What Causes Motor Mounts to Go Bad? Understanding Engine Mount Failure and Prevention

Table of contents

- Introduction: The unsung heroes under your hood

- What are motor mounts and why do they matter

- The primary causes of motor mount failure

- Age and general wear and tear

- Exposure to harmful fluids and elements

- Driving habits and vehicle use

- Impact and trauma

- Manufacturing defects or poor quality parts

- Improper installation or maintenance

- Common symptoms of bad motor mounts

- What happens if you ignore failing mounts

- How I diagnose bad motor mounts step by step

- Preventing premature motor mount failure

- Special cases and advanced tech: hydraulic and active mounts, manual vs automatic, EV notes

- Quick answers to common questions

- Conclusion: Protect your mounts, protect your ride

Introduction: The unsung heroes under your hood

When someone asks me what causes motor mounts to go bad I start with a simple truth. Motor mounts live a hard life. They sit quietly in the engine bay soaking up vibration and torque load every time you start the car, shift gears, hammer the throttle, or roll over a pothole. They rarely get attention until they fail. Then they shout through the cabin with vibration, clunks, and that uneasy feeling that the engine is dancing in place.

I have replaced more mounts than I can count on cars, trucks, and SUVs. Some died from old age. Some from oil and coolant leaks. A few from enthusiastic owners who loved hard launches and spirited shifting. Along the way I learned the patterns. In this guide I will walk you through the real causes of engine mount failure, how to spot the signs, and what you can do to avoid premature damage.

What are motor mounts and why do they matter

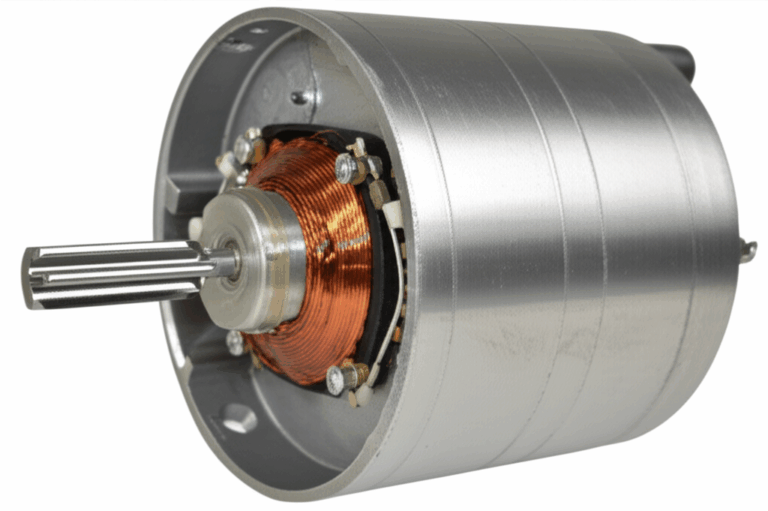

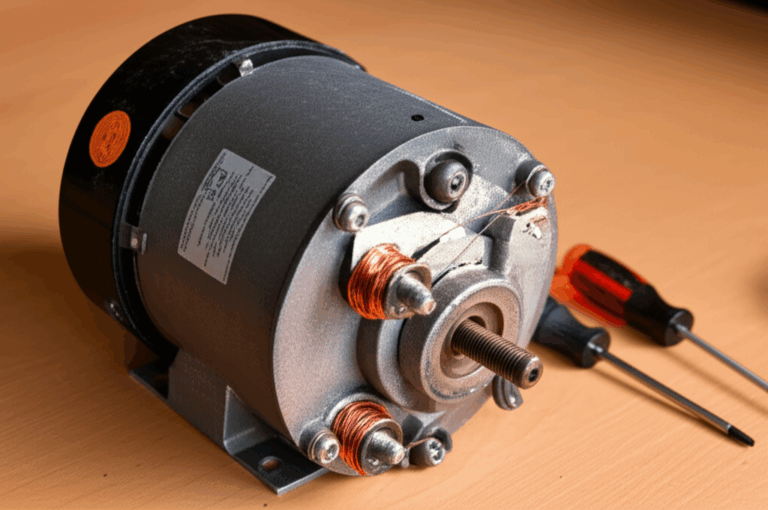

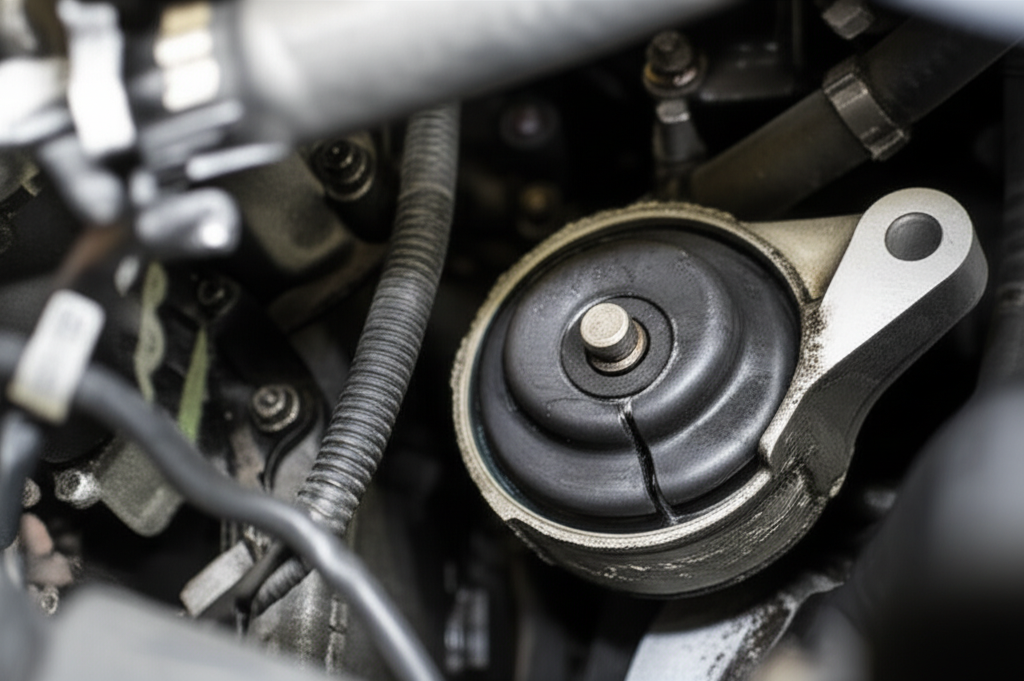

A motor mount (or engine mount) is a structural link between the engine or transmission and the chassis. Most vehicles use several mounts. A typical setup includes two side engine mounts and one rear or front mount near the transmission. Some platforms use a torque strut or dogbone mount to limit engine rocking under load. The purpose of motor mounts is simple. They secure the powertrain and isolate NVH (noise, vibration, harshness) so you feel less of the engine’s shake.

Most modern mounts combine metal brackets with either rubber bushings or hydraulic, fluid-filled chambers. Rubber and fluid act like shock absorbers for engine movement. They filter out engine vibration and limit engine lurch when you accelerate, brake, or shift. Transmission mounts play the same role for the transmission. A worn transmission mount can cause symptoms that look like engine problems, so I always check both.

The primary causes of motor mount failure

I group the reasons mounts go bad into six buckets. Age, fluid and heat exposure, driving style and use, impact damage, part quality, and installation or maintenance issues. Let’s unpack each one.

Age and general wear and tear

- Rubber degradation

Rubber breaks down with time. It dries out, cracks, or hardens. In hot climates rubber can soften and sag instead. Either way the bushing loses its ability to absorb vibration. I often see dry rot on older vehicles where the rubber shows surface cracking and tiny splits near the seams. If a mount flexes beyond its normal range the rubber tears. That tear quickly grows.

- Material fatigue

Even metal gets tired. The mount’s steel or aluminum shell and its bonded rubber insert see constant stress from engine torque. That cyclical loading causes material fatigue. Over years the bond between rubber and metal can separate, or the shell can develop stress fractures. I have caught cracked motor mount housings during routine inspections on high-mileage cars. They looked fine at a glance yet the crack widened under throttle.

- Lifespan expectancy

In my experience OEM rubber mounts last 5 to 10 years or roughly 60,000 to 100,000 miles under normal use. High mileage, lots of heat, or frequent towing can shorten that. Hydraulic motor mounts with fluid-filled chambers can last a similar range, yet when they fail they often fail fast.

Exposure to harmful fluids and elements

- Oil leaks and transmission fluid

Oil is rubber’s worst enemy in this context. An oil leak that drips onto a mount soaks into the rubber. It swells and softens the material, then the mount loses strength and tears under load. I have seen premature motor mount failure within a year on engines with persistent valve cover or oil pan leaks. Transmission fluid can do the same to transmission mounts.

- Coolant leaks

Coolant can damage rubber compounds as well. A small seep from a water pump or hose can run down the block and bathe a mount. That constant exposure degrades the rubber. If the mount is hydraulic, coolant or oil can also attack the external boot or seal, which leads to fluid leaking from the motor mount.

- Road chemicals and corrosion

Road salt and caustic cleaners promote corrosion on mount brackets and bolts. Corrosion weakens hardware, so bolt failure becomes possible, especially in rust-belt regions. When the mount hardware loses clamping force the engine shifts, which accelerates rubber tearing and bushing damage.

- Extreme heat

Heat exposure is a quiet killer. Mounts near exhaust manifolds or downpipes see higher temperatures. Rubber oxidizes faster at high heat. The mount hardens and transmits more vibration. On turbocharged engines I often find the mount closest to the turbo fails first. Heat shields can help. So can addressing exhaust leaks that turn the engine bay into a hot box.

Driving habits and vehicle use

- Aggressive driving

Hard launches, abrupt throttle inputs, and late braking all multiply engine torque reaction. That torque twist hammers the mounts. I have watched an engine rock in the bay like a metronome while a driver practiced clutch dumps. It is fun until it tears the rubber. Aggressive driving can cause premature motor mount failure well before the expected lifespan.

- Frequent heavy loads or towing

Towing and hauling push more torque through the powertrain. That added stress stretches the mount’s limits. Heavy-duty motor mounts exist for a reason. If you tow often consider mounts designed for that load.

- Rough roads and off-roading

Driving on rough roads, washboard surfaces, or off-road trails shakes everything. The mounts fight constant vibration and impact. Off-road motor mount stress shows up as stress cracks in the shell or bond failures in the rubber. I often see this on trucks used for construction work or trail rigs.

- Stop-and-go traffic

City driving creates constant torque changes. On-off throttle movement, frequent shifting, and repeated engine rocking fatigue the mounts. The wear builds slowly then shows up all at once as a clunk.

Impact and trauma

- Accidents and collisions

A minor fender bender can shift the powertrain just enough to tear a mount. A bigger crash can crack a mount housing or bend the bracket. After any collision I check the mounts even if they were not the focus of the repair.

- Potholes and curbs

One nasty pothole can do it. If a wheel slams hard, the jolt can travel through the subframe and shock the mounts. I once inspected a car with a loud thud over bumps. The driver hit a curb the week before. The impact cracked the front engine mount’s metal ear. The thud was the engine dropping against the remaining rubber.

Manufacturing defects or poor quality parts

- Inferior materials

Cheap motor mount issues show up sooner than you think. Some aftermarket parts use softer rubber or inconsistent bonding. I have replaced low-cost mounts that collapsed in months. OEM vs aftermarket motor mounts is a real decision. Quality aftermarket brands exist, yet I avoid no-name parts with vague specs.

- Design flaws and factory defects

Certain model years carry a known weak mount design. I do not call out brands, but I have seen specific car model motor mount issues repeat. In those cases an upgraded mount or revised OEM part solves the problem. Factory defect motor mount failures usually show up under warranty or soon after.

Improper installation or maintenance

- Wrong torque specs

Mounts need correct clamping force. If a technician under-tightens the bolts, the mount can shift. Over-tightening can crush bushings or strip threads. Always follow the engine mount torque specs. I torque the fasteners with the engine supported at ride height to prevent preloading the rubber.

- Damage during installation

Prying against the rubber, nicking the seal on a hydraulic mount, or cross-threading a bolt can shorten a mount’s life. Take your time and use the right tools.

- Wrong type of mount

Using a racing motor mount on a daily driver can raise NVH to annoying levels. Using a cushy mount on a high torque build can let the engine move too much. Choose the right mount for the use case.

Common symptoms of bad motor mounts

When mounts fail they talk. Here are the bad motor mount symptoms I see most often.

- Excessive engine vibration

You feel it in the seat, in the steering wheel, or in the floor. A rough idle with the shifter in gear points to a collapsed mount. Constant vibration in the car can also come from misfire or balance issues, so diagnose carefully.

- Clunking or banging noises

Listen for a clunking noise when accelerating or decelerating. You may also hear a thud when shifting or rolling over a bump. That is the engine or transmission moving against the stops.

- Engine lurching or rocking

If the engine lurches when shifting or you see it rock hard when you blip the throttle, a mount is likely torn. Open the hood with the parking brake set, then watch the engine as a helper shifts from drive to reverse. Excessive engine movement is a giveaway.

- Visible damage

Cracked rubber, separated bonding, or a cracked motor mount housing is obvious. On hydraulic mounts look for fluid leaking from the motor mount. It may look like oil yet smell different.

- Transmission behavior

Worn transmission mount symptoms include harsh shifts or a thunk as the driveline loads and unloads. The mount allows the trans to rotate which makes the shift feel sloppy.

What happens if you ignore failing mounts

You can drive with bad motor mounts for a while. You may not want to.

- Damage to other parts

A loose powertrain stresses the exhaust system, flex joints, and hangers. It tugs on hoses, wiring, and gaskets. I have seen split radiator hoses and cracked exhaust manifolds from excessive movement. Driveshaft vibration can show up if the powertrain shifts far enough to alter alignment. Over time the wear reaches control arms, ball joints, and struts because of the added shock.

- Reduced comfort and safety

The car shakes more. The cabin feels harsh. A hard stop can send the engine forward and backward which can be unsafe if a mount fails fully. In extreme cases the engine cradle and surrounding brackets take the hit.

- Higher repair cost

Ignoring a $150 to $400 mount can turn into a four-figure exhaust or axle repair. I watch budgets and I do not like preventable expenses.

How I diagnose bad motor mounts step by step

I keep the process simple and consistent.

1) Start with the complaint

Is it an engine vibration cause at idle, a clunk on acceleration, or a thud over bumps. I note when the symptom happens. Under load. At idle. Only during shifting. That timing matters.

2) Rule out engine tune issues

A misfire from a spark plug, coil, or fuel injector can mimic mount problems. So can a bad harmonic balancer. I check for codes. I listen to idle quality. If the engine runs rough, mounts will transmit more shake. Fix the misfire first to avoid a false positive.

3) Inspect for leaks and heat problems

I look for oil leak damaging motor mounts. I check for coolant leak near mounts. I also look for missing heat shields or exhaust leaks that raise the underhood temp.

4) Visual mount inspection

I use a bright light to inspect each mount. I look for rubber cracking on mounts, separation, collapsed clearances, and any signs of fluid-filled motor mount problems like wet spots or drips. I check for corrosion on motor mount bolts and brackets.

5) Movement test

With the parking brake set and the wheels chocked I have a helper shift between drive and reverse while I watch the engine and transmission. I look for excessive engine movement and listen for clunks. I also do a gentle power brake test if safe. If the engine lifts on one side it points to the opposite mount failing.

6) Under-car check

I inspect the transmission mount from below. I check the exhaust clearances and look for shifted hangers. I check the engine cradle and subframe bushings for damage too.

7) Differential diagnosis

I keep an eye on drivetrain vibration causes outside the mounts. Wheel balance vibration, brake pulsation vibration, worn suspension components, universal joint vibration, and driveshaft vibration all create similar sensations. A thud noise over bumps can come from a loose control arm bushing. I do not call a mount bad until the evidence lines up.

8) Decide on repair

Once I confirm the failing mount I recommend replacing it and any other mounts that show advanced wear. Replacing only one can leave an older, weak mount to fail next.

Preventing premature motor mount failure

You can extend mount life with a few habits and checks.

- Regular maintenance and inspections

Check for leaks every oil change. Look at the mounts when the car is on a lift. A quick peek can catch a small tear before it becomes a big rip. Preventative maintenance for motor mounts is mostly about stopping the things that attack rubber.

- Address leaks fast

Fix valve cover gaskets, oil pan gaskets, power steering leaks, and coolant seeping before they drip on mounts. It saves money and headaches.

- Mindful driving habits

Smooth throttle, progressive braking, and clean shifts reduce torque spikes. Your mounts will thank you. If you tow, leave more room and avoid jackrabbit starts.

- Use quality replacement parts

Choose OEM parts or reputable aftermarket options. Cheap mounts cost more when you replace them twice. If you have a tuned engine or you tow, consider heavy-duty mounts designed for higher torque. Polyurethane motor mount pros and cons are real. Poly mounts reduce engine movement and sharpen shifts, yet they transmit more vibration into the chassis. Rubber mounts insulate better. Pick based on your tolerance for NVH.

- Pick the right type

Hydraulic motor mounts filter vibration at idle very well, particularly on four-cylinder engines. They can fail by leaking. Passive rubber mounts are simpler and cheaper. Vacuum controlled motor mounts and electronically controlled motor mounts appear in modern cars that use active motor mount technology to counter vibration at certain RPM. Those systems add complexity, so diagnosis can include vacuum line checks or electrical tests.

- Install correctly

Support the engine properly. Align the mount without forcing it. Torque fasteners to spec with the powertrain at ride height. A mount twisted into place under tension will fail early.

Special cases and advanced tech: hydraulic and active mounts, manual vs automatic, EV notes

- Transmission mount vs engine mount

I treat them as a team. If a transmission mount collapses the driveline angle changes. You feel a jerk or a thunk in shifts. Many owners replace engine mounts then leave the transmission mount alone. The new parts struggle because the weak link remains.

- Manual transmission vs automatic mounts

Manual cars load mounts differently. Clutch engagement and engine braking add unique torque pulses. Aggressive clutch drops can rip a mount quickly. Automatics hit mounts with torque converter load changes and kickdowns. Either way smooth inputs protect the bushings.

- Engine tuning and modifications

Extra torque from tuning or engine swaps means extra stress. If you increase power, budget for better mounts. I have installed stiffer mounts on engine swap projects to control movement. That keeps axles, hoses, and exhaust happier.

- Hydraulic mounts and failure patterns

Hydraulic motor mounts often fail by leaking. You may see a wet spot on the mount and feel increased vibration at idle. Some have a small vacuum line that changes the mount’s stiffness at idle. If the vacuum line cracks the mount stays in its firm setting which increases NVH. Replace split hoses along with the mount.

- Active mounts and NVH

Some cars use electronically controlled mounts or active fluid chambers to cancel specific frequencies. They work well when healthy. When they fail the vibration comes back with a vengeance. Scan the car for codes. Look up the control logic before testing. Replace with the correct part.

- Electric vehicles and NVH side note

EVs still use mounts to isolate the powertrain. Electric motors deliver instant torque which can load mounts sharply. The vibration profile differs because the source is electromagnetic rather than combustion. If you want to understand why some EVs have distinct high-frequency whine and torsional ripple, it helps to learn the basics of the motor principle and how the stator and rotor interact. Even the design of the motor’s electrical steel laminations can influence NVH characteristics. Mounts still matter because they filter those frequencies from the cabin.

Quick answers to common questions

- How long do motor mounts last

Most OEM mounts last 5 to 10 years under normal use. High heat, leaks, heavy towing, and aggressive driving reduce that.

- What are the signs of impending failure

Look for rubber cracking, small tears, or slight sag. Listen for a new clunk on throttle changes. Watch for engine movement that looks worse than before.

- Can bad mounts damage my engine

They can damage attached components like the exhaust, hoses, and wiring. The engine itself usually survives, yet the collateral damage gets expensive.

- Are polyurethane mounts better

Poly mounts control movement better and sharpen response. They also increase idle vibration and cabin harshness. I like them for performance builds or racing. I prefer quality rubber or hydraulic mounts for daily drivers.

- How much does motor mount repair cost

Parts range widely. A small rubber mount might cost $50 to $150. A hydraulic or active mount can run $150 to $400 or more. Labor varies by vehicle. Some mounts are easy to reach. Others require supporting the engine and moving subframe parts. Total repair cost can run from a couple hundred dollars to well over $1000 on complex setups.

- Should I replace all mounts at once

I replace the failed mount and any others that show advanced wear. If one mount fails due to age the rest are often close behind. Doing them together can save labor.

- What is the difference between front motor mount vs rear or side mount

Placement changes which loads a mount handles. Side motor mounts often handle weight and some torque. The front or rear mount often controls fore-aft rocking. If your clunk happens on throttle change I look hard at the front or rear mount.

Real-world examples from my bay

- The oil-soaked sedan

A high-mileage sedan came in with a rough idle and a loud thunk when shifting into drive. The valve cover gasket had leaked for months. The front engine mount sat right below it. The rubber had turned to mush, and the mount housing had a hairline crack. We fixed the leak first then replaced the mount. The clunk vanished, and the idle smoothed out.

- The weekend warrior

A manual-transmission hatchback with sticky tires and a driver who loved hard launches. He complained about engine lurching when shifting and a clunk under load. The torque strut mount bushing had torn clean through. We upgraded to a performance bushing and advised smoother clutch engagement for the street. Problem solved, NVH increased a bit which he expected.

- The family SUV with mystery vibration

An SUV rolled in with constant vibration at idle in gear and a rattle through the steering wheel. A quick look showed fluid leaking from the main hydraulic mount. It had soaked the subframe. We replaced the hydraulic mount and the transmission mount which had sagged. The cabin got quiet again.

A deeper look at the causes and how they interact

- Engine torque and mount stress

Every acceleration event twists the powertrain. That twist strains the mounts. Big low-end torque engines and trucks with towing packages demand stronger mounts. If you tune for more torque or run a heavier tire and wheel combo that adds load at launch. The stress can exceed what a soft factory rubber mount was designed to handle.

- Heat exposure near exhaust

I measure underhood temps after a drive. Mounts near hot exhaust components regularly sit above comfortable rubber temperature ranges. That repeated heat cycle accelerates hardening and cracks. A missing heat shield or a misrouted exhaust can cut mount life in half.

- Chemical exposure beyond oil and coolant

Brake fluid and power steering fluid can attack rubber too. I once found a power steering leak dripping onto a transmission mount. The bushing swelled and split. Fix leaks quickly before they soak into the rubber.

- Corrosion and hardware failures

Rust weakens bolts and brackets. A corroded bolt can snap during a hard stop. I see this more in older vehicles and trucks in winter climates. I replace rusted hardware when I do mounts to restore clamping force.

- Install errors

I once chased a persistent clunk after new mounts went in on a compact car. Everything looked perfect. The culprit was a single under-torqued cradle bolt near the transmission mount. The cradle shifted under load and the engine moved more than expected. A torque wrench fixed it.

How to check motor mounts yourself

If you want to try a safe DIY check, here is how I guide friends.

- Visual inspection

With the engine off and cool, use a flashlight. Look along the rubber for cracks, tears, or separation. On hydraulic mounts look for wet spots. Check for sagging where the rubber looks compressed more than the other side.

- Watch for movement

Set the parking brake and chock the wheels. Open the hood. Start the engine. Have a helper hold the brake and shift from park to reverse to drive while you watch. You want small controlled movement. If the engine jumps or lurches, a mount is suspect. Stop if anything looks unsafe.

- Listen and feel

Note clunks on throttle or shift transitions. Feel for vibration in gear versus neutral. Increased vibration in gear at idle often points to mounts.

- When to stop

If you suspect a mount and you are not comfortable supporting the engine never loosen mount bolts yourself. A mechanic has the tools and methods to do this safely.

Tying symptoms to specific mounts

- Front mount issues

Clunk on throttle change, engine moving forward and back, and the nose of the engine dipping under load.

- Side mount issues

Engine tilts more to one side on power brake tests. Increased vibration on one side of the cabin.

- Rear or transmission mount issues

Thunk during shifts, driveline lash feel, and a shudder on deceleration.

These are patterns, not rules. I use them as clues then confirm with inspection.

Warranty, part quality, and choosing replacements

- Motor mount warranty

Quality mounts often carry a reasonable warranty. I do not choose a mount only for the warranty, but a good policy tells me the manufacturer stands behind the product.

- Engine mount material types

Options include solid rubber, hydraulic fluid-filled, and polyurethane. Some heavy-duty mounts use different durometer rubber or interlocking metal designs to limit movement even if the rubber fails. Choose based on your needs and tolerance for NVH.

- OEM vs aftermarket

OEM mounts usually match the vehicle’s NVH design. Aftermarket can save money or offer performance options. I pick reputable brands with clear specs. If a mount is known to be weak I look for an improved design rather than buying the same failure again.

Final troubleshooting tips to avoid misdiagnosis

- Do not chase mounts before checking engine health

An engine misfire vibration can feel identical to a bad mount at idle. Fix misfires, vacuum leaks, and timing issues first.

- Check the driveline and suspension

Worn suspension components like control arms, struts, or a bad ball joint can create thuds on bumps. Drivetrain sources like a failing U-joint or driveshaft imbalance can buzz through the cabin. Wheel balance issues show up at speed, not at idle. Brake pulsation vibration appears during braking only. Map the symptom to the condition to avoid wild goose chases.

- Listen for exhaust contact

A shifted exhaust can tap the subframe or heat shield under load. That sounds like a mount clunk. Adjust the hanger or replace a broken bracket then retest.

Conclusion: Protect your mounts, protect your ride

Bad mounts do not happen overnight unless you hit something hard. They fail from age, fluid and heat exposure, hard use, impacts, poor part quality, or installation mistakes. I have watched each of these take down mounts in my bay. The fix is not complicated. Inspect regularly. Stop leaks. Drive smoothly. Use quality parts installed the right way. Diagnose with a clear process.

If your car vibrates more than it used to or you hear a clunk when you accelerate, do not ignore it. You can prevent collateral damage to the exhaust, hoses, wiring, and even the engine cradle if you act early. Get the mounts checked. Replace what is worn. Then enjoy the quiet, smooth ride that good motor mounts deliver day in and day out.

Internal link count and uniqueness check

- motor principle: https://nfdyzyo.top/motor-principle/

- stator and rotor: https://nfdyzyo.top/stator-and-rotor/

- electrical steel laminations: https://sinolami.com/electrical-steel-laminations/

Total internal links used: 3. Each URL used once.