuel. This directly lowers your company’s carbon footprint and helps you meet sustainability goals. Replacing just one old 100 kW motor can be like taking several cars off the road each year. It’s a powerful way to show your customers and community that you care about being a “green” business.

Third, you get enhanced operational performance. Because these motors run cooler, they last longer. The parts inside don’t wear out as fast, which means increased reliability and a longer motor lifespan. This leads to less downtime for repairs and reduced maintenance costs. They also tend to be quieter and have less vibration, which makes for a better and safer work environment.

Are There Different Kinds of Efficient Motors?

Yes! While they all aim to save energy, they do it in slightly different ways. There are a few main types of energy-efficient motors you’ll run into.

The most common is the Premium Efficiency Induction Motor. This is the classic workhorse of the industry, but it has been redesigned with all the improvements we talked about—better steel, more copper, and tighter tolerances. They are reliable and a great choice for many jobs. They are a direct replacement for older, standard induction motors.

Then you have the more advanced types. Permanent Magnet Synchronous Motors (PMSM) are a great example. They have powerful magnets built right into the rotor. This design makes them incredibly efficient, especially when the motor isn’t running at full speed. They are a bit like the engine in a hybrid car—super efficient.

Another cool type is the Synchronous Reluctance Motor (SynRM). These are very clever. The rotor is made of special layered steel with no magnets or wires at all. This simple, rugged design makes them very efficient and reliable. Plus, they don’t use rare-earth magnets, which can be expensive and hard to get. Both PMSM and SynRM motors require a special controller to work, which brings us to our next point.

What is a Variable Frequency Drive (VFD)?

I’ve mentioned it a few times, but what is a Variable Frequency Drive (VFD)? A VFD, sometimes called an inverter, is a motor’s best friend. Think of it as a smart gas pedal or a dimmer switch for your motor. A standard motor only knows two speeds: OFF and FULL BLAST. But many jobs, like a fan or a pump, don’t always need to run at 100% power.

A VFD allows you to precisely control the motor’s speed. If you only need 80% airflow from a fan, you can use the VFD to slow the motor down to 80% speed. This saves an incredible amount of energy. According to the “Fan Laws” in physics, slowing a fan down by just 20% can cut its energy use in half!

Pairing a high-efficiency motor with a VFD is the ultimate combo for energy savings, especially in applications like HVAC motors and pump systems. The VFD handles the speed control, and the efficient motor makes sure that whatever energy is used, it’s not wasted. This combination can lead to energy savings of 50% or more.

Where Can I Use These Super Motors?

You can use energy-efficient motors almost anywhere you’d use a standard motor. They are perfect for jobs that require long run times, where the energy savings can really pile up.

Here are some of the most common applications:

- Pumps and Pumping Systems: Moving water, chemicals, or other fluids. This is a huge area for savings.

- Fans and HVAC Systems: The fans that provide ventilation and air conditioning in buildings are perfect candidates.

- Compressors: Providing compressed air for tools and factory processes. Compressor motor efficiency is critical.

- Conveyors: Moving products along an assembly line or in a warehouse.

- Manufacturing Machines: Powering everything from grinders to mixers in industrial automation.

Basically, if you have a motor that runs for more than a couple of hours a day, you should think about an electric motor upgrade. The more it runs, the faster a new, efficient motor will pay for itself.

How Do I Choose the Right Motor?

Choosing the right motor doesn’t have to be complicated. You just need to ask a few simple questions. First, what is the job? Does it need to run at a constant speed or does the load change? For jobs with changing loads, a motor paired with a VFD is almost always the best answer.

Next, look at the efficiency rating. Today, you should be looking for a motor that is at least IE3 (NEMA Premium). If the motor will be running nearly 24/7, investing in an IE4 or even an IE5 motor can have a very fast payback. The higher initial cost is quickly erased by the much lower electricity bills.

Finally, think about the Total Cost of Ownership (TCO), not just the sticker price. A cheaper, less efficient motor will cost you far more in the long run. Many utility companies and government agencies offer government incentives for EE motors, like rebates, that can lower the purchase price. Ask your motor supplier or local power company about these programs.

Can’t I Just Rewind My Old Motor Instead of Replacing It?

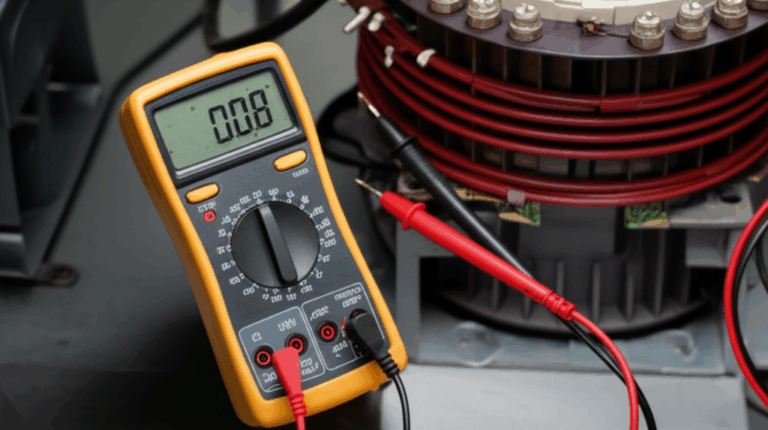

This is a common question. When a motor fails, your first thought might be to send it to a shop for a rewind. While motor rewinding can get a motor running again, it often comes at a cost to efficiency. The process can damage the core of the motor, increasing energy losses. A poorly done rewind can lower a motor’s efficiency by several percentage points.

If an old, standard-efficiency motor fails, it almost never makes financial sense to repair it. The cost of the wasted energy will quickly add up to more than the cost of a brand-new, high-efficiency motor. A modern motor is built with superior motor core laminations from the start, materials that can be damaged during the high-heat rewind process. Replacing it is a smarter investment that starts paying you back from day one.

Your Next Step to a Smarter, Greener Future

Energy-efficient motors are not just a trend; they are a fundamental part of modern, responsible business. They are a proven solution to the problem of high energy costs and environmental impact. By turning wasted electricity into productive work, they improve your bottom line, boost your operational reliability, and help you build a more sustainable future.

The next time you walk through your facility, listen for the hum of your electric motors. Each one is an opportunity. It’s an opportunity to cut costs, reduce waste, and make a smart investment that pays dividends for years to come. Evaluating your current motors and planning for an upgrade is one of the most powerful financial and environmental decisions you can make.

Key Things to Remember

- Energy-efficient motors save money by turning more electricity into useful work and less into wasted heat.

- Efficiency ratings like IE3, IE4, and NEMA Premium help you choose the best motor. Higher is better.

- The main benefits are lower electricity bills, a smaller carbon footprint, and longer motor life with less maintenance.

- Pairing an efficient motor with a Variable Frequency Drive (VFD) provides the biggest energy savings for applications like fans and pumps.

- Always consider the Total Cost of Ownership (TCO). The energy savings will quickly pay for the higher initial price of a better motor.